We install a gas boiler

As a rule, installing heating boilers of this type in a private house requires a separate non-residential premises (boiler room). This is necessary for the removal of combustion products, that is, for the installation of a chimney. The boiler room must be equipped with flow ventilation. A hole is made under the ceiling for air outlet, and for air inflow - 30 cm from the floor level. Floor-standing boilers are installed using:

- welding machine;

- drills and drill sets;

- keys, including gas keys;

- set of screwdrivers;

- metal scissors;

- building level;

- tape measure and marker.

Preparation and connection

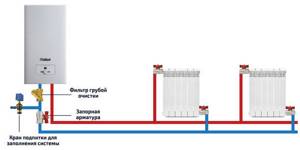

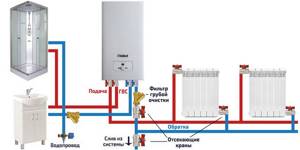

The surface for installation must be strong and level, and ideally a foundation should be poured. To ensure safety during operation of the equipment, it is necessary to place a sheet of iron on the foundation. The first step is to install the chimney and check for draft. Then connect the boiler to the internal heating system: in front of the return entrance of the pipeline, install a filter that protects the heat exchanger from clogging, and the tap into the water supply should be located as close as possible to the entrance of the water pipe into the room.

This scheme will ensure high pressure in the system and a constant supply of water.

This is necessary to dismantle equipment without discharging water. It should be noted that installation of gas equipment is carried out only after agreement with the supervisory authorities with the involvement of certified gas service specialists. Don't skimp on safety!

Nutrition

How to install an electric boiler in a private house and connect it to power?

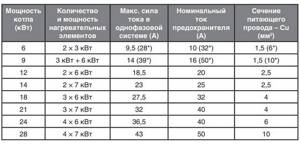

You can power it yourself without resorting to the services of an electrician. The connection rules are quite common:

- Through the socket you can connect low-power boilers and electric radiators up to 3.5 kW inclusive;

- A separate wire from the panel can power a device with a power of up to 7 kW. In this case, the cross-section of the copper wire is selected at the rate of 10 amperes of maximum current (at 220 volts - 2.2 kW of power) per 1 mm2;

- It is recommended to connect boilers with a power of 8 kW and higher to a 380-volt power supply

- The boiler is connected via its own automatic machine . The operating current of the circuit breaker should only slightly exceed the maximum operating current.

Let me remind you: the current is calculated as a quotient when dividing the power consumption by the supply voltage.

How to connect an electric boiler to a heating system

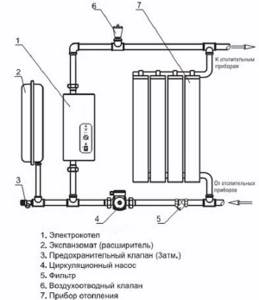

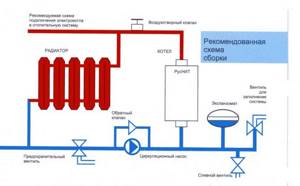

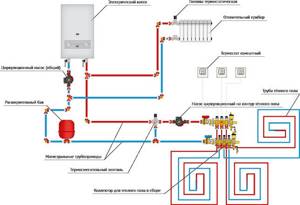

There are several standard piping schemes, one of which must be selected before connecting the electric boiler to the heating system:

- installation of the unit with piping of the electric pump and expansion tank;

- installation of an electric boiler in a parallel operation scheme with a solid fuel or gas boiler unit;

- connection with a hot water storage tank or an external electric water heater;

- connection of a double-circuit modification of an electric boiler to heating networks and hot water supply;

- connection to an indirect heating boiler.

Typically, modern electric boilers are equipped with all the necessary auxiliary equipment. The safety group protects the unit from high pressure and releases air from a closed water circuit using a membrane expansion tank.

Connection diagram for a double-circuit electric boiler

A safety group is installed on a straight section of the supply pipeline, and after it - a ball valve that cuts off the coolant supply. The circulation pump and dirt filter are installed on the return pipeline.

If it is necessary to connect the boiler to an open heating system with natural circulation, then the heating pipes will need to be placed with a slope of 3 mm by 1 pm.

Electric boiler circuits for preparing hot water supply are used in two versions:

- double-circuit design of the boiler, which has two built-in heaters for the heating circuit and DHW;

- single-circuit boiler with external indirect heating water heater.

In the first option, connecting the electric boiler to the heating system is carried out according to the standard scheme. There are practically no difficulties here, the main thing is to correctly install the shut-off valves.

Single-circuit diagram. Photo source: twlwthrt.appspot.com

Connection to an indirect heating water heater is made using three-way shut-off valves. Based on a signal from a thermostat integrated into the battery tank, the valve switches the movement of heating water to heat up the DHW circuit or heating system.

DHW loading is a priority: until the water in the tank warms up to a certain temperature, the heating network will not receive thermal energy.

Features of parallel connection

Let's take a closer look at what a standard parallel connection diagram for gas and electric boilers looks like:

- Each unit has coolant supply circuits. They join the common line.

- It is imperative that there are safety groups and shut-off valves.

- The return lines, also equipped with shut-off valves, are connected to the other line.

- A circulation pump is installed on the return line (or supply), in front of the unit for combining the piping circuits.

- The lines of both heating units are connected to the collectors.

- An expansion tank is installed on one of the distribution manifolds. A make-up circuit is also connected to its pipe, equipped with a check valve and shut-off valves.

- From the distribution manifolds there are main branches to the heated floor, radiators, boiler, each with circulation pumps and valves for draining the coolant from the system.

This is not a schematic diagram, but only its main features. It gives a general idea of how best to connect an additional electric boiler to the main gas boiler. The assembly option can be complicated and improved, for example, with an automation system and a servo drive.

With a parallel connection, you can also install a hydraulic arrow and an automation unit, but before doing this, carefully consider this decision; installing them is not always advisable

Safety regulations

When installing the boiler, the following safety precautions must be observed:

- All work must be carried out in a disconnected section of the electrical network.

- The wiring must match the power of the device.

- The device must be grounded.

- All recommended distances must be maintained between building structures and the boiler body.

- Power cables are mounted in sealed protective casings to protect them from water ingress.

- The power line feeding the device is equipped with an individual circuit breaker.

- The boiler piping is attached to the wall or supports to reduce the load on its body.

- The wall on which the device is mounted is protected from overheating by a sheet of non-combustible material.

- The electric boiler is not installed near water sources or plumbing.

Failure to comply with these rules can not only lead to failure of the device, but also lead to human casualties. It is not difficult to avoid sad consequences if you carefully and slowly carry out all work in accordance with the recommendations.

Principle of operation

When boilers operate, electrical energy is converted into heat to heat the coolant, which is water, antifreeze or oil. Although all electric boilers have similar housings, many of them differ in operating principle. Their internal structure, performance and safety depend on it. The following types of boilers exist:

- induction;

- electrode;

- equipped with heating elements.

Induction model

They heat the coolant passing through the circuit. Such a system, despite its complexity, has a high efficiency. Its advantages:

- Long service life. The core does not develop scale and does not overheat during operation. The device works almost flawlessly.

- Versatility. The boiler can use any coolant liquid.

- Reliability. Due to the absence of detachable connections, the risk of leaks is minimal.

Electrode systems

These devices use electric current passing through electrodes. Salt is dissolved in the water inside the installation, due to which the liquid turns into an electrolyte. Two electrodes are lowered into it, the polarity of which changes with a frequency of 50 hertz. As a result, an alternating current appears in the coolant, the water is ionized and heated. Advantages of the installation:

- Compactness. For efficient operation, you do not need a large tank and circulation pumps.

- Affordable price. Thanks to its simple design, installation costs are low. It is affordable for most homeowners.

