A thrifty owner dreams of cheap energy resources, efficient waste disposal and obtaining fertilizers. A DIY home biogas plant is an inexpensive way to make your dream come true.

Self-assembly of such equipment will cost a reasonable amount of money, and the gas produced will be a good help in the household: it can be used for cooking, heating the house and other needs.

Let's try to understand the specifics of this equipment, its advantages and disadvantages. And also whether it is possible to build a biogas plant yourself and whether it will be effective.

Specifics of biogas production

Biogas is formed as a result of fermentation of a biological substrate. It is decomposed by hydrolytic, acid- and methane-forming bacteria. The mixture of gases produced by bacteria is flammable, because contains a large percentage of methane.

Its properties are practically no different from natural gas, which is used for industrial and domestic needs.

If desired, every home owner can purchase an industrial-made biogas plant, but it is expensive, and the investment pays off within 7-10 years. Therefore, it makes sense to make an effort and make a bioreactor with your own hands

Biogas is an environmentally friendly fuel, and the technology for its production does not have much impact on the environment. Moreover, waste products that need to be disposed of are used as raw materials for biogas.

They are placed in a bioreactor, where processing occurs:

- the biomass is exposed to bacteria for some time. The fermentation period depends on the volume of raw materials;

- As a result of the activity of anaerobic bacteria, a flammable mixture of gases is released, which includes methane (60%), carbon dioxide (35%) and some other gases (5%). Fermentation also releases potentially dangerous hydrogen sulfide in small quantities. It is poisonous, so it is highly undesirable for people to be exposed to it;

- the mixture of gases from the bioreactor is purified and supplied to a gas tank, where it is stored until it is used for its intended purpose;

- gas from a gas tank can be used in the same way as natural gas. It goes to household appliances - gas stoves, heating boilers, etc.;

- Decomposed biomass must be regularly removed from the fermenter. This is additional labor, but the effort pays off. After fermentation, the raw material turns into high-quality fertilizer, which is used in fields and vegetable gardens.

A biogas plant is beneficial for the owner of a private house only if he has constant access to waste from livestock farms. On average, from 1 cubic meter. You can get 70-80 cubic meters of substrate. biogas, but gas production is uneven and depends on many factors, including biomass temperatures. This complicates calculations.

Biogas plants are ideal for farms. Animal waste can provide enough gas to fully heat residential premises and outbuildings

In order for the gas production process to be stable and continuous, it is best to build several biogas plants, and add the substrate to the fermenters with a time difference. Such installations operate in parallel, and raw materials are loaded into them sequentially.

This guarantees a constant production of gas, so that it can be continuously supplied to household appliances.

Ideally, the bioreactor should be heated. Every 10 degrees of heat increases gas production by half. Although heating installation requires investment, it pays off in greater design efficiency

Homemade biogas equipment, assembled from scrap materials, is much cheaper than industrial production plants. Its efficiency is lower, but it is well worth the investment. If you have access to manure and the desire to put in your own effort to assemble and maintain the structure, this is very profitable.

Factors influencing biogas production

The volume of biogas produced by a friendly team of microbes under different conditions can vary and depends on a number of factors.

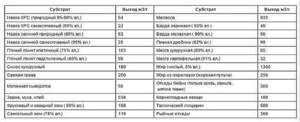

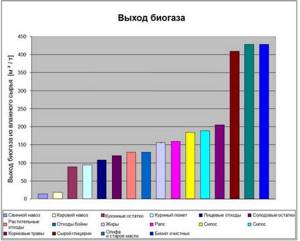

Type of raw material

Most biogas can be obtained from food industry waste containing sugar pulp and large amounts of fat. The least profitable type of raw material is cattle manure.

Manure is a raw material for biogas

Temperature

As the temperature rises, the productivity of bacteria increases. According to temperature conditions, gas generators are divided into three types.

Psychrophilic

These are unheated installations in which the temperature is maintained between 18 and 25 degrees. At the moment they are almost never used.

Mesophilic

Thanks to heating, the temperature is maintained within the range from 25 to 40 degrees.

Advantages:

- low energy consumption;

- The amino acid composition of fertilizers is as beneficial as possible.

Flaws:

- relatively low biogas productivity;

- lack of disinfecting effect (the raw materials contain pathogenic bacteria that should be eliminated).

Gas generators, previously used for cars, are quite suitable for home use. How to make a gas generator with your own hands step by step, read the article.

Read about the advantages of using a wood-burning electric generator here.

If you live in a private house, then you have a unique chance to try various options for alternative energy sources. Here https://microklimat.pro/sistemy-otopleniya/alternativnoe-otoplenie/alternativnye-istochniki-energii-dlya-chastnogo-doma.html you will find an overview of installation options for obtaining free energy.

Thermophilic

Intensive heating is used, the temperature exceeds 40 degrees.

Advantages:

- high performance;

- pathogenic bacteria die.

Flaws:

- high energy consumption;

- low quality fertilizers.

