Electrical connection

The power supply circuits are the same for all electric boilers, the only difference is the number of phases. Devices with a power of up to 12 kW are connected to a single-phase 220 V network, more than 12 kW - to a three-phase (380 V). What you will need for installation:

- power cable with copper conductors;

- differential circuit breaker or combination of RCD + conventional circuit breaker;

- ground loop.

A VVG cable of any type is used as a power line; the number of cores depends on the number of phases - 3 or 5. Select the cross-section of the current-carrying part according to the power of the heat generator, usually this parameter is indicated in the product’s operating instructions. To simplify the task, we present the data for different boilers in the form of a table.

The rating of the differential circuit breaker also depends on the power consumption of the heater; the operating current is 30 mA. For example, to protect the power line of a 3 kW (220 volt) unit, you will need a device rated at 16 A; for a power of 16 kW (380 V), you need a 32 A difavtomat. The exact ratings are indicated in the product data sheet.

To independently connect a wall-mounted electric mini-boiler room, you need to remove the front panel, run the power cable inside and connect the wires of the corresponding colors to the terminal block contacts. As a rule, the neutral wire is indicated in blue, grounding in yellow-green. The control box of the induction and electrode boiler is connected in the same way.

Electrical connections between the control cabinet and the heating block of an electrode or induction boiler are made according to the individual diagram presented in the instructions. As an example, we give a connection diagram for the popular Galan electric boiler.

Automation diagram for single-phase 220 V network

The temperature of the coolant here is monitored by overhead sensors installed on the metal sections of the supply and return pipelines. The devices are connected in series with the contacts of the thermal relay that controls the magnetic starter. When the upper temperature threshold is reached, the circuit breaks and the starter turns off the heating.

Connection diagram for connecting the boiler to a three-phase 380 V network

Electrical installation in a three-phase network

The diagram for connecting an electric boiler to a three-phase network is more complex, but even a beginner can do it.

The three phases must be connected as follows:

Please pay attention to the following nuances:

- Each water heater comes with a technical passport, which must indicate the manufacturer’s recommended wiring diagram for the electric boiler. Be guided only by this document in your case, because... The examples provided on the Internet may not always be suitable for your heating system.

- Be sure to protect the boiler with a circuit breaker and RCD. These devices will prevent overload of the unit, short circuit and current leakage in the electrical network.

- The wiring must be grounded.

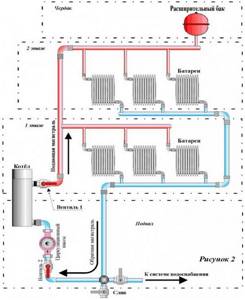

For your attention, a visual project of electric heating in a two-story dacha using a boiler:

In addition, we recommend watching a video that clearly demonstrates connecting a 380 V electric boiler:

Related materials:

Installation process in the right order (video)

So, check the wall to which the boiler will be attached and make sure it is able to bear the required load. we leave a little free space for access to the boiler (usually it is indicated in the instructions) and install the unit, checking its evenness using a level.

The wall on which the boiler is mounted must be made of non-combustible materials.

The mounting plate will be useful to you for proper installation of the boiler. Pipelines should be selected based on which pump is installed in the system.

Basically, installing an electric boiler is not difficult, however, as in any business, there are some interesting aspects. Thus, boilers with low power always work well in a regular network with a voltage of 220V. Another thing is that if the model is powerful enough, it needs to be connected to a three-phase network

This is why it is so important to correctly calculate the cable cross-section. A correctly selected cable can withstand the power of the unit and pass the required current without failure.

After the boiler is installed, the heating system and water supply system pipes are connected to it. This is where couplings and flanges come in handy.

The next step is to connect to the mains. RCDs and circuit breakers with the required ratings are pre-installed, and grounding work is carried out. The cable is equipped with a switch, the distance between the contacts of which is 3 mm. As soon as the device is connected to the system, you can draw water, start the unit and check it in action.

There is almost no difference between installing wall-mounted and floor-standing boilers, except that floor-standing boilers are installed on a special stand.

We install protective equipment

When all the input wires are connected to the electric boiler, it will be necessary to additionally protect it with RCD circuit breakers installed in the main panel.