- Work safety. If a coolant leak occurs, the heating is turned off very quickly and without insurance. Heating stops when there is no current.

The installation has certain disadvantages. Water with certain parameters can be used as a coolant. If its resistivity does not meet the standard, the boiler will not work.

Devices with heating elements

These are convenient and safe devices of simple design. To heat the coolant, they use several spirals placed in heat-conducting tubes. The power of the installation is regulated by connecting or disconnecting some of the heating elements. Hot water from these boilers can be used for household needs. Installation benefits:

- Affordable price due to simple design.

- Antifreeze, water or oil can be used as a coolant. The main thing is that the liquid does not freeze if the boiler is stopped in cold weather.

Boilers with heating elements have some disadvantages. One of their disadvantages is their large size. Large containers are needed to accommodate heating coils. The boilers themselves are quite bulky. Also, when using such devices, problems with scale may arise. But due to the low price, installations with heating elements are most popular among consumers.

Detailed step-by-step instructions for installation and connection

Installation of an electric boiler on the wall

- Clean the wall from dust and dirt.

- Mounting kit: hinged mounting plate, dowels and screws, usually included with the boiler.

- Make a mark on the wall in accordance with the mounting strip and drill holes corresponding to the diameter of the dowels (usually Ø 10 mm), insert the dowels into the holes.

- Hang the boiler on the threaded hooks, then tighten the screws.

How to choose an external thermostat for an electric boiler and save up to 30% on heating every month

Organization of strapping

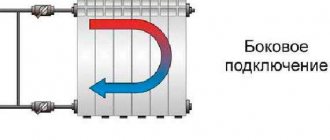

For heating element electric boilers in a monoblock housing, which already have all the necessary elements of the system, it is enough to connect the supply and return lines to the corresponding pipes. It is necessary to supply water to the system through the return valve.

For simple heating element boilers without a circulation pump and an expansion tank, all elements are connected in accordance with one of the diagrams given above.

- First, the hydraulic manifold and expansion tank are mounted on special mounts.

- Next, in accordance with the diagram, pipe routing is laid with a circulation pump, filter, and safety group installed on them.

Supplying electrical wiring and connecting an electric boiler to it

Electric boilers have high power and only low-power models up to 3.5 kW, usually used in apartments, are allowed to be connected to an outlet. In other cases, the connection is made exclusively directly.

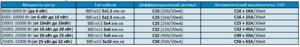

The boiler unit is connected to the electrical network through a differential circuit breaker or a combination of RCD + circuit breaker (1 switch for each phase). The power cable must have a sufficient cross-section, which can be calculated, for example, based on the power of the electric boiler.

| Cable cross-section, mm 2 | Copper conductors, kW | Aluminum conductors, kW | ||

| 220 V | 380 V | 220 V | 380 V | |

| 1,5 | 3,3 | 5,7 | — | — |

| 2,0 | 4,1 | 7,2 | 3,0 | 5,3 |

| 2,5 | 4,6 | 7,9 | 3,5 | 6,0 |

| 4,0 | 5,9 | 10 | 4,6 | 7,9 |

| 6,0 | 7,4 | 12 | 5,7 | 9,8 |

| 10,0 | 11 | 19 | 8,3 | 14,0 |

| 16,0 | 17 | 30 | 12 | 20,0 |

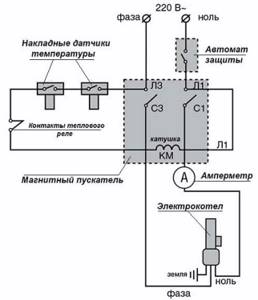

The electrical connection diagram itself is the same for all electric boilers, the only difference is in the number of phases.

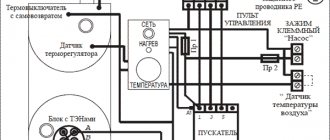

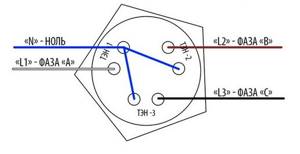

When connecting to a single-phase power supply, it is enough to connect the phase to any of the contacts (U, V or W). When connecting the electric boiler to a three-phase (380 V) electrical network, you must remove the jumper (see diagram) and connect a phase to each of the 3 contacts. Zero and grounding (N and PE, respectively) are connected in the same way in each case.

An example of a Protherm Skat contact block, the connection is to a three-phase power supply.

Connecting an electric boiler automation system via a magnetic starter.

Grounding

High-power electrical installations, which include household electric boilers, require high-quality grounding in compliance with all standards and requirements. A wire of the required cross-section must go from the boiler body to the internal grounding distribution board, if it is already organized, or directly to the electrodes dug into the soil, if there is no grounding in the country house.

The outer part of the protection should be located in a place where it is guaranteed that no one will be present at the time of a power failure, but preferably no further than 1 meter from the foundation of the house.

Work order:

- Using a shovel, dig a triangle and a connection to it with a depth of 0.5-0.7 m, the length of the sides of the triangle is 1.2 m. The photo shows an example of a trench and a ready-made grounding structure.

- Sharpen with a grinder and drive vertical grounding rods into the ground at the vertices of the triangle - metal corners 50*50, 2.1-2.2 meters long. They should only stick out a little from the ground so that horizontal grounding plates can be welded to them later.

- Forming the sides of a triangle, weld 3 strips of metal 1.2 m long, 4 cm wide and at least 4 cm thick to the vertical electrodes.

- Weld a 4)*4 mm stainless steel strip to the nearest vertex of the triangle and pass it along the trench to the foundation of the house.

- Connect the grounding wire coming from the distribution board or the electric boiler body with a bolted connection.

- Cover the structure with soil.

Poll: is your country house fully grounded?

Test run of the boiler

- Check the insulation of all wires, the reliability of couplings, taps and pipe joints.

- Run water into the heating system through the make-up tap, opening the valve not all the way so that water is drawn under less pressure.

- Bleed the air through the air vent; some models have an automatic air vent.

- Check the pressure in the system using a pressure gauge; the exact nominal values are indicated in the electric boiler's passport; usually it is 1.3-2.0 bar in operating mode and 1.0-1.3 bar when the boiler is turned off.

Test run of the boiler

- Thoroughly check the insulation of all wires. Make sure couplings, taps and joints are securely fastened. Let water into the heating system through the make-up tap, slowly opening the valve so that the water does not flow in suddenly, without creating a large pressure.

- Release the air through the vent. Some electric boilers have a built-in air vent that operates automatically.

- Assess the pressure level in the system using a pressure gauge; the exact nominal values are indicated in the electric boiler passport. Typically, they are 1.3-2.0 bar when the boiler is operating, and 1.0-1.3 bar when the boiler is off.

Stages of installation work

Heating system installation diagram

Each heating equipment has its own individual installation scheme, which must be strictly adhered to. Stable operation and high efficiency of the equipment depend on this. Installation of the wiring diagram occurs in several main stages.

As mentioned above, it includes several mandatory elements: the device itself, temperature sensors, drain and shutter valves, an expansion barrel, a circulation pump and a filter.

- The installation process begins with marking and installation. To avoid short circuits in case of leaks, the boiler must be installed as far as possible from the water supply. The electric boiler is installed using dowels or anchor bolts; it must be leveled both vertically and horizontally. If you are using a floor-standing model, it is recommended to place a special stand under it.

- Next, you need to connect the boiler to the system using adapters and couplings. Before connecting, the water must be turned off in advance by any type of tap.

- After connecting the device to the heating system, they proceed to the implementation of the electrical part of the circuit, which includes an RCD and a circuit breaker of certain technical characteristics.

