A certain Italian concern produces boards for Ferroli gas boilers. The boilers themselves are positioned on the market as economical, budget devices. Unfortunately, all the benefits from purchasing such a boiler, as well as the economic effect of its use, are eaten up by a periodic annoying nuisance - the boiler’s Honeywell-DBM01 control board fails with enviable regularity, or rather, the 24V power supply on the FSD210 chip is dying for a long time.

There are many supporters and opponents of this microcircuit; personally, when faced with the repair of these boards, I prefer to power the board from a more reliable source, so that people do not chatter their teeth in the cold because of a “good” microcircuit that decided to give up the ghost at the most inopportune moment.

I won’t scold the Italians, who probably made a fortune producing such junk; after all, they help our repairmen survive in difficult Russian conditions, who charge 50-80 green rubles for repairing a board, while a new board costs about $450.

I’ll just tell you and show you how this board can be revived without resorting to a service:

I omit the moments of dismantling the board and the need to first turn off the mains power, since anyone familiar with a soldering iron understands this, and I categorically do not recommend that others get into the boiler electronics!

So, we have a board with a power supply torn to shreds. First, without regret, remove all elements of the power supply from the board from the input filter to the output capacitor.

There is no need to try to check the removed elements for serviceability - as a rule, most of them, including the transformer, are damaged. The rest may have hidden defects, so toss them in the trash! It is convenient to “blow” surface-mount elements off the board with a soldering hair dryer at 300 degrees. Next, the board must be cleaned of soot and burns using a scalpel and alcohol.

The next step is to decide what kind of power source we have in stock, if there is a 24V 200mA power supply of a fairly compact size - you are especially lucky! Such a unit can be mounted directly on the board, soldered to the 220V points and to the output filter capacitor. In my case, I wasn’t so lucky... But I found a power supply from an old dot matrix printer with an unpronounceable name. On the board of a fairly high-quality power supply, I found the voltage I needed, and judging by the size of the Schottky diode, the current significantly exceeds the minimum 150mA.

We will make an external power supply; there is more than enough space in the boiler. In order to avoid errors during connection and for speedy installation and dismantling, I mount connectors on the board for connecting the power supply. The 220V connector of the 4R-2.5ХН brand fits very conveniently into the holes of the dismantled mains choke, using the two outer pins.

For low voltage I used a 4SP2.5 connector. For ease of installation, the output filter capacitor was removed and a connector was installed in its place. Removing the capacitor will not have any negative consequences, since the power supply you are using already has a capacitor.

Next, we solder the wires with mating connectors to the power supply, trying, of course, not to confuse the polarity of the output voltage. I placed the block itself in a piece of plastic cable channel as a housing.

And one more small note: These blocks DO NOT WORK without connecting the mains voltage, which is supplied to the controller in the form of a signal through an optocoupler. For this reason, do not try to connect the boiler via UPS, pulse stabilizers and other nonsense that significantly distorts the shape of the network sine wave!

Italian gas boilers Ferroli are products of one of the strongest European manufacturers.

The equipment manufactured by this company demonstrates high quality and stable operation; all components and parts of Ferroli gas boilers are assembled on the basis of advanced technologies and fully meet the most stringent technical requirements.

Each unit is equipped with an extensive self-diagnosis system, consisting of a network of sensors that are located on all critical components and parts of the boiler.

If any malfunction occurs or the unit leaves the set mode, the self-diagnosis system immediately reacts by notifying the user using an alphanumeric code on the boiler display.

Let's take a closer look at her work.

All main error codes and their interpretation and solution

Let's consider the main errors of Ferroli gas boilers and options for eliminating them:

| Code | Decoding | Ways to solve the problem |

| A01 | No flame (ignition attempt failed) | Check the presence of gas in the line, open the gas supply valve, |

| A02 | False presence of flame (voltage detected at the ionization electrode when the burner is off) | Check the condition of the ground loop or the presence of condensation drops on the control board |

| A03 | Boiler overheating | Wash the heat exchanger, check the condition of the circulation pump |

| A06 | No flame after ignition cycle | Check the gas supply system, clean the gas burner nozzles |

| A08 | Coolant temperature sensor failure | Replace element |

| A09 | Gas valve failure | Check functionality, replace element |

| F04 | Flue gas thermostat overheating | Clean the chimney, check the operation of the fan |

| F05 | Failure of the smoke removal system, fan shutdown | Replace fan |

| F08 | Primary heat exchanger overheating | Rinse the heat exchanger and, if necessary, replace it |

| F10 | Break or short circuit of the exhaust temperature sensor | Restore contact or replace sensor |