The purpose of the first device is to protect equipment from short circuits and wiring overloads. Connecting an electric boiler through an RCD will protect you from leakage currents.

It is also recommended to connect a voltage stabilizer, since even small surges can damage the unit. I don’t think it’s worth talking about the need to ground an electric boiler. The main requirement is that the ground wire runs directly from the bus to the equipment frame.

Electrode (ion) boilers

This is a more advanced system for heating water.

It has no heating elements. Only 2 electrodes. An electric current is passed through them. It passes through prepared water or a special coolant that corresponds to electrical conductivity. The liquid, having great resistance, begins to heat up. This system is very simple and more economical and reliable than the heating element system. But there are 2 troubles. The first is the need for good grounding to avoid damage from leakage currents. The second is the inability to use most common antifreezes. Also, this system cannot be used for hot water supply. It’s just that water, due to the consequences of electrolysis, is no longer suitable for domestic needs, as it is saturated with gases harmful to health. This cannot cause any harm when heating the house, unless, of course, you drink such water.

electrode electric boiler

It is believed that such a system has higher efficiency indicators than a heating element, and the house will warm up faster. But at the same time, its price will be slightly higher, due to a technologically more complex design. By the way, the scale that forms on the electrodes and walls of ion boilers can reduce their power, but will never damage them.

Detailed step-by-step instructions for installation and connection

Installation of an electric boiler on the wall

- Clean the wall from dust and dirt.

- Mounting kit: hinged mounting plate, dowels and screws, usually included with the boiler.

- Make a mark on the wall in accordance with the mounting strip and drill holes corresponding to the diameter of the dowels (usually Ø 10 mm), insert the dowels into the holes.

- Hang the boiler on the threaded hooks, then tighten the screws.

How to choose an external thermostat for an electric boiler and save up to 30% on heating every month

Organization of strapping

For heating element electric boilers in a monoblock housing, which already have all the necessary elements of the system, it is enough to connect the supply and return lines to the corresponding pipes. It is necessary to supply water to the system through the return valve.

For simple heating element boilers without a circulation pump and an expansion tank, all elements are connected in accordance with one of the diagrams given above.

- First, the hydraulic manifold and expansion tank are mounted on special mounts.

- Next, in accordance with the diagram, pipe routing is laid with a circulation pump, filter, and safety group installed on them.

Supplying electrical wiring and connecting an electric boiler to it

Electric boilers have high power and only low-power models up to 3.5 kW, usually used in apartments, are allowed to be connected to an outlet. In other cases, the connection is made exclusively directly.

The boiler unit is connected to the electrical network through a differential circuit breaker or a combination of RCD + circuit breaker (1 switch for each phase). The power cable must have a sufficient cross-section, which can be calculated, for example, based on the power of the electric boiler.

| Cable cross-section, mm2 | Copper conductors, kW | Aluminum conductors, kW | ||

| 220 V | 380 V | 220 V | 380 V | |

| 1,5 | 3,3 | 5,7 | — | — |

| 2,0 | 4,1 | 7,2 | 3,0 | 5,3 |

| 2,5 | 4,6 | 7,9 | 3,5 | 6,0 |

| 4,0 | 5,9 | 10 | 4,6 | 7,9 |

| 6,0 | 7,4 | 12 | 5,7 | 9,8 |

| 10,0 | 11 | 19 | 8,3 | 14,0 |

| 16,0 | 17 | 30 | 12 | 20,0 |

An example of a table from the Protherm Skat 9KR 13 operating instructions.

The electrical connection diagram itself is the same for all electric boilers, the only difference is in the number of phases.

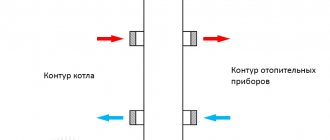

When connecting to a single-phase power supply, it is enough to connect the phase to any of the contacts (U, V or W). When connecting the electric boiler to a three-phase (380 V) electrical network, you must remove the jumper (see diagram) and connect a phase to each of the 3 contacts. Zero and grounding (N and PE, respectively) are connected in the same way in each case.

An example of a Protherm Skat contact block, the connection is to a three-phase power supply. Connection of an electric boiler automation system via a magnetic starter.