When connecting an electric boiler, it is necessary to consider grounding. In this case, all cables must be protected with a special casing and laid in cable ducts. The cable cross-section depends on the power of the device.

Which electric boiler is the most economical?

The criteria by which heating boilers for a private house using electricity are selected are as follows:

- heating area, on which the boiler power will depend;

- characteristics of the premises;

- equipment prices;

- size and weight of the heating boiler;

- life time;

- boiler efficiency.

We will choose from the following types of electric boilers for heating:

- Induction. The main working unit of such boiler boilers is the inductor. These boilers have great power, but are large in size and high in cost.

- Heating elements. The coolants in such boilers are heated by thermoelectric heaters (TEHs), working with power controllers and temperature sensors. The heating element heats the water, which transfers heat to the room. The disadvantage of such boilers is the deposit of scale, which interferes with normal operation and disables the heating elements.

- Electrode. The most economical boilers are approximately 40% more economical than heating elements. The advantages also include small size, fast heating of water and the absence of scale during operation.

Electric boilers, in addition to the listed types, can also be:

- Wall or floor. Wall-mounted boilers, as a rule, are low-power, and are used for heating country houses;

- Single- and three-phase;

- Single and double circuit.

The final decision on which most economical electric boiler to choose for your home depends on your living conditions. In my opinion, this is an electrode boiler, which is connected to a standard electrical network and uses water or non-freezing liquid as a coolant.

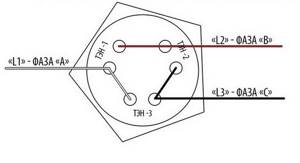

Diagram of the electrode boiler

Safety regulations

Installation of an electric boiler must be carried out in compliance with safety rules:

- Before starting work, make sure that the electrical supply is turned off.

- It is prohibited to install an electric heating boiler in close proximity to a water supply or water source.

- The recommended distances between the unit body and building structures should be observed.

- Make sure that the electrical wiring parameters correspond to the power of the boiler (connecting a powerful unit to a 220 V household network can cause overload and short circuit).

- The boiler must be connected to a grounding circuit.

- Installation of an electric boiler is permitted on a wall made of non-combustible material. If the wall structures are made of wood or other material prone to fire, non-combustible sheathing made of basalt cardboard and sheet metal is mounted on the wall.

- Power cables must not be laid under heating circuit or water supply pipes. If this cannot be avoided, use special sealed housings made of metal or plastic to protect the cable from possible moisture ingress.

- When installing a heating boiler with your own hands, the heating circuit pipelines that are connected to it should be securely attached to the wall so that they do not add load to the body of the unit.

Installation of a residual current device

Installation site requirements

Recommended electric boiler assembly diagram.

When carrying out installation work, it is necessary to follow the rules that will make it easier to service the equipment in the future.

Heating elements units must be hung at a height of 1.5 m from the floor for the convenience of regular technical inspection of the device. Induction and ion instruments can be placed at low heights, but only require vertical installation.

For operation, single- or three-phase voltage is supplied.

When mounting it on the wall, you need to make sure of its quality - it must withstand the weight of the device and the devices connected to it. When laying pipelines, it is not allowed to secure heating pipes near the water supply, but if this option is not possible, then use a protective box or sleeve.

When installing an electric boiler, the distance from the ceiling to the unit must be at least 70 cm, and on the sides - 50 cm from the walls of the room.

The place where equipment is hung must be protected from moisture . Free space is needed nearby, since the power supply circuit requires the installation of automatic circuit breakers and RCDs on each phase.

Heating schemes for a private house with an electric boiler

The simplest heating scheme for a private house with forced circulation by a heating element monoblock electric boiler, which already has an expansion tank, a circulation pump, a safety valve and an air vent.

Heating diagram for a private house with a simple electric boiler that does not have an expansion tank and a circulation pump.

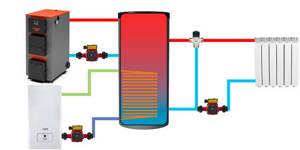

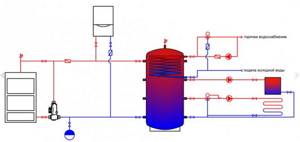

A simplified diagram of using an electric boiler as a backup heating equipment in conjunction with the main boiler and buffer tank. The electric boiler can be used during the night zone with reduced tariffs, and during the day the buffer tank will release the accumulated heat for a long time.

Connection diagram for a double-circuit electric boiler.

Heating scheme with electric boiler and heated floors. Hydrocollectors are used to distribute heated floors into several circuits.

Connecting an electric boiler - electrical and hydraulic diagrams

Electric boilers are now installed quite often. But in most houses they serve only as a reserve. As a rule, the main ones are gas and solid fuel boilers, the operation of which is several times cheaper. But sometimes, with appropriate equipment, an electric boiler is used as the main one...

How is thermal energy from an electric boiler reduced in price? How to connect correctly, what circuit to use?

One of the most important advantages of this heat generator is known - better comfort and trouble-free operation, and then...

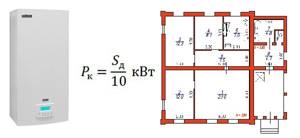

How much power will be required

How much power will be required to heat the house?

- It is known that for a well-insulated house you will need 10 kW per 100 sq. m.

- For houses built using energy-saving technologies, such power will be excessive.

- But if the box is characterized as “very cold”, then 20 kW will not be enough....

For an average house, the selection can be done exactly this way - 1 kW per 10 square meters. If in practice it turns out to be not enough, then it is economically feasible not to increase the power, but to insulate it - first change the windows and doors, then increase the layer of insulation in the attic...

Is an electric boiler suitable for constant heating?

From the point of view of convenience and reliability, the cost of repairs, an electric boiler is the best heat generator. The problem is the cost of electricity. It is not profitable to heat with it at a daily rate.

The second problem is the power allocated to the facility. Is it enough to fully heat the house?

It’s good if 15 kW of three-phase 380V power supply is allocated. Then you can install a boiler with a capacity of 12 kW, another 3 kW will be used for domestic needs.

But if the power supply is 220V and the permissible power of the boiler is only 4 kW, then it can only be considered as an emergency option to maintain heat in case the main one fails. Or for heating in the off-season, at a cheap rate, but such schemes will be discussed further...

We connect the electricity - so as not to catch fire

In order for the electric boiler to work without problems, first of all it must be correctly connected to the power supply. Different models have their own characteristics. But all factory units are equipped with an electrical circuit diagram and instructions. These documents are executed exactly.

The following remains common to all options.

- The use of cables of a certain type with copper conductors of the appropriate cross-section.

- Connection only with solid sections of cables, splices are not allowed.

- It is inadmissible to use automatic (VA) and other protection switches for constant switching on/off - if the boiler is not equipped with a switch, then such a device is installed additionally in the circuit.

- Application of electrical protection - ground leakage relay (Residual Current Device) and overcurrent protection (Automatic Circuit Breaker). These two devices can be combined in one housing and called a Differential Automatic.

What cross-section of cores and type of protection will be needed

Most likely, the manufacturer will give comprehensive recommendations on the selection of electrical conductors for connections, and on the choice of the type of differential circuit breaker.

However, you can use the following table, which shows the characteristics of cables and electrical protections depending on the power of the electric boiler. Data shown here is for a 380V three-phase power supply.

For a 12 kW boiler with three-phase power, you will need a VVGnlLS cable, which includes 5 copper conductors, each with a cross-section of 4 mm square. And also an AV with a shutdown current of 25A, an RCD with a differential current of 30 mA.

Connection diagram

General circuit diagrams are shown in the figures. For three-phase 380V and two-phase 220V power supplies.

But the principle is the same - the phases are protected and, if necessary, switched off by a differential circuit breaker (safety shutdown and overcurrent protection).

