Soundproofing walls in an apartment, modern materials for which can be found in hardware stores today, is becoming more and more relevant. This is explained simply - fences in multi-storey standard buildings are not able to completely protect the home from external street noise and from sounds coming from neighboring apartments.

Soundproofing walls in an apartment using modern materials

Medical scientists have long noticed that the presence of constant noise has an extremely negative effect on the human psyche, preventing him from getting complete relaxation and rest. That is why, unable to withstand the constant sound pressure, many city residents, especially those who live in panel houses, begin an active search for a suitable soundproofing material that will meet all the requirements for its use in apartments.

Almost all modern acoustic materials are made on the same basic principles as traditional ones. However, they have undergone significant improvements due to recent production technologies.

Today, a very large number of new soundproofing materials are being produced, and it is simply impossible to cover the characteristics of all of them in one article. Therefore, attention will be focused on the most effective ones, which are used specifically in apartment conditions.

4 StopSound BP

To minimize the cost of heat and sound insulation of a house or apartment, you should pay attention to StopZvuk BP slabs. The material has unique abilities due to the presence of basalt mineral in its composition. This component plays the main role of a universal insulator. In addition to high noise absorption (up to 99%), the slab can withstand high temperatures (up to 1000°C). Owners of private houses will benefit from such properties as resistance to rodent penetration, preservation of their properties in a humid environment, and inertness to biodestruction.

StopZvuk BP is an environmentally friendly material, since basalt is a natural substance. The products meet all the requirements of European standards. Quality is controlled at all stages of production.

The low density of the material allows for complete thermal and sound insulation of a house or room, without fear of the load on the supporting structures. Sound insulation is installed in the same way as in the case of mineral slabs. A frame is made with a pitch of 600 mm, and an insulator is placed in the resulting space.

Homeowners note in reviews such advantages of StopZvuk BP as reduced costs for a set of insulation measures, simple installation, and low weight. Disadvantages include insufficient protection from strong noise and vibration.

Extruded polystyrene foam

Externally, extruded polystyrene foam is similar to regular polystyrene foam, but has a higher density and thinner thickness. An extruder is used in its production. Thanks to this, extruded polystyrene foam has closed cells of the same size.

Due to its high density, extrusion is used in the construction of railways and highways, as well as runways. This material has excellent strength, so it can be used not only as thermal insulation, but also as an auxiliary or load-bearing structure.

Positive qualities of extruded polystyrene foam:

- does not absorb liquids;

- does not sit down;

- not afraid of chemicals;

- does not rot and is not overgrown with mold and fungi;

- service life - about 50 years;

- has one of the lowest thermal conductivity coefficients.

It is used for insulation of walls, ceilings, floors, foundations in private houses, apartments and industrial facilities. Just like polystyrene foam, it is used only as thermal insulation.

3 Schumanet BM

The Schumanet BM mineral plate will help you make high-quality noise insulation of a room cheaply. This non-combustible material has a low specific gravity, which reduces the load on the walls. The slabs are designed to fill voids between the wall and the cladding. Installation is carried out using frame structures. The quality of each slab is strictly controlled by the manufacturer. Therefore, excellent acoustic properties are guaranteed.

Builders have no problems installing the material. As a rule, a frame is installed on the walls of houses with a pitch of 600 mm. The minislab has the same width with a length of 1200 mm and a thickness of 50 mm. The package contains 4 slabs, which allows you to immediately insulate 2.88 square meters. m walls. Soundproofing material is placed between the profile or wooden beam. For fastening, it is enough to use several plates designed for installing heat-insulating boards. If Shumanet BM will be used in rooms with high moisture, then each slab is first wrapped in non-woven material, for example spunbond.

Russian homeowners and builders note a number of positive qualities of soundproofing material. This is an affordable price, ease of installation, good noise absorption coefficient. The disadvantages include the presence of loose and prickly elements.

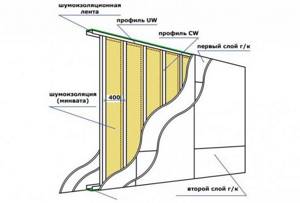

Features of frame installation

The main feature of the frame method of soundproofing walls is already stated in the name of the operation - it is necessary to build a frame from wooden beams or metal profiles, to which the rest of the material is later attached. It seems that this information alone is enough to understand: for very modest rooms this method is undesirable. The fact is that the frame with the subsequent fixation of soundproofing material risks seriously reducing the space, up to 12 centimeters. For spacious apartments this is a drop in the ocean, but for Khrushchev-era apartments that are not spoiled by extra square meters, this is a serious figure.

Mineral wool

Stages

- the base wall is marked;

- a guide metal profile is mounted;

- a rack-mount metal profile is installed;

- installed profiles are covered with polystyrene tape to improve noise reduction performance and avoid contact of the metal part of the profile with the wall;

- cut pieces of mineral wool are inserted between the metal profiles;

- the cotton wool is secured with wide-headed anchors;

- all existing joints are carefully puttied;

- installation of a profile for the ventilation gap between the mineral wool and the plasterboard sheet is carried out;

- gypsum board sheets are fixed.