Grounding

High-power electrical installations, which include household electric boilers, require high-quality grounding in compliance with all standards and requirements. A wire of the required cross-section must go from the boiler body to the internal grounding distribution board, if it is already organized, or directly to the electrodes dug into the soil, if there is no grounding in the country house.

The outer part of the protection should be located in a place where it is guaranteed that no one will be present at the time of a power failure, but preferably no further than 1 meter from the foundation of the house.

Work order:

- Using a shovel, dig a triangle and a connection to it with a depth of 0.5-0.7 m, the length of the sides of the triangle is 1.2 m. The photo shows an example of a trench and a ready-made grounding structure.

- Sharpen with a grinder and drive vertical grounding rods into the ground at the vertices of the triangle - metal corners 50*50, 2.1-2.2 meters long. They should only stick out a little from the ground so that horizontal grounding plates can be welded to them later.

- Forming the sides of a triangle, weld 3 strips of metal 1.2 m long, 4 cm wide and at least 4 cm thick to the vertical electrodes.

- Weld a 4)*4 mm stainless steel strip to the nearest vertex of the triangle and pass it along the trench to the foundation of the house.

- Connect the grounding wire coming from the distribution board or the electric boiler body with a bolted connection.

- Cover the structure with soil.

Poll: is your country house fully grounded?

Test run of the boiler

- Check the insulation of all wires, the reliability of couplings, taps and pipe joints.

- Run water into the heating system through the make-up tap, opening the valve not all the way so that water is drawn under less pressure.

- Bleed the air through the air vent; some models have an automatic air vent.

- Check the pressure in the system using a pressure gauge; the exact nominal values are indicated in the electric boiler's passport; usually it is 1.3-2.0 bar in operating mode and 1.0-1.3 bar when the boiler is turned off.

Installation options

So, first, let’s look at the options for connecting an electric boiler in a private house or apartment with our own hands:

- If the power of the water heater does not exceed 3.5 kW, then it is usually powered from an outlet. In this case, the use of a single-phase 220V network is allowed.

- In the event that the power varies between 3.5-7 kW, it is necessary to carry out the electrical installation yourself directly from the junction box. This is due to the fact that the outlet may not withstand high current loads. As in the previous case, a 220-volt network is allowed for use.

- Well, the last option that may come up is an electric boiler with a power of over 7 kW. In this case, it is necessary not only to run a separate cable from the distribution box, but also to use a more powerful 3-phase 380V network.

Connecting an electric boiler to the heating system

First you need to install the unit itself, securely attaching it to the wall. The heating element boiler is suspended at a level not lower than 1.5 m from the floor; the induction or electrode unit can be placed lower, as far as is convenient when piping. In this case, the last two types of heat generators are mounted in a vertical position.

Connecting a heating element boiler, equipped with a circulation pump and automatic safety system, to the heating system is quite simple. Below is an installation diagram according to which the piping must be performed:

The outlet pipes are connected to the pipelines through ball valves, equipped with American valves for convenience. A membrane expansion tank is connected to the return line, and a strainer - a mud filter - is installed on it. To make it convenient to clean it without emptying the entire system, an additional ball valve is placed in front of the dirt trap.

The installation of induction and electrode type electric boilers is somewhat more complicated. The reason is that these units are not equipped with pumps, which must be used separately in the piping. In addition, the peculiarity of the operation of these boilers requires the inclusion of a safety group in the diagram. It consists of a pressure gauge, an automatic air vent and a safety valve. The latter is adjusted to the response pressure, which is indicated in the technical documentation supplied with the electric boiler. The wiring diagram is shown in the figure:

Note. The figure shows the connection of an induction heat generator; turning on an electrode boiler will look identical.

Very often, homeowners install an electric boiler as an addition to a solid fuel boiler. This creates additional convenience in operating heating equipment, especially at night. When the firewood in the firebox burns out, and there is no one to make a new stack, the electric heater comes into operation, maintaining the temperature in the system until the morning. In addition, the nighttime electricity tariff is significantly lower than the daytime one. In this case, the joint strapping scheme looks like this:

Note. The diagram shows a heating element boiler in use with a built-in pump. If you need to install an electrode or induction heater, you will have to buy the pump and install it separately on the return line.

