10/07/2019 There are many skeptics who claim that insulating a house or apartment from the inside is not the best option. But, in some cases, it is simply not possible to insulate the walls from the outside. Internal thermal insulation is becoming practically the only way that can provide a home with warmth and comfort and reduce energy consumption.

How to insulate a house from the inside, what features of the process need to be taken into account - we tried to cover the topic to the maximum. In the publication you will find the following:

- Features of internal insulation of a house: what is important to know first;

- Preparing the room for internal insulation;

- Insulation of walls from the inside with polystyrene foam; Selection of expanded polystyrene for internal insulation;

- Installation of extruded polystyrene foam for internal insulation;

- How PIR boards are installed for internal insulation;

- Selection of mineral wool for internal insulation;

Why external insulation and not internal

The most understandable argument for a non-specialist sounds very convincing, although this is a secondary factor - insulation from the inside “takes away” the useful volume of residential and office premises.

Builders are guided by the standard according to which insulation must be external (SP 23-101-2004). Insulation from the inside is not directly prohibited, but it can only be carried out in exceptional cases. For example, when work on the outside cannot be carried out due to the design features or the facade “belongs” to a house that is classified as an architectural monument.

Where does the heat go?

A large amount of heat generated by heating in the house ends up going in the following directions:

- Ventilation - about 40%;

- External walls - 20%;

- Window and door openings - up to 25%;

- Floors – 5-10%;

- Roof - up to 15%.

And all this in the absence of high-quality insulation. Cold bridges should not be discounted either. Heat loss through them is about 5%. Cold bridges are cracks in the walls, floors, and houses. Any technical gaps at which a mixture of two temperatures occurs - low and high.

Video description

The result of proper internal insulation of a house in the video:

Even such protection from the inside will not provide a 100% guarantee against the wall getting wet - water vapor will find its way into the film joints and fastening points Source domvpavlino.ru

That is, when deciding how to properly insulate a house, in the vast majority of cases, the answer will be based on clear regulatory recommendations - from the outside.

Additional ways to keep your home warm

There are several other options to keep the room warm. Experts recommend doing the following:

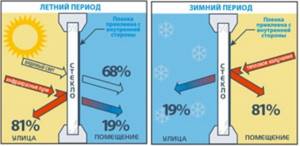

- If the apartment is located on the south side, then on a sunny day try to open the curtains as much as possible. Even the seemingly cold winter sun provides a sufficient level of heat through the prism of the glass.

- You can additionally stick a thermal protective film on the windows. It does not reduce visibility. But it retains heat well in the room.

Windows with film

- If you have a fireplace or stove in your home that you are not using, be sure to cap the chimney. 30% of the heat escapes through it.

But do not forget to open the chimney when using the fireplace. Otherwise, carbon monoxide will go into the room.

- If it is possible to install heating in the house in addition to centralized heating, use oil radiators or ceramic panels. They are the safest and provide a large percentage of heat. If possible, abandon central heating in favor of individual heating. This way you can control the temperature in your home yourself.

And of course, just dress warmly in winter. Warm socks, knitted by the hands of a caring grandmother, will give not only warmth, but also spiritual comfort.

Having figured out how to insulate an apartment from the inside with your own hands without repairs, do everything necessary to preserve heat. And in the spring and summer, if possible, do major work on replacing windows, doors and insulating the floor.

But there are exceptions! Insulation from plant materials.

Environmentally friendly insulation made from flax and hemp fibers have unique properties and, using them, you can deviate from generally accepted rules. Thermal insulation made from plant materials does not require the use of vapor barrier. Such thermal insulation can be used both internally and externally in almost any structure. If additional wall insulation is performed, then vapor barrier is not used at all. This is especially important when insulating wooden walls. This method of insulation allows you to maintain a favorable microclimate for a person in a wooden house, while significantly improving the heat-saving characteristics of the structure. If a frame house or roof is insulated with flax insulation or hemp insulation, then instead of a vapor barrier, special vapor barrier cardboard is used. Flax and hemp are natural antiseptics, they are not afraid of moisture and can remove moisture from the structure through their capillary fibers; this is their main difference from other non-organic insulation materials. Linen and hemp insulation are absolutely safe for humans, are not afraid of rodents, are durable and will last more than 70 years.

