The arrangement of any communications inside the apartment requires a careful approach - they must function normally, not cause trouble to owners and neighbors, and be constantly available for repairs. The last point makes capital sealing of pipes and/or wires undesirable.

Special attention during repairs is required for drain pipes. Due to their large diameter and frequent use of liquid, they produce quite a lot of noise - this is undesirable and needs to be corrected, that is, noise protection is required.

How to soundproof a sewer riser

To reduce the noise level in the bathroom you can:

- wrap the riser pipe and all adjacent components (including areas passing through ceilings and walls) with a porous material that absorbs sound well. If it is foiled, the pipes will be thermally insulated at the same time;

- arrange a box made of hard material (plasterboard, chipboard, fiberboard, OSB, wood) around the riser and fill it with sound-absorbing bulk material. In this case, it is also necessary to wrap sections of communications passing through building structures;

- replace conventional plastic risers with special “silent” pipes;

- secure the structure using clamps or damper rings with rubber or other elastic inserts.

A combination of methods is also possible, for example, fastening the riser with a clamp, wrapping the pipe and all adjacent sections, enclosing the wrapped riser in a box with a loose sound absorber.

Recommendations from experts

When replacing a cast iron riser with a modern plastic one, you should not completely remove the old pipe. It is better to leave the crosspieces and areas that are located within the floor slabs. The next sequence of actions is as follows:

- the middle part of the channel is dismantled using a grinder and a cutting wheel for metal;

- the internal walls in the remaining pipes are cleaned of plaque and fat accumulations mechanically and chemically;

- a plastic pipe is installed and secured using plumbing adapters and fasteners.

In this case, noise insulation of pipes is carried out partially with entry into cast iron pipes. If you plan to replace the entire channel, then it is better to perform the task together with your neighbors. And in the ceilings a damper gasket is installed here.

Insulation materials are often mistakenly used to soundproof sewers. This is acceptable with mineral wool, but not with options such as polystyrene foam shells. Spraying polyurethane foam or polyurethane foam directly onto the fan pipe is also excluded.

There is an opinion that after completely wrapping the channel with a sound insulator, it is not necessary to use damping pads. They are necessary in any case. This eliminates the transmission of structural noise.

Why is soundproofing of a sewer riser needed and what noise should it remove?

Where does the noise in the sewer come from? It occurs as a result of the flushing of water from the toilet, bathtub, shower, sinks and sinks both in the apartment itself and in all neighbors. Moreover, depending on the floor, the noise may be more or less - after all, the lower the apartment is located and the more other apartments above it, the greater the volume of wastewater passes through the sewer riser and the higher the flow rate.

As a result, the main riser (usually located in the toilet or combined bathroom) is a source of the following types of noise:

- percussion Water hitting the walls of the pipe makes a booming sound. The same applies to solid waste discharged into sewers;

- air - air is present in the riser along with the water, its bubbles burst and appear, increasing the turbulence of the water flow;

- Structural noise generated by impacts is vibration of the pipe walls transmitted to building structures (ceilings, walls, etc.).

Moreover, the thinner the walls of the riser pipe, the stronger its vibration. The wall thickness does not affect the operational properties of the sewer (it is calculated taking into account the permissible pressure in the system), but you can’t expect silence in the bathroom.

Conclusion - it is necessary to supplement the structure with soundproofing or sound-reflecting materials that will “dampen”, absorb or reflect impact and airborne noise and will not allow pipe vibration to transfer to building structures.

Why doesn't cast iron make noise?

Why doesn't cast iron make noise? Metal is not noisy, but plastic is noisy? Metal, but not quite. Cast iron is a eutectic alloy, a collection of microscopic grains of different composition and properties. Because of this, cast iron has a low mechanical quality factor: the grains rub against each other, absorbing vibration. And the cast iron pipe quickly becomes overgrown with plaque inside, which additionally dampens vibrations.

Due to the eutectic structure, the elasticity of cast iron is also negligible - everyone knows how fragile it is. Before a cast iron product dings for any reason, it will fall apart. The frames of grand pianos and pianos are still cast from cast iron, ignoring the most modern materials: any other frame will either not withstand a string tension of 20 tons, or will produce overtones.

Materials for soundproofing sewer risers

Very dense materials can reflect sound - heavy concrete, sand-lime brick, pressed rubber and other analogues. It is inconvenient to use them in the bathroom.

“Dampening”, noise absorption, is designed to ensure that a layer of sound-absorbing material is placed around the pipe, with the closest possible fit to it. This includes loose, loose and fluid substances; both dense liquid and sand can absorb noise. But taking into account the design features of the sewerage system, porous materials in the form of a “shell” or winding are convenient.

