quote: Originally posted by ShopForPlumbing:

in which active repair and restoration work was going on and we were forced to change the dryers there for free once a month

again the memories flooded. there was a man for whom we changed three dryers in a row. the fourth he bought was no longer made by us. and then two or three complaints immediately came from the same house. There, the risers were being replaced and all the residents were changing their dryers. and therefore more complaints. and then we went to IZhSTU.

and how much nonsense we heard along the way about ourselves and our product. and after 6 months the confrontation ended as if it had never happened: the dryers stopped becoming covered with white spots on the folds, I wrote because they stopped welding

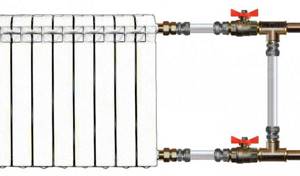

Connecting a heating radiator

I wrote about how to replace a heating radiator yourself at the very beginning of creating the site.

Since then, many questions have been asked, and this material is devoted to one of the frequently asked questions.

Good afternoon Please help with advice. 2 years ago I made a repair with the corresponding replacement of radiators (I didn’t do it myself since I’m a complete amateur at this), this is what happened:

Everything was fine, but then, during the next drain/fill of water, an American leak began to flow down my heating risers and more than one on another radiator too ((. I called a plumber, he tightened the American pipe a little tighter (the leak stopped) and said that now it will happen periodically leak, since the rubber dries out when the temperature drops, when asked what to do, he said we need to install taps. But I don’t understand how to install taps before the bypass))

Please help me with advice on what to do now with this installation? And how to do it right? Otherwise I’m afraid they’ll do it again and in about 2 years it’ll start leaking again ((Thanks in advance!

It turns out that I cannot call American polypropylene fabrics reliable and do not recommend sewing them up with finishing. I need to start by completely eliminating the Turkish Pils pipe from the material I work with. There were cases not only where an American woman simply leaked, but such an American woman was even torn out of the nut. What can I not say about Valtek and Ekoplastik.

Specifically in your case, it wouldn’t hurt to completely solder the bypass. Not soldered very well. The jumper pipe is too short and it “pulls” the feed and the header together.

If you solder the bypass from polypropylene, then the American one can be eliminated altogether. The scheme is something like this:

In your case, soldering such a jumper without an American wire will not be difficult. They are long enough to push the pipes apart and solder them.

What to do if the length does not allow you to solder the jumper in this way. For example, the bends are much shorter and cannot be opened.

Then use an American cone.

The essence of the American cone is that it does not have a gasket. It has a precisely fitted cone, which, when tightened with a nut cape, does not allow water to pass through. The connection is cheap but reliable. If tightened correctly, there will be no leakage.

In general, it is better to install the bypass as close to the battery as possible, but if there is no more than half a meter from the taps to the radiator, then the jumper can be installed immediately on the taps. In the case of polypropylene, you cannot do without an American one.

But if your system is made of metal-plastic pipes, then the American one is excluded, because such a pipe can be bent.

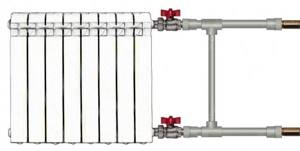

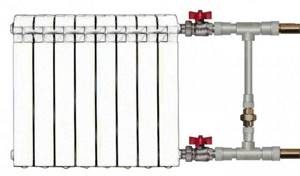

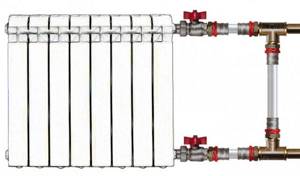

Sometimes metal-plastic is connected like this:

But I recommend the following connection diagram:

Moreover, it does not matter whether you assemble using press fittings or crimp fittings.

According to the second scheme, we block the outlets to the radiator, which will allow us to completely shut off the radiator at any time if a leak appears on the nuts or on the press.

In both cases, we do not block the jumper and do not disrupt the circulation.

If you look at the first diagram, you need faucets or thermostats with American ones, and I also recommend choosing them without gaskets. Look for conical ones.

In the second diagram, you need separate American ones that need to be screwed into the heating radiator.

The heating battery is leaking, what to do, how to fix the leak in a short time

Sooner or later everything goes wrong. But when the heating battery leaks, many people don’t know what to do. But almost everyone has to face this problem.

In order to avoid damage to your own and your neighbors’ property, you must adhere to a certain procedure. In addition, during the heating season, hot water flows in the radiators, which can burn you. Therefore, everyone should know what to do if the heating battery is leaking.

The American is leaking - we are drowning our neighbors

AN63555

Well, the neighbors upstairs have a European-quality renovation, tiled floors, if this is possible, then of course it’s not a problem, but the craftsmen told us that it’s impossible to do this now, and the neighbors upstairs don’t need it at all, they’re already fine. We and the neighbor below are suffering. If only we try to its pipes, but we also have floor tiles, we won’t move them. Who would give competent advice?