| F11 | Break or short circuit of the DHW temperature sensor | Restore contact or replace sensor |

| F14 | Malfunction of sensor No. 2 direct line of the heating circuit | Restore contact or replace sensor |

| F34 | The supply voltage dropped to 180 V | Check the line, install a stabilizer or uninterruptible power supply |

| F37 | Exhaust pressure drop | Detect heating agent leak and fix it |

| F40 | Excessive exhaust pressure | Check the condition of the expansion tank |

| F47 | Open or short circuit of the exhaust gas pressure switch | Restore or replace the relay |

| F50 | Problems with the control board | Replace control board |

Ferroli boiler errors are divided into critical (A) and non-critical (F). Those with the letter A lead to independent blocking of the boiler, but those with the letter F do not.

Operating instructions - how to start correctly

The operation of Ferroli boilers does not differ in any specific actions or procedures.

The owner is only required to organize periodic maintenance, clean the body and interior of the boiler, and maintain the burner nozzles in proper order.

The procedure for starting the boiler is similar to the procedure for igniting other gas units.

A special feature is the need to maintain a pause between startup attempts, during which code D3 or D4 appears on the display (50 or 30 seconds).

The first code occurs after a critical error appears and the unit is blocked.

Until the required time interval has been met, a repeated restart is not possible.

The second code appears between attempts to start normally, if the previous one was unsuccessful.

This is usually due to air in the pump, piping or heat exchanger . Attempts are repeated until the air is removed from the boiler.

Connection types

For excellent functioning and long service life, the hydraulic system of the boiler must be sized to comply with the standards of the instructions, and ensure proper operation and continuous flow of water.

To connect the gas connections, the gas pipes must be cleaned. Connection takes place strictly in accordance with current standards.

In addition, the boiler has an electrical connection, which requires proper connection to the ground loop.

The boiler must be commissioned by highly qualified specialists.

Today we will look at the types of gas heaters from the Italian manufacturer Ferroli. Thus, there are two types of Ferroli boilers: wall-mounted and floor-mounted. Units that are suspended are also divided into two groups - conventional and condensing. The latter are characterized by high efficiency.

The boiler does not start (the burner does not turn on)

Problems with starting a boiler occur most often, since there are many reasons for such a situation.

Among them may be:

- The gas supply valve is closed.

- Gas valve problems.

- The burner nozzles are clogged with soot.

- The control board has failed.

- The boiler is blocked due to a problem with a component.

Most possible causes are detected by the self-diagnosis system and display the corresponding code.

However, some possible reasons - failure of the gas supply system, a closed valve and other mechanical obstacles may not be noticed by the system, so you should independently verify that it is ready for operation . In addition, it is necessary to take into account the phase dependence of the boiler and the need for grounding.

Sometimes, after connections have been made, the wires on the panel are mixed up.

Why does blood pressure drop?

A drop in pressure in the boiler can be due to three reasons::

- The appearance of a leak in the heating circuit (including in the boiler itself). The peculiarity of this option is the constancy of the process, since the coolant will not stop leaving, no matter how much the system is recharged. In this case, you need to find the location of the leak. First of all, you need to check the condition of the drain tap or valve to see if it is open or damaged. If no problems are found in this unit, the entire heating circuit is checked sequentially. Sometimes they forget to close the drain valve on radiators, fistulas appear in pipelines, and connections fail. It is most difficult to detect a leak if the tap supplies a water-heated floor system embedded in a concrete screed. You can detect the problem by a wet spot on the floor or ceiling of the lower floor, and to do this you often have to remove the floor covering or suspended ceiling.

- Circulation pump failure. This problem is immediately detected by the self-diagnosis system, and it is easy to check the functionality of the pump. It is enough to carry out a visual inspection of the element and take appropriate measures.

- Expansion tank membrane rupture. In this case, the pressure will drop until the coolant fills the entire volume, after which the process will stop. Then an uncontrolled increase in pressure is possible, especially intense as the temperature of the heating agent increases. If it turns out that the problem element is the expansion tank, urgent measures must be taken to repair or replace the unit. Otherwise, with thermal expansion of the liquid, the heat exchanger or other element of the system will fail, which will require significant costs for repairs and restoration of the boiler’s functionality.

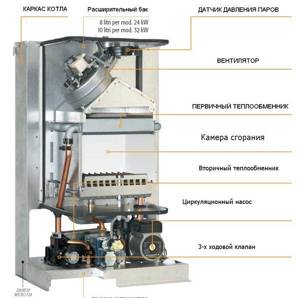

Device

Ferroli double-circuit boilers are designed based on the most efficient designs used in the global heating industry. The main elements are the gas burner, which is located in close proximity to the heat exchanger.

The hot coolant passes into the secondary heat exchanger, where it transfers some heat to prepare hot water.

IMPORTANT! In models with a bithermal heat exchanger, both processes occur simultaneously.

At the exit from the secondary heat exchanger, the heating agent enters a three-way valve, where the hot and colder return flows are mixed in the required proportion to obtain the desired temperature, after which the liquid is sent to the heating circuit.

All processes are controlled by an electronic control board equipped with an extensive network of sensors.

They form the core of the self-diagnosis system, which constantly monitors the condition of the boiler components.

Positive reviews

Italian equipment from Ferroli is characterized by ease of settings, excellent design and ease of operation. The company has been on the market for more than 50 years, and this is not much when compared with other manufacturers. But during this time, the brand became one of the European leaders in the production of heating equipment.

Consumers note that the equipment is constantly being modernized, and its appearance has an increasingly attractive design. The devices meet safety and performance requirements, which is important for the consumer, as well as maintainability, as well as ease of maintenance.

If you are also interested in the products of Ferroli, you can consider gas boilers from this manufacturer in more detail. For example, mounted models are the most popular in Russia and are offered for sale in a wide range. They are compact in size and practical. According to users, such a boiler is an ideal option for heating an apartment or a medium-sized house. The range of mounted boilers is quite wide; the manufacturer offers users many models, this allows them to choose the desired configuration that will meet all requirements. Owners of property with a larger area can consider Ferroli floor products; gas boilers in this line are highly reliable and durable.

Peculiarities

To choose the right heating boiler from Ferroli, you can identify some of the main characteristics of its products.

The devices produced by the company can be divided into a number of categories:

- By location - Ferroli designs come in 2 types. These are either floor or wall-mounted products. Floor-standing ones are available for large rooms, wall-mounted ones are excellent for heating oversized spaces.

- In terms of the number of circuits, a double-circuit wall-mounted unit, as well as a floor-standing unit, is ideal for heating the coolant itself and heating liquids for domestic purposes.

- According to the operating principle, devices with atmospheric flame burners are produced at a low price and are extremely easy to maintain, since they will operate according to a simplified scheme. In condensation units that have closed chambers, air flows by force. Thus, their efficiency increases and gas consumption decreases. To use devices with closed combustion chambers, you cannot do without electricity.

- According to the material from which the heat exchanger is made. Steel appliances provide increased heat transfer. A cast iron boiler will have low efficiency, but will last much longer.

Taking into account the competition, the company’s specialists offer more effective and popular solutions. Thanks to this, gas designs from Ferroli guarantee the required level of performance while consuming a small amount of fuel.

It is especially important for consumers that the company produces models that can be adapted to work in difficult domestic conditions. Ferroli products will last 35-40 years even in harsh climates.

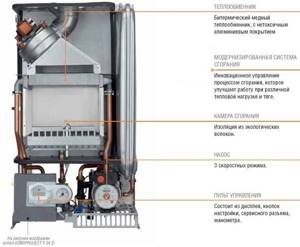

Ferroli differs from other companies that produce boilers in its product control system using innovative microprocessors, and it is they that will keep the level of flame combustion in these devices under control. The company's engineers also came up with a unique copper heat exchanger with compact parameters, which is coated with a special aluminum composition against corrosion.

Stylish design, simple care and control, ease of setup - all this is present in Ferroli products, for which customers appreciate them.

Wall-mounted boilers are the most popular type of heating products, which are represented by such interesting models as “Diva” and “Divatop Domina”. Due to its affordable cost and simple structure, the popular “Arena” model is in greatest demand. This is a wall-mounted double-circuit design with 2 heat exchangers. The combustion chamber here can be either open or closed. In the model you can find parts from well-known companies (Siemens and Wilo).

For high-quality operation, the Ferroli unit is equipped with a control board that is not afraid of power fluctuations in the network. All these elements guarantee reliable operation of the devices and their safety during use.

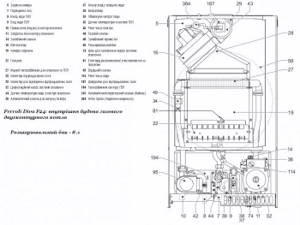

Floor products are represented by the “Pegasus” and “Atlas” series in various models. Usually these are weighty devices, so they are mounted on the floor. The “Pegasus” model consists of a cast iron heating device, a Honeywell valve, a reliable burner, an alarm contact, and also includes connectors for high-quality connection of pumps and a small thermostat. For ease of use, ignition from the mains and the possibility of connecting a boiler were provided. The device has a built-in smoke removal control, an ionization sensor, and a bimetallic indicator for monitoring overheating. These products have many options - a separate control unit, elements for switching on the thermostat and turbo nozzles.