Thermophilic manure bioreactor

For each type of raw material there is an optimal temperature regime. Why can't you just heat the reactor to the highest possible temperature? For two reasons:

- due to rising energy costs, the profitability of the installation will decrease;

- As the temperature increases, the amount of free ammonia also increases.

The latter dependence leads to inhibition of gas generation (this gas is toxic to bacteria).

Metabolism and freedom of movement

The raw material must be liquefied enough so that microbes and gas bubbles can move in it. To do this, hot water is added to the installation, bringing the humidity of the load to 85% in winter and up to 92% in summer.

In order for metabolic processes to occur better in the reactor, its contents must be stirred from time to time (approximately every 4 to 6 hours).

Fermentation time

If raw materials are unloaded ahead of schedule, the bacteria will not have time to compensate for the loss in numbers and the productivity of their colonies will drop.

If held for too long, productivity also decreases due to lack of nutrients.

On average, the optimal fermentation time is:

- for the psychrophilic regimen: 30 – 40 days or more;

- for mesophilic: 10 – 20 days;

- for thermophilic: 5 – 10 days.

Acid-base balance

The highest productivity is observed at pH values from 6.5 to 8.5 (depending on the raw material).

Carbon to Nitrogen Ratio

The optimal value again depends on the raw material. There should be 10–20 times more carbon than nitrogen.

What is this?

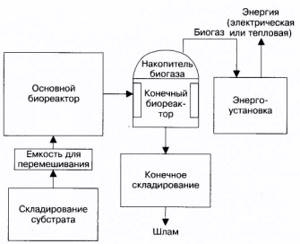

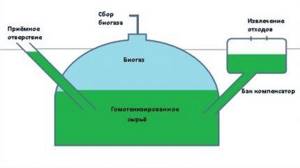

Biogas, which is an environmentally friendly fuel, is produced in biogas plants, units that are a complex of technical structures and devices combined into a single technological cycle.

The configuration of a biogas plant can be different, depending on its power, the type of raw materials and the resulting final product in the form of thermal or electrical energy, both types of energy, or only biogas used in household gas stoves and as fuel for cars.

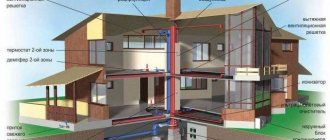

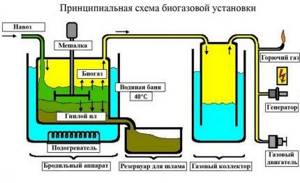

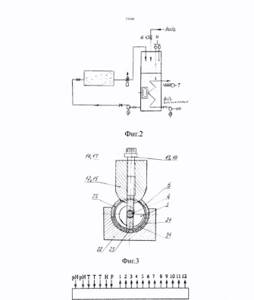

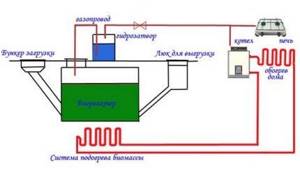

Standard installation consists of the following components and assemblies:

- A storage tank in which raw materials used to produce biogas are accumulated;

- Mixers and mills of various designs, dividing large fractions of raw materials into smaller ones;

- Gas holder, a hermetically sealed container that serves as a storage tank for the resulting gas;

- A reactor, container or reservoir in which the process of biofuel formation occurs;

- Systems for feeding raw materials into the reactor of the installation;

- A system for transferring the resulting fuel from the reactor and gas tank, further to the stages of processing and conversion into other types of energy;

- Automation systems, protection and control over the production processes of gas and its processed products.

The above diagram roughly shows the technological cycle of biogas production using liquid and solid raw materials, with its further processing and production of thermal and electrical energy.

Comparison of biogas with more traditional fuels

The strengths of this technology include the following:

- The raw materials used to produce biogas are an inexhaustible resource and are free of charge.

- Biogas energy is not tied to a specific location - raw materials for installation can be found in any region.

- Wide range of applications: biogas can act as a source of heat, electricity and motor fuel.

In terms of construction costs (3–4 thousand euros per kW of power), biogas plants are between nuclear (5 thousand euros per 1 kW) and coal (2 thousand euros per 1 kW) stations.

Biogas technology

The operating principle of a biogas plant is based on the fermentation of a biosubstrate. It decomposes under the influence of hydrolysis, methane- and acid-forming microorganisms. A flammable gas containing a high volume of methane is produced.

Gas is actually not inferior to natural gas used in everyday life and industry. There are ready-made installations. But their cost is quite high, the payback period reaches 10 years.

To operate a biogas plant, you can use available raw materials - recyclable waste. They are processed as follows:

- Raw materials ferment under the influence of microorganisms.

- Combustible gases are released - methane, carbon dioxide and others. The main volume is represented by methane

- The gases are purified and enter a gas tank, where they remain until they are used directly.

Gas can be used similarly to natural gas. It can be used as fuel for boilers, furnaces, gas stoves, etc. Waste raw materials must be removed from the installation in a timely manner. The waste can be used as fertilizer.

