In apartment buildings, one of the most common problems with the heating system is leakage of heating batteries; this happens less often in autonomous systems of private houses. Basically, depressurization occurs during hydraulic tests. Weak and worn joints cannot withstand strong pressure and begin to leak water through joints or microcracks in radiator housings.

This can happen in the most harmless situation; residents should always be prepared for such cases. People who have not encountered a similar problem immediately panic, not knowing what actions to take. First, you should place a suitable container under the flowing stream so that water does not spill onto the floor.

Where to call if the heating battery is leaking

If a person lives in an apartment building and the battery begins to leak during the heating season, the responsibility for eliminating the malfunction lies with the management company. Such a case is considered an emergency.

First of all, the resident needs to prevent the possible consequences of a leak. In order to prevent damage to the floor covering or, even worse, to avoid flooding the neighbors below, you need to find dishes to place under the leak. After this, immediately call the management company. The repair team must fix the leak in the heating battery as soon as possible and inspect the entire system in the apartment.

You can find out the phone number of the management company from your neighbors by studying the information on the walls of the entrance, in receipts, in the contract for the provision of services (for example, intercom service) or in online directories (for example, reformagkh.ru).

Types and signs of breakdowns

Before starting repairs, it is worth taking a closer look at what types of breakdowns of heating radiators can occur, as well as studying their signs. There are some problems that only specialists can handle. For example, if noise is heard from the radiators, then the reason most likely lies in the airiness of the entire heating system. In such cases, you cannot do without a master. After all, which radiator is faulty can only be determined with a special device.

Incorrect selection and connection of the radiator

If the ratio of the heating system does not coincide with the technical characteristics of the radiators, then they will not fit each other, and connecting them will be quite problematic. So, if you take ordinary pipes and select copper adapters for them, and the battery housing turns out to be aluminum, then their contact can provoke corrosion of the metals. Therefore, it is worth choosing batteries very carefully and installing them correctly.

Leaks

If they appear, then this is the first sign that the radiator has burst and there are malfunctions in the operation of the entire heating system. This could be due to incorrect connection of the battery to the pipeline, blockages, destruction of threaded nipples, and many other reasons.

Heavy weight

If you pick up cast iron radiators, you should immediately notice that they have quite a lot of weight. This becomes the biggest problem when installing them. After all, even a small error in installation work can lead to system malfunction. The presence of weak brackets will lead to misalignment of the battery, and subsequently cracks may even form on the wall.

High pressure and water hammer

Even with excellent technical characteristics, cast iron is still not an ideal material. It is susceptible to too much stress created by the circulation of water in the system. If a water hammer occurs, then in the places where the sections are connected, you can see the resulting leak.

Dirt

Along with the coolants, various impurities and small particles of rust or even dirt are carried through the pipeline. This often leads to blockages in the channels. If the radiator is not flushed in time, it may begin to leak. Also, dirty batteries often result in them not warming up properly.

Reasons why depressurization occurs

Leakage problems in heating systems do not arise on their own. In each case, shortcomings are revealed that led to sad consequences.

The most common causes of leaks in the heating system:

- Exposure to external factors (impact or attempt to move the battery using force, for example, during apartment renovation).

- Manufacturing defects.

- Violation of technology during system installation.

- Radiator wear and tear over time.

- Exceeding the permissible level of water pressure in the heating system.

If the cause of depressurization is associated with an excessive increase in pressure, responsibility for the malfunction of the system lies with the management company, which is called upon to monitor the normal level of water pressure in the general heating system.

If it is possible to shut off the coolant supply to your apartment, this must be done during testing and startup of the system at the beginning of the heating season.

Recommendations for the care and prevention of battery leaks in the summer season

All of the above methods are relevant in winter, when you urgently need to do something. After the end of the heating season, it is necessary to organize scheduled maintenance of radiators and pipes. The batteries are removed and disassembled into sections, the old seal is removed from all threaded connections, sometimes it is necessary to replace the nipples with new ones, a mandatory measure is the preparation of new intersectional gaskets. If fistulas are found, they need to be welded, then you can return the radiator to its place.