Connection diagram for boiler heating elements

Boilers, which are most often used in everyday life, have a low power - up to 15 kW, since they no longer allow connecting energy supervision. Such units can be equipped with heaters designed for a 220 V power supply. At the same time, they are connected to a three-phase 380 V network in a star circuit with a common zero.

The diagram shows 3 heating elements designed to operate on a 220V network, which are connected to three 380V phases. For example, 3 heaters of 4 kW each give a total electrical power of 12 kW. With this connection, it is possible for each heating element to operate independently of the neighboring one. Those. You can select a power mode of 4, 8 and 12 kW.

The connection of heating elements and automation of a particular electric boiler is shown in the electrical diagram attached to it, which is what should be done.

If the heaters are designed for a voltage of 380V, then they are switched between phases in a “triangle”.

How do electric boiler protections work?

The residual current device (leakage relay) compares the strength of the current passing through it in phases. These values in a normally operating circuit will be approximately equal. But if damage occurs (the sheath of the cable cores is destroyed, the consumer is destroyed, for example, the heater burns out and there is water in the housing...), or a person touches the current-carrying part, then a current leakage will appear from some phase. And between the conductors a difference (differential) of current strength is formed. In this case, the relay will turn off the network in a very short period of time. The response time for shutdowns is short; a current dangerous to health does not have time to arise through the human body.

The automatic switch (maximum current) is triggered when the specified current strength in the circuit is reached. For example, in case of a short circuit between phases. In this case, the protective relay does not operate, since the current strengths in the phases will be equal. But maximum current protection will turn off the network and prevent ignition of electrical devices and conductors.

How to make installation

For direct installation of electrical protection, laying the selected cable and connecting it to the electric boiler, it is recommended to invite a qualified electrician. And don’t do these important jobs yourself.

As a rule, a specialist will not allow violations of regulations and the creation of a dangerous environment.

For example, in a wooden house, electrical wiring is laid in a non-flammable casing. A metal corrugated tube can play this role.

Or, for example, it is not allowed to make grooves in the supporting structures of a house for laying electrical conductors.

Clamping of conductor cores in contact groups is carried out according to the rules.

Specialists perform these and other nuances quickly and efficiently.

Hydraulic circuit

A typical connection diagram for an electric boiler is shown in the figure. Here, “electric boiler” means a simple water heater that requires all the additional equipment.

Important elements in the diagram.

- Coarse filter - installed on the return line in front of the pump, the collector downwards and along the flow.

- Circulation pump - in houses up to 200 sq. m. As a rule, a pump of 25 - 40 is sufficient. It is recommended to install it on the return line in front of the boiler.

- An expansion tank with a volume of 1/10 of the volume of liquid in the system prevents a dangerous increase in pressure during heating (expansion) of the coolant.

- The safety group is a mandatory element and consists of an air vent, a pressure safety valve, and a pressure gauge. It is installed on the supply, at the highest point of the heating pipeline, at the outlet of the boiler.

But expensive models are equipped with such equipment in one case.

Cheap electricity for heating

For your information: the cost of thermal energy for heating with gas, in a rough approximation, is estimated as 0.8 rubles/kW. When heating with wood - 1.3 rubles/kW.

During the day, electricity costs 5.4 rubles per kW, and at night 1.6 rubles/kW (approximate tariffs for the Moscow region).

Those. Night electricity is comparable in price to other types of fuel. And due to its ease of use, it is a winner in terms of price/quality ratio for most users.

If you install a meter with a night tariff, which is decided by energy supervision, then this can be used.

But how to use night electricity during the day?

The usual scheme for using an electric boiler

The maximum power of an electric boiler at night may be excessive, otherwise it will be hot, for example, for a house with an area of 100 square meters. with a 12 kW boiler, also in the off-season.

It is optimal to accumulate excess night energy at night and use it during the day. To do this, it needs to be converted into heat (heat water) and stored in a heat accumulator.

Buffer containers with a capacity of 1 ton of liquid are used. How is buffer capacity used?...

Then the circuit for switching on the electric boiler is as follows.

Here the electric boiler is switched on in parallel with the solid fuel one. With a night tariff, the electric unit acts as the main one, providing users with an existence without worrying about heating. In extreme cold, when electrical power and accumulated energy are not enough, solid fuel is connected to the heating process.

How to save money when heating with an electric boiler

- Do not overheat the room. It’s not uncommon for the automation to be set up incorrectly and the room to become too hot. Waste +20% of money on inconvenience. To automatically control the boiler, it is better to use air sensors - room thermostats. And do not be guided by the temperature of the coolant.

- Shutting down unused rooms. It is not uncommon for individual rooms, for example a workshop, to be cool for a longer period of time. With an automated electric boiler, it is advisable to use thermostatic regulators on each radiator. Then thrifty owners will be able to regulate the temperatures in the rooms. In some cases, you can save 25% of energy.

- Optimal temperature distribution. Warm floors are up to 15% more economical than radiator heating. In addition, it is comfortable and convenient. Temperature distribution in rooms will be both beneficial and useful.

- Make ventilation. Ventilation removes up to 50% of the heat from the room. It is important to eliminate drafts and provide ventilation according to modern standards. How is ventilation done in a house?

- It is advisable to insulate. Electricity is expensive, and with its use there is much more economic benefit from insulation than when using the same gas. If for gas 10 cm of insulation thickness in the attic may be sufficient, then for electricity 22 cm is more appropriate. You need to add as much insulation as possible, based on the payback period in 12 years. In uninsulated houses, energy overconsumption reaches 200–300%.

Why do you need boiler piping?

The unit comes with compounds, their task is to increase the electrical conductivity of the liquid.

Best product

In order for home heating to be highly efficient, it is necessary to use powerful equipment that consumes a significant amount of electricity. Read more: "Electric boiler: electricity consumption - economical calculations." Connecting an electric boiler - electrical and hydraulic circuits Connecting an electric boiler - electrical and hydraulic circuits Electric boilers are now installed quite often. Equipment is being improved at a slow pace. Types of electric boilers Heating element boilers - heating elements are used as a heating element and are considered the most common.

It is necessary to start only if these conditions are met: There are no leaks, all components in the system have been checked. With pipes the situation becomes more complicated. This process occurs in the expansion tank; there are no other open sections of the circuit. Heating the garage with an electric boiler

Insulation of the house

The first recommendation is, of course, good insulation of the house or its construction in compliance with energy-saving technologies. If, when using gas boilers, many may approach this task somewhat carelessly, then when heating a house with an electric boiler, the need for good insulation becomes a priority. Example: if a brick wall made of hollow bricks 40 cm thick is insulated with mineral wool only 5 cm thick, heat loss through this wall, and therefore electricity consumption, will be reduced by more than 2 times!

How to connect an electric boiler

From the previous article on how to choose an electric boiler, we know that there are three methods for heating the coolant. Accordingly, there are three types of boilers: heating element, induction and electrode. Today we will tell you about connecting an electric boiler to a heating system. Installation is carried out in two stages. The first stage is connecting to the heating system, and the second - to the electrical network. Considering that the units can operate on both 220 and 380 volts, the connection diagrams to the power source are slightly different. You need to know how to properly connect an electric heating boiler to a network with different power levels.

How to make an electric boiler with your own hands

Electric boilers for heating a private house at 220 volts are often made independently - it is not difficult if you have the necessary materials and skills. The simplest boiler is a metal container in which heating elements are installed. Usually they make their own boilers with a power of 6 kW - such equipment is enough to heat a small apartment or country house. A DIY boiler will cost at least half as much as a purchased one. You can make a heating or electrode boiler yourself.