Features of electric heating equipment

There is a widespread belief that all types of electric heaters provide savings of about 30-40%, and installation of an electric heating boiler will be as profitable as possible. The values described are large, and in theory they allow you to save a significant amount on heating. As a rule, the reason for such efficiency is given as reduced power - i.e. When calculating a heating system, you need to assume that heating one square meter of room requires about 60 W of energy instead of the required 100 W.

Everything said in the previous paragraph is the erroneous opinion of most users. It is not advisable to compare direct heating devices in terms of efficiency, since they will all be equal. This statement is based on the law of conservation of energy, according to which energy cannot appear out of the blue and disappear into nowhere.

In relation to electric heating devices, this means that all generated energy will be converted into heat. Of course, this phenomenon will be accompanied by certain losses - nevertheless, part of the heat will certainly dissipate in the air and will not be transferred to the coolant. But the volume of losses directly depends on the insulation of the device body, and not on the type of heating equipment. In addition, the heat released outside will directly warm the room where the boiler is installed.

If we look at the problem from the other side, then heating is designed to compensate for heat losses, the amount of which is determined by:

- The quality of building insulation, which is completely independent of the efficiency of the heating boiler;

- The difference in temperature in the house and outside, which also does not depend in any way on the heating equipment used.

To summarize, we can definitely say that the type of heat source has no relationship with the thermal power required to heat the building - which means that the vaunted efficiency of electrical devices is simply absent.

However, this only applies to efficiency - each electrical device has special performance qualities:

- Electric radiators. Such devices load the electrical network evenly, so there are no wiring requirements.

- Induction boilers. Such heating equipment is compact and reliable. The latter quality is due to the fact that there is no heating element in the heat exchanger, and the power controller and coil are located outside, so water does not have any effect on them. In addition, induction boilers can work with any coolant.

- Electrode boilers. Differ in smallest sizes. Such boilers require constant replacement of electrodes, since they dissolve in water over time. Only water containing a certain amount of salts can be used as a coolant.

- Heating element boilers. The main problem of boilers with heating elements is the constant deposition of scale on the heating elements (this factor is irrelevant for closed heating circuits, in which the amount of salts is initially limited). In addition, these devices are quite large in size.

Heating system with electric boiler diagram

The electric boiler has become an indispensable assistant for residents of apartments and private houses. Usually, when purchasing in a store, you are already offered to connect the boiler for money. The amounts are different everywhere, but every owner who spends 20 minutes reading this article can perform this operation. You can install an electric heating boiler using the diagrams that are present in our material. And another mandatory requirement is to read the instructions for the electric boiler, since the basic design does not change, but little things can affect the operation of the unit in the future.

Nuances of work

Two-pipe system with bottom distribution and forced circulation. What an electric boiler is can be seen in the photo.

It is better that it is slightly narrower than the main highway. To increase the efficiency of heating systems in everyday life, either heat accumulators or bypasses are used.

Mandatory piping elements An electrode or induction boiler for the safe operation of the water circuit requires the following set of additional equipment: Piping and connection diagram for an electric heating boiler Special offer!

The heating elements themselves are connected to the network as follows: one end of each of the tubular electric heaters is connected by a jumper, the remaining three free phases are alternately connected: L1, L2 and L3. Particular care should be taken when installing grounding: inexperienced owners often connect it to the zero phase of the wiring.

General features of electric boilers

Any heating system consists of three basic components: a heat source - this role can be played by a boiler, stove, or fireplace; heat transfer line - usually this is the pipeline through which the coolant circulates; heating element - in traditional systems this is a classic radiator that converts the energy of the coolant into thermal radiation. And this is not related to the costs of equipment and installation, it is related to the cost of electricity.

In one of the articles we said that the design of a solid fuel boiler may have design differences. There are different installation methods, which differ somewhat in their operating principles. After connecting the device to the heating system, they proceed to the implementation of the electrical part of the circuit, which includes an RCD and a circuit breaker of certain technical characteristics.

What does the wiring of an electric heating boiler look like?

If you install the device in a separate room, kW will be wasted every month. They run along the load-bearing walls of the house, from the boiler to the location of the outermost battery. The spark generator works in conjunction with the gas valve and is an integral part of it. Then, it enters a large circuit whose task is to heat the entire building. Naturally, there must be a connecting section between the inlet and outlet pipes of the coolant into the radiator.

