A huge amount of biomass grows on the marine and continental expanses of our planet. At the same time, humanity uses a very small share of the energy contained in this plant mass, preferring to burn hydrocarbons. But times are changing and previously unnecessary waste is becoming raw material for the production of various types of biofuels. Various European firewood, pellets and briquettes made from such waste have appeared on sale. However, if there are suitable conditions at home, then why not make biofuel with your own hands? This material will tell you what and how you can make fuel at home.

What is biofuel?

The energy hidden in plant matter is practically inexhaustible, because its source is our sun. Plants know how to use the energy of the sun, processing it for their growth. In turn, animals and birds receive energy by eating biomass, while producing waste products. By definition, biofuel is a fuel obtained from raw materials of plant or animal origin, as well as waste products and various industries associated with the processing of biomass.

Modern technologies make it possible to obtain biofuel in three forms: solid, liquid and gaseous. We encounter solid fuel in life most often in the form of pellets and various briquettes obtained by pressing. Liquid fuel - biodiesel - is still rare in the countries of the post-Soviet space, this is due to the presence of a large amount of fossil hydrocarbons at an affordable price. While obtaining liquid biofuel from vegetable oil is quite expensive and technologically difficult.

The production of combustible biogas is much simpler and cheaper, as a result of which it is gaining increasing popularity. Owners of livestock and poultry farms are increasingly thinking about purchasing a biogas plant, because they have at their disposal a huge amount of litter and manure, which is perfectly suitable for this purpose.

It makes no sense to list here all types of plant raw materials for processing into fuel, their sources and production technology. We are only interested in those types of biofuels that can be successfully produced at home without investing large amounts of money. Here they are:

- biogas extracted from waste products of domestic animals and poultry;

- briquettes from various plant wastes;

- charcoal.

Of course, if you try really hard, you can make pellets, eco-diesel, and even eco-gasoline yourself. People do such things as a hobby, spending years of their lives and often considerable money on it. Such complex technologies are inaccessible to a wide range of users, and therefore we will not consider them.

Main advantages

There are many advantages to using biogas.

- Low cost, today it costs about the same as gasoline, but at the same time it is much cleaner, which allows you to significantly save on maintenance of boilers running on this fuel.

- You will not depend on oil, which, as you know, is not available in all countries.

- The source from which biofuels are extracted is renewable, unlike gasoline. Oil is not infinite; sooner or later it will run out, but the listed materials necessary for the production of biological fuel will always be there.

- The amount of harmful gases released into the atmosphere is reduced. If you give figures, this is approximately 65% of the difference.

Producing biogas at home

The flammable gas released from manure and other similar materials consists mainly of the same methane that we are used to using every day in our kitchens. The share of methane in biogas ranges from 50 to 70%, depending on the quality of the raw materials and the efficiency of the technological process. The remaining chemical compounds in the gas are non-flammable, carbon dioxide and hydrogen sulfide. It is thanks to the latter that the whole process is accompanied by a well-known smell.

Gaseous biofuel is a flammable substance released as a result of a chemical reaction of fermentation of organic waste without the presence of oxygen. Therefore, the main element of technological equipment is a closed cylindrical container (reactor) of large capacity, preferably at least 1 m3.

Many home craftsmen use ordinary plastic or iron barrels for this purpose. This is quite acceptable; the reaction will occur in such vessels. Only a little gas will be released, as a result it is disproportionate to the time and labor expended. The minimum capacity of the reactor must be at least 600 liters.

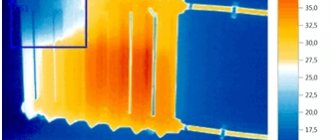

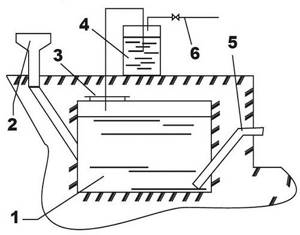

In order for the process to proceed as quickly and efficiently as possible, according to the technology, the contents of the reactor must be constantly heated to a temperature of 35-40 ºС. At home, this is not always possible, and it also entails energy costs. The solution is as follows: it is better to install the container from which biofuel is obtained in a fairly deep hole made in the ground. Ideally, the bottom and walls of the pit are made of concrete, and the upper protruding part of the reactor is insulated for the winter. How this is done correctly is shown in the figure:

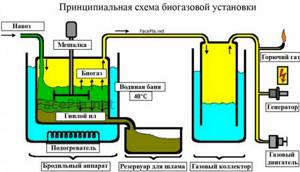

The general design of the installation, which allows the production of biofuel from manure, contains the following elements (see diagram below):

- reactor – a cylindrical metal vessel;

- loading hopper for filling the reactor with substrate (a mixture of raw materials and water);

- service hatch;

- outer container - water seal to maintain the required pressure in the reactor;

- pipe for unloading waste material;

- branch pipe with a tap for supplying biogas.

Note. To improve the fermentation of the substrate, it is recommended to add an auger to the design, similar to a construction mixer. It is installed in the center of the tank, and a handle is brought out through the seal to periodically mix the contents.

The technological process is performed as follows. First, the waste must be crushed. The size of the fraction should not exceed 10 mm, this will ensure good penetration of bacteria that cause fermentation. Then the raw material is filled with water and mixed thoroughly. The amount of water is approximately 0.7 liters per kilogram of manure. The resulting substrate is used to produce biofuel at home.

