SavingSavingDelete 3

- What to look for when choosing a gas boiler

- The best manufacturers of gas boilers

- The best wall-mounted convection gas boilers

- The best wall-mounted condensing gas boilers

- The best floor-standing convection gas boilers for a private home

- The best floor-standing condensing gas boilers for a private home

- The best single-circuit gas boilers

- The best double-circuit gas boilers

- Let's compare the models

- Which gas boiler is better to choose?

Choosing gas boilers is difficult - they are usually sold with apartments or houses, so people simply don’t know what to look for. But what if you urgently need to purchase good equipment, but don’t have time to delve into all the design features? In fact, you don’t need a lot of knowledge to make the right choice. And having a ready-made rating of gas boilers for 2021 makes the buyer’s task easier.

| Place | Model | Rating | Characteristic | Price |

| The best wall-mounted convection gas boilers | ||||

| 1 place | BAXI ECO-4s 24F 24 kW | 9,4 | Buyers' choice | RUR 35,700 |

| 2nd place | Viessmann Vitopend 100-W A1HB001 24 kW | 9,2 | Sophisticated security system | RUR 39,470 |

| 3rd place | Vaillant turboFIT VUW 242/5-2 23.7 kW | 9,0 | Closed extended tank of seven liters | 39100 rub. |

| The best wall-mounted condensing gas boilers | ||||

| 1 place | Vaillant ecoTEC plus VUW INT IV 346/5-5 30 kW | 9,8 | High power - 30.6 kW | 99250 rub. |

| 2nd place | BAXI Duo-tec Compact 28 28 kW | 9,3 | Best quality | 55880 rub. |

| 3rd place | Protherm Lynx condensing 25/30 MKV 25 kW | 9,1 | Approximate efficiency - 104% | 58860 rub. |

| The best floor-standing convection gas boilers for a private home | ||||

| 1 place | Lemax Premium-20 20 kW | 9,7 | Heats up to 128 square meters | 26430 rub. |

| 2nd place | BAXI SLIM 1.230 iN 22.1 kW | 9,5 | Best functionality and quality | 58720 rub. |

| 3rd place | Protherm Wolf 16 KSO 16 kW | 8,8 | Profitable price | 21030 rub. |

| The best floor-standing condensing gas boilers for a private home | ||||

| 1 place | BAXI POWER HT 1.450 45 kW | 9,3 | Highest efficiency - 107.5% | RUB 148,930 |

| 2nd place | Vaillant ecoCOMPACT VSC 306/4-5 150 30 kW | 9,0 | High efficiency with maximum reliability | RUR 219,800 |

| The best single-circuit gas boilers | ||||

| 1 place | Lemax Leader-25 25 kW single-circuit | 9,4 | Optimal performance and safety | 44850 rub. |

| 2nd place | Protherm Panther 25 KTO (2015) 25 kW single-circuit | 9,2 | The boiler saves up to 15% gas | 45000 rub. |

| The best double-circuit gas boilers | ||||

| 1 place | Viessmann Vitopend 100-W A1JB010 24 kW dual circuit | 9,2 | German assembly | RUR 41,370 |

| 2nd place | BAXI LUNA-3 240 Fi 25 kW dual circuit | 8,9 | Provide heat for an area of up to 188-240 sq.m. | RUR 49,950 |

What to look for when choosing a gas boiler

When choosing a gas boiler, you need to rely on the company’s reputation and its breakdown statistics. But there are also some criteria, without which it is simply impossible to find a good device. Let's try to figure out what you need to remember before purchasing gas equipment:

- Boilers are divided according to the installation method into wall-mounted and floor-mounted, so analyze where you have more space;

- The type of boiler - convection and condensation - should be selected depending on the desired price;

- The number of circuits - there are double-circuit and single-circuit boilers - affects whether the boiler can heat water;

- The greater the heating power, the better the device will work;

- The type of combustion chamber - closed or open - indicates whether a person can see how the boiler works;

- There are different sizes of boilers, so it is important to consider the area of the room where it will be installed;

- High level safety is literally vital, because gas equipment can explode.

back to menu ↑

Lifehack

Freezing of a coaxial pipe can be prevented in several ways:

- insulate the outer pipe with mineral wool and a protective casing made of plastic pipe;

- cut the outer pipe or increase the inner pipe by 15-20 cm so as not to create a dew point;

- initially take the maximum length of the coaxial chimney recommended by the manufacturer;

- increase the slope to the ground by 2-3 cm.

