Ceiling insulation using mineral wool

Who wants to pay to heat the street? It is unlikely that there will be at least one person willing. That is why most homeowners, when preparing for winter, consider insulating the ceiling with mineral wool a priority. This material combines excellent fire protection, environmental, heat, sound insulation and antifungal properties.

- Characteristics

- Material thickness

- Prices

- Installation

- conclusions

The article will discuss all the main characteristics of basalt wool, and also provide recommendations for carrying out installation work with your own hands.

It is made at a temperature of 8000 ⁰C from the melt of various rocks, due to which it has good fire-fighting properties, is also very resistant to moisture and is excellently ventilated. All materials that make up mineral wool are environmentally friendly, therefore, as insulation for the ceiling, it is completely safe for humans. The thermal conductivity coefficient of stone wool is 0.046 W/m*⁰С, which is one of the best indicators among known thermal insulation materials.

Cost of insulation

When making an estimate, in addition to the prices for mineral wool and installation work, you need to take into account the costs of steam and waterproofing - approximately 40 rubles per square meter, and payment for installation of the frame base - about 100 rubles per sq. m. m. if you have your own material. If it is not there, the cost will rise to 170 rubles.

Installing mineral wool 10 cm thick on average costs 100 rubles per “square”. If the insulation is thicker, the price will increase by 1.5–2 times, since it is more difficult to install.

But all these expenses will later pay off in heating. If you insulate the ceiling with mineral wool, heat loss can be minimized even in cold regions.

Types of insulation for ceilings and recommendations for selection

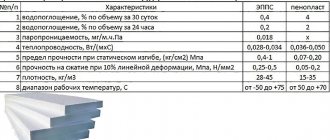

It is slightly ahead of polystyrene foam with its 0.041 W/m*⁰С, but it has problems with fire safety and toxic emissions.

Calculation of the required thickness

If you need to calculate the size of the insulating layer of the ceiling in a private house with a cold attic, use the formula δ = R*λ, where δ is the required thickness, R is the coefficient that determines the amount of heat transfer resistance, and λ is the thermal conductivity coefficient of the material. For the Moscow region, for example, R = 4.15 m2*⁰С/W. Knowing this, we calculate: 4.15x0.046 = 0.191 m. It turns out that mineral wool 20 cm thick or two layers of 10 cm each is suitable. For a multi-story concrete building it should be 2-3 times less.

The cost of ceiling thermal insulation may depend on a number of factors: density, thickness and number of layers, manufacturer, release form, installation method.

In order to somehow understand the flow of this data, let’s take the main characteristics of basalt wool. Traditionally, rolled thermal insulators are cheaper than slabs, since the manufacturer has lower costs for such production. Density determines how much material is spent on producing the same volume. For example, let’s compare the prices for ceiling insulation in a private house when using materials from different manufacturers with similar characteristics:

- Basswool: density – 40 kg/m3, cost – 1512 rub/m3, release form – slabs 1200x600 mm;

- Izol: density 40 kg/m3, cost – 1667 rub/m3, release form – slabs 1000x1600 mm;

- Isover: density 40 kg/m3, cost – 1288 rub/m3, release form – roll 7000x1220 mm.

The average price for ceiling insulation work can range from 160 to 600 rubles. per m2 depending on the number of layers and technology.

Laying, installation procedure

The first method is carried out at the stage of building a house and is preferable.

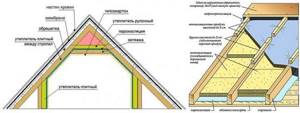

Ceiling insulation scheme from the outside:

- a sheathing is sewn onto the rafters or beams from below, onto which a vapor barrier or membrane is attached;

- Mineral wool is placed on top in the space between the beams;

- on top is a hydraulic barrier, after which the roof or floor is installed.

The second method - installation from the inside, is used when the ceiling is insulated with mineral wool with your own hands after completion of construction for the purpose of additional heat or sound insulation of the room.

The order of work in this case is as follows:

- a vapor barrier or membrane is sewn onto the ceiling;

- a wooden or aluminum frame is mounted taking into account the dimensions of the mineral wool;

- a thermal insulator is installed;

- a vapor barrier or membrane is again sewn underneath.