Evgenik

do you think we are all the same? Every time different companies and specialists - and the same thing. Disappointment in people until you understand everything yourself - they cheat you, it’s even offensive, because we don’t do repairs every year and the pipes were changed for the first time, who would know. Before the repair began, not a single company was invited for consultation, and since we women understand little about pipes, we did not know the pitfalls, we did not even imagine that this could happen, that the iron could not be left. Not even all men understand the subtleties. Only those who face this problem first-hand. Moreover, the pipes did not leak for the first year. It all started a year later. We were told to just pull up the American girl. They pulled it up. But after the next hot water shutdown, it started dripping again. They came and said - the reason is that the pipe goes straight, we need to make an elbow. Done. Half a year later again. Another master came and said - a knee is not enough - and he twisted a whole caral for us. And so it started leaking from below - it didn’t leak from below for 3.5 years, then this donut started leaking from above, the rubber bands on the heated towel rail also rotted and started dripping. Now, as you can see, they have given us the letter P. In short, the P is complete. But financially there is also no way to redo the renovation, we did it this way, I will study the topic further, since the situation is the same in the rooms, it’s not dripping yet, but I don’t want to wait until it starts to leak.

So I came here for a consultation, everyone has their own opinion, but things are still there. I began to study the issue myself. Now we need to make the box again and attach the sink back. And all this is not free of course. There would be money. And how the doors were made - they redid it several times, also unfortunate specialists, until she took it upon herself and studied the issue. But everyone must mind their own business and do it well. Unfortunately, life turned out to be not so simple. The financier is already studying the installation of doors and the laying of pipes... You should have seen how we sawed old birch trees at our dacha this summer... according to the contract, the company. As a result, a birch tree almost fell on the house, and we were sitting in the house, dragging the head of this company with us - he was screaming like crazy, rolling on the ground - a broken sacrum and coccyx, a broken porch... so come back. I had to study the cutting technology myself again and control it in the future. There are few good specialists, and finding one is a great success.

The heating battery is leaking - what to do?

The first thing to do if the radiator is leaking, as in the photo, is to turn off the water. But if the leak is serious, then it is urgent to call an emergency team - plumbers have all the necessary tools and materials to eliminate the problem if the battery leaks.

If boiling water is pouring out of the radiator in all directions, then you need to throw something thick over it - for example, a blanket. This is not a way to get rid of a leak, but at least you will be able to approach it without fear of injury.

Next, if possible, you need to turn off the water. It’s good if there is a tap or valve in the apartment itself - this will allow you to quickly turn off the water supply and save your property. But what if there is no such valve and the radiator is leaking - what to do? Then you need to turn on the coolant supply valve to the heating system, which is located on the main pipe near its entrance to the basement. If the leak is minor, then you can try to fix it yourself (for more details: “How to fix a leaking heating pipe if it is leaking”).

Materials from which American women are made

American women are made of cast iron, brass, steel or stainless steel. Of course, the material ultimately determines the price. The performance characteristics also depend on the material : the type of pumped liquids, permissible temperature, pressure. The range of these products is huge and can always be selected to suit any need. As a rule, a nickel-plated coating - this provides both protection from the external environment and a presentable appearance.

Recently, plastic pipelines have been increasingly used in plumbing, so the American has also become a “half-breed” - some fittings with a stop collar are made of plastic. During installation, such a fitting is welded to the pipe, and the nut presses it to its counterpart - a counter fitting, which is made of metal, and is screwed onto the steel pipe. But if the pipeline is made of plastic, then the fitting is pressed into plastic, which is welded to the pipe.

How to fix a leak

There are several options for solving the problem, using:

- self-tapping bolt;

- rubber pad with wire or clamp;

- cement-plaster bandage;

- fabric impregnated with heat- and water-resistant glue;

- special sealant;

- welding

The easiest way to fix a small leak in a cast iron radiator is to fix a self-tapping bolt in the hole.

It must be remembered that all these methods of eliminating leaks are only a temporary measure - it is advisable to replace old radiators with new products as soon as possible.

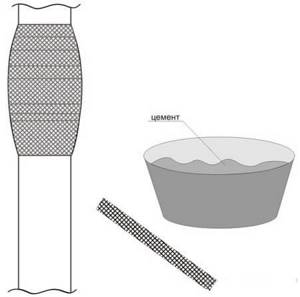

Cement-plaster dressing to eliminate leakage of the heating radiator

Before fixing a leak in the heating battery, you need to prepare the required materials and tools:

- cement;

- alabaster (plaster);

- container with water;

- salt;

- medical bandage

To eliminate the leak, a bandage is applied to the damaged area.

The procedure after turning off the water is as follows:

- dilute cement in a container with water to the consistency of thick sour cream;

- cut the bandage into strips 25-30 centimeters long;

- thoroughly soak the bandage with the cement mixture;

- wrap strips around the damaged area.

The process is repeated until a durable bandage is obtained.

If it was not possible to turn off the water, then instead of cement you need to use alabaster, which dries much faster. Then a cement bandage is applied to the plaster cast.

If the heating battery leaks at the threaded connection, you can use salt:

- wet strips of cloth or bandage in water;

- roll the material thoroughly in salt;

- wrap the leak area.