According to heat exchanger material

The heat exchanger is the most worn-out element of the boiler, so the trouble-free operation of all equipment depends on its material. They are produced:

- stainless steel;

- copper;

- cast iron (extremely rare for wall mounting due to the weight of the metal).

Table of consumer qualities of heat exchanger materials:

| Material | Advantages | Flaws |

| Cast iron | the most reliable, durable and optimal heating material | heavy, does not like temperature changes |

| Stainless steel | durable, will not burn out | conducts heat poorly |

| Copper | durable, excellent heating metal | expensive, if the integrity is broken, it will immediately burn out |

By manufacturer

Leaders of the world gas equipment:

- German manufacturers (brands: BUDERUS, BOSCH, VAILLANT, VIESSMANN, WOLF);

- Italian (FERROLI, BAXI, ARISTON);

- Korean (NAVIEN);

- Slovak (PROTHERM).

And, of course, domestic manufacturers, whose products are distinguished by their unpretentiousness and survivability in the difficult conditions of the Russian winter and the unstable operation of the gas system and electricity supply:

By set of additional functions

To organize hot water supply, single-circuit boilers must be supplemented with an indirect heating boiler. Double-circuit systems also do not always cope well with the task of providing DHW, because flow heating has its disadvantages: when the tap is opened at the second point, barely warm or cold water flows from the first. Therefore, for double-circuit systems, a boiler is also a solution.

In regions with harsh climatic conditions, the boiler must have frost protection. In expensive models it is built-in.

For the “smart home” system and the owners’ desire for maximum comfort, the equipment is equipped with numerous sensors and relay control processes (traction sensor, outside and room temperature, media temperature, auto shutdown, protective relays, etc.).

The best manufacturers of gas boilers

Not all companies involved in the production of gas boilers can be trusted. The fact is that low-quality materials or the use of old technologies can negatively affect the durability of the device. But you can take a closer look at the products of the following companies:

- BAXI is a powerful European holding that appeared in 2009 and produces home appliances;

- The German company Viessmann creates cooling and heating systems for various types of buildings;

- Vaillant is licensed equipment from Germany, mainly heating boilers and regulators;

- Protherm is developing heating boilers with high efficiency, including gas boilers;

- Lemax holds the lead among Russian manufacturers of temperature control equipment;

- Buderus is a brand that has been producing boilers and other heating devices since 1731.

back to menu ↑

Principle of operation

The fuel for a condensing boiler, as for a conventional gas boiler, is natural or liquefied gas. But the operation of condensing boilers is based on simple physical laws.

When natural gas burns, it produces carbon dioxide and water. The process of evaporation of a liquid is accompanied by the release of thermal energy, and the condensation of steam makes it possible to recover the energy lost during the evaporation process.

Due to this feature, condensing boilers have increased productivity and efficiency, although they consume less fuel.

Let's compare the models

| Model | Efficiency, % | Max. thermal load, kW | Expansion tank volume, l | Natural gas consumption, m³/hour | price, rub. |

| BAXI ECO-4s 24F 24 kW | 92.9 | 25.8 | 6 | 2.73 | 35700 |

| Viessmann Vitopend 100-W A1HB001 24 kW | 91 | 26.2 | 6 | 2.77 | 39470 |

| Vaillant turboFIT VUW 242/5-2 23.7 kW | 93.5 | 25.3 | 7 | 2.66 | 39100 |

| Vaillant ecoTEC plus VUW INT IV 346/5-5 30 kW | 107 | 30.6 | 10 | 3.7 | 99250 |