Materials for making a boiler using heating elements

For such a boiler you will need a tank of any shape in which the water will be heated by heating elements. The tank can be made from a 150 mm pipe. For a small boiler, 2-3 heating elements are enough, each costing about $10. Materials:

- steel pipe 150 mm;

- round plates l. 150 mm, 2 pcs.;

- nozzles no less than the contour - 3 pcs.;

- heating elements;

- nuts;

- automatic air vent;

- ball valve

Materials for making an electrode boiler

To make an electrode boiler with your own hands you will need:

- pipe 50 mm;

- steel bar 20 mm;

- flange and coupling with internal thread (2 pcs.);

- any dielectric;

- sealing rubber;

- bolts, nuts.

Detailed manufacturing instructions are presented on many websites on the Internet, so we will not repeat ourselves. There you can also see descriptions and connection diagrams for a simple control unit with a temperature sensor.

Greetings, comrades! There are many myths surrounding electric heating systems, created by false advertising. Today I will dispel some of them and tell you how different electric boilers differ from each other and how to properly connect such a device.

Strapping scheme (“classic” version)

The connection diagram of the electric boiler must ensure that there are no significant temperature changes. The most commonly used are double-circuit boilers. passing through the small circuit, the water (oil or antifreeze) heats up, after which it flows through the large circuit. This also needs to be taken into account in the diagram.

Electric boiler wiring requires the presence of:

- Brackets;

- Filter;

- Shut-off valves;

- Valves (check and safety valves);

- Expansion tank;

- Pump (if required);

- Thermometer and pressure gauge;

The following types of strapping are distinguished:

- With the installation of a hot water circuit (oil or antifreeze): before entering the tap, the coolant passes through an electric boiler;

- With connection to the heated floor system;

- Regular electrical connection.

When piping a double-circuit boiler, its type is determined by the model (with or without a mixer). It is quite difficult to install it at home with your own hands, since here, along with the correct connection to the electrical network, you also have to control the connection to the hot water supply.

Each model has its own connection diagram for the electric boiler (it is included when purchased along with the device). If you don’t have enough time or you are not sure that you can do everything correctly yourself, it is better not to start tying, relying only on your intuition and videos on the Internet. For 5-30 thousand rubles, specialists will do such work. But if you make mistakes at the first stage, you can subsequently not only incur much greater expenses, but also endanger yourself and other residents of a private house.

What are they like?

There are three types of boilers on sale:

- Heating elements (on tubular electric heaters). A battery of heating elements placed in the heat exchanger tank is responsible for heating;

- Electrode . The water is heated by the current flowing through it;

Thanks to the salts dissolved in it, water is an electrolyte - a liquid conductor with high resistance. When voltage is applied to the electrodes immersed in it, a current arises between them. When ions moving in an electromagnetic field collide with water molecules, they cause them to move faster, that is, they cause heating of the medium.

- Induction . The heat exchanger is a ferromagnetic rod fixed in a dielectric tube. When current flows through an inductor coil wound on a pipe, eddy currents are induced in the body of the heat exchanger, heating it.

In addition to the boilers themselves, current heating equipment stores offer electric radiators - aluminum sectional batteries with their own heating elements. Several of these radiators allow you to organize heating of a house with a distributed load on the wiring: instead of one device with a power of 6-24 kW, several 1-2 kW devices are installed.

The advertisement positions electrode and induction water heating boilers and electric radiators as economical solutions. Cost-effectiveness preferences, of course, are determined by what exactly the advertiser is selling. The typical savings amount is 30-40%, which amounts to a fairly significant amount over the course of a season.

In particular, advertising suggests calculating the power of the heating element of the boiler as 50–60 watts per square meter of heated area. For comparison: the norm in central Russia is 100 watts per m2.

Data

Dear reader, if you are looking for an economical electric boiler, this only means that you have completely forgotten your school physics course. Advertising lies.

No direct heating device can be more economical than others.

Why? This directly follows from the law of conservation of energy. If electrical energy is not converted into mechanical energy (that is, your boiler or other objects around it do not bounce or fly), it has only one way out - to be completely converted into thermal energy. In heating

Yes, some of the heat will not transfer to the coolant, but will dissipate in the air. However:

- The amount of losses is determined by the quality of the body's thermal insulation , and not by the type of heating element;

- It will serve to heat the room in which the boiler is installed.

Am I still not convinced? Okay, let's look at the problem from the other side.

The function of the heating system is to compensate for heat energy leaks through walls, ventilation, windows, floors, etc. The number of leaks is determined:

- Thermal insulation of enclosing structures. The type of boiler, of course, does not affect it in any way;

- Temperature difference on both sides of the external walls. The colder it is outside and the warmer it is in the house, the more heat will be lost. Again, regardless of the type of boiler.

I emphasize: the type of heat source does not in any way affect the required power of the heating boiler.

Does this mean that there is no difference in performance between different electric boilers and electric heaters?

There is, and another one. But it has nothing to do with efficiency.

| Electric radiator : creates a distributed load on the wiring and is therefore undemanding to its cross-section. |

| Induction boiler : has small overall dimensions. |

It is extremely fault-tolerant, since the heat exchanger does not have its own heating element, and the inductor and power controller located outside the working environment are not subject to the destructive effects of water and salts dissolved in it.

Works with any coolant.

Only water with a strictly defined amount of salts can be used as a coolant (read: drinking water GOST R 51232-98).

In a closed heating system, there is no need to worry about scale on the heating elements of an electric boiler. The volume of the circuit contains a limited amount of salts, and after they precipitate, scale formation will stop.

Where to install and how

Different models have different wattages, which affects what kind of line they will need. According to this criterion, today there are two types of electric boilers: floor-mounted and wall-mounted. The first type is characterized by high power (more than 60 kW), the second, correspondingly, lower (from 5 to 60 kW).

Important: for any type of electric generator with a power of more than 12 kW, a three-phase network is required. In other cases, two-phase is sufficient

In addition, when installing, the lower pipe must be located below the radiator so that water (oil or antifreeze) does not remain in the system.

As for the installation location, it can be any room, the main thing is that there is always unhindered access to the device. However, as practice shows, most often the kitchen or some non-residential premises are chosen for this. Much more important is the absence of flammable materials on the wall where the boiler will hang. If you doubt that you understood everything correctly, we advise you to find a suitable video and check this information with a clear example.

Models of electric boilers

The principle of any electric boiler is the conversion of electricity into heat. Electric units are not the most cost-effective, but the efficiency of their use is 95-99%, which is quite good for such units. Such boilers are divided into three types according to the type of coolant. Let's talk about each of them in more detail.

Electric heating element boiler

Electric heating boilers equipped with heating elements operate on the principle of an electric kettle. Water passes through tubular heating elements - heating elements. Acting as a coolant, it passes through the entire heating system, circulating using a pump.

One of the advantages is its compactness, neat appearance and the ability to be mounted on a wall. The installation process will not cause any particular difficulties, and operation is comfortable and simple, thanks to thermostat sensors. Automation allows you to maintain the required heating, focusing on data from sensors that measure the ambient air temperature.

The coolant can be not only water, but also a non-freezing liquid, thanks to which scale will not form on the heating elements, which cannot be avoided by using water.

Attention. Scale formed on heating elements impairs the heat transfer and energy-saving properties of an electric heating boiler. This option for heating a house is also good because it has a low cost.

For the convenience of regulating electricity consumption, it is equipped with several heating elements that can be turned on separately

This option for heating a house is also good because it has a low cost. For the convenience of regulating electricity consumption, it is equipped with several heating elements that can be turned on separately.

Electrode electric boiler

The operating principle of an electrode electric boiler for heating a house is completely different from the previous model. The liquid is not heated by a heating element. An electrode installed in the housing gives the liquid an electrical charge, under the influence of which the molecules are split into negatively and positively charged ions. The coolant has its own resistance, which provides intense heating. Either water or a special compound (similar to antifreeze) is poured into the system.