Environmental friendliness and savings

Such equipment is perfectly adapted to conditions of low pressure in the system. But the PegasusF2 model has a two-stage burner, which ensures economical operation and durability of the components. The air during operation of such a device is much less polluted. This modification, according to users, can even be used to install cascade heating systems. If you additionally purchase a controller, you will create a system of 4 boilers, the total power of which can reach 1 MW.

Manual

Quite often lately, consumers have been choosing Ferroli devices. Gas boilers, which can be floor- or wall-mounted, must be operated according to the instructions. The company includes a warranty card and an instruction manual for each device. If malfunctions occur during operation, the consumer should contact technical support specialists. As an alternative solution, the owner of the equipment should consult the user manual.

The most common problems that may arise are low pressure levels, the device will report this with error f37. In this case, the user should check the gas and water supply and clean the system. If you do not want to encounter malfunctions, you must remember that when the equipment is disconnected from the power supply system or gas main, the antifreeze function will be disabled. In order to prevent damage from freezing, which can occur when the boiler is turned off for a long time in winter, the water from the boiler should be drained, this also applies to the heating system, as well as the hot water supply circuit. Otherwise, water is drained only from the DHW circuit, and antifreeze is added to the heating system, and you should read the manufacturer's recommendations.

The operating instructions for the Ferroli gas boiler indicate the possibility of adjusting the air temperature in the room; this can be done using the optional thermostat. The latter allows you to set a specific temperature. If you need to adjust the water temperature in the heating system, you should use the remote control or interactive panel on the device.

Model Ferroli Fortuna F24 PRO

The Italian company Ferroli was founded in 1955 as a small workshop for the manufacture of gas boilers. Today, the Ferroli company is known throughout the world and is a serious manufacturing concern, which includes many subsidiaries.

This allows the manufacturer to ensure high quality products at low costs, produce all the necessary parts and components at its own sites, and engage in scientific and technical development.

The Ferroli Fortuna series was released specifically for use in Russia. Difficult climatic conditions, deterioration of networks, gas pressure drops and electrical voltage surges are taken into account.

The series consists of 12 models of different power, designed for wall mounting. Fortuna F24 PRO is a 24 kW double-circuit gas boiler with a separate heat exchanger and a closed-type turbocharged burner.

It is possible to use a coaxial (pipe in pipe) horizontal or vertical type, or a separate chimney, the choice of which is made according to the installation conditions.

Not included in delivery.

Installation nuances

The Ferroli wall-mounted gas boiler, installation instructions for which are presented in the user manual, must be installed in a room where the ventilation system is constantly operating. If the air flow is insufficient, the device will not be able to operate normally, and combustion products will not be removed. If such conditions are created, then harmful substances can penetrate into the premises of the house, which can cause harm to human health. If you purchased wall-mounted equipment, you can use a kit with a bracket that attaches to the wall. To mark the surface of the suspension points, a metal template can be supplied upon special order.

Basic malfunctions and ways to eliminate them

The Ferroli gas boiler diagram will allow you to understand what design features the purchased equipment has. Some home craftsmen are also able to figure out the causes of the malfunction, as well as fix the problems themselves. If the device does not turn on, then there may be no gas in the network, but when the water pressure in the boiler drops, the main reason may be a malfunction of the circulation pump. Similar problems sometimes arise when the ignition power is insufficient; in this case, it needs to be increased. However, damage to the boiler electronic control board cannot be ruled out.

If you purchased a Ferroli gas boiler, malfunctions can also be expressed in extraneous noise inside the device. Only a specialist can handle such a problem, and you need to contact support as quickly as possible. If the water pressure drops, the water supply system may be clogged, so the plug should be removed immediately.

Advantages

Automated control.

Owners of Italian equipment do not need to turn knobs, set the temperature or other parameters - the settings are performed automatically. Adjusting modes allows you to save fuel. Self-diagnosis. To find out what problems the device has detected in its “organism”, its owner only needs instructions - to decipher the error codes. This is very valuable for users who are not well versed in technology. Adaptation to harsh operating conditions characteristic of Russia - low temperatures in winter, pressure drops in gas and water supply pipes, poor water quality, power surges. The manufacturer claims that the service life of its equipment is 40 years or more. Installation is quick and easy

It is advisable to call a specialist - he knows how to set up the device and how to carry out the first start-up. It will also adjust gas flow, ignition, connect temperature sensors - external and internal, and set the program. Adjustment and startup after the initial setup will be adjusted automatically. High efficiency and economical fuel consumption.