| BAXI Duo-tec Compact 28 28 kW | 105.8 | 28.9 | 7 | 3.06 | 55880 |

| Protherm Lynx condensing 25/30 MKV 25 kW | 104 | 25.5 | 8 | 3.2 | 58860 |

| Lemax Premium-20 20 kW | 90 | — | — | 2.4 | 26430 |

| BAXI SLIM 1.230 iN 22.1 kW | 90.2 | 24.5 | — | 2.59 | 58720 |

| Protherm Wolf 16 KSO 16 kW | 92.5 | — | — | — | 21030 |

| BAXI POWER HT 1.450 45 kW | 107.5 | 46.4 | — | 4.91 | 148930 |

| Vaillant ecoCOMPACT VSC 306/4-5 150 30 kW | 106.2 | 30.6 | 12 | 3.67 | 219800 |

| Lemax Leader-25 25 kW single-circuit | 90 | 30 | — | 3 | 44850 |

| Protherm Panther 25 KTO (2015) 25 kW single-circuit | — | 27.1 | 10 | 2.8 | 45000 |

| Viessmann Vitopend 100-W A1JB010 24 kW dual circuit | 91 | 26.2 | 6 | 2.77 | 41370 |

| BAXI LUNA-3 240 Fi 25 kW dual circuit | 92.9 | 26.9 | 8 | 2.84 | 49950 |

back to menu ↑

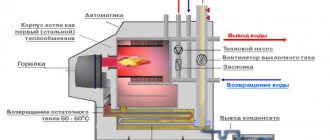

Device

The main components of a wall-mounted gas boiler are:

- gas-burner;

- primary and secondary heat exchangers;

- turbocharger fan;

- circulation pump;

- gas equipment;

- electronic control board and self-diagnosis sensor system.

The operation of all components is continuously monitored by a sensor system. If a problem occurs, they immediately issue a command to the control board, which displays the corresponding error code on the display.

In difficult situations, the boiler operation is stopped and blocked to avoid accidents.

The design of a wall-mounted gas boiler does not differ fundamentally from floor-standing models. However, the hinged installation method dictates its own conditions, limiting the weight of the units.

Because of this, the power of wall-mounted boilers is never too high, so that massive and heavy components and parts do not have to be used . There are some requirements for installation - it is necessary to ensure proximity to the outer wall so that the length of the chimney is sufficient for normal operation.

Typically, wall-mounted gas boilers are installed in kitchens, where they fit harmoniously into the interior.

Which gas boiler is better to choose?

All boilers sold in online stores or in real retail outlets have the right to exist. At a minimum, because some models are inexpensive, while others cost almost six figures. Therefore, the main advice for choosing a gas boiler is that you need to choose one that can safely warm a room of a predetermined area or at the same time heat water. Be sure to check reviews about the fire hazard of the product you are purchasing and choose only one that has a clean reputation. Other favorable parameters are considered only desirable.

15 best hair curlers – 2021 ranking

15 best tonometers for measuring blood pressure – 2021 rating

15 best exercise bikes for home – 2021 ranking

Top 12 best electric scooters – 2021 ranking

15 best oral irrigators – 2021 ranking

15 best screwdrivers – 2021 rating

15 Best Treadmills – 2021 Ranking

22 best DVRs – 2021 ranking

14 Best Elliptical Trainers – 2021 Ranking

12 best glucose meters

15 best welding machines – 2021 ranking

Comparison of domestic heating equipment

The situation does not change much when considering thermal units of Russian or Ukrainian production. For the most part, gas floor-standing single-circuit boilers manufactured in the former CIS countries have the following functional features:

However, if power requirements are lower, for example in houses with one and two-family houses, as well as with decentralized heating, wall-mounted devices are more preferable. An important advantage of thermal baths is already obvious before purchase: these devices require significantly less space than kettles and can therefore be placed well in tight spaces or niches. If space requirements are a particularly important factor, combinators may be an even better alternative since no more space is required for the storage tank.

- do not need to be connected to the house electrical network, that is, they are non-volatile;

- equipped with an open combustion chamber;

- are not equipped with their own circulation pump and expansion tank;

- do not have a circuit for heating water for household needs.