The gap will close as a result of the salt dissolving in the water. A cement bandage is applied on top.

Using a clamp and rubber as a means to eliminate radiator leaks

If you cannot find a special remedy for eliminating radiator leaks, then you can simply cut pieces of rubber from a bicycle inner tube - the strips should be 30-35 centimeters long and 4-5 centimeters wide. Using a clamp, you can stop the leak for a while. For this reason, it doesn’t hurt to have a few clamps in stock at home - their price is low.

Hermetic seal to eliminate leaks

Such a composition polymerizes upon contact with air, and as a result of hardening, a strong filling is formed, which gives time for significant repairs. Some sealants are two-component polymer compounds, and harden as a result of mixing their two components. Other products harden as a result of a chemical reaction with air. Using sealants designed specifically to fix leaks, you can solve the problem in a matter of minutes.

Welding Application

If you have certain skills and a welding machine, you can simply weld the leak. This is the best way to solve the problem, but it is not suitable for all radiators - only for steel appliances.

If the battery is leaking, what should you do? The first thing you need to do is stop the water supply to the heating device. It’s good if the leak occurred in the summer, but much more often they happen during the heating season. Since you can simply scald yourself with hot water, you must first turn off the coolant supply.

In case of serious damage, it is necessary to call an emergency team - experienced plumbers will be able to quickly solve the problem. If the leak is small, then it can be eliminated using improvised means. But you need to remember that any method of eliminating a leak will only help temporarily restore the operation of the heating device, so it is recommended to change it in the near future.

One way to fix a battery leak is shown in the video:

American for heating radiators - device and methods of application

One of the bottlenecks when installing a heating system has always been connecting the battery using threaded connections. Conventional couplings with locknuts were good for massive cast iron radiators. But the era of multi-ton cast iron panels is already a thing of the past, giving way to compact and more efficient systems that use American-type connections as a connection system.

Why is the American faucet leaking?

Imagine a situation when you come home from work, hungry and tired, and find a large puddle of water in the room flowing from the radiator. What are your actions? Instead of doing personal business, you will have to drop everything and crawl along the floor with a rag in your hands, collecting water? Call plumbers, wait for their visit and part with a certain amount of money? And all because of what? Because of a leaking nut at the connection between the faucet and the radiator... But this could have been avoided if you knew how to tighten all the necessary connections with your own hands, using a tool. In this article I want to share simple skills, so to speak, of preventive maintenance of your radiators.

After all, every year, mainly in the spring, I receive a large number of orders with such problems. As winter ends and the heating season closes, I hear more and more about leaks. This happens because the water from the pipes is not drained in the summer. Many people reading now will be very surprised by this... Yes, yes, the water remains in the pipes under pressure until the next heating season! This was done to prevent air from entering the pipes, due to which corrosion of steel pipes occurs much faster.

But now the time comes for the end of the heating season. The heating system cools down completely, and then they appear - small leaks. The metal narrows, micro-cracks form between the sealing materials, through which cold water flows. Therefore, all manufacturers of American-type collapsible joints advise tightening them every year, rather than using various containers to collect water.

To tighten such a connection, you can take two adjustable wrenches of a suitable diameter and tighten the nuts. Use one key to hold the base of the connection so as not to turn it and damage the joint with the pipe, and use the other key to tighten the union nut. In this case, turning off and draining water from the risers is not required. However, such work must be carried out very carefully, without fanaticism and great effort. If you are making a connection on a tap, the tap must first be closed.

PS By the way, when ordering work, I provide my clients with free preventive maintenance 2 times a year! Including work on pulling dismountable connections. I visit my clients for free and inspect the work performed for any defects. If they are found, repairs will be made at my expense. You can view the price list on the Golden Hands website or call 903-36-05.

What is "American"

Among the methods of connecting pipes and heating devices, two main methods are used - using bends and couplings, using nuts and fittings, or in other words, American ones.

In technical language, this connection is referred to as a union nut connection. Unlike traditional couplings and fittings, the American one is a separate unit with a thread for installation in a radiator and in a pipeline connected by a union nut. Both halves have a connecting unit in the form of a cone and a funnel. When tightening, the parts of the connection fit tightly against each other and are tightened with a nut.

Unlike drives and couplings, when connecting with an American, fewer operations are performed, firstly, and secondly, the connection is more dense and reliable.

American types used

When installing plumbing and pipes for different purposes, you have to deal with many ramifications. An American connection has been developed specifically for this purpose. What kind of device this is and what type it is can be understood based on its purpose. For example, to connect radiator or toilet pipes, corner and combination couplings are used. Many types of fittings are used for different purposes, since the fastening must not only be of high quality and tight, but also have an acceptable appearance.

Corner type

Before the introduction of connector fittings, welding of adapters was mainly used for corner joints. Now this is not necessary - it is much more convenient to install the coupling. American women are available in various sizes and degrees of bending. On sale you can find corner joints from 45º to 135º.

With such a variety of fittings, joints can be connected smoothly and without additional intervention. The union nut on the American one will ensure a tight fit and sufficient pressure on the internal gaskets. This connection is convenient both during installation and disassembly of the line.