This type of electric unit for heating a house is completely safe; if a liquid leak occurs, it will simply turn off. Electrode models are very compact (looks like a small cylinder with pipes), equipped with sensors for measuring ambient air temperature, and controlled automatically.

Maintenance of this model comes down to replacing the electrode, since they gradually dissolve as they work, which worsens the heating of the house. It is also necessary to ensure that the circulation pump is working properly so that the liquid in the system does not boil. Correct and efficient operation of an electrode electric boiler for heating a private house is only possible with prepared water - it must have the required resistivity value. Measuring them yourself is not always convenient and easy, just like preparing water. Therefore, it will be easier and more reliable to buy a liquid specially designed for use in electrode boilers.

Electric induction boiler

This type of electric heating unit for the home operates on the basis of induction heating of liquid with ferromagnetic alloys. The inductive coil is located in a sealed housing and does not have direct contact with the coolant, which flows around the perimeter of the device. Based on this, not only water, but also antifreeze can be used as an energy carrier for heating a house. This electric boiler for home heating is not equipped with a heating element or electrode, which improves its efficiency. Also, the absence of heating elements ensures complete safety during operation. This version of the boiler for heating a home is not subject to scale formation, practically does not break and does not leak.

The only disadvantage of induction models is their higher cost and larger dimensions. But over time, the size problem is eliminated - the old ones are replaced by improved models.

In addition to this classification, electric boilers for heating a private home are divided into:

- single-circuit (intended only for heating the entire house);

- double-circuit (provide not only heating throughout the house, but also water heating).

You also need to highlight:

- wall-mounted boilers;

- floor-standing boilers (high-power models are produced).

How to choose?

To choose an electric boiler, the client should pay attention to the characteristics of the devices; they should also be taken into account before purchasing

Number of circuits

Single-circuit boilers heat the coolant in the heating system. To provide hot water, you should choose an additional water heater or a double-circuit boiler.

Their design includes two operating circuits, one for heating, the other for providing hot water. But these boilers consume a lot of electricity, increasing the cost of water and heating.

Power

The main parameter you need to pay attention to is the power of the electric boiler. It is worth considering the area and intensity of heat loss of the building

When the supply voltage decreases, the power also decreases.

If you use a double-circuit electric boiler for hot water supply, then a power reserve of up to 25% is provided.

Supply voltage

The next point is the type of supply voltage. Most often, boilers have low power, and the power comes from a single-phase 220V network.

If you need to connect more powerful equipment up to 10 kW, then you should lay a separate connection line.

Equipment

The basic equipment of the unit consists of the following elements: circulation pump, expansion tank, safety group, temperature sensors and programmer.

Safety

Additional protective devices of the device will help save electricity and protect the owner from breakdowns. The fuse is located outside the device.

NOTE!

It is advisable that the fuses have different directions - they are triggered by overheating, freezing of the coolant, or critical measurement of electricity data.

Installation

When installing, it is worth considering the location where the unit is installed. This can be wall mounted or floor mounted.

For heating a private home, a wall-mounted installation is more suitable. But if the device is large, the client may only have the full version. In this case, it is worth putting the unit away in a storage room or a special boiler room in the house.

For an average apartment, it is better to choose a wall-mounted design of devices.

Heated area (calculation)

It is worth taking as an example the calculation for a room of 18 sq.m., the formula will look like this:

18 sq.m x 100 W = 1800 W

It turns out that an hour of heating eighteen square meters will require 1.8 kW of power. The result is divided by the heat that is released into a certain part of the heating radiator.

If we take into account the data from the 170 W passport, then we should:

1800 W/170 W = 10.59

The resulting number is rounded up to the nearest whole number - 11. Therefore, it follows that for an area of 18 sq.m, it is recommended to purchase a unit with 11 sections.

To heat an area of 160 m2, the boiler power should be 16 kW.

It is worth making a calculation for an apartment area of 65 m2 with three-meter ceilings:

- Determine the power by area - 65m2/10m2 = 6.5 kW;

- An adjustment is made for the region - 6.5 kW * 1.2 = 7.8 kW;

- 25% should be added, taking into account water heating 7.8 kW * 1.25 = 9.75 kW;

- 10% is added to account for cold temperature: 7.95 kW * 1.1 = 10.725 kW.

The result is rounded to a power of 11 kW.

Control

When choosing a control, you should consider the convenience of the design and ease of use. Basically, boilers have electronic panels with several keys and a rotary switch. But there is also something completely mechanical.

It all depends on the personal preferences of buyers, which it is advisable to voice before purchasing.

Additional functions

When paying attention to additional functions, take into account the built-in controls that complement the functionality. All additional options also need to be checked with the manager in a specialized store.

All additional options also need to be clarified with the manager at a specialized store.

- Protection from cold temperatures;

- Fuses are installed to prevent excessive temperatures;

- Thermometer for determining temperature;

- Indication when the device is activated;

- Blocking nas also has protection;

If you have not yet chosen an electric boiler

The choice of a heater operating in conjunction with a water heating system is made based on power and operating principle (the cost of the equipment depends on the latter). Electric boilers have no problems with functionality - any model is equipped with an automation unit. If desired, various peripheral devices can be connected to it - weather sensors, room or overhead thermostats and GSM modules for control from a mobile phone or via the Internet.

Important note. Some, Protherm or “Evan” require in the operating instructions that the installation and connection of the electric boiler to the network be carried out by specially trained personnel. Self-connection will result in a waiver of warranty obligations.

Before choosing and purchasing a heating device, check how much electrical power has been allocated to your home by the management company. It may happen that it is not enough for individual electric heating. Point two: a single-phase 220-volt network is capable of powering boilers that consume up to 12 kW/h inclusive. More powerful water heaters are connected to a three-phase 380 V power supply.

Determination of thermal power

This indicator is calculated using the standard formula: calculate the heated area of a country house or cottage, then multiply the quadrature by 0.1 kW. Obtain the thermal energy demand that the electric boiler must cover.

Consider a number of nuances:

- the height of the ceilings of the rooms is up to 3 m, otherwise the calculation is carried out according to the volume of the premises: the cubic capacity is multiplied by 40 W;

- the heat generator must be selected with a minimum margin of 20%;

- if the heating unit is planned to be used to provide domestic hot water, the reserve must be at least 50%;

Dividing a quadrature by 10 is the same as multiplying by 0.1, the result is the same - in the northern regions, the square footage of the building is multiplied by 0.2 kW, in the southern regions - 0.08 kW;

- The power of the boiler, which operates only at night and charges the heat accumulator, is assumed with a double margin.

Example. A small house of 100 m² on average requires 100 x 0.1 = 10 kW of heat. The power of the electric heating installation is 10 x 1.2 (20%) = 12 kW. We need to heat water for household needs - multiply by a factor of 1.5 and get 15 kW.

To obtain more accurate results, we suggest studying the methodology for calculating the load on the heating system

Which type of heater is better

Next, you need to select a water heating device based on its operating principle. What types of household electric boilers can you buy:

- Traditional, equipped with tubular electric heaters (TEHs).

- Electrode, where the salted coolant is heated by passing current through the water.

- Induction devices heat the liquid using Foucault eddy currents that arise in the metal core of a multi-turn coil.

Electric mini-boiler room with tubular heaters (TEN), fully equipped

Valuable advice. Do not listen to the tales of salesmen praising the efficiency of certain electric boilers. They like to use the expressions “energy-saving”, “eternal”, “economical” and so on. Remember: all types of heaters are equally effective at converting electrical energy into heat with an efficiency of 98-99%.