Option for insulating a balcony from the inside

In the case of a loggia and a balcony, the situation is often completely different. If the authorities do not allow the installation of a wall, they require that the existing reinforced concrete screen be left; it is cut off from the warm air by careful thermal insulation made of extruded polystyrene foam (EPS).

Insulation of the balcony from the inside

In this case, it is better to make the insulation excessive than at least slightly insufficient. The total thickness is divided into two layers. They are laid without a gap (preferably with locks), and so that the seams of the first layer overlap the sheet of the second. There should be no through access of warm air to the screen.

It is necessary to approach the issue of insulating the floor and ceiling of the loggia/balcony very carefully and ensure tightness at the junction of them with the walls. Also pay attention to how the glazing will be installed: there may also be problem areas: the joint with the screen, walls, insulation of the part above the frames. All of them must be well finished, excluding the possibility of contact of warm/cold air. In this case there will be no problems. Even if the balcony is combined with the room.

Video description

Which insulation is better? Watch the test of mineral wool, polystyrene and NPE Tepofol in this video:

Tepofol

This is a new type of thermal insulation made of polyethylene foam with a heat-reflecting layer. Made from LDPE - high-density polyethylene. This raw material is widely used in the food industry, which confirms its safety. Surely you have already come across similar material. Previously, it was used in conjunction with other types of thermal insulation only as a vapor barrier. This was due to the production of small thickness - up to 10 mm. The Tepofol company has developed and patented a system of interlocking connections and has the ability to produce insulation up to 150 mm thick. Despite this possibility, in the central region for year-round use, the optimal thickness is 60-80 mm. This allows it to be used as the main thermal insulation without the use of other types of insulation. Tepofol does not absorb moisture and does not lose its properties; it is no longer necessary to use vapor barrier and wind protection. With traditional insulation technology, thermal insulation is laid between the frame. But since the thermal conductivity of wood is higher than that of any thermal insulation, in this case the frame itself will act as a cold bridge. In the case of insulation with Tepofol, the rolls are rolled out along the structure itself, after which the locking joints located on the top and bottom of the roll are soldered together with a construction hairdryer. This allows you to achieve a solid, sealed fabric, without cracks and without cold bridges, without resorting to the use of foam and sealants.

External insulation of the house Source tepofol.ru

Example of internal roof insulation Source tepofol.ru

Expanded polystyrene

Better known as "foam". To be precise, in addition to slabs, this material is also used in granular form as bulk thermal insulation.

Its thermal conductivity varies with density, but on average it is one of the lowest in its class. Thermal insulation properties are provided by a cellular structure filled with air. Its popularity is explained by its availability, ease of installation, good compressive strength, and low water absorption. That is, it is cheap, quite durable (as part of the structure) and is not afraid of water.

Polystyrene foam is considered low-flammable, and those marked PSB-S are self-extinguishing (does not support combustion). But during a fire, it emits toxic gases, and this is one of the main reasons why it cannot be used for insulation from the inside. Its second drawback is low vapor permeability, which imposes restrictions on the use of “breathable” materials when insulating walls.

Extruded polystyrene foam

See also: Catalog of companies that specialize in insulating country houses.

It differs from polystyrene foam by a fundamentally different manufacturing technology, although the raw material is the same polystyrene granules. In some respects it is superior to its “relative”. It has the same percentage of water absorption (no more than 2%), on average, thermal conductivity is 20-30% lower (Table D.1 SP 23-101-2004), vapor permeability is several times lower and compressive strength is higher. Thanks to this set of qualities, it is the best material for insulating the foundation and basement, that is, the walls of the basement and the “zero” floor. The disadvantages of EPS are the same as those of polystyrene foam, and it costs more.

EPPS is usually made “colored” Source footing.ru

Stone, also known as basalt, cotton wool

This is a subtype of mineral wool, the raw materials of which are rocks of stone (most often basalt). A completely different type of thermal insulation material, the low thermal conductivity of which is ensured due to its fibrous structure and low density. It is inferior to foam plastic and EPPS in terms of thermal conductivity (on average 1.5 times higher), but unlike them, it does not burn or smolder (flammability class NG). Refers to “breathable” materials - according to the new standard this sounds like low “breathing resistance”.