Combined type

It is common when connecting straight sections and allows you to install various PVC metal pipes. The quality and tightness of the joints is ensured throughout the entire operation of the pipeline.

Ball Valves

This type of coupling has replaced drives, which are inferior in quality, although they are cheaper. The ball valve is made of stainless steel with brass inserts and is resistant to most types of corrosion. Installation is simple and reliable; the absence of internal gaskets eliminates breakage and rapid abrasion of the fitting. Basically, taps according to the American standard are installed when installing flush tanks and at the junction of the main line at the entrance to the building.

How to choose American taps for central heating radiators

When choosing fittings for connecting heating radiators, attention is usually paid to two points - the quality of the product and its technical condition.

The taps for installation in the battery are selected depending on the type of radiator and the manufacturer’s recommendations are taken into account. The correct choice depends on taking into account the size of the mounting hole in the battery, the type of thread and the diameter of the pipes used in the system.

To connect to the system, straight and corner fittings with American females are used. This makes it possible to optimally select the installation option. In the connection diagram, you can install both American fittings and the control valve itself in the mounting socket.

When installing an American fitting into a battery, sealing tape or tow with sealant or paint is used.

Experienced builders recommend choosing American ones with a conical connection; it is stronger and more reliable, since it does not have a seal. In addition, when choosing, it is recommended to carefully examine the body of the parts - the thicker the body, the more reliable the connection. And be sure to pay attention to how many turns of thread are cut into the nut and into the body of the fitting. If there are only 2-3 turns, then such an American one is not worth buying.

How to properly install an American on a heating radiator

Installation of shut-off valves is done in the battery according to the installation diagram. To install a radiator in a private house, a diagonal pattern is usually used, and for an apartment building, a one-sided pattern is usually used. After the transportation plugs are removed from the seats and the threads are inspected, they proceed to installing the valve under the American one.

The algorithm looks like this:

- The type of thread in the radiator seat is determined;

- The sealing tape is wound onto the threads of the fitting;

- The fitting together with the nut is screwed into the thread and secured with a key;

- The valve is tried on in the pipeline, the fitting is installed in the pipe and fixed;

- After this, according to the installation diagram, the tap is fixed with a union nut on the radiator;

- The next step is to fix the tap with a union nut on the pipeline side.

- Finally, both nuts are tightened using a wrench, and the connection is finally sealed.

American connection.

An American in plumbing is not an American citizen. American, this is a detachable threaded connection.

Before the advent of this compound, they used squeegees for a long time. Yes, in attics and basements it is the squeegees that reign to this day, because they are much cheaper than American type detachable connections.

Where to use:

Either American or American, they are used in cases where it is necessary to connect two sections of threads without rotating them. For example, when you need to connect a soldered wiring to a shut-off valve. Not the faucet, not the pipes, it is no longer possible to turn, or when a filter or angle cannot be screwed onto the thread, because the thread is located too close to the wall. It is in such a situation that this invention comes to our aid.

Only the American one is more compact compared to the squeegee, looks more aesthetically pleasing, but is more expensive.

As the name suggests, this quick-release connection came to us from the most democratic country in the world.

Consider:

What individual American women look like:

Or American ones with shut-off valves:

American women come with or without pads. Without gaskets - cone type, and I recommend using them, despite the fact that they are much more expensive than their counterparts with rubber or flat gaskets.

Here is an example of a conical American type where there are no seals:

Installing such an American on a heated towel rail:

American conical thermostats are installed on good thermostats instead of American thermostats with a rubber seal.

Now let's look at the American one with a rubber seal:

Combinations of threads can be absolutely any; now we are only talking about the type of connection:

To tighten American women you need special keys or a hexagon:

There are American ones with a flat laying; more often they are used with polypropylene pipes.

It may happen that for heating or hot water with pipe diameters of more than 3/4 inch, the nuts of such American ones will have to be periodically tightened. Don't hide them in walls.

But that same flat gasket, which sometimes tends to let water through. Many people do not know, and some do not even want to know, that this gasket is not the same on both sides. Outwardly, it certainly looks the same, except that one of the sides is a little darker and more contrasting.

The more contrasting side is coated with some kind of grease. And if you put the coated side against the polypropylene, then when you tighten the nut, the polypropylene will not rotate along with the nut.

If you don’t have a special key for tightening American women, you can use a handy tool:

But this method is only suitable as a last resort. Because it’s very easy to damage an American this way. You will deform it and it will become unusable. There must be a special round key.

1. An American cone without a gasket is more reliable. The main thing is to take a quality one. 2. American ones with a flat gasket may require tightening 3. American ones with a rubber gasket, require replacement of the gasket when dismantling and reassembling. 4. You will definitely need a special key for such connections.

To facilitate the repair of some components in the systems, separate them with American ones.

For example, meters, boilers, circulation pumps, geysers….

Tools and materials

To obtain a strong and reliable connection, in addition to high-quality fittings and nuts, you also need reliable tools. This applies, first of all, to the keys for installing fittings into the radiator body.