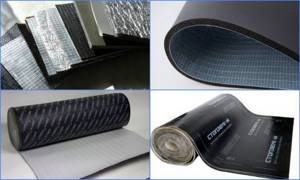

Soundproofing membranes and roll materials

To absorb and partially isolate noise coming from utilities, the industry offers membranes with additional layers of protection made of foam rubber or polymers, as well as a layer of foil. Usually the material has an adhesive fastening, is pressed close to the pipe and wrapped around it so that the edges of the sheet do not meet end-to-end, but overlap.

| Alufom R-TK | Material composition |

In fact, this material simultaneously performs the functions of thermal and sound protection.

In addition to the named material, you can use almost any rolled materials for sound and heat insulation, for example, Zvukoizolo, Folgoizol, Stopzvuk, Penofol, Energoflex, foamed polyethylene.

Their effectiveness will depend on:

- composition, quantity and thickness of layers;

- fastening method - simple wrapping or installation with glue, with a tight fit to the pipe (a more effective solution).

If the noise level is significant, you can use two layers of the same material or one layer at a time. For example, foamed polyethylene in two layers with glue and a soundproofing membrane on top in one layer (overlapping).

The proposed master class shows a ready-made solution for sound insulation based on rolled foil material, suitable metallized tape and special ties for installation.

Shown here is an option with independent cutting and fastening of the rolled material with tape over the entire surface of the riser and adjacent areas.

Shell made of mineral wool or polystyrene foam

This type of soundproofing of a sewer riser in an apartment is selected precisely according to the diameter of the riser and requires additions to protect the joints and adjacent sections of the pipeline.

The pipe is enclosed in a “shell”, connecting the halves of the hollow cylinders using a special adhesive edge (pictured above) or tape. The installation of such insulation is shown in the video, but the effectiveness of the system specifically for absorbing sound is not too great - heat losses are removed much better.

Soundproofing a sewer riser using a duct

In this case, the rigid structure performs two functions - it serves as an additional barrier to noise penetration and gives an aesthetic appearance to communications. If a bulk noise absorber is used, the third function of the box is to limit the specified volume for the filler.

Creating a box from plasterboard or similar sheet rigid materials is discussed in detail in the article “How to cover pipes in a toilet.” Moreover, if it is necessary to make a duct only for the sewer riser, it is advisable to use an option with a reduced cross-section of the structure.

The sound insulation itself is carried out using mineral wool or specialized materials, for example, Knauf Acoustic wool. After this, a box is mounted - it will protect the loose winding from mechanical stress and hide its unsightly appearance. The box installation process is discussed in detail in the video.

Filling a box with bulk materials is a rarely used method. In this case, sand, sawdust, polystyrene foam granules and other similar materials are used as a noise absorber.

It is important to understand that inspection and repair of the riser in this case is very difficult, and the appearance of a leak may not be noticed in a timely manner.

This method of soundproofing a sewer riser with your own hands in an apartment is not very appropriate; it is more suitable for a private house.

Noise Elimination Methods

If it turns out that the sewerage system runs in the living room, then the most correct solution would be not to soundproof the pipes, but to relocate them. Such a solution to the problem can be carried out exclusively at the construction stage. It will no longer be possible to move after the work is completed. The funny thing is that this situation also occurs in new buildings due to miscalculations in the design. In practice, the drain pipe most often runs in the bathroom or toilet, if the bathroom. the node is not combined. Now directly about the methods.

Soundproofing a toilet in a private low-rise building or in an apartment as a whole can be done through the following operations.

- Installation of silent pipes.

- Fastening soundproofing materials.

- Installation of rigid clamps in order to make the sewerage structure more static.

- Box installation.

- Installation or repair of a drain pipe.

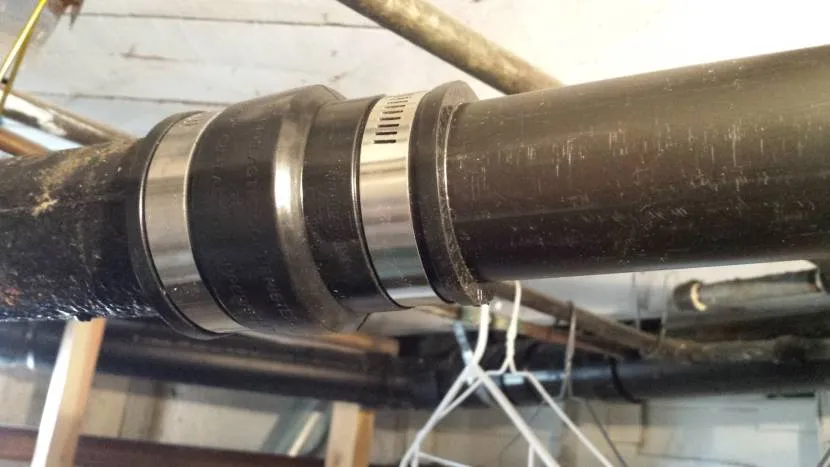

Photo: sewer pipe secured with a clamp

Silent pipes

Silent pipes can be called a novelty on the building materials market. They are not yet used so often, but are successfully gaining recognition among buyers. Distinctive features of such a riser are a thickened wall and special components that are designed to prevent the penetration of sound and vibration into the room. It is noteworthy that silent pipes dampen even infrasound.