Emergency piping scheme for boilers The supply of water from the water supply system to the system is used quite rarely, as it is ineffective. Over time, scale builds up on tubular heaters, which reduces the power of the equipment and increases the likelihood of heating elements overheating. If you don’t have enough time or you are not sure that you can do everything correctly yourself, it is better not to start tying, relying only on your intuition and videos on the Internet. How to connect correctly, what circuit to use? What is cheaper to heat? I installed 4 boilers!

DIY heating connection diagrams for a private house

In the case of installing a parapet gas boiler, which can also be double-circuit, you will need to separately install a circulation pump placed on the return pipe, as well as an expansion tank and other additional piping. Even today there are supporters of this method of wiring communications for heating a room.

Heating devices

In the absence of special instructions, the following rules are used when installing the boiler: The width of the passage on the front side of the boiler must be at least 1 m. In small private houses, the following types of two-pipe heating systems are used: dead-end; collector beam. The main disadvantage of such wiring is a slight increase in pipe footage. In this case, the hot water coming from the boiler flows to the radiators through one pipe, and the already cooled coolant is removed through another. They are considered one of the most durable and economical boilers.

Fluctuations are recorded by sensors, and if necessary, the system brings them to normal parameters. This pump belongs to the category of emergency equipment and runs on a battery. The main task of the pump is to supply cooled water to the boiler to heat it and distribute the already heated coolant throughout the system. In addition, the use of such a heating scheme with an electric boiler implies a complex balancing process. The equipment must include a box with C16 circuit breakers, which are installed at home next to the unit.

A prerequisite for proper circulation of water in a gravity system is the installation of pipes at a slight angle. Even when using a multi-tariff system, the cost of heating a house in this way will be an order of magnitude higher than in the case of a wood heater. All solid fuel boilers are based on the Kolpakov principle, when the boiler is first heated, and then the temperature is maintained at a certain level to ensure stability of heating of the coolant. To achieve a good effect in using the generated energy, it is necessary to install a heat accumulator. After all, the batteries will go along the internal perimeter, along the load-bearing walls, and even the last radiator should be located slightly above the boiler. Connecting a heated floor to the heating system. 4 connection methods.

If you have not yet chosen an electric boiler

The choice of a heater operating in conjunction with a water heating system is made based on power and operating principle (the cost of the equipment depends on the latter). Electric boilers have no problems with functionality - any model is equipped with an automation unit. If desired, various peripheral devices can be connected to it - weather sensors, room or overhead thermostats and GSM modules for control from a mobile phone or via the Internet.

After completing the work, the craftsmen make a note in the technical data sheet of the product.

Before choosing and purchasing a heating device, check how much electrical power is allocated to your home by the management company. It may happen that it is not enough for individual electric heating. Point two: a single-phase 220-volt network is capable of powering boilers that consume up to 12 kW/h inclusive. More powerful water heaters are connected to a three-phase 380 V power supply.

Determination of thermal power

This indicator is calculated using the standard formula: calculate the heated area of a country house or cottage, then multiply the quadrature by 0.1 kW. Obtain the thermal energy demand that the electric boiler must cover.

Consider a number of nuances:

- the height of the ceilings of the rooms is up to 3 m, otherwise the calculation is carried out according to the volume of the premises: the cubic capacity is multiplied by 40 W;

- the heat generator must be selected with a minimum margin of 20%;

- if the heating unit is planned to be used to provide domestic hot water, the reserve must be at least 50%; Dividing the quadrature by 10 is the same as multiplying by 0.1, the result is the same

- in the northern regions, the square footage of the building is multiplied by 0.2 kW, in the southern regions - 0.08 kW;

- The power of the boiler, which operates only at night and charges the heat accumulator, is assumed with a double margin.

Example. A small house of 100 m² on average requires 100 x 0.1 = 10 kW of heat. The power of the electric heating installation is 10 x 1.2 (20%) = 12 kW. We need to heat water for household needs - multiply by a factor of 1.5 and get 15 kW.