. It must be glued immediately after installation. This combination significantly increases sound insulation characteristics, but will require you to invest significantly more in repairs.

Detailed installation instructions on the walls in the apartment in the video.

Of course, instead of profiles, you can use ordinary wooden slats. But the wood used must be well treated with an antiseptic and is much less durable than ready-made profiles sold in hardware stores.

2 Soundline-dB

The acoustic triplex Soundline-dB has unique soundproofing properties. It is made on the principle of a car windshield. A special sealant is applied between two moisture-resistant weighted sheets of plasterboard (8 mm). Due to the elasticity of the layer, the sound flow is reduced due to the gradual absorption of waves. In other words, each sheet of drywall vibrates on its own. The total sound insulation is significantly higher than that of the same two sheets of drywall without an acoustic layer.

Testing of the material has shown that it has the lowest levels of flammability, toxicity, combustibility and smoke formation. Triplex Soundline-dB fully meets all the requirements of sanitary and hygienic standards of the Customs Union.

Among the advantages of sound insulation, it should be noted ease of installation, high degree of sound insulation (up to 69 dB), preservation of its properties for up to 25 years, and low cost.

Installation of triplex is in many ways similar to the creation of plasterboard structures. You just need to select the appropriate screws for the thickness of the sound insulation (17.5 mm). You should also make adjustments for the heavy weight of the three-layer fabric.

Owners of houses and apartments in reviews praise the soundproofing qualities of the Soundline-dB triplex. It is easy to install, effective in reducing noise, and has a small thickness. Disadvantages include heavy weight and bulkiness.

Manufacturers of heat and sound insulation panels

On the market of heat and sound insulating materials, cork insulation is represented by the Portuguese company Amorim Group.

The most popular brands of basalt wool are:

- TechnoNikol;

- Paroc;

- Isover;

- Linerock;

- Rockwool.

Well-known trade brands of expanded polystyrene are Penoplex, URSA and TechnoNikol. Of the foam manufacturers, the Knauf brand is the most popular.

Using foam mats as sound insulation

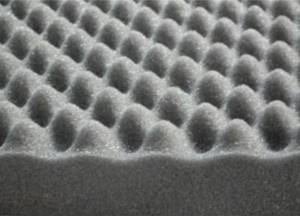

The most effective affordable material for soundproofing walls in an apartment can be called acoustic foam rubber. Due to its porous structure, this material perfectly absorbs and dissipates sound vibrations.

Foam rubber has the highest sound-proofing qualities, especially in the profile version.

Acoustic foam rubber is capable of neutralizing two types of noise - sound and vibration waves, that is, it muffles sound and dissipates low frequencies arising from vibrations of surfaces, for example, knocking or “bass” of music.

The material is quite durable and can be installed either as an independent soundproofing material or in combination with drywall. Foam mats are available in a wide range of sizes and can be textured or have a flat surface.

Foam rubber is made by pressing polyurethane foam, after which it is cut into standard blocks measuring 1000x2000 mm. The thickness of the mats varies from 10 to 120 mm. Domestic material is available in two or three colors, while imported options have a more varied range of colors, including 10 ÷ 12 colors.

Types of material relief

The types of relief patterns of acoustic foam rubber can be different. The total thickness of the material and its noise-absorbing properties depend on the depth of the relief.

The main types of reliefs used for the purpose of soundproofing rooms are presented in the tables below:

| Material relief height (mm) | 25 | 50 | 70 | 100 |

| "Wedge" | ||||

| For moderate sound insulation of walls and ceilings. | Effective for absorbing standing sound waves and echoes in medium to small rooms. | For effective soundproofing of rooms of any size. | To absorb low frequencies, most often used in large halls. |

| "Pyramid" | ||||

| For moderate protection of walls against penetration of high and medium frequencies. | Protection against standing waves in small spaces. In combination with traps for low frequencies, they can completely soundproof a room. | It is used for rooms of any size and is used in conjunction with additional soundproofing elements, such as sound traps. | Same characteristics as wedge material type |

| Relief height | 40 | 80 |

| "Wave" ("egg tray") | ||

| It has the qualities inherent in the “wedge” or “pyramid” thickness of 25 and 50 mm, but has a lower cost. | Corresponds to the characteristics of “wedge” or “pyramid”, having a thickness of 70 and 100 mm, and also has a lower cost. |

There are other, less commonly used elements made of acoustic foam.