Mineral wool mats for wall insulation must be “hard” Source konveyt.ru

But there are other materials for insulating a house outside, which, although used less frequently, have their own advantages.

Features of internal insulation of a house: what is important to know first

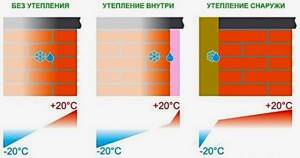

The main and hidden “enemy” of internal insulation is condensation. The air around us contains vapors in different concentrations. As a rule, in residential premises the concentration of vapors is often high. This is due to cooking in the kitchen, using bathrooms, watering flowerpots, wet cleaning and other reasons. Excess moisture is always removed through ventilation ducts and open windows. But in addition, they penetrate into the walls due to the porosity of the materials. When passing the wall, the vapor molecules necessarily collide with a conventional line, at which they turn into a liquid state - they condense. This line is called the "Dew Point".

With internal insulation, the dew point will always be located immediately behind the installed thermal insulation - that is, on the inner surface of the wall. When steam hits the wall, it forms condensation and moistens the wall material. The consequences of this are sad: immediately behind the insulation, a zone is formed with ideal conditions for the growth of bacteria, fungi, and mold. Thus, the premises may even become dangerous for living.

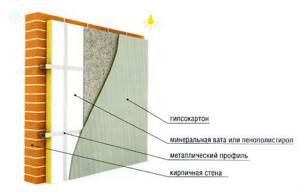

Based on what was described above, we conclude that the main task with internal insulation is to do everything possible to prevent contact of moist air with the dew point. That is, task No. 1 is to protect the inner surface of the wall from the slightest contact with steam . And this can be done quite simply. You need to do three things:

- follow the insulation installation technology;

- be sure to install a vapor barrier;

- choose the right material for wall insulation.

Thermal insulation materials - new products on the market

Additionally, you can always consider new options - they are a little more expensive, but often somewhat more effective than traditional ones.

Foamed polyurethane

A common polymer material for “household use”. Also well known as foam rubber for furniture (in the form of “soft” mats) or as polyurethane foam for sealing cracks. When insulating, it is also used in the form of slabs or sprayed insulation.

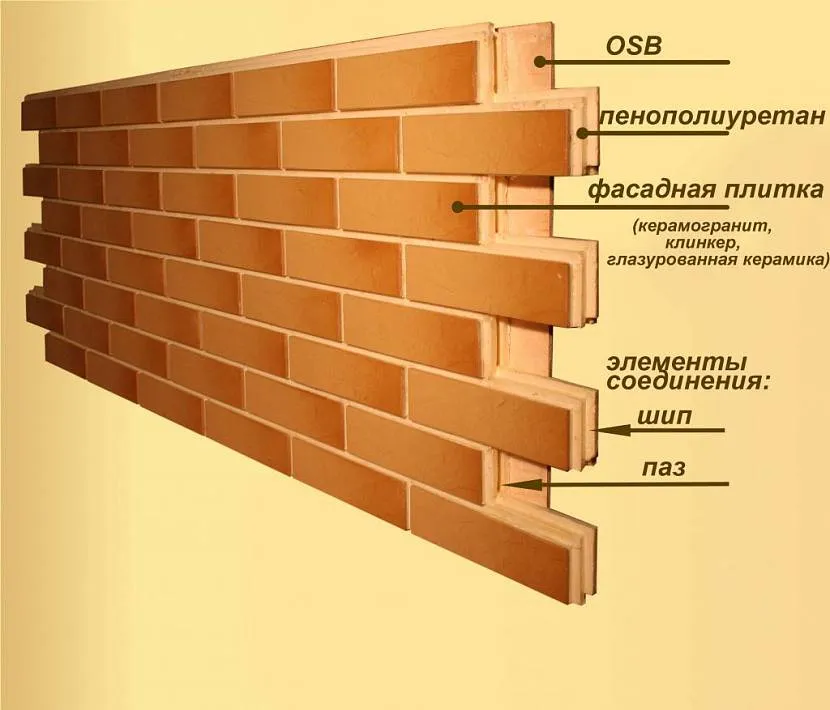

Polyurethane foam slabs have low tear-off holding properties, so they are not used in “wet façade” systems.