If the house has not undergone a comprehensive replacement of all components of the heating system, the risk of a leak increases due to the natural wear and tear of communications. Experts recommend always having at least rubber gaskets and clamps and cold welding available to immediately block the flow of moisture.

Cases in which you can fix a pressure leak without draining the water

If a minor water leak occurs in a private home, you should use one of the appropriate methods to eliminate the leak without draining the water and reducing the pressure. The same applies to an apartment, if the accident does not cause difficulties.

Before you get to work, you need to make sure that the water in the radiator is not very hot. Otherwise, you may suffer serious burns.

No special equipment is required to eliminate minor accidents. The most suitable chemical materials that can stop leaks include various sealants used in automobile engine repair (BBF Super, Liqui Moly Kuhler Dichter). They are able to withstand high temperatures and withstand high pressure. A leak in a straight pipe should be stopped using sealant in the following order:

- Apply sealant to durable cloth.

- Wrap the fabric tightly around the pipe.

- Secure the bandage with clamps, wire or rope.

At high temperatures, the sealant hardens quickly and retains its properties for a long time even at high water pressure. In addition to sealants, compositions based on epoxy resin are used to eliminate leaks.

If a metal pipe is leaking, it is customary to use rubber-based materials. Such compositions are also able to withstand high temperatures and are used to seal leaks without draining the liquid. This is done as follows:

- The pipe is wrapped with serpyanka.

- A rubber compound is applied to the winding.

Such methods of eliminating leaks are effective only in cases where the liquid only drips. If the problem is more serious, you will have to resort to mechanical methods. They are able to completely eliminate water leakage under pressure. However, all these methods are used only as temporary ones.

Effective mechanical methods include a crimping device and installing a self-tapping screw if there is a hole at the leak site.

The crimping device is very simple to make:

- Take a rubber band.

- The leak area is tightly wrapped with rubber.

- The winding is fixed with a clamp or wire.

A metal self-tapping screw with a rubber gasket under the head is suitable for sealing the hole. You can tighten the hardware with a wrench, pliers or a screwdriver.

General recommendations

There are many ways to fix a radiator leak available to the owner, and he can choose the most suitable option based on the equipment available. However, the above recommendations make it possible to urgently solve problems in the winter season, when it is not possible to turn off the heating system for a long time and carry out major repairs of heating devices.

It is quite natural that homeowners have a question: the heating battery is leaking, what to do in the summer? Having survived the winter with a hastily patched radiator, in the summer you should remove the battery from its mounts, inspect for damage and carry out a number of measures:

- remove old patches;

- clean leaks with a wire brush;

- treat cracks and holes with a grinder and a cleaning wheel;

- eliminate the defect by soldering or welding.

Next, you should paint the battery (you can read about paint for radiators here) and install it in place. In this case, it is important to follow the installation rules - use tow, FUM tape, high-quality shut-off valves and pay special attention to the joints.

Having installed the battery in the circuit, it is worth filling the system with water and checking the tightness of the heating device. It is important to carry out this step while the boiler is running, since the circulation of coolant under pressure can reveal leaks and weak points in connections. If no leak is detected during intensive use of the heating system during the day, then the problem can be considered solved.

If the Mayevsky tap is leaking

This part is used in heating radiators as air valves. Over time, the rubber gasket becomes unusable and the faucet begins to leak water. Ideally, it is better to replace the damaged gasket with a new mechanism. If there is no spare part, a special product called “Santech Master Gel” will come to the rescue. It has detailed instructions for use. Based on the recommendation, you should do the following:

- Unscrew the tap and remove the rubber gasket.

- Liberally lubricate the threads on the tap with gel.

- Apply the product to the rubber seat.

- Lubricate the initial threads on the battery.

- Install the tap, unscrew halfway and tighten completely.

- Wipe off any remaining gel from the surface.

- Wait 15 minutes and check the operation of the tap.

Instructions for Santech Master Gel sealant (click to enlarge).

Ball valve repair

New-fashioned ball valves are somewhat more complex than traditional valve models. So, what should you do if the ball valve is leaking? Most often, the problem is that dirt has gotten inside the housing and interferes with the operation of the mixer.