The inconvenience of the second method is that this insulating material does not retain its shape well and constantly crumbles, so insulating the ceiling in a wooden house yourself is quite problematic; at least one assistant is needed.

- The cost of work can be reduced by using a vapor barrier instead of a membrane, but at the same time it is necessary to leave an air gap of 2-3 cm on top. In case of moisture penetration, this will avoid loss of insulating properties.

- It is much easier to insulate a ceiling from the outside than from the inside, so if you have the opportunity to do everything at once, do not put it off “for later”, then you will save much more resources.

- The density of mineral wool should be in the range from 40 to 75 kg/m3.

Regardless of whether we are insulating a wooden or concrete ceiling, whether this happens in a residential or utility room, you must strictly follow the installation technologies described above. Violation can lead to moisture accumulation in supporting structures, which will significantly reduce service life.

Despite the widespread use of mineral insulation materials, there are also negative reviews about their use. He supposedly insulated the balcony or the floors, but there was still no heat. The reason may lie not only in violation of simple installation requirements (large cracks, cold bridges), but also in the fact that the thickness of the mineral wool was chosen incorrectly.

Characteristics and manufacturers

Mineral wool is a heat-insulating material with a fibrous structure. Based on the main natural component, the following types of insulation are distinguished:

- Basalt (stone). The basis is rock melts erupted from the depths. The composition includes gabbro or diabase, mixture. Mineral filler – dolomite, limestone, clay. Additives are needed to ensure product fluidity. The binder is a formaldehyde substance made from resins (no more than 2.5-10%).

- Slag. The basis is melted blast furnace slag. It has a fine-fiber structure (thickness 4-12 microns). Waste from blast furnaces during iron smelting is used as slag. This base ensures high strength of the material.

- Glass. The basis is melts of glass, sand, broken glass. Fillers: dolomite, soda, limestone, borax. The material has high hydrophobic properties and is durable and resistant to stress.

Component ratio: 80% – natural materials, 20% synthetic binder.

Product labeling depends on the density of the insulation:

- P-75. Cotton wool density 75 kg/m3. Application: insulation of external horizontal surfaces, pipelines, heating networks and other highways.

- P-125. Density 125 kg/m3. Application: insulation of unloaded surfaces of any location, floors, ceilings. Insulation is also used as a middle layer in three-layer wall panels of low-rise buildings made of brick, gas, foam, and expanded clay concrete.

- PZh-175. Scope of application: insulation of walls, ceilings made of profiled metal sheets, reinforced concrete structures.

- PPZh-200. The scope of application is the same as that of the PZh-175 brand with additional provision of fire resistance of engineering and building structures.

Pros and cons of insulating the ceiling with expanded clay in a private wooden house

Depending on the shape of the material, the characteristics and scope of application of the product differ:

- basalt slabs have a high density and are used in areas with increased load, under concrete screeds;

- roll products are indicated for insulation of unloaded structures;

- Stitched mineral wool mats have found application in insulating the surfaces of production equipment with temperatures up to 400 C.

Established characteristics of mineral wool:

- Strength. 0.08-0.6 kg/cm2. The brand of insulation matters.

- Density. 35-100 kg/m3. The average size is 0.6 m2, low weight facilitates the installation of insulation.

- Shrinkage. It is negligible and does not amount to a fraction of a percent. The indicator guarantees long-term preservation of the positive properties of the product: fire resistance, sound absorption.

- Thermal conductivity. The average coefficient is calculated based on density indicators and is 0.036-0.060 W/mG. During the first years of operation, due to moisture absorption, thermal conductivity can increase up to 50%.

Important! The thermal conductivity of mineral wool is second only to expanded polystyrene derivatives. The price has been reduced several times.

- Frost resistance. Depends on the manufacturer. The parameter is not fixed by GOST, TU.

- Water absorption. The average is 6-30%, subject to complete immersion in water. The moisture level of the dry material is 1%.

- Vapor permeability. If there is insufficient or complete absence of vapor barrier materials, the indicator is 1.

- Fire resistance. The material is marked NG, therefore it is used for insulating surfaces up to +400 C. The fiber begins to melt after 2 hours of exposure to fire at a temperature of 1000 C.