What is biogas? Beginner's Guide

Biogas is a type of biofuel that is naturally produced by the decomposition of organic waste. When organic matter, such as food and animal waste, breaks down in an anaerobic environment (an environment in which there is no oxygen), it releases a mixture of gases, mainly methane and carbon dioxide. Since this decomposition occurs in an anaerobic environment, the process of producing biogas is also known as anaerobic digestion.

Anaerobic digestion is a natural form of waste to energy that uses the fermentation process to break down organic matter. Animal manure, food waste and sewage are all examples of organic matter that can produce biogas through anaerobic digestion. Due to the high methane content of biogas (usually 50-75%), biogas is flammable and hence produces a deep blue flame and can be used as an energy source.

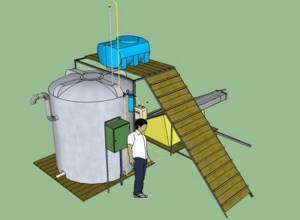

Complete set of installation for biogas production

Special installations are being built to process waste. Equipment for processing manure into gas consists of six main elements.

- A bioreactor in which raw materials are decomposed.

- Automatic raw material supply system.

- Device for mixing the mass.

- Equipment that maintains the desired temperature.

- Gas holder in which the obtained gas is stored.

- Solid waste receptacle.

Not a single installation used in industry can do without these elements. However, those digesters that are used in everyday life by farmers who have their own agriculture are much simpler in design.

Use Cases

Processing manure into biogas makes it possible to obtain electrical, thermal and mechanical energy. This fuel is used on an industrial scale or in private homes. It is used for:

- heating;

- lighting;

- heating water;

- operation of internal combustion engines.

Using a bioreactor, you can create your own energy base to power your private home or agricultural production.

Thermal power plants using biogas are an alternative way to heat a private farm or small village. Organic waste can be converted into electricity, which is much cheaper than running it to the site and paying utility bills. Biogas can be used for cooking on gas stoves. The great advantage of biofuel is that it is an inexhaustible, renewable source of energy.

Advantages and disadvantages of the system

Biogas plants have many advantages, but there are also a lot of disadvantages, so before starting design and construction you should weigh everything:

- Recycling. Thanks to a biogas plant, you can get the maximum benefit from waste that would otherwise have to be disposed of. This disposal is less hazardous to the environment than landfilling.

- Renewability of raw materials. Biomass is not coal or natural gas, the extraction of which depletes resources. When farming, raw materials appear constantly.

- Relatively small amount of CO2. When gas is produced, the environment is not polluted, but when it is used, a small amount of carbon dioxide is released into the atmosphere. It is not dangerous and is not capable of critically changing the environment, because... it is absorbed by plants during growth.

- Moderate sulfur release. When biogas is burned, a small amount of sulfur is released into the atmosphere. This is a negative phenomenon, but its scale can be seen in comparison: when burning natural gas, environmental pollution with sulfur oxides is much greater.

- Stable work. Biogas production is more stable than solar panels or wind turbines. While solar and wind energy cannot be controlled, biogas plants depend on human activity.

- Multiple settings can be used. Gas always carries risks. To reduce potential damage in the event of an accident, several biogas plants can be dispersed throughout the site. If a system of several fermenters is properly designed and assembled, it will operate more stable than a single large bioreactor.

- Benefits for agriculture. Some types of plants are planted to obtain biomass. You can choose ones that improve the condition of the soil. For example, sorghum reduces soil erosion and improves its quality.

Biogas also has disadvantages. Although it is a relatively clean fuel, it still pollutes the atmosphere. There may also be problems with the supply of plant biomass.

Irresponsible plant owners often harvest it in such a way that they deplete the land and upset the ecological balance.

Benefits of biogas

Biogas is environmentally friendly

Biogas is a renewable as well as clean energy source. The gas obtained as a result of biodegradation does not pollute the environment; it actually reduces greenhouse gas emissions (i.e. reduces the greenhouse effect).

There is no combustion during the process, which means no greenhouse gases are released into the atmosphere; so using gas from waste as a form of energy is actually a great way to combat global warming.

It is not surprising that concern for the environment is the main reason why the use of biogas has become more common. Biogas plants significantly curb the greenhouse effect: plants reduce methane emissions by capturing this harmful gas and using it as fuel.

Biogas production helps reduce dependence on the use of fossil fuels such as oil and coal.

Another advantage of biogas is that, unlike other types of renewable energy, the process is natural and does not require energy for the generation process.

Additionally, the raw materials used in biogas production are renewable as trees and crops will continue to grow. Manure, food scraps and crop residues are raw materials that will always be available, making them a very sustainable option.

Biogas production reduces soil and water pollution

Overflowing landfills not only spread foul odors—they also allow toxic liquids to flow into underground water sources. Therefore, another benefit of biogas is that biogas production can improve water quality. In addition, anaerobic digestion inactivates pathogens and parasites; thus, it is also quite effective in reducing the incidence of waterborne diseases. Likewise, waste collection and disposal are greatly improved in areas with biogas plants. This in turn leads to improved environmental conditions, sanitation and hygiene.

Bioreacor produces organic fertilizers

The by-product of the biogas generation process is enriched organic (digestate), which is an ideal complement or replacement for chemical fertilizers.