Which type of heater is better

Next, you need to select a water heating device based on its operating principle. What types of household electric boilers can you buy:

- Traditional, equipped with tubular electric heaters (TEHs).

- Electrode, where the salted coolant is heated by passing current through the water.

- Induction devices heat the liquid using Foucault eddy currents that arise in the metal core of a multi-turn coil.

Electric mini-boiler room with tubular heaters (TEN), fully equipped

The first place in the user rating is occupied by heating element heaters. The only weak point - the heating element itself - has long been protected with ceramics, and in addition it is easy to replace. Modern models of heat generators are wall-mounted mini-boiler rooms with a built-in expansion tank and circulation pump. There are simpler versions that include only heaters and an automation unit.

The cheapest and most reliable option is an electrode boiler with a control cabinet, shown in the photo. Its disadvantages:

- loud switching sounds from the operation of a contactor or magnetic starter;

- gradual degeneration of salts in the coolant, which reduces heating efficiency, which is why the water in the heating system will have to be added with salt 1-2 times a month;

- The electric device works stably with radiators, but is poorly compatible with heated floors, where it is necessary to maintain a low coolant temperature of 35-50 ° C.

Induction electric boilers for heating a private home are quite expensive, and there are questions about the reliability of the devices. There are known cases of phase burnout inside the coil, the power of the heat generator dropped by a third. Fixing the breakdown is very problematic.

An induction heater heats water with a metal core located in the vortex field of the coil

How much does it cost to heat a house with an electric boiler?

This was all theory, with little impact on the wallet. How much will it cost to heat a house with an electric boiler? By the way, the cost of electric boilers themselves is lower compared to other heating boilers.

Given: For the calculation, let's return to my example above. House 100 sq. meters, electric boiler 10 kW (for 10 meters we take 1 kW boiler).

Question: How much will it cost to heat a house with such a boiler in the winter from October to May.

Solution:

- Calculation 1. We assume that the boiler operates constantly. Power consumption is 10 kW per hour, per day 240 kW, per month 7200 kW. At 2017 prices, 1 kW/hour = 5.38 rubles (one Moscow tariff). We get 38,736 rubles per month with constant operation of the boiler, which does not happen in practice.

- In practice, the boiler will operate at full capacity for 10-14 days during the entire winter period. During the rest of the winter (December-February) the boiler will operate at 50% power. In other months, the boiler will operate at 30% capacity.

We get: For the entire season, in Moscow prices, the boiler will “eat” 116,190 rubles in 8 months. Which is an average of 14,523 rubles per month. That's the math.

Electric boiler wiring diagram

When executing the piping diagram, it should be taken into account that in addition to calculating the power for an electric heating device, it is necessary not to forget about its main purpose - to control the temperature difference of the liquid at the inlet of the device and its outlet.

Initially, after reaching a certain temperature, the coolant moves along a small circuit and only after passing through it is the heated water transported through the system, heats the electric batteries and thereby heats the room. Thus, in order to ensure the required temperature conditions and high-quality functioning of the heating structure, it is necessary to install several circuits.

To complete the strapping you will need:

- pipes of different diameters;

- heating radiators (read: “Tying heating radiators with polypropylene - simple and affordable “);

- circulation pump;

- pressure gauge;

- balancing valve;

- distribution valve;

- pass filter.

Equipment and tools should include a welding machine and wrenches.

As for additional and fastening products, the following will be needed:

- tees, adapters;

- safety, check, air valves;

- bolts, nuts, couplings.

The piping of an electric heating boiler is carried out according to one of four different principles:

- with forced water circulation;

- with natural coolant circulation;

- classic wiring option;

- using primary-secondary rings.

A room heating system with natural water circulation consists of:

The circuit providing forced circulation includes the following elements:

- room temperature regulator;

- radiators;

- electric boiler;

- open type expansion tank;

- safety unit consisting of a safety valve and pressure gauge;

- tap for replenishing the amount of coolant;

- pump;

- check valve;

- anti-condensation pump;

- minimum temperature sensor.

If the heating structure operates using a wall-mounted electric heating device, then all its elements are also included in the piping, which, in addition to heat supply, can provide hot water supply and the functioning of the “warm floor” heating system.