The first place in the user rating is occupied by heating element heaters. The only weak point - the heating element itself - has long been protected with ceramics, and in addition it is easy to replace. Modern models of heat generators are wall-mounted mini-boiler rooms with a built-in expansion tank and circulation pump. There are simpler versions that include only heaters and an automation unit.

The cheapest and most reliable option is an electrode boiler with a control cabinet, shown in the photo. Its disadvantages:

- loud switching sounds from the operation of a contactor or magnetic starter;

- gradual degeneration of salts in the coolant, which reduces heating efficiency, which is why the water in the heating system will have to be added with salt 1-2 times a month;

- The electric device works stably with radiators, but is poorly compatible with heated floors, where it is necessary to maintain a low coolant temperature of 35-50 ° C.

Induction electric boilers for heating a private home are quite expensive, and there are questions about the reliability of the devices. There are known cases of phase burnout inside the coil, the power of the heat generator dropped by a third. Fixing the breakdown is very problematic.

An induction heater heats water with a metal core located in the vortex field of the coil

Classic harness

Let's look at the basic wiring diagrams for an electric heating boiler.

There are currently four common methods:

- With natural circulation.

- With forced circulation.

- Classic collector distribution of the thermal circuit.

- Primary-secondary ring method.

All components of a wall-mounted electric boiler are also included in the piping. Internal heating circuits (“warm floor”) are also included in the boiler arrangement.

Electric boiler wiring diagram

Let's take a closer look at the classic version of collector wiring

An important task of this scheme is to ensure minimal temperature differences. It is assumed that when working in double-circuit boilers, the already heated coolant passes from the small circuit to the large one

The classic piping of an electric heating boiler takes this feature into account. First of all, you need to understand what components are used to build an electric boiler.

The following elements are used to arrange the thermal circuit:

- network pump;

- bypass valve;

- pressure gauge and thermometer;

- pass filter;

- PVC pipes, fittings (couplings, tees, adapters) and fasteners;

- safety block valves;

- shut-off valves (taps, valves);

- expansion tank;

- radiators.

You will also need tools and equipment for welding.

Classic strapping scheme

Classic boiler piping can be done:

- With a DHW circuit: water passes through the boiler before entering the mixer;

- With “warm floor”;

- Easy connection to the mains.

In single-circuit systems, it is not difficult to understand the principle of piping - you just need to follow the instructions from the technical documentation of the electric boiler.

However, it is worth considering that when using an indirect heating boiler, it also needs to be tied according to the recommendations. When operating dual-circuit equipment, it is a little more difficult to figure out the piping.

A direct piping option is possible - the temperature is regulated by a burner, and a mixing option - the heating mode is regulated using a burner and a servo drive.

Purpose of the harness

The primary task of the piping is to keep the boiler from overheating. Accordingly, a correctly executed wiring diagram for an electric heating boiler can significantly save money by reducing the level of heat loss. In addition, correctly performed piping eliminates the need to use high-quality and expensive equipment that allows you to monitor the operation of the system. The need for it simply disappears.

Heating boiler piping

Inserting an electric boiler into an existing heating system

If the electric heating boiler is not equipped with an automatic control unit, correctly installed piping is extremely important. After all, it allows you to achieve maximum efficiency from even the most powerful boiler.

Which brand of electric heating boiler is better?

Good inexpensive electric boiler RusNIT 209M

Photo: www.teplosila.ru

Rating: 9.9 out of 10.

Average price: RUB 16,279

A compact, lightweight, domestically produced electric boiler can be called the best among inexpensive ones. The total power of the boiler is small, 9 kW, but this is enough to heat rooms with a total area of 70-90 m2 (living area of a medium-sized house or cottage, country house). At the same time, the quality and range of functions are no worse than those of expensive imported models: the work is fully automated, you can configure all the main indicators (power in three stages, air temperature, coolant temperature).

From reviews of the electric boiler RusNIT 209M:

“I’ve had an electric RusNIT in my dacha for 2 years now. Never let me down yet. The house still warms up perfectly. The good thing about it is that when you turn it on, it doesn’t immediately load the system; it distributes the load evenly across each phase. This means that, including other devices, you don’t have to worry about them burning out.

It is only important that the boiler is installed by specialists, and maintenance must be carried out on time.”

- low price

- easy installation

- smooth power adjustment

- precise temperature adjustment (+/- 0.5 °C)

- air heating within 5-30 °C

- overheat protection

- coolant presence sensor

- The housing is splash resistant.

Disadvantages of the model:

not suitable for a large house.

The best electric mini-boiler EVAN Warmos QX-18

Photo: warmos.ru

Rating: 9.8 out of 10.

Average price: 31,400 rub.

The best among powerful Russian-made electric boilers. It can safely be called a mini-boiler room: heating elements (material - stainless steel), a membrane expansion tank, and a circulation pump are assembled in one housing - all this allows you to save space during installation and reduce time. The LCD display is located at the bottom of the case. The convenient control panel is hidden behind a special door. The operation is regulated by a microprocessor, the control is fully automatic, but you can switch the device to manual mode and adjust all the parameters to your taste and needs. It works stably even with voltage fluctuations, but it is still better to connect the boiler through a stabilizer. Versatile. Suitable for heating residential premises (houses, apartments) and industrial facilities (warehouses, shops, etc.)

From reviews of the electric boiler EVAN Warmos QX-18:

“I bought Varmos and installed it at the dacha parallel to the old solid fuel one. Installation is elementary. It has been working for 5 years, no problems"

- works quietly

- built-in expansion tank 12 l

- 3 stages of power adjustment

- microprocessor control

- smooth power adjustment

- control panel at the bottom of the case

- thermostat (air temperature adjustment for 7 days)

- manual adjustment mode available

- built-in pump

- overheat protection, short circuit protection

- coolant level sensor

- pressure meter

- indication of emergency condition (light, sound).

Disadvantages of the model:

- bulky and heavy

- weak point - capacitor

- It is necessary to install a voltage stabilizer

When choosing heating equipment today, it is easy to get confused, since there is a very wide selection of models on the market. There are both simple boilers for apartments and more complex equipment designed for installation in a large country house or country house. They all differ in power, additional features, and connection technologies.

In order not to make a mistake with your choice, you need to pay attention to the rating, which clearly demonstrates which equipment is optimal in certain conditions

To choose the right boiler, you need to pay attention to the rating, which demonstrates all the advantages or disadvantages of the equipment. Choosing a gas boiler will be much easier if you know exactly what functions are needed, what estimated power can satisfy all the needs for heating and hot water supply. The rating will help you understand all the intricacies of such installations

The rating will help you understand all the intricacies of such installations

Choosing a gas boiler will be much easier if you know exactly what functions are needed, what estimated power can satisfy all the needs for heating and hot water supply. The rating will help you understand all the intricacies of such installations.

Types of electric boilers for the home

When choosing a device, you need to pay attention to the variety of types of equipment designed for heating residential premises. All models of electric boilers can be divided into groups according to several criteria.

The devices differ:

- principle of heating the coolant;

- installation method;

- voltage used.

The following equipment options are available for sale:

- heating element;

- electrode;

- induction.

The most reliable in operation are units that use tubular heaters (heaters). The disadvantage of the device is the need to periodically replace the heating element.

Electrode devices are more affordable, but have several disadvantages, the main ones being:

- loud sounds made by equipment when turned on;

- degeneration of salts in the circulating fluid;

- poor compatibility when using a system with heated floors.

Induction devices have the highest cost, but they are less reliable in operation compared to electrode and heating elements models. Additionally, the units differ in power and number of circuits.

Depending on the type of installation, wall-mounted and floor-mounted devices are distinguished. Installations are produced that operate from single- and three-phase networks. There are devices with one and two circuits. The second type is used not only to maintain an optimal microclimate and temperature in the room, but also to provide the home with hot water supply.