In addition to such positive qualities of the new material, there are a couple of significant drawbacks. The prices for such pipes are significantly higher compared to the classic PVC version. They also do not have a long service life, no more than 30 years. Of course, you can find more durable options, but the price will also increase progressively.

Fan pipes

At its core, this is ventilation for sewerage. In a private house, the height of which does not exceed two floors, the installation of vent pipes is not carried out, and there is actually no need for this. The legislation also does not impose requirements for this. For multi-storey buildings, the presence of a drain pipe is mandatory. It allows not only to equalize the pressure in the riser, but also through it the accumulated gases are released into the atmosphere, which can cause airborne noise.

A function similar to vent pipes, but indoors, can be performed by air valves. Their purpose is to let air into the sewer and at the same time prevent reverse movement. You can make noise insulation for air ducts using soundproofing materials, but so as not to block the flow. If the flow capacity is disrupted, water from the riser can be directed through the inlet channel.

Soundproofing

In practice, the most common situation is when the sewerage system has already been installed and its replacement will lead to unnecessary financial and labor costs. Thus, apartment residents who need to reduce the noise level from the riser resort to using various types of soundproofing materials. There are many options that can be used as such.

Soundproofing a sewer riser does not require any special skills; it is enough to have at least a little experience in installation work. The easiest way to do this is by using polyethylene foam or polyurethane foam.

As for the places where the riser passes through the floors of the building, as mentioned earlier, you should not use polyurethane foam, since it only increases structural noise. Instead, you should take porous rubber. This will minimize the likelihood of vibration transmission to the building structure and eliminate the acoustic effect.

The box will not only create a more attractive appearance, but will also provide additional sound insulation

It is important to take into account the fact that it should not be made deaf. Access to the water supply is necessary, as it often runs in close proximity to the sewer pipe

There is a chance that you won’t have to do anything else behind the box, but the likelihood of an emergency should be taken into account. It is then that ease of access and efficiency of work can significantly reduce the harmful consequences of an unforeseen situation.

Materials

Among the materials that give the maximum effect can be used:

Foamed polyethylene.

Photo: foamed polyethylene

- Polyurethane foam.

- Foam rubber.

Photo: foam rubber

- Foam shell.

- Mineral wool.

Photo: mineral wool

Clamps with rubber inserts and damping pads

This method of dealing with excess noise is based on reducing the level of pipe vibration associated with the beating of the flow against the walls. Due to the fact that the clamps are equipped with internal ring inserts made of dense but elastic rubber, the pipe maintains a stable position, vibrations are damped and are not transmitted (or transmitted to a lesser extent) to building structures.

The video shows a simple method of installing a riser using clamps with damping inserts. Also, such inserts are convenient for isolating the riser where it passes through the wall and/or ceiling of the building (photo below).

When using the last option, a hole is cut in the building structure with a diameter that corresponds to the diameter of the pipe, taking into account the damping insert. The pipe should pass through the hole with little effort, “with interference.” If the riser must pass not through solid material (concrete, wood, panels of various kinds), but through masonry or a frame wall, the hole is reinforced and limited by a metal insert ring.

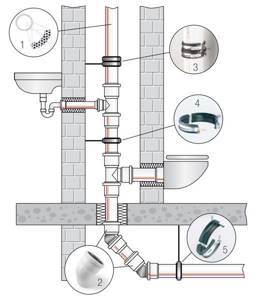

"Silent" pipes

This is perhaps the most reliable and modern method of removing noise from the sewer system, but it is only available at the stage of installing a drainage system or its major repair. Moreover, when installing sewerage systems in apartment buildings, such a system is effective only if it is used on at least two or three adjacent floors.

The principle of “silent” pipes is the use of a multilayer structure of the pipe itself plus special noise-absorbing fasteners.

In our country, the Rehau Raupiano system is quite widely represented, which includes a wide variety of pipes of different diameters, lengths and purposes, connections for them and fastenings.

There are also Ostendorf, Waving and Politek (Russia) systems.

With the help of such “silent” products, home communications can be completely formed, as shown in the diagram below.

You can learn more about the features of pipe communications from the Rehau company from a video recording of a seminar dedicated specifically to silent sewerage.