The design of the fitting provides for the use of a key for the internal volume of the fitting. To avoid damaging the thread during installation, the inner surface is made in the form of a hexagon or has two protrusions for gripping with a special key.

This feature is extremely important during installation work. Experienced experts recommend not making mistakes, but immediately purchasing keys for American women. I can recommend a key for American women, Good-natured Plumber, this is the optimal price/quality ratio for this type of tool. The key is a stepped cone with grooves. Each diameter corresponds to the size of the inner diameter of the fitting. For operation, a ratchet handle is used, which allows you to change the direction of tightening. For hexagonal shapes, regular hexagons are used.

The external threads of the fittings on many models are jagged. This shape is not something unusual; it’s just more convenient to wrap sealing tape or hemp tow on such a thread. When screwed into the battery, it is the notches that prevent the seal from sliding along the threads. This connection turns out to be quite reliable. As for the sealant, it is recommended to use sealing tape for modern radiator models, and for traditional cast iron radiators to use the classic method - packing tow.

By type of materials used

This ensures the use of homogeneous elements, primarily to avoid electrolytic corrosion, therefore the fittings are manufactured in various designs:

- The life cycle of such parts is also limited by the tendency of limestone to form on internal surfaces.

- Copper

is less susceptible to corrosion and is used only on pipelines made of the same material. - Brass

is the most popular in use, resistant to oxidation, durable for at least 50 years. - Polypropylene

- in terms of strength properties and ease of use, competition for metal products is increasing. - Polymer

- has all the advantages of plastic products. For polypropylene pipes, the best connection is American. - Connected

- They are used as fittings to connect metal and plastic pipes with partial replacement of the pipeline. To make these fasteners, a threaded metal part is pressed into a plastic housing.

In American women, cylindrical threads are used for domestic purposes; to ensure a stronger and more reliable connection in critical components, conical threads are used.

Polypropylene (PP) pipes are widely used in household communications for supplying cold and hot water, supplying coolant to radiators and heated towel rails. When installing water supply lines, American fittings for polypropylene pipes are widely used, which is the main method of connecting plumbing fixtures, fittings, and heat exchange devices. The use of American fittings has replaced obsolete threaded methods of connecting pipelines, fittings and plumbing fixtures using various couplings, adapters such as sockets that require sealing various types of sealants - flax fiber, FUM tape, plumbing thread, anaerobic sealants. An American connection is made in a matter of seconds and provides a reliable and tight joint for many decades without the use of any additional sealing materials.

Rice. 1 American with PP coupling

- American - what is it?

- Distinctive features

- American for polypropylene pipes - types

- Typical sizes

- Installation

Which American crane is better?

Traditionally, when choosing an American crane, preference is given to foreign models. There is an opinion that the quality of these particular ones is the standard. At the same time, the point is missed that much depends on the operating conditions of the crane and components.

In apartment buildings, especially high-rise buildings, where high pressure is maintained in the heating system, the use of American-style heating systems with thin walls is fraught with constant leaks. This especially affects the unqualified installation of heating devices. Due to constant high coolant pressure in the system or water hammer, thin-walled connections are prone to deformation.

In private houses, where the pressure in the system is much lower, the risk of leaks is less, therefore for multi-storey buildings it is recommended to install high-quality fittings from well-known brands.

Which faucet is better?

This question will only be answered when specific conditions and characteristics that are a priority are identified. In the absence of any need for regulation or automation, simple structures (for example, common ball valves) are quite suitable. If the priority is the function of maintaining the optimal air temperature in the room without much effort (automatic adjustment), then it is preferable to choose a thermal head. The problem with the thermal head is that it cannot be used in systems with central heating. A more economical option is to use valve balancing valves.

What you need to know about American crane manufacturers

In the age of information technology, consumers have a unique opportunity to verify for themselves the reality of information about the manufacturer. It is enough to look on the Internet to find the manufacturer’s website and make sure that the purchased part is not a fake. But the online representation of hardware manufacturers is not only additional advertising, but also an opportunity to confirm your name and the quality of the product.

When purchasing accessories, it is recommended to pay attention to the following American faucet manufacturers:

- Arco – valvulasarco.com;

- Bianchi – bianchifratelli.it;

- Bugatti – it;

- Fiv – fiv.it;

- General Fittings – generalfittings.it.

In addition to Italian manufacturers, it is worth paying attention to one domestic manufacturer of high-quality fittings - Valtec - valtec.ru

Key for American women

For all its simplicity and attractiveness, the American woman has a secret that does not lie on the surface, but everyone involved in editing should know it - do you know what to use to twist it? The fact is that the union nut is controlled by a regular open-end wrench, but there are also press fittings for metal-plastic pipes that need to be screwed into place using an internal wrench. And this can be either a hexagon, which is simpler, or a cylinder with recesses for hooks, which is more complicated, but more reliable.

American battery is leaking

somehow it’s not at all clear.

somehow it’s not at all clear.

if you can really get to them, then turn off the riser, unwind and update the flax.