- Noise insulation. Acoustic slabs have an indicator of 0.7-0.9.

- Toxicity. As a result of changes in the component composition, raw materials and finished materials do not pose a health hazard. Mineral wool belongs to the 3rd group of carcinogenic substances, which includes coffee, tea, and chocolate.

Manufacturers claim a 50-year service life of the material without compromising practical and performance qualities. But it all depends on compliance with installation technology, the use of waterproofing, conditions of use, and other things.

Proven and reliable brands/manufacturers:

- Rockwool;

- Paroc;

- Isover;

- Knauf;

- Ursa;

- IZOVOL;

- Beltel.

The cost of the material is from $2 per m2. Depends on the brand, type, quality indicators of the product.

How to choose the right insulation thickness?

Since the thickness of mineral wool affects the thermal characteristics of the thermal insulation system, it should be selected taking into account the climatic conditions of the region of residence, air humidity, and technical characteristics of the insulated surface. The averages are approximately as follows:

- For an external wall, where it is necessary to achieve the standard indicator of the material’s resistance to heat transfer, the recommended thickness of mineral wool should be from 8 to 10 cm.

- For basements (walls, ceilings), surfaces in contact with the ground - the layer of insulating material should be from 6 to 15 cm.

- The thickness of mineral wool for the floor in a heated room is at least 6 centimeters, with a maximum thickness of 15 cm.

- The thickness of mineral wool for the ceiling of a house in contact with an unheated attic should range from 10 to 16 cm.

- Pitched roofs should be insulated with thermal insulation material with a thickness of 15 to 30 cm.

Insulation for the ceiling - in whose favor is the choice?

The thickness of mineral wool slabs should also be selected taking into account the climatic conditions of residence.

It is quite natural that the thickness of mineral wool affects its cost, so choosing insulation of a “universal” thickness cannot be considered the optimal solution. Since this will either lead to a large overexpenditure of funds, or the created thermal protection system will not provide the necessary resistance to thermal conductivity. When performing any installation work with mineral insulation, it is imperative to use personal protective equipment (respirators, long sleeves).

Why and how to insulate the ceiling

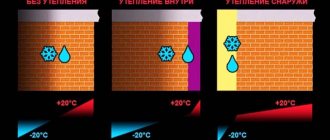

Some owners of residential buildings mistakenly believe that only the floor and walls need to be insulated.

- Typically, the temperature in the attic is much lower than the temperature in the room. And thus, 20.0% of thermal energy can be lost

- Another reason for insulating the ceiling is the direct threat of the formation of biological factors. Due to condensation that appears at different temperatures inside the room and on the upper surface of the ceiling, the level of humidity increases, which is an ideal environment for the development of fungi and mold.

- Creating sound insulation is another reason to start insulating the ceiling structure. Moreover, mineral wool is excellent for this purpose with its soundproofing properties

An additional reason for insulating ceilings can be a consequence of redevelopment in the apartment, in which loggias or balconies were combined with living space. After redevelopment, a large volume of cold enters through them.

By insulating the ceiling, you can achieve results for all these arguments simultaneously. But for this it is necessary to determine one of two types of insulation work:

- Internal ceiling insulation

- Insulating the ceiling from the outside

In both situations, the efficiency characteristics, complexity and labor intensity of the process may differ. Much depends on the choice of insulation, for example, polystyrene foam or mineral wool, which is better suited for the roof of the house, which will be easier to install, it’s up to you to decide. And besides, this or that method is used to achieve a specific goal and eliminate a specific problem.

Insulating the ceiling with mineral wool from the outside

Since mineral wool does not have a high degree of adhesion, insulation with it is carried out without additional surface preparation. The only thing you need to prepare is a vapor barrier device.

This method is more suitable for insulating ceilings in private residential buildings, where there is more free access to the outer surface of the ceiling structure or, for example, for insulating the ceiling of a bathhouse with mineral wool.