The process of connecting equipment according to the instructions is not a problem if all the instructions written in it are followed exactly. But self-installation applies exclusively to single-circuit systems. In the case where it is planned to install a double-circuit electric heating boiler. the work is complex and then the tying is done at a professional level, both direct and mixing. Both types of strapping are necessary to control temperature levels. How to make a boiler piping, watch the detailed video:

Connection of an electric boiler with other types of equipment and a heat accumulator

Let's look at how to connect an electric boiler with solid fuel equipment. This option is convenient for owners of country houses where interruptions in the power supply to the network are possible.

Procedure:

- In a network with a solid fuel boiler - it is the main worker, the electrical equipment acts as an auxiliary one.

- When wood or coal is burned, the air temperature in the room decreases, the electric boiler starts working when the temperature reaches below the standard level. The operating mode is set by the user himself, setting the cooling and heating temperatures according to his own preferences.

- The thermostat will detect a decrease in temperature in the return pipe going to the solid fuel boiler and turn off the equipment pump.

- As soon as the owner loads a portion of firewood into the firebox, heating of the heat exchanger of the solid fuel boiler will resume, and the thermostat will start forced circulation of water. In the process of starting liquid transportation, the electric boiler “recognizes” the heating of the coolant by sensors and does not start heating until the next moment the temperature cools to lower limits.

In this way, a floor-standing or wall-mounted electric boiler can be connected to heating with any other types of heaters. The main nuance is that equipment powered from the mains is considered backup; another heat source will be the main one.

To accumulate thermal energy, a buffer tank is inserted into the network; this is a heat accumulator, where the coolant is constantly maintained in a hot state. Such a storage device allows you to reduce the cost of servicing the system - tariffs are cheaper at night, the boiler will heat water for distribution to the heating system during the day.

Water heating safety

Continuous cycling of electrical equipment and trouble-free operation require the installation of protective devices and devices in the heating circuit.

They are mounted separately or assembled into a security group, which is represented by the following parts:

- Automatic valve for releasing air from the water circuit (AVK).

- A diaphragm-type safety valve for relieving excess pressure from the system in the event of a thermostat failure or a blockage in the pipeline.

- Pressure gauge. The control and measuring device is used to visually monitor the state of the working environment in the circuit. Sometimes, instead of a pressure gauge, a combined device is used, which shows, in addition to pressure, the temperature of the coolant.

Specialist's note: in a closed heating scheme, it is imperative to install an expansion tank with a displacement that provides compensation for the linear expansion of the entire volume of coolant in the system.

Disadvantages of electric boilers

Electric boilers have many disadvantages. These include:

- High energy consumption

. In order for home heating to be highly efficient, it is necessary to use powerful equipment that consumes a significant amount of electricity (more details: “Electric boiler: electricity consumption - economical calculations”). From an economic point of view, installing an electric boiler is not the best solution. - Equipment is being improved at a slow pace

. Electric heating devices appeared quite a long time ago, but the principle of their operation has remained virtually unchanged. The purpose of boilers is to transfer coolant within the house. Low-temperature ceramic and film heaters have recently appeared - they are quite efficient (no heat dissipation occurs when transporting water) and economical. - Water is usually used as a coolant

. Therefore, when the heating system is turned off, pipes and radiators may freeze. Electric convectors and oil radiators do not have this disadvantage. To solve the problem, you can also use oil or antifreeze in the heating system rather than water.

Useful features and disadvantages

It is also worth considering installing a universal solid fuel boiler with built-in electric heating elements.

Some models even have a hob, which does not require additional external finishing. Electric boilers can easily withstand power outages for up to 6 months. This makes them a good option in case of irregular use of the system or in case of interruptions in the supply of electricity needed to heat a private home.

The disadvantage of using an electric boiler is the need for powerful supply cables with a large cross-section.

Sequence of work

The installation diagram of the heating device is carried out according to a certain algorithm. The reliability of the equipment in the future depends on how accurately this scheme is executed.

The general kit includes:

- electric boiler;

- temperature sensors;

- batteries;

- shut-off and drain valves;

- expansion tank;

- coolant circulation pump;

- filter.