Gas boiler piping and its purpose

Piping refers to pipes and mechanisms that are used to supply coolant from the boiler to the radiators. This is almost the entire heating system, with the exception of the batteries.

The system includes a large number of components, but the simplest version of the harness can be installed by a non-professional. But if a diagram is required, then in this case it is better to seek help from specialists.

When choosing a piping scheme, in each specific case it is necessary to take into account the type of boiler, construction features, and type of heating system. Any gas unit is dangerous

If you make mistakes during the connection process, the result can not only be problems with heating your home, it is also fraught with explosions and destruction

That is why it is very important to strictly comply with safety standards and requirements. When piping a gas boiler for heating a private house, you should rely on the requirements of SNiP

Any gas unit is dangerous. If you make mistakes during the connection process, the result can not only be problems with heating your home, it is also fraught with explosions and destruction

That is why it is very important to strictly comply with safety standards and requirements. When piping a gas boiler for heating a private house, you should rely on the requirements of SNiP

It is necessary to plan the heating scheme well, decide where the equipment will be located, and the features of laying pipelines.

The boiler piping performs a number of very important functions:

- Controls pressure. If all the conditions of the piping are met and it is done correctly, then thermal expansion is compensated. This means that the pressure in the heating system will not increase to too high levels.

- The next function is air removal. Due to air bubbles, traffic jams appear, which negatively affects water heating. In such situations, radiators heat up unevenly, but resource consumption remains the same. It is necessary to perform high-quality boiler piping in order to avoid such unpleasant moments.

- Prevention of blockages in the system. If you make mistakes during the boiler piping process, there is a high probability of scale appearing in radiators and pipes. Small debris in the coolant pollutes the system, which leads to excessive fuel consumption, and this increases the cost of heating, while its quality decreases.

- Other circuits can be connected. You can additionally install underfloor heating and a storage boiler.

Choosing a boiler

Let us repeat: the main component of any heating system, and a closed type in particular, is the boiler. In order for the installation work to be carried out successfully, it must first be selected, and correctly.

To begin with, we note that from the boiler the heated coolant moves through the pipeline to the heating devices, which, in turn, transfer thermal energy to the room.

First of all, you should calculate the required power of such a boiler. To do this, it is necessary to take into account the individual characteristics of a particular building. These features include the area of the heated room, the thickness and height of the walls, the material from which they are made, and a number of other parameters.

To at least approximately calculate the required boiler power, you can use the generally accepted approximate thermal power consumption per 10 square meters - it is 1 kilowatt. Let us repeat, this is only an approximate formula, therefore, when calculating, you should use a correction factor relating to the heat loss of all enclosing structures. If the power of the heating boiler is calculated correctly, you will thereby create the most comfortable living conditions in your house/apartment during the cold season. Moreover, it will help you save significantly on electricity and reduce your heating costs.

You can find out how to calculate heating costs in an apartment here

So, let’s draw some conclusions regarding the installation of a closed-type system.

- When designing it, you must calculate the required power of the heating boiler.

- Find out what materials and in what quantities you will need.

- Determine how many radiators are needed. (for more information on calculating the number of heating radiator sections, see here)

- Take into account all the features of building structures.

- Choose the most suitable place to install heating equipment.

Creating an efficient and, most importantly, high-performance heating system requires carefully planned preparatory work.

As a conclusion

As we can see, there are many types of heating systems, and a closed heating system is perhaps the best option. Regardless of what wiring you choose or what material for the pipeline, installation must be taken with great responsibility. If you feel that you cannot cope on your own, then contact a specialist. Yes, it will cost more, but you will be protected from all possible troubles in the future.

Emergency harness

No matter how the dual-circuit circuit is implemented, it must certainly contain methods for monitoring and managing the system in case of unforeseen emergency situations. Most often this is a sudden power outage.

However, if the batteries are used quite rarely, they should be checked periodically and, if necessary, charged.

If the operating principle of an electric heating boiler assumes that the system uses only tap water (which is rare), then it is important to consider that often when the electricity is turned off, the water supply also stops. And auxiliary batteries will not help restore the amount of coolant

Sometimes, in case of emergencies, an auxiliary circuit with natural coolant circulation is created. As a rule, it is much smaller in size and covers only part of the premises.

Connection diagram of an electric boiler to the network

Before connecting an electric heating boiler, please note that the electric boiler must be connected to the network using copper wiring. The cross-section of the wire must be no smaller than that specified in the document that came with the device. Electrical connections of the external type device must be made through special cable terminals. These pins should be located in the lower left corner. There should also be a brass grounding terminal with an M6 bolt.

Power cable connection diagram

When inserting an electric boiler into the heating system and installing grounding, you need to ensure that good and reliable contact is ensured between the metal body of the device and the brass bolt. Before connecting the bolt to the frame of the device, you need to thoroughly clean the connection area.

If electric heating is planned to be organized for a building with a large area, then when purchasing equipment you need to choose one that provides the possibility of installing a cascade. In order for the devices to operate normally in a cascade, the terminals of the control device must be connected to the unit that is being controlled. If the system installation is controlled using a room-type regulator, then the control contacts must be connected to the terminals of the control device.

Diagram of the electrical heating system of a two-story house

The device must be inspected visually and make sure that it is in the correct position, the water pressure in the system is normal, and all communications are connected. All this is defined in the unit documentation.

After this, the installation diagram for an electric heating boiler involves the following steps:

- It is necessary to check the serviceability of the pipeline fittings located in front of the unit. To do this, you need to switch it from the “closed” to “open” position, and vice versa.

- All pipeline fittings of the electric heat generator are moved to the “closed” position. It is also necessary to move the pipeline fittings of the water supply and heating systems to this position.

- On those pipelines that supply cold water to the unit, you need to open the shut-off valves. If you use an electric heating system, it is not recommended to use antifreeze liquids for it. This is because they have properties that can affect the operation of equipment in a negative way. Antifreeze fluids have a composition that can cause aging or rapid wear of rubber components.

- It is necessary to install a sump filter or filter before entering the unit on the return pipeline. You can install both of these elements.

- After the heating system is completely filled with water, you need to check how tight it is.

When the installation of an electric boiler with heating radiators is completed, you need to check how efficient the system sensors are. These include sensors such as: temperature controller, water pressure sensor, signal and control components of the unit, emergency temperature sensor.

During repairs to the heating unit or during unfavorable installation conditions, an electric heating unit can be connected using rubber hoses.

For the heating system it is necessary to use water with a minimum hardness level. Then the service life of the heating elements can be significantly extended.

Boiler power calculation

To understand which unit will be the most acceptable in the house, you should calculate its power using the following formula: F=S*F1/10, where F is the boiler power, S is the area of the room, F1 is the design parameter of the unit per 10 m². You should focus on the number found. In addition, the following factors should be taken into account:

- Type of thermal insulation.

- Number of premises.

- The area of window openings and doors is where heat loss is most noticeable.

- Additional rooms - attic and basement. Are they insulated, do they have ventilation, etc.

You can calculate and order a regime card with the help of professionals who will not only suggest the most appropriate solution, but also describe in detail the parameters for optimizing energy costs.

Selecting a circulation pump

For a circulation pump, two parameters are important - pressure and performance. The amount of pressure in most cases is practically irrelevant. The minimum pressure for the weakest pumps is 2 meters, which is quite enough to ensure normal operation of the heating system of any private home.

Pump performance is more important and the following formula is used to calculate it:

- Q = 0.86 * R / Dt, where

- R – total radiator power or boiler power,

- Dt is the temperature difference in the supply and return circuits (in autonomous systems this value is 20 degrees).