- It is necessary to lay a layer of vapor barrier material over the entire area of the insulated surface, which will protect the insulation structure from destruction. If there are lags, a vapor barrier material is placed under them

- Logs can be made from wooden slats of small thickness (10-12 cm), since cold bridges are formed at their locations, leveling the efficiency and heat capacity of the material. You can also use a metal profile for this purpose. The height of the resulting sheathing should correspond to the thickness of the insulation

- Mineral wool slabs are laid in the spaces formed between the joists, or a roll is rolled out. The tightness of the material in individual areas between the slabs should be maximum

Note! Particular attention must be paid to the installation of joists in the corner parts of the ceiling structure, where significant islands of cold may remain. Do not overly clutter these areas with joist structures, leaving more space for insulation.

- To securely fix the insulation, you can use special fastening dowels with a wide head diameter, the so-called mushrooms for fastening the insulation, which are attached at the joints of the material

- The final stage is laying the waterproofing layer.

Special cases

Let's look at a few special cases

In an apartment building

Apartments on the top floors of apartment buildings are known to be cold. Especially if the builders performed thermal insulation of the ceiling in violation of the technology. Any independent work in the attic of an apartment building is illegal; it is better to spend time complaining to the construction or operating organization and forcing them to fulfill their obligations to ensure normal temperatures. But the claim process is not a quick process, and the rooms are already cold today.

However, you can quickly and inexpensively insulate the ceiling from the inside and do it yourself. You will have to “please” your neighbors by drilling numerous holes in the ceiling for dowels, but the result is worth it.

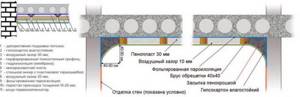

Ceiling insulation in an apartment building

Another drawback will be a reduction in the height of the rooms by 4-5 cm, and around the perimeter of the ceiling - up to 40 cm. But heat is more expensive.

A system of guides made of wooden slats or a metal profile 4 cm high is installed on the warm ceiling. Sheets of foam plastic 30 mm thick are laid between them and attached to the ceiling with disc-shaped dowels.

After this, a foil vapor barrier is attached along the lower edges of the guides. Slopes with a radius of 40-40 cm are made along the perimeter, ensuring a smooth connection between the planes of the lines of the false ceiling and walls. At the last stage, sheets of moisture-resistant drywall are attached. Curvilinear slopes are covered with foam chips, starting from the short sides of the room. Ecowool is also suitable for this.

Attic

A residential attic must be insulated. Insulation of a non-residential attic will not hurt either - this will be an additional barrier to the cold on the residential floors. How to reliably insulate the ceiling in a residential attic? The most common scheme is insulation with mineral wool or polyurethane foam slabs laid between the rafters. For vertical walls, you will need to take special cotton wool with a low shrinkage coefficient.

Attic thermal insulation diagram

Particular attention will need to be paid to vapor barrier. In an already built house, the space under the ridge is not always available. In this case, ecowool can help out - it can be blown through temporary technological holes, which are then sealed with polyurethane foam.

Garage and bathhouse

The roof of a garage is often supported by metal I-beams. When installing guides for insulation, drilling holes from bottom to top in a steel beam is inconvenient, so the method shown in the figure is used. Thermal insulation boards are laid in two overlapping layers. Instead of fibrous materials, you can try ecowool. In this case, you can do without foil insulation, and instead lay kraft paper on the false ceiling.

What layer of insulation is needed for the ceiling?

It is necessary to prevent moisture from entering the attic space as a result of condensation.

Insulating the ceiling with mineral wool from the inside

Internal ceiling insulation is carried out in two ways:

- Fastening the insulation with a special adhesive composition

- Laying mineral wool between the ceiling and suspended structure

In the first case, it is necessary to clean the ceiling surface from finishing materials, which ensures reliable adhesion of the adhesive. Gluing is carried out with dense placement of insulation mats.

In the second option, you first need to equip the frame for the suspended ceiling using metal profiles. Next, using a screwdriver, sheets of drywall are attached to the profiles. A vapor barrier film and mineral wool in mats are laid on top of them.

Features of insulation

Mineral wool has become a universal material for insulation. But it is important to understand: the result largely depends on a competent approach to using the material.

If the work algorithm is violated, the insulation is not fixed correctly, the insulation layer will not be effective.

The best solution is to entrust the installation of mineral wool to professionals.

The optimal solution would be to entrust the laying of mineral wool to professionals.