Work begins with marking and installation. The device should be located away from the water pipe so that a short circuit does not occur if there is a leak. Installation of equipment is carried out using dowels or bolts, and the surface should be leveled both horizontally and vertically. For floor-standing units you will need a special tray.

The next thing to do is to connect to the system, for which you need to turn off the water supply to the taps. Connection is carried out using adapters and couplings.

Then comes the turn of the electricians. It includes a circuit breaker and a protected shutdown device of the required ratings. Correct connection requires grounding. The wiring is laid in cable channels protected by casings. The cross-section of the wires must correspond to the power of the equipment.

An electric boiler requires a circuit breaker

Only after completing work with the electrical part of the circuit can you begin to test the operation of the electric boiler.

Note! Such devices are responsive even to minor voltage surges in the electrical network, which means that the use of a stabilizer is mandatory

Installation stages

Installation of the harness consists of several stages:

- First, marking and installation are done. To avoid a short circuit in the event of a boiler leak, it is placed away from the water supply. To install this device, dowels or anchor bolts are used. The boiler is leveled horizontally and vertically using a level. When choosing a floor-standing model, place a special stand under it.

- Then the electric boiler is connected to the heating system using adapters and couplings. Before this, the water is first shut off using taps of any type.

- After completing the connection of the boiler to the system, it is necessary to complete the electrical part of the structure, which consists of an RCD and a circuit breaker. To connect the boiler it is necessary to make grounding. All electrical cables are placed in a special casing and laid in channels intended for wiring. The cable cross-section depends on the power of the equipment.

- After the electrical part, grounding is done and the heating system is tested.

| Sales are conducted through Avtomash JSC |

+7, 652-51-16

| JSC "Avtomash" | ||

| Directions >>> | View price list | |

Customs Union. Certificate of Conformity No. TS RU С-RU.АВ98.В.00335 Series RU No. 0206144 Valid from November 26, 2014. until November 25, 2019 Manufactured according to specifications 3468-015-49110786-04. Complies with the requirements of the technical regulations of the Customs Union TR CU 004/2011 and TR CU 020/2011

Due to the constant improvement of the design and manufacturing technology of the product, deviations in the design of the product from the requirements of the passport are possible, which do not affect the operating conditions.

1. Purpose of the product

1.1. Electric water heater type EVPM (hereinafter referred to as “water heater”), climatic modification UHL4, is intended for operation as part of a water heating system for residential and office premises with natural or forced (pump) circulation of coolant (water) at a pressure of no more than 0.25 MPa and water heating temperature up to 85°C. Operating ambient temperature range from + 1°C to + 40°C.

1.2. It is recommended to install a circulation pump in all heating systems, which improves coolant circulation and increases the efficiency of the entire system.

1.3. In heating systems, in addition to water, non-freezing coolants such as Argus-Hatdip and Dixis can be used as a coolant if the conditions for their use in heating systems specified in the instructions are met. The use of other coolants in heating systems is not permitted.

2. Specifications

Technical characteristics Electric water heaters EVPM-3. EVPM-12

| EVPM-3 | EVPM-4.8 | EVPM-6 | EVPM-9 | EVPM-12 | |

| Supply voltage (three-phase), V | – | 3х380±10% | 3х380±10% | ||

| Supply voltage (single-phase), V | 220±10% | 220±10% * | – | ||

| frequency Hz | 50 | ||||

| Rated power, no more, kW | 3,0 | 4,8 | 6,0 | 9,45 | 12,0 |

| Heated room area, m2 | 30 | 48 | 60 | 95 | 120 |

| Water heater capacity, l | 3,5 | ||||

| Amount of coolant in the system, l/kW | 25 . 35 | ||||

| Water pressure in the heating system, MPa, no more | 0,25 | ||||

| Degree of protection from the external environment | IP21 | ||||

| Insulation resistance, MOhm, not less | 0,5 | ||||

| Electrical protection class | 01 | ||||

| Overall dimensions, mm | 270 x 165 x 625 | ||||

| Weight, kg, no more | 12,7 | 13,2 | 13,5 |

* Performed in accordance with clause 6.17 and the electrical circuit diagram Fig. 3.

3. Scope of delivery

Electric water heaters Electric water heaters EVPM-3. EVPM-12 is supplied in packaging (corrugated cardboard). The package includes: