The presence of running water in the house for us means not just comfort, but a necessary condition for our existence. Lack of water in the tap is a small disaster. But what to do if the water trickles out drop by drop or stops dripping completely, but there is water in the main?

We welcome our reader and bring to his attention an article on how to clean a water pipe at home.

Causes of clogging

Most often, steel pipelines become clogged. The inner surface of steel pipes is rougher, and plaque settles on it. In addition, steel is prone to corrosion - peeled rust plates also clog pipes. This is especially true for the heating system. The second reason for clogging can be the poor quality of water in the main water supply - it may contain sand, scale, slag, poorly soluble salts, and in some cases even biological contaminants.

The roughness of plastic pipes is approximately 20 times lower than steel pipes, so they can become clogged only when very contaminated water enters (for example, after accidents on main pipelines).

How to fix a pipe body leak

How to repair a leak in a pipe if there is a crack in the body? To resolve the problem, you can use one of the following methods:

- install the clamp;

- apply a bandage;

- use cold welding.

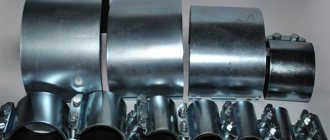

Installation of the clamp

The easiest way to eliminate a leak on the pipe body is to install a repair clamp. The special device consists of:

- metal case;

- rubber seal located inside the housing;

- fixing bolts.

Special device for eliminating pipe leaks

You can install the clamp yourself in the following way:

- the leak site is cleaned of dust and rust;

- the pipe is wrapped with a clamp;

- The device is fixed.

Eliminating leaks using a clamp

The choice of clamp should be based on the size of the crack. To completely eliminate the fault, the clamp must be 1.5 - 2 times larger than the size of the leak.

Applying a bandage

How to seal a leaking pipe if there is no clamp? To eliminate a leak, you can use a rubber, adhesive or cement bandage.

The rubber bandage is:

- piece of rubber. A cut from a bicycle inner tube or a medical tourniquet used to stop bleeding is ideal. Use a rubber cut to wrap around the cracked section of the pipe;

- small clamps, wire or other fastening straps for securing the rubber to the pipe.

Pipe bandage made from scrap materials

The adhesive bandage is installed according to the following scheme:

- the section of the pipe where the leak has occurred is cleaned of dirt using a solvent;

- fiberglass or medical bandage is impregnated with special glue;

Special composition for eliminating leaks

- the pipe is wrapped in prepared material in several layers;

- the applied composition is expected to dry completely.

Instead of special glue, you can use epoxy resin or, when using metal pipes, ordinary table salt.

Watch the video to see how to cover a leaking pipe with epoxy resin.

A cement bandage is an analogue of an adhesive bandage. The bandage or fiberglass is impregnated with cement mortar prepared in a ratio of 1:10.

Cold pipe welding

A relatively new way to eliminate leaks is to use a so-called cold welding composition. How to coat a pipe to prevent it from leaking? For different types of pipes (metal, plastic, metal-plastic, and so on), different cold welding compositions are used.

Composition for various types of plastic pipes

Detailed instructions for using the mixture are given on the bottle with the active substance. Here is the general algorithm:

- Before applying the mixture, the damaged section of the pipeline is cleaned of dirt. If the composition needs to be applied to a metal pipe, then the crack is additionally cleaned of paint and rust;

Cleaning the pipe before cold welding

- A special composition is applied to the damaged area. If liquid cold welding in the form of glue is used, it is advisable to apply it with a brush. If a plasticine-like composition is used, then before application it is necessary to knead it thoroughly until a homogeneous mixture is obtained;

- the cold welding substance is evenly distributed throughout the entire area of the cracked pipeline, covering 3–4 cm more than the crack itself;

Coating the damaged area with a cold welding substance

- the composition is left until completely dry, which takes an average of 2.5 - 3 hours.

To ensure that the area restored by cold welding does not stand out, the dried compound can be cleaned with sandpaper and painted.