When repairing a ball valve, you must carefully remove the valve. To do this, first remove the decorative plug, under which there is a fixing screw. In short, the faucet needs to be disassembled, cleaned and reassembled

They do it like this:

In short, the faucet needs to be disassembled, cleaned and reassembled. They do it like this:

Use a screwdriver to unscrew the screw that secures the lever. Carefully remove the lever from the tap. Use a screwdriver to unscrew the threaded screw. Remove the mixer dome and plastic seal. Inspect the seal gasket and remove accumulated deposits. If the seal is worn out, you need to purchase and install a new part. Remove and inspect the ball. If it is damaged, it will also have to be replaced with a new one. Using a thin screwdriver, carefully pry off the seals that secure the ball.

If they are even slightly worn, they will also need to be replaced. After replacement, lubricate the seals with the composition recommended by the manufacturer. Carefully reassemble the mixer in reverse order.

All procedures when cleaning a ball mixer must be carried out carefully, since its parts are easily damaged. If all steps are completed correctly, leaks will stop.

In the same way, problems with temperature control in mixers of this type are eliminated.

Sometimes you just need to change the faucet cartridge. This procedure is described in detail in the video:

Leak between two battery sections

Cast iron batteries are considered the most popular. But they are often the culprits of leaks. This usually happens at the points where sections connect to each other. During operation of the heating system, it can be difficult to determine the location of the leak, since the battery gets completely wet. In this case, you have to shut off the water supply. To identify the location of the leak, you need to wipe the battery dry.

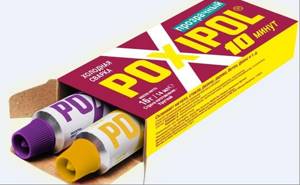

If there is a leak between sections, cold welding is used. It is based on epoxy glue and metal powder; the product is sold in small tubes. Before using welding, the leak site must be thoroughly cleaned of all excess impurities, treated with sandpaper and degreased. As a rule, any such product is supplied with instructions for use.

Algorithm for applying cold welding (click to enlarge).

Some of them are not suitable for use with water. Welding can be liquid, and more often in the form of plasticine. Its two components need to be kneaded in your hands until a homogeneous mass is obtained. The finished weld is applied to the joint where there is a leak. Complete polymerization is expected only after a few hours.

Causes and types of leaks

The elements of the heating system located in residential premises are pipes and metal radiators; the risk of depressurization is highest in the areas of their connections. A leak is the direct release of coolant to the outside; it can manifest itself in the form of rusty smudges on the battery and drops falling on the floor.

Experts identify 4 key types of defects, which manifest themselves depending on the specifics of the installed connecting elements:

- cracks that have appeared in the radiator section,

- loss of tightness of pipelines leading from the riser to the battery,

- leak between radiator sections,

- depressurization of the area connecting the pipe and the battery.

When a radiator leaks, it is important to take immediate action to prevent flooding of the room and neighbors below

Depending on where the problem occurred, specific measures are taken to eliminate it.

Leaking from the connection between the radiator and pipes

Most often in this case, problems arise with the seal on the thread. Troubleshooting will require shutting off the water and reducing the pressure.

For such cases, it is advisable to keep spare nuts and couplings at home. The old ones could become unusable. Rusted parts do not always withstand the stress of working with them. In cases of thread damage, a die will be needed. When everything is ready, tow is wound onto the threads and a layer of Unipak paste is applied on top. The parts are tightly screwed. Gradually opening the water supply tap, the reliability of the work done is checked.

Instructions for sealing a threaded connection with tow and sealing paste (click to enlarge).

Why do pipes wear out?

For the installation of heating systems in residential buildings and apartments, metal pipes and radiators are most often used. They are highly wear-resistant, have a long service life, and high heat transfer. But even the most wear-resistant structures have a limit of strength and lifespan.

Steel heating radiator

Most often, leaks occur on metal pipes and batteries. Possible causes of wear

:

- Aggressive coolant environment and external factors causing metal corrosion. This process occurs due to condensate entering hard-to-reach and unprotected areas and contributes to the gradual destruction of the walls.

- Factory defects - to protect yourself from purchasing such products, ask the seller for a quality certificate with a Quality Control Department stamp.

- Long service life and mechanical damage. No matter how strong the metal is, it cannot withstand constant increased physical and mechanical loads. The equipment is constantly under high pressure, so it gradually becomes thinner and wears out.

- Incorrect insertion, violation of threaded connections, installation technologies. The most vulnerable places where water leaks most often are welds, joints, threaded connections and the areas around them.

- Violation of the normal operating mode: the cause of a battery breakthrough can be excessive or, conversely, insufficient pressure in the system, as well as a violation of the operating mode.

Depressurization of the radiator wall or fin

This kind of damage brings big trouble. It is extremely difficult to fix a problem when the battery is leaking, but for a short time you can find a way out of the situation. The method is quite simple.

The small hole on the battery needs to be enlarged. Before doing this, you need to turn off the water and reduce the pressure. Using a drill, make a hole larger than it was. A wooden peg is inserted into the drilled hole. When exposed to water, it swells and stops water leakage.

You can also use a self-tapping screw with a rubber washer instead of a peg.

Of course, leaving the battery in this state for a long time is dangerous; the section must be urgently replaced with a new one.

What to do if a leak is detected

One of the main causes of leaks is wear and tear of materials. But due to different types of connections, leaks need to be eliminated in different ways. This means that the only answer to the question “what to do if the radiator leaks?” does not exist.

To avoid flooding, the following rules should be followed:

- If a leak is detected, it is tedious to place a basin or jar in a certain place, but after this it is necessary to immediately take measures to eliminate the problem. If you increase the amount of containers used, this will ultimately lead to more serious damage to the radiator.

- After eliminating the leak on your own, you should think about replacing faulty components, because it will be more difficult to eliminate a leak in one place the second time.

- Until the problem is resolved, the water in a certain section of the heating system should be completely shut off.

But what to do if the heating battery leaks in winter? In this case, you should use several proven methods. If a serious leak appears and hot water begins to splash, then for protection you should first throw a blanket over the radiator, which will stop even strong pressure and direct the water to the floor. You should also find several large containers for water.

Liquid sealants to eliminate leaks in the heating system

Liquid sealant is designed to eliminate water leaks. It is better suited for repairing heating systems. The liquid product can cover hidden damage from the inside. This applies, first of all, to pipes that can be walled up in the wall or located under the floor. The sealant is poured into the pipe, it penetrates the problem area and fills it.

How to choose

There are various types of sealants available on the market. They are designed for use in different situations, which makes the problem of choice much more difficult. To avoid mistakes, you should familiarize yourself with the characteristics of a particular type of sealing agent. The product for use in heating systems must meet the following requirements:

- high level of temperature resistance;

- resistance to moisture;

- endurance to temperature changes in the system;

- resistance to mechanical influences that can deform parts.

Depending on the scope of application, sealants differ in composition and are divided into the following types:

- For external use . It is applied to the leak site and eliminates the problem as it hardens.

- For indoor use . Liquid sealant is poured into the system, finds the leak and eliminates the leak.

- For compaction . Used to strengthen joints in heating systems.

All this information is on the packaging. It must be read carefully.

We select fasteners for heating radiators Selection criteria, calculation of the required quantity, marking and installation

Based on their composition, the products are divided into three types:

- Silicone.

- Based on acrylic glue.

- From rubber and aerobes.

Acrylic sealant is not suitable for heating systems. It instantly hardens, becoming rocky. Having lost elasticity, the product is destroyed. Rubber and silicone based sealants are ideal. If the product is manufactured for use in automobile engines, it can be safely used in heating systems.

Important: To seal heating systems, you should choose a product based on neutral silicone. The acid content leads to aggressive reactions with the metal.

The choice of sealant also depends on the place to be repaired. A paste-like product is more suitable for joints; it is produced in two versions:

- Drying sealant . After application, it hardens quickly if the drying technology is not followed. The hardened composition is deformed and covered with cracks.

- Non-drying sealant . Ideal for filling small holes and sealing joints. This product has one drawback: it can be squeezed out as a result of exceeding normal pressure levels.