| Name of relief type | Characteristics |

| "Peak" | This mat relief is less popular and has an unusual pattern. Its lack of demand is explained by lower soundproofing qualities than those of the materials mentioned above. |

| "Bass Trap" | Low-frequency waves are more difficult to dampen because they are longer. For this purpose, bass traps are installed in each corner of the room, which are designed for rooms of any size. |

| "Treble and Mid Frequency Traps" | These elements are installed in large halls. They are designed to capture mid and high frequencies, and create a low frequency diffusion effect. They are installed in a vertical position, but if the blocks are cut in half and installed in the corners, they will become low frequency traps. |

| "Corner block" | Corner blocks are produced in the form of a triangular beam. They are installed in the corners of the room and at the junctions of two surfaces, and also serve to dissipate low frequencies. |

| Decorative ceiling tiles | They are produced with or without a relief pattern. They are designed to change the relief and shape of the ceiling, thereby achieving an additional soundproofing effect. |

| Insulating wedges | Used to reduce vibrations from studio equipment and used as a substrate for it. |

Until recently, acoustic foam rubber was rarely used in apartments, since the material tends to accumulate dust. But in recent years, more and more residents of panel houses are choosing foam rubber to reduce the sound conductivity of the walls. Thanks to its high sound-absorbing and dissipating properties, this material can make a room almost completely soundproof, provided it is installed not only on walls, but also on the surface of the ceiling and floor.

Sound studio room, completely finished with profile foam rubber

It is very important to note that acoustic foam rubber does not lose any of its soundproofing qualities when covered with plasterboard. The main condition in creating such a structure is that the foam mats themselves must be glued directly to the base of the wall, without any lining.

Preparing the walls

Regardless of the chosen material and method of sound insulation, it is necessary to prepare the walls. It includes:

- Cleaning the surface of old wallpaper and loose plaster.

- Carefully inspect the wall for cracks. If they are, then they need to be primed and plastered.

- Check connections at corners. If there are holes, fill them with foam.

- Be sure to seal the holes for water and heat supply pipes.

- Pay special attention to sockets. Often in panel houses, holes for sockets are made through in the inter-apartment partitions. In this case, it would be best to move the outlet and carefully seal the existing hole.

- After cleaning the walls and filling cracks and holes, it is advisable to plaster them.

This preparation alone will reduce noise by 2-3 dB.

Determine the type of noise

In the field of housing construction, it is customary to distinguish two types of noise:

- airy (speech, music, sound of operating mechanisms, etc.)

- impact (clatter of heels from neighbors above, hammer blows on the wall from neighbors on the side, etc.).

Each of them, in turn, can be direct and indirect.

- In the first case, the source acts only directly on the structure separating the rooms (wall or ceiling).

- In the second, it penetrates through an adjacent surface (for example, if the neighbors above have turned on a music center, the speakers of which are located near the wall, then the sound will penetrate into your room not only through the interfloor ceiling, but also along the walls).

Only after analyzing all of the above points and accurately determining the type of noise that you have to deal with, you can understand what kind of sound insulation for walls is suitable for your apartment.

How to choose the best sound insulator

Before choosing such a material, you should determine what type of noise needs to be eliminated. The main types of noise in modern apartments include:

- Drums. Sound waves penetrating through solid materials of ceilings and walls. For example, the noise of a hammer drill, impacts, steps.

- Airborne. They enter the house through the air, for example, the noise of cars on the street, conversations, the sounds of TV, music.

- Structure noise. They combine the properties of percussion and air.

Each type of noise requires the use of different materials and sound insulation methods.

Cork coverings

Cork also has many advantages:

- It is waterproof.

- Fireproof.

- Resistant to deformation and pressure.

- Doesn't collect dust and gets dirty a little.

- It perfectly isolates extraneous noise and retains heat.

- Not susceptible to mold and mildew.

- Hypoallergenic.

The disadvantages include:

- High cost of material.

- Low durability of the protective coating.

- Traces from heavy furniture and equipment.

Cork can be presented to the consumer in various types:

- Tiles made of cork chips.

- Rolls of cork.

- Wallpaper made of cork chips.

- "Liquid" plug.

- Technical cork covering for other types of finishing.

Installing a cork in any form is not a complicated process, but quite painstaking. It is glued to a special acrylic or contact compound. Contact adhesive has a two-sided application principle, that is, it is applied both to the wall and to the material, ensuring reliability and strength of fastening; the second fastening option implies that the glue will be applied only to the material. Builders prefer contact adhesives.

When gluing on both sides, you need to ensure that air bubbles do not get under the material, and that the glue is evenly distributed over the entire surface. Before gluing, you need to wait a while for better adhesion of the materials. Before the gluing stage, the cork must acclimatize in the room, for this it must take at least a day. The walls and the room where the work will be carried out also need preparation. The room temperature should not be lower than 19 degrees Celsius, and the relative humidity should fluctuate between 35-65 percent. The walls must be dry and smooth, their maximum humidity is 3%.

If you are not sure of compliance with these indicators, then carry out the appropriate work - level or dry them. When installing cork coverings, the use of materials containing gypsum is prohibited. Cork is glued in almost the same way as tiles, with the difference that the seams here should be minimal, and the materials should be laid end to end. If the covering has a pattern, then lay out the combination on the floor before gluing it to the wall and stick to the sequence you chose.