But this is a common thermal insulation material for making sandwich panels. The same technology underlies the production of thermal panels for facade cladding. Such a panel is a heat-insulating board with a decorative layer (clinker tiles or stone chips) already applied at the factory. Two types of insulation: polystyrene foam and polyurethane foam. In the first case, the thermal panel is two-layer, in the second – three-layer (OSB or moisture-resistant plywood is used as the supporting base). Two mounting options: on dowels/anchors (open method) or on your own hidden fastening system.

Three-layer thermal panel Source zafasad.ru

Sprayed polyurethane foam is in demand if it is necessary to create a seamless layer of thermal insulation on complex surfaces. Until recently, there was only one technology for applying such a layer - using professional installations working with a two-component composition (mixing occurs during spraying).

Spraying polyurethane foam onto the base of a house Source nauka-i-religia.ru

Now in Russia, for household use, the production of one-component polyurethane foam has been launched, which is produced in an aerosol can with a capacity of 1 liter. As the manufacturers assure (there are two competing companies), insulating 1 m2 with your own hands is much cheaper than concluding an agreement with specialized enterprises that use professional equipment. And this option for insulating a house from the outside is quite attractive if literally 2-3 cm of the thermal insulation layer is missing.

Insulation using sprayed polyurethane foam "Teplis" Source m.2gis.kz

Ecowool

Preparing the adhesive solution

The dry adhesive mixture is poured into a bucket, diluted with water in accordance with the proportions specified in the instructions and mixed using a construction mixer or drill until the composition is homogeneous. Lumps should be especially avoided. After 5-10 minutes, repeat the procedure. The glue is ready.

The glue is evenly applied in a layer 2-3 cm high both in the middle and along the perimeter of the plate. The total surface of the glue should occupy at least half of the entire surface of the insulation sheet.

After the slopes and window sills have been insulated, you can begin gluing the walls.

When installing insulation on a wall, you should avoid its deformation, which leads to loss of functional properties.

Two spatulas are used as tools for applying glue. They are used in the following way: one glue is applied to the second. The glue is applied to the wall, and not to the insulation sheet, taking into account the configuration of the surface (in some places more solution is placed).

The sheets are attached in a T-shape. The slabs are laid with a small gap of 20-30 mm. After installing the sheet, it must be pressed to the level of adjacent slabs. In this case, excess glue will appear and be removed from the surface.

Correct installation is checked using a level and plumb line.

It is important to ensure that the glue does not get into the seams separating the plates; if this cannot be avoided, then this place should be filled with pieces of material or foamed. The distance between sheet joints should not exceed 3 mm

To connect the corners of facades, a gear method of connecting slabs is used

It is important to ensure that a long vertical seam does not form. To prevent it, you can wedge adjacent rows of slabs into the area of adjacent walls

For re-layering, a release should be left on the corners and slopes, and after the glue hardens, when the angle is determined, the foam is trimmed and sanded.

After 3 days, the glue will finally set and the material will reach a stable state.

The better way to insulate a house from the outside - standards for the number of layers

If you follow the regulatory documents, there are two options for how to insulate a house from the outside in terms of the number of structural and thermal insulation layers: two-layer and three-layer. Moreover, in the second case, the external paneling or plaster is not considered an independent layer, although their thermal insulation properties are taken into account. In three-layer walls, the outer (third) layer is the structural material.

Brick cladding with insulation Source pinterest.ru

In addition to this classification, there is also a division based on the presence of a ventilated and non-ventilated layer.

Total: four recommended types of technical solutions for thermal protection of walls. The standards already indicate insulation options depending on the wall materials and thermal insulation:

- brickwork, reinforced concrete (with flexible connections), expanded clay concrete - all types of solutions;

- wooden houses - enclosing structures with two-layer, three-layer walls and a ventilated air gap;

- frame houses with thin-sheet cladding - three-layer walls with thermal insulation in the middle, as well as with a ventilated and unventilated air gap;

- cellular concrete blocks - two-layer walls with brick cladding, as well as with a ventilated or non-ventilated layer.

In practice, for insulating low-rise buildings, such a variety of solutions comes down to the choice between a “wet” or a curtain wall. Although, it is those recommended by the standard that are considered as thermal insulation materials - mineral wool or expanded polystyrene (EPS as an alternative).

But each case has its own preferences.

How to properly insulate a corner apartment of an apartment panel building

A corner apartment has a big disadvantage - its walls freeze more strongly and the room is always damp and cold. Condensation collects in the corners, which contributes to the appearance of fungus, so the corner room requires more insulation than other rooms.

It is, of course, better to insulate it from the outside, but this is not always possible.

In such an apartment, 2 walls at once are exposed to atmospheric influences, and especially carefully it is necessary to insulate their junction points.

Before laying the insulator, the walls are treated with antifungal drugs, allowed to soak well, after which the main work begins. The material is chosen with a vapor barrier film so that condensation does not accumulate in the corner.

Covering walls with the heat insulators discussed above or taking additional measures to conserve heat will help reduce heat loss:

- flush the radiators and thereby increase the degree of heating;

- add heating sections to the batteries;

- reinstall the batteries closer to the cold corner.

In the corner room, it is necessary to install heat-retaining windows or stick energy-saving film on them.

Features of insulating a room in a panel house

The main problem areas of city apartments in panel houses are most often interpanel connections. To ensure sufficiently effective insulation, you must first seal the joints of the panels.

To do this, you need to open the gaps as much as possible using a spatula or other suitable tool and, carefully removing the old filler with your hands, fill the joint with polyurethane foam. This option is considered optimal, quick to implement and effective.

Important! When the foam hardens, you need to carefully trim off the parts protruding from the gap to form an even angle. Subsequent work is carried out in accordance with the general insulation technology.

Features of insulating a room in a brick house

Since the brickwork is well tied at the corners and has no external cracks, there is no need to pre-insulate the joints between the walls.

But at the same time, before starting insulation measures, it is imperative to waterproof the brick wall. First, the walls are cleaned of plaster, and then a layer of deep penetration water repellent, intended for indoor work, is applied to the surface with a roller or brush.

When using this material, it is correct to follow the instructions on the packaging. When the treated wall has dried, you can proceed to installing the heat insulator using the usual technology.

Nuances when processing a balcony

The specifics of insulating a balcony look almost identical to the thermal insulation of the walls inside the building. At the same time, on the loggia you also need to protect the ceiling and floor.

If polystyrene foam is chosen as an insulator, it can be attached to the walls using foam adhesive. The next layer is to install a wooden sheathing. It can be secured with dowels.

The optimal insulation thickness is between 50 and 80 mm.

In addition, you can insulate the balcony before painting. To do this, putty, reinforced mesh and another layer of putty must be applied to the foam plastic. After the surface has dried, it must be coated with a primer and painted. In this case, foam plastic with a density of 25 kg / cubic meter is used. m.

The better way to insulate a house from the outside, depending on the wall material

For insulating a brick house, there are no restrictions when choosing technology. Different options can be considered only depending on the chosen method of finishing the facade:

- Facing brick. This is a classic three-layer wall construction with flexible ties. Even when using polystyrene foam, a ventilated air layer is provided to ventilate water vapor and prevent the wall materials from getting wet.

- Wet facade. You can use mineral wool and polystyrene foam. The first option is preferable - ceramic bricks have higher vapor permeability than foam plastic. And according to clause 8.5 of SP 23-101-2004, the arrangement of layers should facilitate the weathering of water vapor to prevent moisture accumulation.

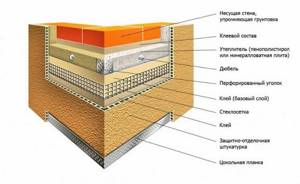

Scheme of a “wet facade” Source deskgram.net

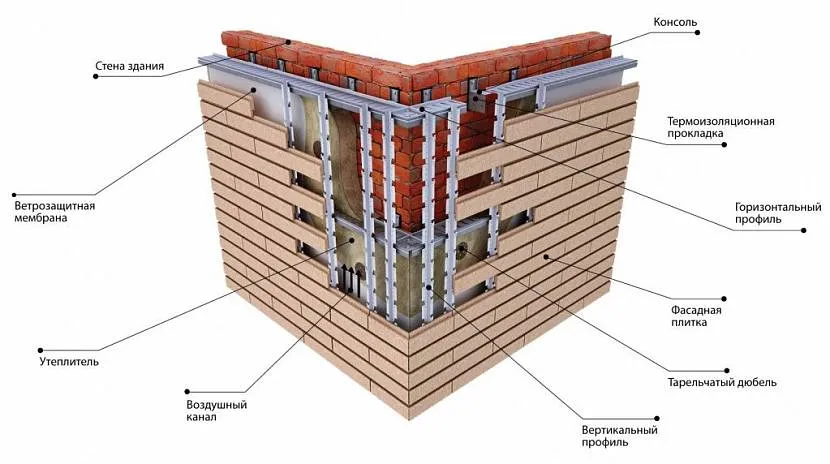

- Ventilated facade. With cladding with wall panels or large-format porcelain tiles on the sheathing. The insulation is traditional for all suspended facades - mineral wool.

Wooden houses (logs or beams) are insulated exclusively with mineral wool using curtain facade technology.

For them, you can find examples of using polystyrene foam and plaster using the “wet facade” method. In this case, a ventilated gap is created between the wall and the foam boards using spacer sheathing. Although in this case the main advantage of the “wet facade” is lost - simplicity of design and installation.

Features of using polystyrene foam as insulation

When securing material from the warm air side, special attention should be paid to safety. It is worth considering several disadvantages of wall insulation with polystyrene foam, which can be combated at the construction or repair stage

These disadvantages include:

- flammability;

- low vapor permeability;

- the need for additional vapor barrier;

- the likelihood of a greenhouse effect occurring indoors with insufficient ventilation.

To prevent the risk of fire, strict compliance with all fire regulations is required. When choosing a material for thermal insulation of the walls of a house from the inside with your own hands, you should give preference to those types that are highly resistant to fire. The flammability group is indicated by the letters:

- NG - non-flammable;

- from G1 to G4 - varying degrees of flammability.

The higher the number on the label, the more dangerous the material is offered. In the store, it is recommended to choose the foam that has the lowest degree of flammability of all those presented. You can additionally consult with the seller.

To prevent the appearance of mold and mildew on the walls, it is necessary to move the point of condensation from the surface of the connection between the wall and the insulation. The thermal insulation material is attached to the wall from the inside with your own hands without any gaps. This way you can avoid problems with condensation.

The most important task when using polystyrene foam as a heat insulator is to ensure the necessary air exchange. If there is insufficient ventilation of the premises of the house, the microclimate is disrupted. There may be problems with humidity and indoor air temperature. To prevent troubles, you need to think about ventilation at the building design stage.

To prevent condensation, use the following techniques (simultaneously):

- a small ventilation gap is provided between the wall insulation and the interior decoration;

- a vapor barrier is attached on top of the insulation;

- carry out measures to install a forced air ventilation system.

The most reliable insulation scheme from the inside

If you take into account all the features of polystyrene foam as a building material, you can use it for the wall of a house without fear. Installing thermal insulation with your own hands requires attention to every detail and adherence to the technology for performing the work.

How to calculate the thickness of insulation

If you look through SP23-101-2004 or a similar but later set of rules SP 50.13330.2012, you can see that calculating the thickness of the insulation is not so easy.

Each building is “individual”. When developing a project and approving it, such thermal calculations are made by specialists. And here a whole range of parameters are taken into account - the characteristics of the region (temperatures, length of the heating season, average number of sunny days), the type and area of glazing of the house, the thermal capacity of the floor covering, the thermal insulation of the roof and basement. Even the number of metal connections between the wall and the cladding matters.