Some owners manage to carry out all the work themselves and achieve the desired result. To do this, you must carefully follow the recommendations and follow step-by-step instructions. Reliable installation, tightness of fastenings, and a clear sequence of actions are ensured. Remember that mistakes during insulation provoke losses, since the investment of money is no longer justified.

When the algorithm is followed, insulation with mineral wool is beneficial. You can save a lot of money since it is a budget option. Less time is spent, while the desired result is achieved.

Thickness of mineral wool for ceiling insulation

The choice of insulation thickness depends on the material from which the ceiling is made and what type of insulation is planned to be produced.

- When installing insulation on concrete ceilings with high thermal conductivity, it is better to use mineral wool 10-15 cm thick

- If the house has a heated attic space, then in this case it is allowed to use insulation with a thickness of 60-80 mm

- Ceilings in houses with a pitched roof structure made of a material with high thermal conductivity must be insulated with mineral wool with a thickness of up to 30 cm

Moreover, these parameters are not fixed, since the choice of mineral wool thickness is influenced by the structure of the material, as well as its density. With a density of 50 kg/m3, you should choose insulation with a greater thickness. If the density of the material is 100-150 kg/m3, then the thickness can be chosen half as much.

Cost of ceiling insulation with mineral wool

Prices for ceiling insulation with mineral wool depend on several parameters:

- Type of insulation – roll or in slabs. The latter usually costs more

- Thickness of mineral wool - the higher this indicator, the more expensive the insulation will be

- Density of the material – mineral wool with a higher density will be more expensive

Advantages and disadvantages of mineral wool

The quality of insulation depends on the type of raw material. In the production of mineral wool, rock and synthetic binder fillers are used.

Thanks to the components, the material has high strength, low thermal conductivity and advantages such as:

- Fire safety. The material does not burn and does not emit harmful substances when heated.

- Resistant to temperature changes. Cotton wool does not deform when heated/cooled.

- Chemical, biological resistance. Bugs, rodents, and mold do not grow in mineral wool. Fibrous material is difficult to destroy by exposure to alkalis and acids.

- Vapor permeability ensures the free passage of air masses. This is especially important when insulating wooden buildings inside and outside.

- Noise insulation. Fiber insulation absorbs noise well, neither letting it in nor letting it out.

- Easy to install. The products are produced in sheets and rolls - this makes it easier to lay and fasten materials on a plane.

- Versatility. Sheets of products can be attached outside and inside buildings.

- Durability. If the work technology is followed, the insulation will last at least 30 years.

- Cheapness. One of the main advantages of the material. Mineral wool as insulation significantly reduces the cost of current or major repairs.

Another advantage is the light weight of the material. Thanks to this property, mineral wool can be used on dilapidated floors and in apartments - additional insulation with the material does not violate building standards and does not require permits.

The product's disadvantages are minimal:

- When laying out, the material must be protected from water. Cotton wool absorbs moisture well, so water-repellent compounds and high-quality waterproofing are useful.

- Compared to foam plastic and other lightweight materials, mineral wool has more weight.

The disadvantages are offset by the affordable price, practicality and durability of the material. In addition, not every insulation is unpleasant for rodents, like mineral fiber, and this is one of the main conditions for the owner of a private house.

Mineral wool insulation is the best choice for ceiling insulation

Particularly effective when insulating ceilings are materials based on mineral wool, which, having high heat and sound insulation characteristics, also have other positive qualities, thanks to which their use in premises, and above all, residential ones, is absolutely safe. This:

Ceiling insulation with mineral wool

- environmental friendliness of the material;

- absence of toxic substances in the composition;

- high fire safety;

- preventing the appearance of condensation, and, as a consequence, the development of fungi, mold and other microorganisms;

- durability;

- light weight;

- a variety of types of mineral wool products, which are produced in the form of rolls, slabs, and can also have a special foil layer, which simultaneously reduces thermal conductivity and protects the insulation from the influence of moisture.

Having given preference to Rockwool stone wool, it will be much easier to choose the appropriate material, since the product line of this manufacturer is quite wide and the appropriate product is used to insulate various building structures.

If you have work to insulate the ceiling, you should pay attention to Light Butts and Roof Butts.

To insulate the ceiling, our experts recommend:

Rockwool LIGHT BUTTS SCANDIC

Rockwool Acoustic Butts

URSA GEO M-11

About mineral wool

Insulation with mineral wool in the Russian Federation is breaking all popularity records: the material is inexpensive and easy to work with. This is explained primarily by large reserves of easily accessible raw materials and production technology that has been developed over many decades. The disposal of blast furnace slag in the USSR had to be taken care of even during the industrial leap of the first five-year plans, and for a breakthrough into space, thermal protection for return capsules was developed based on fibers from melted heat-resistant rocks. So “modern” methods of producing slag wool and stone (especially basalt) wool are actually not that new.

Professionals especially like mineral wool: it does not require expensive special equipment, but there is a wide range of special fasteners and accessories for it on sale. As a result, the ceiling area is up to 20-25 square meters. m can be insulated in less than 1 work shift, or even in 2-3 hours, it depends on who knows how. How it looks technologically can be seen in the video below.

Video: example of ceiling insulation with mineral wool

https://youtube.com/watch?v=_rdfDyEej6w

After reading what follows, you may have a question: where is the membrane between the insulation and the ceiling? It is quite possible that in this case it is not needed if the attic and roof are already insulated; Why do the owners have to shell out too much?

More attention should be paid to the following precautions when working with mineral wool:

- The standard electrical wiring is rolled into a coil and hangs on the wall.

- Judging by the fact that a temporary light bulb is used for working lighting, the room is completely de-energized, and its wiring is disconnected at the nearest junction box or at the input panel - this is absolutely correct and absolutely necessary.

- The master puts on a full set of personal protective equipment (PPE): special overalls, gloves, goggles, and a respirator. For an amateur master, this is an important point, because... Quite expensive PPE will have to be used once.

It is already clear here that mineral wool is not without its drawbacks: it is a group 3 allergen and carcinogen, i.e. Suitable for residential premises, but it is necessary to work with it using PPE. In addition, which all manufacturers and sellers without exception are wisely silent about, under the influence of even insignificant amounts of moisture vapor and its own weight, mineral wool shrinks irreversibly, as a result of which its thermal conductivity drops by 50% in 3 years: air gaps in the insulation are the same thermal bridges , like metal jumpers, only based on microconvection. Gaps between slabs in 5% of the insulated surface area increase heat loss by 30-35%

This leads to another unpleasant circumstance: the simplicity of working with mineral wool is apparent. When cutting slabs/rolls to size, you need to give an overlap (usually 20-40 mm) so that the slabs fit tightly into the openings without sticking out, as on the right in the figure, but also so that further cracks do not appear due to shrinkage. Perhaps this is only based on experience, because... the properties of the material vary significantly from batch to batch.

Correct and incorrect installation of thermal insulation

Finally, the thermal conductivity of brand new mineral wool significantly depends on its humidity - in the direction of deterioration. An increase in air humidity in a room insulated with mineral wool from 60% to 85% leads to an increase in heat loss by 10-12%. Therefore, in further presentation, we, still focusing on mineral wool as the most popular insulation, will give, where possible, recommendations for replacing it with something better.

Note: Also take a closer look at the mounting jig (circled in green on the left in the figure). If you use a propylene linen cord instead of a fishing line, the conductor can be left permanent. Then there will be no need for special fasteners and, when installed on the ceiling and surfaces with a negative slope, sagging in the middle and corners of the slabs will be eliminated.

How to correctly calculate the thickness of insulation for a ceiling?

If, after taking measures to thermally insulate the ceiling structure, the result is not satisfactory, there is only one reason - the incorrectly selected thickness of Rockwool Roof Butts insulation, the characteristics of which are stable. Incorrectly processed joints with external walls, the appearance of cold bridges due to errors in the installation of the frame, and other shortcomings will also certainly have an impact.

Mineral wool slabs

The thickness of the insulation must be calculated based on several indicators:

- thermal conductivity coefficient of insulation;

- thermal resistance of the ceiling, which is determined by two indicators: the thickness of the material and its thermal conductivity (if different materials are used, then their thermal conductivity indicators are summed up);

- calculated temperature indicators of the external and internal surfaces of the ceiling;

- design features;

- climatic standards.