The plastic of my riser is connected to the stainless steel risers of the neighbors below and above.

did you tighten this thing (the American one apparently) doesn’t last long, apparently you need to catch it while the cold water is flowing through the hot pipe?

Which? Some combine, some destroy each other.

Washers? If the area between the riser and the entrance to the apartment - only a plumber from the UK or emergency services. If after, unwind and redo. There will be no big defeat.

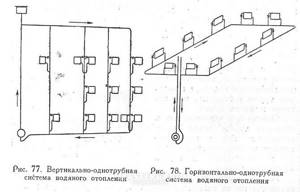

Private house, gas boiler, Leningrad heating system. Radiators are installed with bottom connections using American corner taps. A few years later, a leak appeared from under the American radiators on some radiators, I tried to change the gaskets, but so far it didn’t work. Physically, there is nowhere to tighten it, since the main pipe is steel, and it is also welded crookedly. I had an idea to make a diagonal connection (make the media inlet through the top, for example), but the boiler specialist said the radiator would stop heating (the water would just flow through the lower pipe).

Are there any other ways to solve this problem without completely redoing the heating system? Can I use any squeegees?

Dmi Clo wrote: the boiler specialist said the radiator will stop heating

Dmi Clo wrote: I had an idea to make a diagonal connection

Fixing a leak is not a fun idea.

Dmi Clo wrote: Are there any other ways to solve this problem?

Coat the American battery on the side and the inner conical part of the ball valve with silicone and tighten. With a clamp, the silicone holds under pressure.

Dmi Clo wrote: Physically, there is nowhere to tighten it, since the main pipe is steel, and it is also welded crookedly.

Initially, the connection (welding) under the radiator was not performed correctly? Cut off the branch - digest. With the right procedures.

I tried changing the gaskets, but it didn't work. If the rubber bands are torn (stuck), change the rubber band (buy an American one with the same design)

The boiler seems to be normal, according to the passport the maximum power is 28 kW, the area of the house is around 190 square meters (2 floors). But there is a problem that in severe frosts the coolant is at maximum temperature (that is, the boiler stops heating it further), and the house is cool. I believe that the problem is precisely the low efficiency of the Leningrad pipe, the pipe is hot, but the radiator is not, if in a diagonal connection the coolant flows into it even worse, this will further aggravate the situation.

If you invite a welder and digest the connection, then how to do it correctly so that you can remove the battery (in case of repair, for example) and there will be no leaks?

About silicone - thanks, I'll try it.

Dmi Clo wrote: I had an idea to make a diagonal connection (make the media input through the top, for example), but the boiler specialist said the radiator would stop heating (the water would just flow through the lower pipe).

Supply to the top of the radiator is a classic from the 19th century. See Fig. 78 from Scanavi’s textbook, which you advise your “specialist” to study -

Such a reconnection will increase circulation through the radiators and increase their heat transfer. The increase in heat transfer will be more noticeable if bimetallic and small-section radiators are currently used. Those. reconnecting diagonally, in your case, will be equivalent to increasing the number of sections by 10-30%.

Hydraulic calculation of heating systems. Heat calculation (calculation of insulation) of houses and apartments.

Dmi Clo wrote: I had an idea to make a diagonal connection (make the media input through the top, for example), but the boiler specialist said the radiator would stop heating (the water would just flow through the lower pipe).

Supply to the top of the radiator is a classic from the 19th century. See Fig. 78 from Scanavi’s textbook, which you advise your “specialist” to study -

Such a reconnection will increase circulation through the radiators and increase their heat transfer. The increase in heat transfer will be more noticeable if bimetallic and small-section radiators are currently used. Those. reconnecting diagonally, in your case, will be equivalent to increasing the number of sections by 10-30%.

How much are small-section ones? We have ordinary aluminum ones of standard height (57cm), the number of sections is from 8 to 16. If only it doesn’t get worse (the picture at the beginning of the topic - there is a low radiator, mostly 57cm around the house).

Find out the cost of repairs

Repair work?

Why do clients choose us?

Heating and Repair

We have the best prices!

How to understand what kind of heating is needed in our home? Heating has firmly taken root in the way of life of fellow citizens as a unique cause of warmth in winter. It is impossible to imagine living in a mansion without a heating system. Warmth carries with it a variety of criteria. There are many qualities that can be described. Briefly: autonomous, gas, infrared, solid briquettes, geothermal, alternative, economical and wasteful, water, electric.

Heating American installation method

All people prefer to live in a comfortable environment with all amenities. Everyone wants their home to be cozy and warm. Residents of city apartments have an easier time in this regard. But the owners of private housing construction have to take care of themselves. To ensure a comfortable temperature in the rooms even in cold weather, you need to heat the room.

There are several options for this, depending on the heat source and installation method. Among owners of country houses, the most popular is a single-pipe heating system, the installation of which is cheaper than a two-pipe one. However, in order to obtain maximum heat transfer with minimal energy costs, you need to calculate everything correctly.

In a single-pipe heating system there is no distribution between the supply and return pipes. Therefore, the entire line is divided conditionally in half and the pipe leaving the boiler is called supply, and the second half is called return.