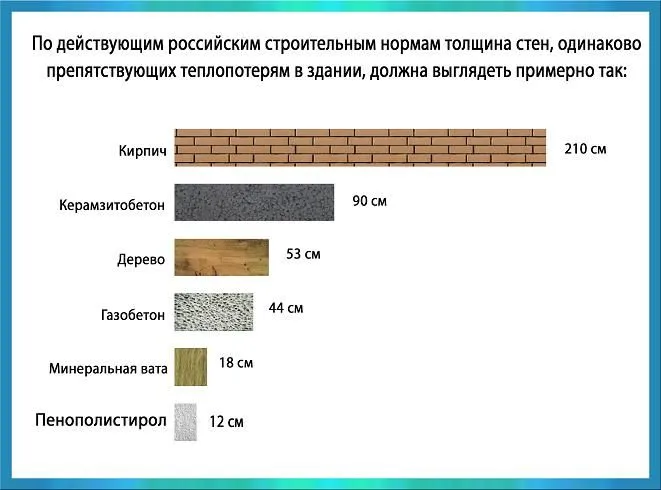

But if the owner of a previously built house decides to insulate it (and the new standards introduced in 2003 are much stricter than the old ones), then he will have to choose between three parameters of the “standard thickness” of insulation - 50, 100 and 150 mm. And here the accuracy of calculations is not needed. There is a diagram that shows the equivalent dimensions of the thickness of different materials (in average form), the wall of which will meet the new requirements for thermal protection.

Only a house made of aerated concrete blocks with a thickness of 45 cm does not need insulation Source legkovmeste.ru

And then it’s simple. They take the thickness of a wall made of a certain material and see how much is missing from the standard. And then they calculate in proportion what thickness of the insulation layer of the outside wall of the house should be added. Taking into account that a wet façade also has a layer of plaster, and a ventilated façade has an air gap, plus the interior finishing of the façade walls, you can be sure of sufficient thermal protection.

And the issue of insulating the roof, floors and choosing good windows is decided separately.

It’s even easier to use one of the many online calculators. The figure here, of course, is approximate, but rounded up to the nearest standard insulation thickness, it will give the required result.

When is insulation necessary?

If we are talking about a wall made of blocks with a thickness of 375 mm, then such a structure will be quite capable of retaining heat. All you need to do is install the outer cladding yourself.

But this is only a general rule. In reality, it's not that simple. In addition to thickness, what also matters here is how well the masonry was made and whether heat escapes through its seams.

Heat can escape through the seams between blocks

An important factor is the strength of the material used. The higher it is, the worse the thermal insulation properties of this product will be.

But this is particular. At the same time, there are also common cases when insulation of a foam block house is simply necessary.

Let's list them:

- the use of high-density foam blocks in the construction process - it is denoted by the Latin letter “D”. In this case, we mean the value of this parameter equal to 500 or higher;

- the width of the blocks is less than 300 mm - in this case, the building constructed from them will also have to be insulated;

A house built from such elements cannot do without insulation.

- if the load-bearing frames of buildings are filled with foam concrete products;

- You will have to think about how to insulate a wall made of foam blocks even if the builders made mistakes - for example, using ordinary cement mortar for masonry rather than special glue. It is also a mistake to create thick seams.

The seams should not be thick

How to properly install insulation on a facade

Before installation, the facade must be prepared: cleaned of old finishes, removed dirt and dust, dismantled hanging elements of engineering systems, removed ebbs and canopies (you will still have to replace them with wider ones), remove signs, plates and façade lamps. Then the surface of the wall must be strengthened - cracks and chips must be repaired, crumbling areas must be cleaned, and a deep penetration primer must be applied.

Application of primer composition Source rmnt.ru

For reliable fastening of polystyrene foam or rigid mineral wool mats in a wet façade system, the wall surface must be as smooth as the unevenness can be smoothed out with an adhesive solution. If the height difference is up to 5 mm, the solution is applied over the entire insulation slab, with unevenness from 5 to 20 mm - along the perimeter and in the form of “cakes” on 40% of the slab surface.