All methods given in the article for eliminating leaks on the pipe body, except for the use of cold welding, are only a temporary measure. To completely get rid of the problem, it is necessary to completely replace the damaged section of the pipeline. It is advisable to involve qualified specialists to perform this operation.

Cleaning methods

Cleaning methods should be selected depending on the location of the blockage, the length of the pipelines, the method of installation (welding or threading), and the ability to disconnect the pipeline from the main.

Before starting work, the condition of the pipelines should be assessed - it is better not to touch the old ones or use chemical cleaning methods.

Tapping with an ordinary hammer

The most affordable way to clean pipes from deposits is to tap the pipes with a regular hammer.

The pipe is not disassembled, gently and lightly tapped with a hammer, then the water is turned on - it will wash away the detached plates of rust or calcium deposits. It is worth tapping the system in parts - a separate section going to the bathroom, kitchen, toilet. Tap one area - rinse with water, then the next one - and rinse again. Otherwise, you risk clogging the system completely.

The great advantage of this method is that there is no need to disassemble the pipes.

Tapping can be performed not only by a home craftsman, but also by a home craftswoman.

Plumbing cable

One of the most effective methods of removing blockages is using a small diameter plumbing cable. To do this, you should block the access of water to the area being cleaned, dismantle the tap, mixer, or any threaded fitting. Then the cable is inserted into the opened hole and moves with rotation and is removed. Then the water is opened, the blockage is washed out, then the removed fittings are mounted back.

It should be borne in mind that the cable for heating and water supply systems should not be used for sewage systems; it should not be too “tattered” - it may simply not fit into the pipeline. It is better to use a ready-made cable with a metal ring at the end. You cannot use a cable to clean the metering unit (meter).

Pipe dismantling

If all of the above cleaning methods do not help, they resort to the most extreme option - dismantling the pipes. This is possible if the pipes are assembled on threaded fittings.

First the water is turned off. Then the parts of the pipeline are unscrewed, water is supplied under pressure using a hose and washed.

You can combine cleaning with a cable or chemical methods with washing with water under pressure...

The holes on the connection hoses for the toilet tank, faucet, and water heating tank often become overgrown. You can unscrew the hoses, carefully clean the “overgrown” hole (using a screwdriver or a narrow chisel), rinse it and screw it back on.

Household chemicals

This method also involves disconnecting the system from the network. Mixers are usually located above the connection point, and chemicals must be poured from their side.

Chemical cleaning technology:

- shut off the water supply;

- dismantle the metering unit, while taking care of the safety of the seals;

- drain water;

- dismantle taps and mixers;

- plug the lowest points of the system using plugs;

- wear rubber gloves and safety glasses;

- carefully (you can use a watering can) pour in the product used; stand for 30 minutes - one hour;

- place a plastic basin under the lower part of the system;

- unscrew the plugs and drain the liquid;

- flush the system from the highest points;

- put everything back together;

- Flush the system well with water.

The ideal chemical for dry cleaning is concentrated hydrochloric acid. Formic and acetic acids can also be used, but they are much weaker, effective against plaque and ineffective against rust.

You can also use concentrated sodium hydroxide (contained in the Mole product).

Plunger and its analogues

The plunger itself is not suitable for cleaning water supply networks - it is designed for the sewer system.

Professional pneumatic guns can be considered an analogue of a plunger for small-diameter pipes. Their advantage is that they can use a jet of water to clear the blockage at a distance of several tens of meters (sometimes up to 50). But they are rarely found even in the arsenal of a professional plumber and are also expensive. At home, it is worth using other cleaning methods.

Which way is better

The best way is radical. Replace with metal-plastic. Non-galvanized steel will last you 10-15 years; galvanization - 20 years. And metal-plastic on the heating system will last at least 25 years; on water supply systems – about 50 years. And no rust!

If it is not possible to change the pipes in the near future, you can try cleaning them. The best methods are disassembly; using a cable and a pneumatic gun. Then comes the chemical one. Then tapping. This is where you should start - all other methods require skills and time. In any case, steel will have to be replaced with metal-plastic.

Eliminating leaks at the junction of other types of pipes

To eliminate leaks at the joints of a pipe made of metal, plastic or metal-plastic, you can use one of the following methods:

- replacement of fitting;

- cold cooking;

- adhesive bandage.

Replacing fittings

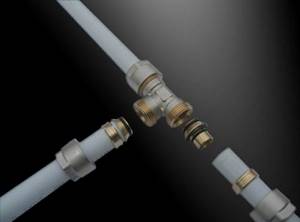

The following can be installed on pipelines:

welded fittings. Mainly used for connecting plastic pipes;

Connecting element installed by welding

compression fittings. Can be used for joining both plastic and metal-plastic pipes. Unlike a welded fitting, the connection is more reliable and durable;

Element for forming a permanent connection

threaded fittings. They are used for various types of pipes if it is necessary to arrange a detachable connection.

Element for creating a detachable connection

If a pipe connection is leaking and it is necessary to replace the welded fitting, proceed as follows:

- disconnect the pipeline from the water supply;

- cut the connecting element with special scissors;

When cutting the connecting element, it is important to take into account that the total length of the pipeline is reduced.

- prepare a pipe section of the required length and two new fittings;

- sequentially weld the elements using special equipment.

Installing a new fitting by welding

You can use the finished pipe after the pipes have completely cooled. This time is required to strengthen the newly created connection.

If there is a leak at the junction of pipes with compression fittings, then the connecting element is replaced according to the following scheme:

- the connecting element that has become unusable is removed;

- the pipes that need to be connected are chamfered and calibrated;

- crimp rings and nuts are put on the ends of the pipes, which act as clamps;

- the pipe is inserted into the fitting until it stops and the fixing elements are tightened.

Compression fitting installation diagram

You can use the repaired pipeline immediately after replacing the compression fitting.

The process of correctly installing a compression fitting is presented in the video.

https://youtube.com/watch?v=c2QhvEbmqbc

If a pipe is leaking at a joint equipped with a threaded fitting, then you must proceed in the following order:

- first of all, you can try to simply tighten the thread with a wrench, since in some cases a simple loosening of the tightening occurs;

- if tightening does not help, then the connecting fitting is completely removed;

- the thread is treated with FUM tape or any other insulating material;

Sealing the threaded connection before fixing

The insulating tape is wound along the thread in the direction of twisting.

- the new fitting is tightened into its original place.

Fixing the connecting element on pipes

Cold welding

If a leak is detected in pipe connections that are not equipped with a fitting, then the pipeline can be repaired using the cold welding method. To fix the joint, you need to purchase a special compound.

Mixture for quick repair of leaks

This tool must be used according to the following scheme:

- the fragment of the pipeline in which the leak has formed is cleaned of contamination. If the composition needs to be applied to a metal pipe, then the damaged area is first cleaned with sandpaper;

- the mixture in the package is mixed until smooth and applied to the damaged area and carefully leveled.

Using cold welding to eliminate leaks

Until complete drying, which occurs after approximately 3 hours, the pipeline cannot be used.

Adhesive bandage

If plastic pipe joints made without the use of special connecting elements leak, the leak can be eliminated using an adhesive bandage. To equip the bandage you will need to purchase:

- a piece of fiberglass;

- special two-component glue.

You can organize the bandage as follows:

- the pipe joint is cleaned of dust, dirt and foreign particles;

- fiberglass is impregnated with glue;

- the impregnated material is wrapped several times at the leak site;

- expected until the material dries completely.

Installing an adhesive bandage at the leak site

There are a lot of ways to independently seal pipe joints when a leak occurs. Each master can independently choose the most optimal solution to the problem.

Expert advice

Do not use sulfuric acid (such as battery fluid) to clean pipes - it is unsafe to use and produces toxic compounds that can leach into drinking and shower water.

A favorite remedy for home plumbers, vinegar and baking soda are not effective for cleaning pipes.

Before cleaning, you should try to determine whether the entire system is clogged or whether only part of it is clogged - that should be cleaned.

Water meters can only be cleaned by flushing. You cannot clean it with a cable or chemically - you can damage the meter.

If there is a lot of plaque and it cannot be cleaned, it means that the meter is already 12-15 years old and you should think about replacing it.

After disassembling and reassembling part of the network, it is necessary to carry out hydraulic tests - fill the network with water and carefully check all joints for leaks.

Which way is better

There is no clear answer to this question. A lot depends on the nature of the contamination, the diameter and length of the pipes, and its spatial configuration. For local blockages, air blowing or tapping is sufficient. But a pipeline overgrown with solid salts can only be removed chemically, and even then not always.

At the same time, it is simply impossible to see where and how the pipe is clogged. Therefore, very often it is necessary to apply several methods sequentially, moving from simple to more complex ones.

The use of chemical cleaning at home should only be used as a last resort. After completing this work, the water from the pipeline will be unfit for drinking and eating for some time. It is recommended to use store-bought bottled water for at least a week or ask your neighbors to collect it.

Preventing blockages

There is virtually no real prevention of blockages. It is necessary to periodically clean the inlet strainers and the mixer filter from debris and scale, and rinse or clean the pipes. Removing debris has a surprisingly good effect on the pressure in the system. Metal pipelines still become overgrown with calcium deposits and rust.

If plastic pipes are regularly clogged, it means that there are a lot of mechanical impurities in the water - this is a sign of an emergency condition of the main networks. If such problems arise, you should contact the water utility (and possibly higher authorities).

Preventive measures

Without regular maintenance, the pipeline wears out quickly. Lime deposits not only reduce water pressure, but also negatively affect the metal. Under a layer of plaque, it rusts faster and leaks appear. Preventive measures include installing a coarse filter. It is placed at the entrance, before the counter.

The part is a cylinder made of fine mesh. Filter material – stainless steel. The mesh traps large debris and rust particles. It screws into the cork flange. If the water quality is low, the cylinder quickly clogs. Regular cleaning of the filter is required, otherwise the pressure will decrease. To prevent the formation of limescale, it is recommended to use softener filters.

Circumstances of lack of water in the system

The decisive factors determining the circumstance of a drop in pressure in the pipeline may include:

- condition of the pipeline (how worn it is);

- type of material from which the pipes are made (metal or plastic);

- condition of the mixers or valves of the system.

Let us remind you that clogging in metal-plastic pipes practically does not appear under any circumstances.

Taking into account all of the above, the choice of option for cleaning pipes at home is determined by a number of specific conditions:

- the condition of the section of the pipe line where the fault was found;

- the location of this section of pipe;

- your experience capabilities.

- installation location of water meters;

- the presence of valve and mixing elements;

- the presence of filter elements (grids) included in these elements;

- the pipes themselves.

Preventive measures

Preventing a problem from occurring is always cheaper than fixing it. And the point is not that the house may be old. New buildings are connected to the same worn-out utility system, and one cannot expect that the quality of water for residents of a new multi-apartment building will be better.

Through pipes laid near sewers, garbage migrates to residents, being suspended in water and picked up by pressure. But if previously there were pipes with a large diameter along the way, then this “garbage” can form a blockage in the wiring, even if it was laid recently. The new pipeline does not reduce the danger, since no filters are installed at the entrance to the house (riser).

It is the coarse filtration station that will completely solve the problem. The filter must be installed at the inlet before the “dirt” enters the meter. The only element that can stand in front is the shut-off valve. This is necessary for filter maintenance, which consists of periodically cleaning the screens or replacing filters. If this is done in a timely manner, the risk of blockage will be negligible.

Separately, it should be noted that the introduction of preventive measures contributes not only to this. It is enough to install a filter, and the service life of the pipeline will be increased. How much? This depends on the efficiency with the number of degrees of purification. Ideally, the water will be purified from bacteria, scale, solid inclusions, chemical contaminants, and harmful impurities. No build-up will form.