What is a single-pipe heating system or, more simply put, “Leningradka”? To answer this question you need to know what it consists of.

The coolant, entering the radiators, gives off heat to the room, while cooling down

The main elements of such a system:

- A boiler in which the coolant is heated. It can run on solid fuel, electricity or gas.

- Heating elements – radiators. The heated coolant entering them gives off heat to the premises.

- Expansion tank to compensate for coolant expansion.

- Elements of pipe distribution: pipes, shut-off valves and taps.

The operating principle of a single-pipe heating system does not depend on the type of heating device and the fuel used

How does a single-pipe heating system for a private house work? The coolant (usually water) is heated in the boiler and rises upward, being displaced by cold water. Then it enters the first heating element, after which it enters each next one and returns to the boiler for subsequent heating. This creates the movement of coolant through the system. At the same time, heat is lost in each radiator and the last one in the chain will be the coldest. This feature is perhaps the only drawback of the system.

How do you get out of such a situation? The first way is to increase the size of each subsequent radiator or their number in the room. The second is by installing control valves. The third is the use of a circulation pump. For more efficient operation of the system, the pipes are laid so that the radiators located in the rooms with the greatest heat loss go first. These can be rooms with windows facing north or corner ones.

Using the valve, you can regulate the amount of heat entering the radiator

The circulation pump is connected where the coolant has the lowest temperature. That is, at the end of the return.

Here are the advantages of a single-pipe heating system:

- lower material costs compared to 2-pipe;

- more aesthetic appearance, the pipe passes above or below the floor and is easier to hide;

- choice of coolant flow direction;

- the ability to lay pipes under doorways;

It is not advisable to use vertical wiring of single-pipe systems if more than 10 radiators are connected to the riser.

After installing the pipes into the wall, they can be successfully hidden. This will give the room a more aesthetic appearance

To know the required amount of heat to ensure comfortable conditions in the premises, you need to make a thermal calculation. There are special programs for this. Having made the correct calculation of a single-pipe heating system, you will know which radiators to choose and how many, the required power of the heating boiler.

Correct calculation will allow you to choose the amount of equipment you need. And you won’t have to overpay by taking goods in reserve. In addition to the calculations, it is necessary to make a wiring diagram for the heating system. This will be very helpful during installation. It is most correct when a single-pipe heating scheme for a private house is drawn on a building plan made on a convenient scale. This way you can calculate the required length of the pipeline.

In buildings with a height of more than 30 meters, it is not cost-effective to install natural circulation systems.

Vertical heating distribution system

With vertical distribution, the water heats up and rises through the riser, from where it passes through distribution pipes to the radiators.

The coolant moves naturally. The efficiency of the system is achieved by using large-diameter pipes and sloping the pipeline. Such pipes are more difficult to hide. However, this disadvantage is covered by independence from electricity supply.

Examples of a vertical single-pipe system with top distribution

Horizontal wiring system

Unlike a vertical one, a single-pipe horizontal heating system does not have a supply riser. The line can be built into the floor structure itself or run above it. In the first option, in order to avoid heat loss, it is necessary to insulate the pipes. The supply line is also laid down.

Heating American installation method

What is an American? Let's figure it out. American is a relatively new type of connection for us. Invented and first released in the USA. Hence the name. Modern fittings (angle, tee, coupling) are quite diverse. But still, the quick and easy installation of pipelines will be appreciated by any professional, and not only. Any type of pipe can be connected using fittings. Connectors such as American ones for polypropylene pipes, steel, cast iron, copper, metal-plastic, and so on are an excellent solution to the problem of constructing pipelines.

Most professionals prefer American, as it has a number of advantages.

Any plumbing professional will explain to you what is the difference between an American faucet and a regular one, or how such a coupling differs from an ordinary one. Here are some obvious benefits:

- It is quite easy to uncouple a pipeline (made of polypropylene, steel, etc. pipes) without resorting to rotating the pipes.

- The American connection (coupling) is detachable, using a union nut. This is advantageous in that when two parts (pipe and coupling) meet, it is necessary to rotate the nut. But at the same time the details remain motionless. The difference is fundamental.

- Of course, you can use a squeegee, but its features are the length and the use of a thread sealant. Naturally, it is difficult to call this type of connection detachable.

- When using an American connection, tightness is ensured through the use of a special gasket, which simplifies the connection process.

American is a conditional name, and various fittings (coupling, tap, angle) that have a union nut in their design fall under this category.

This type of faucet - an American one - is used during installation for water and gas supply.

The connection, called American, is a threaded connection that can be disassembled, with a seal in the form of a special gasket. It is possible to use the American one more than once. The advantage of such a connection is the quick and effortless installation of various parts (even large ones) in inaccessible places. Repair and preventative maintenance during operation are also not difficult and do not require special equipment or gasket changes.

Two sections of pipes are easily joined using a connection such as an American coupling, using a union nut. As an advantage of such a connection, it is necessary to note the possibility of repeated assembly and disassembly. This connecting structure is small in size. Disassembly and assembly is quick and there is no need to rotate the pipe section. The design of such a connection is straightforward, coincides along the axes of the pipe sections and consists of fittings (2 pcs.), a gasket and a union nut (hexagonal).

The options for connecting to a pipe using an American wire are very different and can be as follows:

- connection with internal thread;

- connection with externally applied thread;

- connection (welded) with a union nut;

- a combination of the above methods in any configuration.

American thread boring, whether external or internal thread, is conical or cylindrical in nature.

Another difference is expressed in how the connecting surface of the fitting is made. This may be a conical or flat connecting surface.

Due to their simple structure, American couplings do not require much effort during installation.

The conical seal wins and has a number of advantages:

- durability and reliability of the metal-to-metal seal without the use of additional materials as a seal;

- homogeneity of material properties - considered the most resistant to temperature changes and chemical influences;

- does not lose tightness even with small axis deviations (no more than 5 degrees) of the connected pipe sections.

A flat seal is not as demanding in terms of precision in the manufacture of its components as a conical seal. The flat design includes a gasket in the form of a ring; most often the material used is Teflon. The American fittings themselves (coupling and others) are made of stainless steel of various grades.

The marking reflects data such as size (indicated in inches), grade of steel used and nominal pressure.

Here is a list of some popular types of American fittings:

- coupling with external thread (used in cold and hot water supply and heating pipelines; it is used to connect a polypropylene pipe to a steel pipe or to a plumbing fixture);

- coupling with internal thread (used in pipelines for cold and hot water supply, heating; used for connecting a polypropylene pipe with a steel pipe or with a plumbing fixture);

- pipe with external and internal threads (object of use - cold and hot water supply pipelines, heating; with the help of such fittings, polypropylene pipes are threaded with steel or with plumbing equipment).

The American angle coupling is often used in hard-to-reach pipe joints.

And now in more detail. An American coupling is used if it is necessary to connect two parts of pipes or switch to a pipe of a different diameter. We can assume that this is the same ordinary coupling. The coupling (one part of it), when used in connecting iron pipes, is screwed; when using iron and copper pipes, it can be welded; when used in conjunction with pipes made of polypropylene or copper, it is soldered. The second part is a collapsible American connection.

The American type corner connection is very convenient for installation in inaccessible places.

Another type is the faucet. Its use is less popular than the coupling, since not everyone knows the advantages of this type of ball valves. But with the help of a crane it is very easy to carry out installation, which before its appearance was carried out using a drive consisting of a long thread, a special coupling, a lock nut and a counter thread. When using a ball valve, the task is simplified several times. A few turns of the wrench will help tighten two parts (self-centering): the faucet itself and the American one. As usual, everything ingenious is simple.

Heating radiators are another area in which these products are indispensable. If the radiator is connected on both sides with their help, it will be easily removed, and it will be possible to adjust the water supply and heating temperature during operation.

And another new product on the market - an American crane (angular). The need for such a fitting is obvious. It alone can replace several connections, simplifying installation. Faucet handles vary in design. These can be butterfly-shaped handles or lever handles. Butterfly handles are suitable for small cross-section taps because the effort required to turn is minimal. And the levers are suitable for large cross-section cranes to make turning easier.

To install or dismantle a pipe connection made using an American pipe, you must have a special key. Most often in plumbing work, American sizes 12 and 34 are used, with two internal projections, rarely a hexagon.

It is possible to make such a key yourself. To do this you will need a piece of profile reinforcement. By heating and flattening it to a square shape, it is necessary to give the future key a cone shape, then harden it.

How to fix a leak in an American

Ask a question you are interested in on our forum without registration

and you will quickly receive an answer and advice from our specialists and forum visitors! Why are we so sure of this? Because we pay them for it!

Many people are already making money just by communicating on our forum! For example, like this. Or like this. You can start communicating on the forum now. Just log in via VKontakte or register, it will take one minute.

Imagine a situation when you come home from work, hungry and tired, and find a large puddle of water in the room flowing from the radiator. What are your actions? Instead of doing personal business, you will have to drop everything and crawl along the floor with a rag in your hands, collecting water? Call plumbers, wait for their visit and part with a certain amount of money? And all because of what? Due to a leaking nut at the connection between the faucet and the radiator. But this could have been avoided if you knew how to tighten all the necessary connections with your own hands, using a tool. In this article I want to share simple skills, so to speak, of preventive maintenance of your radiators.

After all, every year, mainly in the spring, I receive a large number of orders with such problems. As winter ends and the heating season closes, I hear more and more about leaks. This happens because the water from the pipes is not drained in the summer. Many people reading this now will be very surprised by this. Yes, yes, the water remains in the pipes under pressure until the next heating season! This was done to prevent air from entering the pipes, due to which corrosion of steel pipes occurs much faster.

But now the time comes for the end of the heating season. The heating system cools down completely, and then they appear - small leaks. The metal narrows, micro-cracks form between the sealing materials, through which cold water flows. Therefore, all manufacturers of American-type collapsible joints advise tightening them every year, rather than using various containers to collect water.