The calculations are based on the value according to which the thermal conductivity coefficient of the material should be maximum 0.24 W/m²·K, which corresponds to 10-20 cm of thermal insulation layer made of mineral wool. When choosing insulation, experts recommend focusing on a thermal conductivity value of 0.04 W/m²·K.

Slab insulation

It is this type of insulation that is most popular among other thermal insulation options. This is due to its availability, versatility and ease of installation.

Mineral wool

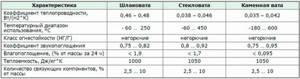

Depending on the raw materials used, basalt (stone), slag and glass wool are distinguished. Thermal conductivity, regardless of the type, is almost the same (from 0.035 to 0.048 W/mK). There is a significant difference in density, fire resistance, environmental friendliness and water resistance.

The lower the thermal conductivity coefficient, the better!

- Glass wool . Retains working properties at temperatures up to +450°C, weight of one cubic meter is 130 kg. It is absolutely non-flammable (doesn’t even smolder), doesn’t cake, dampens vibration well and absorbs noise. Disadvantages: absorbs moisture, including steam; once sufficiently saturated, it thickens and loses all useful qualities (it is impossible to dry); difficult to install (brittle, crumble, causes skin irritation after contact). Modern glass wool-based insulation is more environmentally friendly and comfortable to use. Price – 2500 rubles per m3.

- Basalt (stone) wool . The heat-resistant material (up to +700°C) is almost twice as heavy as glass wool (a cubic meter weighs 220 kg). It is relatively moisture resistant, if it gets a little wet it does not lose its properties, it is environmentally friendly, and does not cause skin irritation during installation. The main disadvantage is the price - about 1000 rubles per 0.15 m3.

- Slag . The most dense insulation, the mass of m3 is 400 kg. It retains its performance characteristics at temperatures up to +250°C; if heated to 300°C, it begins to melt. It is elastic, fits well on curved surfaces, and if the standards of use are observed, it will last more than 50 years. Cannot be used inside residential premises or on metal floors with high humidity.

Tips from our specialist on choosing mineral wool and proper installation:

Slab polystyrene

Foam plastic is a lightweight, affordable and cheap insulation material, durable enough for use on any ceilings, completely moisture resistant, easy to install and has low thermal conductivity (0.04 W/mK).

But there are three significant drawbacks that make the use of polystyrene foam in residential premises undesirable. Polystyrene foam practically does not allow air to pass through (vapor permeability 0.05 mg), it is flammable and toxic.

Cost from 2000 rubles per 1m3.

Penoplex

An improved version of regular foam, often called extruded polystyrene foam. Its porous structure resembles polyurethane foam, with the difference that the cells in it are much smaller - they are almost invisible. Penoplex does not crumble, it is much denser and more elastic than ordinary foamed polystyrene, but is not without all its disadvantages. Thermal conductivity is about 0.03 W/mK, the price per cubic meter is 4,500 rubles.

Table: Comparison of properties of insulation for ceilings

| Characteristics | Light Butts Scandic | Acoustic Butts | Roof Butts N Extra |

| Density, kg/m3 | 35–45 | 45 | 115 |

| Dimensions, mm | Length 800, width 600, thickness 50 - 100 | Length 1000, width 600, thickness 50–70; 75; 80–200 | Length 1000/1200/2000/2400, width 600/1000/1200, thickness 40–200 |

| Flammability group | NG. Fire hazard class - KM0 | NG | NG |

| Thermal conductivity | λ10 = 0.036 W/(m K) λ25 = 0.037 W/(m K) | λ10 = 0.034 W/(m•K) λ25 = 0.036 W/(m•K) | λ10 = 0.037 W/(m K) λ25 = 0.039 W/(m K) |

| Water absorption when partially immersed, no more | 1.0kg/m² | 1.5 % | 1.0% |

| Acidity module, not less | 2,0 | 2,0 | 2,0 |

Also, when calculating the thickness of the insulation, the chosen option for carrying out thermal insulation work should be taken into account, which can be:

Of course, in a city apartment there is no choice, but in a private house with an attic space, the option of insulation from the outside, that is, the attic, is often used. The complex option must be used in cases where it is necessary to achieve maximum effect: it is used mainly in baths or saunas.

Properties and application features of the material

The main property that determines the effectiveness of a particular insulation is the thermal conductivity coefficient.

It characterizes the heat loss occurring through a layer of material 1 m thick in an area of 1 m2 for 1 hour with a temperature difference on opposite surfaces of 10 ° C.

For various forms of mineral wool, this figure is 0.03 – 0.045 W/(m*K).

A distinctive feature of fiber insulation is the dependence of their thermal insulation properties on moisture content.

When wet, droplets of water envelop the fibers and gradually penetrate into the volumetric structure, gradually displacing air from there.

An increase in the amount of water inside, between the fibers, leads to a sharp drop in thermal insulation characteristics. The situation is further aggravated by the fact that water that gets inside is extremely difficult to remove outside.

The insulation can absorb up to 70% of its mass in water. Naturally, under these conditions, the efficiency of its work will tend to zero.

Despite the criticality of getting wet, the scope of application of mineral wool is extremely wide. When building a house, its use is possible almost everywhere where direct contact with water is excluded:

- Hollow walls (frame and brick, made using well masonry technology);

- External surface of wooden or brick walls;

- Internal partitions;

- Floors;

- Interfloor ceilings;

- Roof.

Video: Advantages of Light Butts Scandic

The positive effect of the installed thermal insulation layer on the ceiling is felt not only in the cold season, due to better heat retention, but also in the summer, allowing you to create optimally comfortable living conditions, and in addition, the costs of ventilation and air conditioning of the room will be significantly reduced. The best insulation for the ceiling is guaranteed to be found in our company! Our specialists are always ready to perform its installation efficiently and on time!

Ceiling insulation with mineral wool has found application in the construction of frame houses using Canadian and Scandinavian technologies. If we consider the R-value - a measure of thermal resistance for materials (insulation) and floors (walls, ceilings) in buildings, industrial structures, then the higher this value, the better the thermal insulation properties of the material or floor.

Among the materials with high R-values, mineral wool for insulating ceilings and walls. It is divided into three types based on the composition of the fibers from which it is made: slag , glass fiber , and rock fiber .

Calculation of the amount of insulation for floors

Before you go to the building materials store, you need to calculate how much insulation is needed on the ceiling to create an effective layer of thermal insulation.

To do this, use the general formula:

V – volume of insulation in cubic meters;

L – perimeter of the working surface in meters;

g – material thickness in meters.

According to the EnUV standard, adopted in 2009, the heat transfer coefficient of the thermal insulation coating must be no less than 0.24 W/sq.m.xK. This value can be provided by a layer of insulation 13–40 centimeters thick, depending on the material and its thermal conductivity.

Mineral wool for ceiling insulation is a reliable and affordable material that allows you to create a comfortable microclimate in your home. Installing mineral wool helps prevent the formation of fungus and condensation due to temperature differences. You can do the installation of mineral wool yourself; the only requirement is compliance with technical regulations.

What layer of mineral wool is needed to insulate the ceiling?

The quality of mineral wool is determined by the condition of the material fibers, density, and thermal conductivity coefficient, which for slag wool is in the range of 0.046-0.48 W/ (m °C). When you buy mineral wool, there may be an R-value, which is defined as the ratio of the thickness of the material layer to the thermal conductivity coefficient: R = d/k.

For example, for slag wool with a thickness of 0.25 m we obtain R = 0.25/0.046 = 5.4 m2 °C/W , and the R-value of sand-lime brick with a thickness of 0.25 mm is 0.3 m2 °C/W , which in 18 times lower than that of mineral wool.

Thickness of mineral wool for ceiling insulation

It is not surprising that this material began to be used for insulating structures. This led to savings in building materials and cheaper construction.

Usually they produce standard sizes for material thickness: 50 mm , 100 mm . As can be seen from the example above, a thickness of 200 mm is enough to insulate a room for the harsh climatic conditions of the Russian winter . You need to focus on the material of the walls of the house. If these are wooden walls made of timber 150 x 150 or 200 x 200 mm, then one 50 mm layer of mineral wool is enough.