The container is filled with the substrate through a hopper, which is then hermetically sealed. Whenever possible, the contents should be mixed. After several days, flammable gas begins to be released; it must be pumped out periodically so that the pressure inside the tank does not rise. This will slow down the reaction and force the contents back into the hopper. A compressor and a regular propane cylinder are used to pump out gas. A detailed description of the installation and production technology can be studied by watching the video:

It cannot be said that the extraction of biogas from various types of manure and litter is a simple matter. Home craftsmen have to go through trial and error: sometimes too little fuel is released, sometimes the reaction does not proceed, and so on. You must understand that achieving success will require a lot of work and patience, and the amount of fuel is unlikely to be enough to heat the house. However, it will be quite enough to operate a gas water heater and a kitchen stove, which is already a big plus. How these devices operate on biogas is shown in the video:

Conclusions and useful video on the topic

Review of a unit for the production of biogas, in the manufacture of which a 127 liter plastic tank is used. Features of the device and operating tips.

Of particular interest in the use of installations is manifested among owners of the restaurant and gastronomic sphere, where the topic of processing food waste remains relevant. On this basis there is a good opportunity to create cheap recycling of organic waste for the benefit of farms. Finally, biofuel production technology means real conservation of the environment, which cannot be said about the production of other energy drinks.

Are you interested in the production of biofuels and want to clarify some points? Ask controversial questions in the comments - our experts will try to clarify such points.

Or maybe you are familiar with the manufacture of a bioreactor and the process of producing biogas firsthand? Share your practical knowledge and your opinion on this issue under our article - many business executives will be interested in your experience and recommendations.

Making briquettes

Setting up the production of biofuel from sawdust, straw and other waste at home is somewhat easier. The only equipment you will need is a hand press made specifically for this purpose. It can be purchased ready-made, ordered from craftsmen, or, if you have the appropriate skills, made yourself. A factory-ready press costs a lot of money, so the last option will cost you the least.

The production of briquettes begins with the preparation of the mixture. Sawdust, seed husks, straw and even soaked waste paper are used as raw materials. Of course, such fuel can burn wonderfully in a stove or solid fuel boiler, but due to the low bulk density, the firebox will have to be loaded too often. Ready-made solid biofuel made from straw or sawdust will burn much longer.

The mixture consists of raw materials, water and clay, which serves as a binder. Straw or paper must first be crushed, then mixed with clay in a ratio of 10:1 (1 kg of clay per 10 kg of waste) and water. The amount of water must be selected so as to ensure uniform mixing and the ability of the mixture to be molded. You should not add a lot of clay to the solution; do not forget that it will remain in your boiler in the form of ash.

A special form is filled with the mixture, then it is placed under a press. After pressing, the finished briquette is carefully removed and laid out to dry in the sun. You can see the pressing operation in the video:

What should the composition of the manure mass be?

The mass of manure loaded into the bioreactor should not be considered simply as a raw material suitable in any quality. The component of the substance is of fundamental importance for the fermentation process. In practice, it has been noted that a reduction in substrate particles is accompanied by better process efficiency.

Pronounced fibrousness of the substrate and an increase in the area of interaction of bacteria are the main criteria that contribute to the rapid decomposition of the manure mass. In this state, the manure raw material, when heated and mixed, does not form sediment or film on the surface, which greatly simplifies the filtration of the gas mixture.

Preparation of manure mass for loading into the reactor. This procedure is given no less attention than everything else if there is a desire to obtain a significant amount of biofuel in a short period of time

The degree of grinding of the raw material determines the duration of fermentation, which in turn affects the volume of gas produced. Thus, to reduce the fermentation time, it is necessary to grind the raw materials well: the better the grinding quality, the shorter the fermentation period.

Preparation of charcoal

Charcoal is of interest to homeowners as a fuel used in home grills and barbecues. It is no secret that buying such coal in a store is quite expensive, while at home you can burn it for free, just by spending your time. By the way, it makes no sense to burn it in solid fuel boilers or stoves; it is much easier to put ordinary firewood in the firebox.

Charcoal is burned from wood in 2 ways:

- in barrels;

- in the pits.

The first method requires an ordinary 200 liter steel barrel and a household vacuum cleaner. The latter will serve to pump air, so a pipe must be cut into the bottom of the barrel to connect it. Light a fire at the bottom of the container, then fill it halfway with wood and turn on the vacuum cleaner. Then the wood is piled up to the top, covered with a lid and covered with clay. When everything has burned down and the barrel has cooled, sorting is done to separate the charcoal from the ash.

In a similar way, wood is burned in a pit. The latter is dug 0.8 m in diameter and no more than 0.6 m in depth. The bottom of the pit is compacted, after which a fire is built in it and firewood up to 30 cm long is laid in layers. Filling occurs as the previous layer is burned, the process lasts about 3 hours. At the end, the pit is covered with branches and moss, and sprinkled with earth on top. After 2 days, the coating can be removed and the coals removed.

Biodiesel production from vegetable oil

Diesel fuel can be produced by the interaction of vegetable oil (cooking fat) and widely used chemical components.

The resulting product in its pure form is biodiesel, suitable for any diesel car engine. It can also be used in a mixture with traditional diesel fuel. No modifications are required.

Let's consider the technology for preparing biodiesel with your own hands based on fresh vegetable oil. However, the production of biodiesel from waste vegetable oil cannot be ruled out.

True, this process looks somewhat more complicated. Therefore, first we will consider the basic (simple) option.