Aerobic sealant is a type of acrylic analogue. It is sometimes used to repair leaks and minor defects. It can withstand high temperatures and is resistant to acids and alkalis. The sealant quickly fills the area of depressurization and dries just as quickly.

For internal use, sealants are divided into 3 types according to the following characteristics:

- Mixtures where the coolant is water or antifreeze.

- Compositions for system joints.

- Sealants for boilers operating on gas or solid fuel.

Liquid products from German manufacturers are popular. These compounds provide reliable sealing of equipment and boilers.

The best and most famous remedies

| Name | Photo | Description | Price |

| AQUASTOP |

| High-quality sealant based on rubber. Has a wide range of applications. The unique formula with fibers seals instantly even in extreme conditions. | 3 liters 11,500 rub. |

| HeatGuardex BLOCKSEAL 100 HD |

| Self-regulating agent for sealing leaks in heating systems. Effective in eliminating leaks in hard-to-reach places from the inside. Suitable for sealing gas boilers. | 1 liter 4,700 rub. |

| BCG |

| German-made liquid sealant is ideal for sealing leaks in heating systems from the inside. | 1 liter 3,450 rub. |

Instructions for use

Before you pour sealant into the system, you need to know the volume of water in this system. To accurately and conveniently determine the amount of liquid, it is better to completely drain it into a container whose volume is known. To eliminate possible leaks in the future, it is advisable to regularly fill the system with sealant.

Important: for the sealant to effectively act on the damaged area, it is necessary to correctly determine the appropriate concentration of the product. For 80 liters of water, 1 liter of mixture is enough.

Before pouring sealant, you need to bleed the air from the system. Otherwise, under pressure, the product will not only clog the defective area, but will also cause the circulation of the coolant to stop.

For good sealant passage through the system, all taps must be opened. On the first radiator, unscrew it completely. After completing the process, you need to connect the pump, bring the temperature in the system to 60 degrees and create a pressure of 20 bar.

For quick filling, you can use a regular inexpensive “Malysh” type pump.

Before pouring liquid sealant, you need to remove the mechanical cleaning filters. Under the influence of the product they will fail. Fill the liquid as follows:

- Take 1.5 buckets of heated water, shake the product, add to the buckets and quickly pump into the system.

- Remove air to allow mixture to circulate through the system.

Complete sealing of the system takes about 3 days. After this time, the pressure should be increased to check the result.

Types of cold welding used to repair cast iron batteries

Despite the general disadvantages that are inherent in all types of adhesive compositions, the industry has mastered the production of several compositions that have their own specialization. So there are mixtures for repairing plastic, metal, aluminum and gluing wood, there are universal compositions. For repairing heating appliances, a mixture for gluing ferrous metals and steel or a special composition for repairing radiators and steel heating pipes is best suited. Cold welding for heating radiators, unlike other compositions, has its own characteristics - it must be heat-resistant, quickly fixed on a metal surface, and form a coating that has a linear expansion coefficient similar to metal. Simple or universal compositions can solve the problem of sealing a leak, but at the same time, the service life of the composition will be limited.

Another point that needs to be taken into account when choosing the type of glue is the setting time. If 3-4 hours are enough to splice parts under normal conditions, then if the battery leaks, there is no such time, here the count is in minutes, therefore, the faster the patch hardens, the better.

Correct check of radiators before the heating season

Battery checks should be carried out in the summer. Immediately after the heating season, it is recommended to perform pressure testing. To do this, increase the hydraulic pressure in order to identify weak points. If leaks are detected, they are repaired.

Checking radiators should consist of several stages:

- Thorough external cleaning of radiators . Dirty batteries weaken the system and cause unpleasant odors. In addition, uncleaned batteries can become sources of harmful microorganisms that can bring illness into the home. When servicing equipment, detergents should be used.

- Cleaning the batteries inside . To do this, you can use dust brushes with a long handle. You can buy periscopic devices on the market to get to the most inconvenient corners. It is advisable to carry out internal cleaning at least every 5-7 years.

- Adding water . When the radiators are already clean, you can begin ventilating the heating equipment. During downtime, a large number of air pockets could appear that block water circulation. The air should be completely expelled from the system.