The next advantage is flexibility. Wall-mounted units can usually operate independently of each other, allowing more space for exhaust gas control and more options for positioning the unit. Installing thermal baths is much easier since all the necessary components are already integrated into the device. The weight of such systems is also reduced. And also in the money bag the difference is noticeable because custom wall units are usually much more cost effective to purchase than a boiler.

Of course, gas boilers of such a simple design are also offered by imported manufacturers, but they are 1.5-2 times more expensive than domestic ones. At the same time, some companies from the CIS countries produce double-circuit gas heat generators designed for installation on the floor (for example, Danko and Aton).

Modern suspended units, which have a closed combustion chamber and are equipped no worse than imported ones, are produced by the Neva company from St. Petersburg. To figure out which version of the domestic boiler is better - floor-mounted or wall-mounted, let's compare the models of these manufacturers in the table:

Application area for boilers

Floor-standing units are especially important when energy demand increases in buildings of the same size. It is also pleasant to rely on boilers to provide process heat, since there is usually no need for modulation. Therefore, the advantage of thermal baths that have so-called continuous control does not matter if the differences between the maximum and minimum heat consumption are very small.

Alternative for heating modernization: condensing boilers with chimney

Meanwhile, there are also condensing boilers that can be connected to a normal chimney. Typically, such an undercurrent leads to deflocculation of the chimney, that is, penetration. Thanks to this process, condensation in the chimney can be avoided.

It’s easy to see that buying a suspended turbocharged Neva boiler is much more profitable than a floor-standing version of Danko, which is similar in power. At almost the same price, the St. Petersburg unit is much more equipped and much lighter in weight. A logical question arises - why then are heaters like Danko needed if they are more expensive than “wall units” stuffed with equipment and automation? We will give the answer in the next section.

Holistic systems planning for optimal solution approach

This type of spa is always used when an old boiler or old thermal base is replaced by a modern condensing boiler. Today, craftsmen can take advantage of a wide range of devices from heater manufacturers, which facilitates the development of individual and, above all, needs-based solutions. Especially when installation costs and space requirements are important factors in decision making, in most cases a wall-mounted unit is a more suitable option.

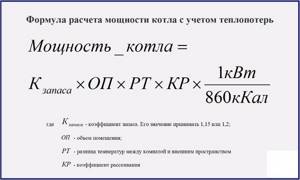

How to calculate power?

Performing a full calculation of the power of a heating system is difficult and beyond the power of a person who does not have special training. However, there is an easy way to determine power.

It has been experimentally determined that heating 10 m2 of area requires 1 kW of thermal energy. This means that a 24 kW boiler is designed to heat a house of 240 m2, and a room of 150 m2 will require 15 kW of power.

Guided by this ratio, you can quickly and accurately select the right boiler . It is necessary to take into account that it is impossible to make a large reserve of power - the unit will operate abnormally, which will cause the burner to constantly turn on and off.

This mode will create conditions for rapid failure of important components and parts of the boiler.

Operating principle

According to the principle of operation, wall-mounted boilers are no different from floor-standing boilers. The main unit is a gas burner combined with a primary heat exchanger . It performs a basic function - heating the coolant.

Then, under the action of a circulation pump, it is discharged into a secondary heat exchanger, from where it enters a three-way valve.

There, the hot liquid mixes with some return flow to reach operating temperature. and enters the heating circuit .

The air supply to the burner is provided by a turbocharging fan. It also creates pressure that displaces flue gases from the burner to the outside. To do this, use your own coaxial type chimney (pipe within a pipe), led out through the wall.

Gas supply and regulation is provided by equipment, which includes:

- gas tap;

- gearbox;

- gas valve;

- feed units and control sensors.

The heating of the coolant, as well as the preparation of hot water, is carried out in flow mode. The hot liquid is removed, it is replaced by a colder flow, which heats up and is also discharged from the boiler into the heating circuit.

With active use of hot water, some models experience a drop in the temperature of the heating radiators.

NOTE!

There are non-volatile boilers that operate on simpler principles. They produce normal heating of the coolant, just like a gas stove does. They do not have any elements that require power supply, which makes the design more primitive, but also more reliable.