Fertilizer release from a biogas plant can enhance plant growth and disease resistance, while commercial fertilizers contain chemicals that are toxic and can cause food poisoning, among other things.

Preparing a pit for a bioreactor

The design of the biogas plant assumes its underground location. It is necessary to prepare a hole of the required volume. Its walls can be hermetically reinforced and finished with plastic, polymer rings or concrete.

The intensity of raw material processing depends on tightness. Ideally, you should purchase factory-made polymer rings that have a dry bottom. This is a more expensive solution, but additional sealing can be avoided.

Polymer materials are resistant to humidity and aggressive environments. They do not need to be repaired, and if damaged they can be quickly replaced.

General principles

Biogas is a product that is obtained from the decomposition of organic substances. During the process of rotting/fermentation, gases are released, collecting which you can meet the needs of your own household. The equipment in which this process occurs is called a “biogas plant.”

In some cases, the gas output is excessive, then it is stored in gas tanks for use during periods of insufficient quantity. If the process is properly organized, there may be too much gas, then the excess can be sold. Fermented leftovers are another source of income. This is a highly effective and safe fertilizer - during the fermentation process, most microorganisms die, plant seeds lose their viability, and parasite eggs become unviable. Exporting such fertilizers to the fields has a positive effect on crop yields.

Conditions for gas production

The process of biogas formation occurs due to the vital activity of various kinds of bacteria that are contained in the waste itself. But in order for them to actively “work”, they need to create certain conditions: humidity and temperature. To create them, a biogas plant is being built. This is a complex of devices, the basis of which is a bioreactor, in which waste decomposition occurs, which is accompanied by gas formation.

Organization of a cycle for processing manure and plant waste into biogas

There are three modes for processing manure into biogas:

- Psychophilic mode. The temperature in the biogas plant is from +5°C to +20°C. Under such conditions, the decomposition process is slow, much gas is formed, and its quality is low.

- Mesophilic. The unit enters this mode at temperatures from +30°C to +40°C. In this case, mesophilic bacteria actively reproduce. In this case, more gas is formed, the processing process takes less time - from 10 to 20 days.

- Thermophilic. These bacteria multiply at temperatures from +50°C. The process goes the fastest (3-5 days), the gas output is the largest (under ideal conditions, with 1 kg of delivery you can get up to 4.5 liters of gas). Most reference tables for gas yield from processing are given specifically for this mode, so when using other modes it is worth making a smaller adjustment.

The most difficult thing to implement in biogas plants is the thermophilic mode. This requires high-quality thermal insulation of the biogas plant, heating and a temperature control system. But at the output we get the maximum amount of biogas. Another feature of thermophilic processing is the impossibility of additional loading. The remaining two modes - psychophilic and mesophilic - allow you to add a fresh portion of prepared raw materials daily. But, in the thermophilic mode, the short processing time makes it possible to divide the bioreactor into zones in which their share of raw materials will be processed with different loading times.

What can be recycled

A biogas plant is essentially omnivorous - any organic matter can be processed. Any manure and urine, plant residues are suitable. Detergents, antibiotics, and chemicals negatively affect the process. It is advisable to minimize their intake, as they kill the flora that processes them.

How much biogas can be obtained from various wastes?

Cattle manure is considered ideal, since it contains large quantities of microorganisms. If there are no cows on the farm, when loading the bioreactor, it is advisable to add some of the manure to populate the substrate with the required microflora. Plant residues are pre-crushed and diluted with water. Plant materials and excrement are mixed in a bioreactor. This “filling” takes longer to process, but at the end, under the correct mode, we have the highest product yield.

Advantages of using biotechnology

The technology for producing biofuel from various natural sources is not new. Research in this area began at the end of the 18th century and developed successfully in the 19th century. In the Soviet Union, the first bioenergy plant was created in the forties of the last century.

Biotechnologies have long been used in many countries, but today they are gaining particular importance. Due to the deteriorating environmental situation on the planet and the high cost of energy, many are turning their attention to alternative sources of energy and heat.

Of course, manure is a very valuable fertilizer, and if there are two cows on the farm, then there are no problems with its use. It’s a different matter when it comes to farms with large and medium-sized livestock, where tons of foul-smelling and rotting biological material are generated per year.

In order for manure to turn into high-quality fertilizer, areas with a certain temperature regime are needed, and this is an extra expense. Therefore, many farmers store it wherever they can and then take it to the fields.

If storage conditions are not met, up to 40% of nitrogen and the bulk of phosphorus evaporate from manure, which significantly worsens its quality indicators. In addition, methane gas is released into the atmosphere, which has a negative impact on the environmental situation of the planet.

Modern biotechnologies make it possible not only to neutralize the harmful effects of methane on the environment, but also to make it serve for the benefit of people, while reaping considerable economic benefits. As a result of manure processing, biogas is formed, from which thousands of kW of energy can then be obtained, and production waste represents a very valuable anaerobic fertilizer.