The first row of slabs is mounted with emphasis on the starting bar, which also sets the horizontal level. The second and subsequent rows are placed with a vertical seam shift (at least 200 mm), leveling the surface of the insulation in the area of the joints so that the height difference is no more than 3 mm. When insulating the walls around the openings, make sure that the seams of the slabs do not intersect in their corners. Each slab is additionally secured with umbrella dowels at the rate of 5 pcs. per 1 m2.

Before applying plaster, the surface of the slabs is reinforced with fiberglass, fixed in the middle of a layer of adhesive solution with a total thickness of 5-6 mm.

The density of polystyrene foam is chosen to be 25-35 kg/m3.

Materials

The choice of materials for insulating the walls of a wooden house should take into account not only the thermal conductivity coefficient, but also the safety requirements for residential premises, namely:

- comply with fire safety class;

- not have any toxic secretions hazardous to health;

- have sufficient strength.

The most commonly used insulation materials include:

- Mineral (basalt) wool. This material has good thermal insulation properties (thermal conductivity coefficient 0.045-0.055 W/(m deg)), but at the same time requires additional work to protect the insulation from moisture. Cotton wool is highly hygroscopic, which reduces its quality characteristics and can lead to mold and rotting of wooden structures.

- Expanded polystyrene. It can be represented by cheap polystyrene foam or higher quality and more expensive extruded polystyrene foam. The thermal conductivity coefficient is lower than that of mineral wool - 0.037-0.043 W/(m deg). More protected from moisture, but it also requires waterproofing

The use of the insulation materials discussed above will require painstaking work on the installation of the so-called thermal insulation cake. Such a pie consists of several layers, the main one of which will be the insulation itself, surrounded on both sides by vapor and waterproofing films. It is also recommended to provide ventilation sheathing during installation, and the entire thermal insulation system is covered with material for finishing.

Video description

Visually about mineral wool insulation in the video:

Attention. In the “wet facade” system, the insulation is installed in only one (!) layer. A vertical surface made of two layers of “soft” slabs loaded with plaster behaves unpredictably, especially with changes in temperature and humidity conditions. Do not be fooled by arguments that the second layer of slabs overlaps the seams of the first and eliminates “cold bridges”.

The ventilated facade uses rigid mineral wool mats with a density of 80 kg/m3. If the surface of the mats is not laminated, then after attaching them to the sheathing, the surface is covered with either fiberglass or a vapor-permeable membrane.

The spacing of the lathing is chosen 2-3 cm less than the width of the mats. In addition to fastening to the sheathing, the insulation is additionally fixed to the wall with umbrella dowels.

The size of the air gap between the insulation and the cladding should be in the range of 60-150 mm.

Important. The size of 40 mm is standardized for non-ventilated air spaces.

To ventilate the layer in the cladding, inlet openings are installed in the base area and outlet openings are installed under the roof eaves. The total area of the holes must be at least 75 cm2 per 20 m2 of wall.

Ventilation grilles in the wall Source tproekt.com

What else to pay attention to

It would not be superfluous to say that insulation must be carried out comprehensively. In our case, when performing work on the indoor side, it is recommended to insulate (with good vapor barrier) also the floors and ceiling, at least in small areas near the problem wall. If there is a window on the wall, then it is very important to make good thermal insulation of the slopes and the area around the window sill.

In order to maximally preserve the integrity of the insulation and especially the vapor barrier sheets, it is better not to place sockets, plumbing outlets, built-in lamps and other mortise elements on this wall.

Sealing a wall insulated in this way (and there may be several of them in a room) sometimes causes a sharp increase in air humidity in the home. Therefore, care must be taken to ensure ventilation.

The solution is to install an exhaust fan on the exhaust duct, install supply valves on the wall or on the window, and maintain the required gap under the interior door leaves, which will ensure normal air flow.

In what cases is this relevant?

Insulating walls from the inside certainly improves the thermal performance of a house. But this is an unconventional technology, because usually they try to do external insulation. However, there are situations when there is no other choice.

Internal thermal insulation is recommended only when external insulation is not possible

This option is also relevant for apartment buildings. It helps not only to increase the comfort of your home, but also to prevent the occurrence of troubles such as mold or mildew.