Poll: Do you carry out annual inspection and pressure testing of your heating system?

Battery leaks in heating systems occur quite often. You always need to be prepared for this. Scheduled maintenance of the heating system guarantees uninterrupted operation for a long time. But it’s still better to always play it safe and keep the necessary tools and supplies at home in case of breakthroughs. The equipment must be monitored at all times to avoid unpleasant consequences.

The main causes of malfunctions of cast iron radiators

Cast iron is highly durable, the service life of heating products is 25–30 years , under optimal conditions - 50 years or longer.

But thick-walled cast iron batteries have vulnerabilities: most often radiators leak between sections, at connections with pipes, and sometimes fistulas and cracks appear on the cast iron itself.

The main reasons why repairs have to be carried out:

- Heavy weight. Depending on the type and manufacturer, the weight of one cast iron section is 4.5–7.1 kg, the filling volume is 1–4 liters , the standard set consists of 4–10 elements. In case of unskilled installation and incorrect calculation of the number of brackets, the radiator becomes skewed. As a result, the joining elements suffer and metal fatigue occurs. In places where there is no coolant, corrosion appears, then a fistula.

- Instability to water hammer and high pressure. When an obstacle is abruptly removed, the liquid acquires enormous speed and rushes to the area of lowest pressure. The power of the water hammer in the heating circuit exceeds the force of a hammer blow. A sudden change in pressure or its high levels threaten depressurization of the heating system - leaks most often occur at the joints where parts of the radiator are connected.

- Dirt and trash. Elements of domestic cast iron batteries are produced by casting. The technology is such that the surface remains rough, which is excluded in imported analogues.

Due to the granularity, particles of rust and suspension that fill the coolant settle on the walls. Gradually, the channels become clogged and cannot withstand the pressure of water - the battery may burst from pressure or water hammer. To prevent repairs, regular flushing of the system is required.

Photo 1. The elements of the cast iron battery are clogged with rust and debris; because of this, the radiator cannot cope with the water pressure.

- Wear of intersection gaskets. The strength of collapsible joints is always inferior to monolithic structures. Intersectional gaskets and threaded battery nipples wear out faster than cast iron and are more susceptible to temperature and pressure. To avoid leaks and emergency repairs, do not forget about prevention: after the heating season, check the connections and change the gaskets.

Tools and materials for eliminating defects with your own hands

Minor repairs of cast iron radiators are possible without the involvement of master plumbers , with your own hands. Depending on the method of restoration work, you will need:

- metal cable or sandpaper - to clean the defect area ;

- for repairing section joints: clamp - a fastener consisting of two rubberized plates from the inside, connected by bolts;

- to eliminate fistulas: cold welding for radiators - a plastic mass intended for fixing metal parts without thermal heating;

- degreasing solvent: gasoline, acetone, white spirit and others;

- one of the sealants: iron powder, polymer, cold welding, epoxy resin;

- bandage or strips of fabric;

- a wrench to match the size of the clamp fasteners, pliers;

- rags, oilcloth, container for collecting water.

Attention! For emergency repairs, instead of a clamp a piece of thin rubber cut from a car inner tube or an elastic rubber bandage and wire for fixation are used.

To wash cast iron batteries, prepare an adjustable pipe wrench, solutions of 10% caustic soda , citric acid ( 50–60 g per liter ) or a special liquid for heat exchangers.

Photo 2. Preparation of a solution for flushing a cast iron radiator; soda and citric acid are added to it.

Repair and cleaning in case of battery leakage

Actions to eliminate the defect depend on its location and the severity of the failure. In all cases, repairs begin with preparing the workplace.

Attention! If the leak is significant, call an emergency team. Attempting to tighten a crack under pressure with a clamp is dangerous to health, as it can lead to rupture of the radiator.

Sequence of work when repairing section joints:

If rubber is used instead of a clamp to repair the joint of cast iron radiators, wrap it around the leak area and tighten it with wire using pliers.

Reference! A clamp without prior application of sealant is used to quickly eliminate minor leaks. The rubberized base ensures tight connections.

If the fistula has formed on a cast iron surface, apply cold welding using the indentation method to the cleaned and degreased area to repair it. A non-standard solution to the problem is to drive a wooden plug into the hole or screw in a self-tapping screw and cover the top with sealant.

Knot near the riser

A leak at the branch point from the riser may occur due to a leaky connection. If it is welded, then the cause of the leak may be a corrosive effect, which intensifies when using the heating system, like zero when unwinding the meter. Another reason for such a leak is the negligence of the craftsman who performed the joint. Also, the problem of leakage may be due to low-quality material that was purchased to save money. Often, a leak appears when the pipes are under high stress, which occurs due to welding work or loads on them with heavy objects.

The simplest way to eliminate a leak in such a place is a metal clamp and a piece of rubber. If such a leak is not uncommon, then you can stock up on a sufficient number of rubber seals in advance to eliminate the leak. They can be cut from an old bicycle inner tube. The sizes can be very different, because you never know where you will have to use this method. The first step is to try to temporarily eliminate the leakage using improvised means. Next, two clamps are loosened and put on the pipe. The cut piece of rubber is placed at the leak site and clamps are placed on it. It is worth clamping them with a screwdriver until the leak stops.

If it becomes clear that in a certain place the pipe wall has become thinner than necessary due to corrosion, then you can use a plaster or cement clamp rather than a rubber clamp to eliminate the leak. This method is also suitable when the leak is due to a crack in the pipe. A small amount of cement and gypsum must be added to warm water. The substances are mixed until a homogeneous mass is formed, but it must have good fluidity. You will need a thick bandage. It must be well soaked in the prepared solution. It is advisable to cut it into pieces of 20 cm. The soaked bandage is wrapped around the damage where there is a leak; this must be done in several layers so that the leak completely disappears.

In some cases, the problem occurs due to a leak directly on the thread. There is no point in delaying the decision to eliminate the leak. It is advisable to take a radical method and cut off the burst part, weld the pipe and cut a new thread. But while waiting for the repair team, you can apply a tourniquet to the leak site. It is done according to the principle of the previous one, but before soaking it in the cement mixture, you need to moisten the bandage with water and sprinkle it with salt.

Note! It is worth remembering that these are only temporary solutions to eliminate leaks and should not become permanent. A pipe that has already been destroyed will continue to rot from corrosion. It’s bad if the next breakdown occurs when no one is at home.

Where is the leak

The entire system consists of heat-transfer devices and wiring, which is represented by pipes. There is also a central riser through which hot water is supplied to the home. Any of the modules can leak. The cause of the leak may be poor-quality assembly, as well as defective material from which the pipes or radiators are made. Knowing this, you can predict where a leak might appear. Among such places are:

- the junction of the outlet pipe with the riser;

- pipe seam;

- leakage between battery sections;

- leak at the pipe inlet to the radiator;

- the appearance of a fistula in the radiator section.

Each type of leak requires its own approach to elimination. In some cases, the same materials may be used.

Radiator repair - what to do in summer

When fixing a leak using any of the methods described above, do not forget that you are only temporarily solving the problem. As soon as the heating season is over, you will have to seriously think about high-quality repair of the breakdown. Once the batteries are no longer in use, the first step is to completely drain the water from the appliances or the entire heating system. Then completely disconnect the problematic battery. Remove from its surface all the patches that were previously used to hide the cracks. Next, clean the seams between the sections. Tighten the nipples with a radiator wrench and repair the crack by soldering.

After this, you will need to reinstall the battery. Regardless of whether you used new linen in winter, replace it this time as well. This way you will be able to extend the battery life. Often a crack may appear in one of the sections of a cast iron appliance. In winter, it is quite problematic to completely eliminate this problem, so we recommend repairing the battery in the summer. To do this, the product must be turned off and dismantled.

After this, estimate the size of the crack. If it is small, then you can use a soldering iron or welding machine. But if the crack is large, then it is best to replace the faulty section with a new one. To do this, use a special key to unscrew the problematic part and install the purchased part in its place. Be sure to apply a high-quality heat-resistant sealant at the joints. After this, replace the battery.