Image galleryPhoto from Organizing a system for producing biogas is economically feasible for farms. If only two cows provide raw materials, it is better to use it as fertilizer. The gas obtained by processing manure will provide heat and energy. After cleaning, it can be supplied to a stove and boiler, pumped into a cylinder and used by an electric generator. Structurally, the simplest processing plant is not difficult to build with your own hands. Its main organ is a bioreactor, which needs to be well hydro- and thermally insulated. For those who want to reduce the construction time of the system, a factory-made plastic container is suitable. When using it, similar principles of construction and insulation apply. Farms are the main suppliers of raw materials for the production of biogas. Production and use of gaseous biofuels. Construction of a processing plant with one’s own hands. Ready-made plastic container in a bioreactor device.

Is it profitable to make a reactor and use biogas?

The construction of a biogas plant has the following goals:

- production of cheap energy;

- production of easily digestible fertilizers;

- savings on connecting to expensive sewerage;

- recycling of farm waste;

- possible profit from gas sales;

- reducing the intensity of unpleasant odors and improving the environmental situation in the area.

Profitability chart for biogas production and use

To assess the benefits of building a bioreactor, a prudent owner should consider the following aspects:

- the cost of a bio-plant is a long-term investment;

- homemade biogas equipment and installation of a reactor without the involvement of third-party specialists will cost much less, but its efficiency is also lower than that of an expensive factory one;

- To maintain stable gas pressure, the farmer must have access to livestock waste in sufficient quantity and for a long period of time. In the case of high prices for electricity and natural gas or the lack of possibility of gasification, the use of the installation becomes not only profitable, but also necessary;

- for large farms with their own raw material base, a profitable solution would be to include a bioreactor in the system of greenhouses and cattle farms;

- For small farms, efficiency can be increased by installing several small reactors and loading raw materials at different time intervals. This will avoid interruptions in gas supply due to a lack of feedstock.

You can find out how to install heating in a private house without gas here: https://aqua-rmnt.com/otoplenie/alt_otoplenie/otoplenie-chastnogo-doma-bez-gaza.html

Beneficial use

If during the operation of the installation excess biogas or fertilizers are generated, then it is possible to sell them at the market price, thereby turning what is literally lying under your feet into profit. If you are a large farmer, then you have the opportunity to purchase a ready-made biogas production station. Such factory-produced installations are very expensive, but have a long lifespan.

A do-it-yourself biogas plant can be made from scrap materials, it will not cost very much, and such equipment will work on the same principle. In this case, you can use available tools, as well as parts available in the master’s arsenal.

Calculation of installation profitability

Cow dung is usually used as a raw material for biogas production. One adult cow can produce enough to provide 1.5 cubic meters. fuel; pig – 0.2 cubic meters; chicken or rabbit (depending on body weight) – 0.01-0.02 cubic meters. To understand whether this is a lot or a little, you can compare it with more familiar types of resources.

Image gallery

Photo from

Construction of a bioreactor made from an insulated plastic container

Convenient transport for transporting substrate

Compact plant for industrial production

Biogas plant on a dairy farm

1 cubic meter biogas provides the same amount of thermal energy as:

- firewood – 3.5 kg;

- coal – 1-2 kg;

- electricity – 9-10 kW/h.

If you know the approximate weight of agricultural waste that will be available over the coming years and the amount of energy required, you can calculate the profitability of a biogas plant.

One of the main disadvantages of biogas production is the smell. The ability to use small compost heaps is a big plus, but you will have to endure the inconvenience and carefully control the process so as not to provoke the spread of pathogens

To put it into the bioreactor, a substrate is prepared, which includes several components in the following proportions:

- manure (best cow or pork) – 1.5 t;

- organic waste (this can be rotten leaves or other components of plant origin) – 3.5 t;

- water heated to 35 degrees (the amount of warm water is calculated so that its mass is 65-75% of the total amount of organic matter).

The calculation of the substrate was made for one laying for six months, based on moderate gas consumption. After about 10-15 days, the fermentation process will give the first results: gas will appear in small quantities and begin to fill the storage. After 30 days, you can expect full fuel production.

Equipment for the production of biogas is not yet particularly widespread in our country. This is largely due to poor awareness of people about the advantages and features of biogas systems. In China and India, many small farms are equipped with makeshift plants to produce additional clean fuel

If the installation is working correctly, the volume of biogas will gradually increase until the substrate rots. The performance of the structure directly depends on the rate of biomass fermentation, which in turn is related to the temperature and humidity of the substrate.

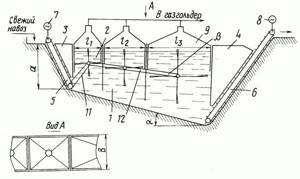

Manual loading reactor without stirring

This is the simplest installation for a home, the volume of which can range from 1 to 10 cubic meters. It is capable of processing up to 200 kg of manure per day.

Manual loading option

It consists of a minimum number of parts:

- Bunker for fresh raw materials.

- Reactor.

- Biogas selection device.

- Capacity for unloading fermented raw materials.

This installation can be used for southern regions, since it operates without stirring or heating, and is also designed to operate in psychophilic mode. The used raw materials are removed from the reactor through the unloading pipe during the loading of the next portion of manure. This occurs due to the biogas pressure in the reactor.

When making such a structure with your own hands, it is recommended to follow the following sequence:

- After calculating the daily volume of manure and selecting a reactor of the required size, it is necessary to determine the location of the future structure, as well as prepare materials for installation.

- Then you need to build a loading and unloading pipe, and also make a pit for installation.

- After installing the reactor in the pit, it is necessary to install a loading hopper and a gas outlet, as well as a manhole cover.

- Check the structure for leaks, paint it and insulate it.

- Put into operation.

Manual loading, heating and stirring design

A biogas plant can be constructed with manual loading of raw materials and periodic mixing. At the same time, it will not require large financial investments from the owner. The design is suitable for a small farm, since its capacity is to process up to 200 kg of manure per day. The drawings of such an installation are similar to the drawings of the previous version, and they can be made by contacting a specialist.

This unit can operate in mesophilic and thermophilic modes

For a stable and maximally intensive fermentation process, a special reactor heating system is installed. The biogas plant can operate in two modes. The reactor is heated using a hot water boiler running on the produced biogas. The rest of the biogas can be used to operate household appliances.

The processed raw materials are stored in a special container until applied to the soil or used as a breeding ground for California worms.

Installation with gas holder, pneumatic loading, heating and mixing of raw materials

A similar installation is intended for small and medium-sized farms with the processing of up to 1.5 tons of manure per day into biogas. The raw materials are heated through a heat exchanger with a water heating boiler, which runs on the resulting gas. The mass unloading pipeline is equipped with a special branch for collecting biofertilizer in storage and for loading into vehicles with subsequent removal to the fields.

The design of such a home-made installation involves pneumatic loading of manure into the reactor, as well as mixing with biogas, the selection of which is carried out automatically. Biogas is stored in a special compartment - a gas holder.

Raw materials for biogas production

There is an opinion that manure is the best raw material for biogas production. From a ton of unadulterated manure you can get only about 60 cubic meters. m of valuable gas. In addition, it is in manure that the largest number of bacterial species are present that can maintain the operation of the bioreactor for a long time.

However, you can first add horticultural and food industry waste to the manure.

Before placing the raw material into the reactor, it must be crushed and diluted with water.

What is biogas?

Biogas is a substance obtained from natural raw materials in the form of biomass (manure, bird droppings) due to its fermentation. Various bacteria are involved in this process, each of which feeds on the waste products of the previous ones. The following microorganisms are identified that take an active part in the biogas production process:

- hydrolytic;

- acid-forming;

- methane-forming.

The technology for producing biogas from finished biomass involves stimulating natural processes. Bacteria in manure should be provided with optimal conditions for rapid reproduction and efficient processing of substances. To do this, biological raw materials are placed in a tank sealed from oxygen.

After this, a group of anaerobic microbes comes into action. They allow the conversion of phosphorus, potassium and nitrogen-containing compounds into pure forms. As a result of processing, not only biogas is formed, but also quality approvals. They are ideal for agricultural needs and are more efficient than traditional manure.

Insulation layer

After manufacturing the bioreactor, it can be immediately filled with raw materials. The biomass must be covered with film. This is necessary to ensure low gas pressure during the fermentation process.

Once the dome is made, this ensures that biogas flows efficiently through the system.

Instructions for self-construction

If you have no experience in assembling complex systems, it makes sense to select online or develop the simplest drawing of a biogas plant for a private home.

The simpler the design, the more reliable and durable it is. Later, when you develop skills in building and handling the system, you can redo the equipment or install an additional installation.

Expensive industrial designs include systems for biomass mixing, automatic heating, gas purification, etc. Household equipment is not that complicated. It is better to assemble a simple installation, and then add elements that are needed

When calculating the volume of the fermenter, you should focus on 5 cubic meters. This installation allows you to obtain the amount of gas necessary to heat a private house with an area of 50 square meters, if a gas boiler or stove is used as a heat source.

This is an average figure, because The caloric content of biogas is usually not higher than 6000 kcal/m3.

In order for the fermentation process to proceed more or less stably, it is necessary to achieve the correct temperature conditions. To do this, the bioreactor is installed in an earthen pit or reliable thermal insulation is thought out in advance. Constant heating of the substrate can be ensured by placing a water heating pipe under the base of the fermenter

The construction of a biogas plant can be divided into several stages.

Stage 1 – preparing the pit for the bioreactor

Almost the entire biogas plant is underground, so a lot depends on how the pit was dug and finished. There are several options for strengthening the walls and sealing the pit - plastic, concrete, polymer rings.

The optimal solution is to purchase ready-made polymer rings with a solid bottom. They will cost more than available materials, but no additional sealing will be required. Polymers are sensitive to mechanical loads, but are not afraid of moisture and chemically aggressive substances. They cannot be repaired, but if necessary they can be easily replaced.

The intensity of fermentation of the substrate and the release of gas depend on the preparation of the walls and bottom of the bioreactor, so the pit is carefully strengthened, insulated and sealed. This is the most difficult and time-consuming stage of work

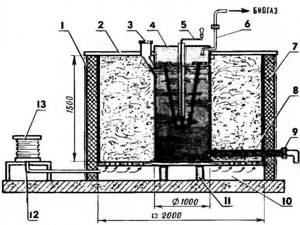

Stage 2 – arrangement of gas drainage

Purchasing and installing special mixers for biogas plants is an expensive proposition. The system can be made cheaper by installing gas drainage. It consists of vertically installed polymer sewer pipes with many holes made in them.

When calculating the length of drainage pipes, you should focus on the planned filling depth of the bioreactor. The tops of the pipes must be above this level.

For gas drainage, you can choose metal or polymer pipes. The former are stronger, and the latter are more resistant to chemical influences. It is better to give preference to polymers, because metal will quickly rust and rot

You can immediately load the substrate into the finished bioreactor. It is covered with a film so that the gas released during the fermentation process is under slight pressure. When the dome is ready, this will ensure a normal supply of biomethane through the outlet pipe.

Stage 3 – installation of the dome and pipes

The final stage of assembling the simplest biogas plant is the installation of the dome top part. At the highest point of the dome, a gas exhaust pipe is installed and extended to a gas holder, which is indispensable.

The bioreactor container is closed with a tight lid. To prevent biomethane from mixing with air, a water seal is installed. It also serves for gas purification. A release valve must be provided that will operate if the pressure in the fermenter is too high.

Read more about how to make biogas from manure in this material.

The free space of the bioreactor to some extent serves as a gas storage facility, but this is not enough for the safe operation of the installation. Gas must be consumed constantly, otherwise an explosion from excess pressure under the dome is possible

Pros and cons of the biological method

Designing biogas plants is a critical stage, so before making a final decision it is better to weigh the pros and cons of this method.

The advantages of such production include:

- Rational disposal of organic waste. Thanks to the installation, it is possible to put into use what would otherwise remain just waste that pollutes the environment.

- Inexhaustible raw material reserves. Natural gas and coal will sooner or later run out, but for those who have their own farms, the necessary waste will constantly appear.

- Small amount of carbon dioxide. It is released into the atmosphere when biogas is used, but carbon dioxide cannot negatively affect the environment.

- Uninterrupted and efficient operation of biogas plants. Unlike solar collectors or wind turbines, biogas production does not depend in any way on external conditions.

- Reduce risk by using multiple installations. Large bioreactors are always a big threat, but this can be eliminated by making a system of several fermenters.

- Obtaining high-quality fertilizer.

- Small energy savings.

Another plus is the possible benefit to soil health. Some plants are planted on the site specifically to obtain biomass. In this case, you can choose those that can improve the quality of the soil. An example is sorghum, which reduces its erosion.

Each type of alternative source has its disadvantages. Biogas plants are no exception. The downside is:

- increased danger of equipment;

- energy costs required to process raw materials;

- insignificant biogas output due to the small volume of home systems.

The most difficult thing is to make a biogas plant designed for the most efficient, thermophilic mode. The costs in this case promise to be serious. It is better to entrust such design of biogas plants to a professional.

Gas usage

Let's try to light it.

We connect the gas burner.

Burns great.

You can cook food.

There is practically no smell during combustion.

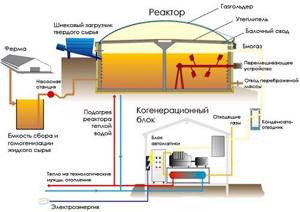

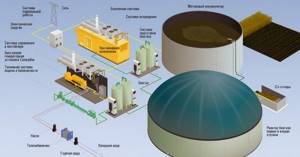

Biogas plant for enterprise

When a large enterprise that has a significant amount of production waste builds a biogas plant, the process itself is no different from the above options (personal and farm).

The only difference is in the power of the installation, its geometric dimensions, and the availability of automation and protection equipment. A variant of such an installation for a large enterprise may look like this:

As a rule, for large biogas plants, in addition to the standard operations discussed in the configuration options discussed above, additional ones are used, these are:

- several stages of gas purification;

- gas preparation before supply for processing;

- cooling before supply to the gas generator;

- other systems, depending on the design of the installation and the types of raw materials used.

Video about producing biogas from manure

You can see how the construction of an underground reactor takes place in the video:

An installation for producing biogas from manure will allow you to significantly save on heat and electricity costs, and use organic material, which is available in abundance in every farm, for a good cause. Before starting construction, everything must be carefully calculated and prepared.

The simplest reactor can be made in a few days with your own hands, using available materials. If the farm is large, then it is best to buy a ready-made installation or contact specialists. published econet.ru

Methods for heating a bioreactor

Microorganisms that process the substrate are constantly present in the biomass, but for their intensive reproduction they need a temperature of 38 degrees or higher.

For heating during cold periods, you can use a coil connected to the home heating system or electric heaters. The first method is more economical, so it is used more often.

The biogas plant does not have to be buried in the ground; there are other options for arrangement. An example of the operation of a system assembled from barrels is shown in the video below.

The easiest way to arrange heating from below is to lay a pipe from the heating system, but the efficiency of such a heat exchanger is relatively low. It is better to arrange external heating, ideally steam, so that the biomass does not overheat

Collection and removal of biogas

Biogas is removed from the reactor through a pipe, one end of which is under the roof, the other is usually lowered into a water seal. This is a container with water into which the resulting biogas is discharged. There is a second pipe in the water seal - it is located above the liquid level. Cleaner biogas comes out into it. A gas shut-off valve is installed at the outlet of their bioreactor. The best option is a ball one.

What materials can be used for the gas transmission system? Galvanized metal pipes and gas pipes made of HDPE or PPR. They must ensure tightness; seams and joints are checked using soap foam. The entire pipeline is assembled from pipes and fittings of the same diameter. No contractions or expansions.

Cleansing from impurities

The approximate composition of the resulting biogas is:

Approximate composition of biogas

- methane - up to 60%;

- carbon dioxide - 35%;

- other gaseous substances (including hydrogen sulfide, which gives the gas an unpleasant odor) - 5%.

In order for biogas to be odorless and burn well, it is necessary to remove carbon dioxide, hydrogen sulfide, and water vapor from it. Carbon dioxide is removed in a water seal if slaked lime is added to the bottom of the installation. Such a bookmark will have to be changed periodically (as soon as the gas starts to burn worse, it’s time to change it).

Gas drying can be done in two ways - by making water seals in the gas pipeline - by inserting curved sections into the pipe under the water seals, in which condensate will accumulate. The disadvantage of this method is the need to regularly empty the water seal - if there is a large amount of collected water, it can block the passage of gas.

The second way is to install a filter with silica gel. The principle is the same as in a water seal - the gas is supplied to the silica gel, and dried out from under the lid. With this method of drying biogas, the silica gel must be dried periodically. To do this, you need to warm it up in the microwave for some time. It heats up and the moisture evaporates. You can fill it up and use it again.

Filter for cleaning biogas from hydrogen sulfide

To remove hydrogen sulfide, a filter loaded with metal shavings is used. You can load old metal scourers into the container. Purification occurs in exactly the same way: gas is supplied to the lower part of the container filled with metal. As it passes, it is cleared of hydrogen sulfide, collected in the upper free part of the filter, from where it is discharged through another pipe/hose.

Gas tank and compressor

The purified biogas enters a storage tank - a gas holder. This can be a sealed plastic bag or plastic container. The main condition is gas tightness; shape and material do not matter. The gas holder stores a supply of biogas. From it, with the help of a compressor, gas under a certain pressure (set by the compressor) is supplied to the consumer - to the gas stove or boiler. This gas can also be used to generate electricity using a generator.

One of the gas tank options

To create stable pressure in the system after the compressor, it is advisable to install a receiver - a small device for leveling pressure surges.

Approximate cost calculation

Before you begin designing an installation, you must carefully calculate all upcoming costs. In some cases - harsh climate, small amount of available raw materials - it is more profitable to refuse construction.

Biogas production costs

A home mini-station will cost about 50 thousand rubles.

The costs of biogas production consist of the cost of equipment, installation and maintenance costs of installations . If purchased raw materials are used, their cost and delivery costs are taken into account.

The installation itself is purchased from a factory or made independently . Factory products are installed, configured and maintained by specialized organizations. For some models you will have to purchase consumables - fermentation activators or bacteria.

During operation, costs consist of electricity costs for mixing the substrate and heating the reactor.

Cost of a ready-made and home-made biogas plant

A farm installation will cost several hundred thousand rubles.

The industry produces biogas plants for farms. The volume of the bioreactor varies from 0.5 to 30 m³ . A ready-made system with a 1m³ , for example, BUG-M, containing all the necessary components, costs about 180 thousand rubles . Installations for farms with a herd of 12 heads of cattle or 1000 heads of poultry will cost 2 million rubles.

Few farms can afford the purchase of such equipment, so they prefer to make the installation themselves.

Home generators can cost from 50 thousand rubles , which allows you to significantly save on the purchase.

How to do it yourself

A biogas plant for farming or household use can be made by a person who has the necessary tools, knowledge of plumbing and basic welding skills.

The sequence of actions taken will be as follows:

- manufacturing the body of the bioreactor, which is used to carry out fermentation (the container can be made of metal or concrete);

- installation of covers on top of the tank, holes in the side walls necessary for loading and, accordingly, unloading raw materials;

- installation of a gas tank;

- construction of a pipeline from the gas tank to the place of consumption of the final product (this design must include valves and protective elements - various valves, valves, etc.).

Installing a biogas plant at a dacha, in a country house, on a farm, or in production will allow you to receive not only economic benefits, but also achieve other positive results, namely in the environmental and energy aspects.

Using such a device, the consumer will not only receive environmentally friendly fuel, several types of energy and biological fertilizer, but will also significantly reduce the opportunity costs that could have been incurred in the absence of such a unit.

Photo of a do-it-yourself biogas plant

Did you like the article? Share