In winter, at least 25% of the heat is lost through the roof of an uninsulated building; the losses are compensated by increased heating. Of course, the load falls on the heating system and entails increased energy consumption. A budget-friendly way to solve the problem is to insulate the ceiling in a private house; the attic remains cold. The overlap is smaller than the roof slopes in area, hence the savings. Our task is to tell you how to properly insulate a ceiling by first selecting the appropriate materials.

The age-old question - to insulate from the inside or outside

Any external fence separating a living space from the street should be sheathed with thermal insulation on the outside. Accordingly, the insulation of the ceiling on the top floor of a private house is done from the attic side. Causes:

- Installation is physically simplified, which is important when doing the work yourself. There is no need to make a suspended frame or attach insulation from below to the ceiling.

- A layer of insulation 10-20 cm thick (depending on the region of residence) will not reduce the height of the rooms. This is an important plus for old buildings and “Khrushchev” buildings with low ceilings.

- In a lived-in house or apartment, you won’t have to redo the renovations.

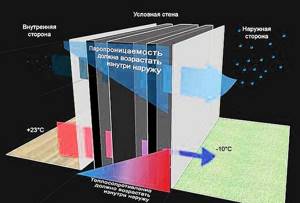

- If you do not follow the internal thermal insulation technology, the surface under the insulation will get wet and fungus will appear. Moisture condensation inside the “pie” is promoted by 2 factors: the penetration of water vapor and the formation of a dew point at the junction of dissimilar materials.

When the outer fence is sewn up from the inside, the point of moisture condensation is located near the junction of 2 different building materials

. About the notorious dew point, which is used to scare ordinary homeowners. To avoid condensation inside the structure, it is worth meeting 2 conditions: do not allow water vapor from the room to enter there and use an insulator of sufficient thickness. Then the dew point will be inside the insulation, where there is nothing to condense. The second way is to organize moisture removal using ventilation (read below).

Reference. Dew point is the phenomenon of condensation of water vapor from the air at a certain humidity and temperature. The lower the air temperature, the sooner the degree of extreme saturation with moisture is reached and condensation begins to form.

There are exceptions to the rules; not every room can be insulated from the outside. Examples:

- ceiling of the upper apartment of a multi-story building;

- attic;

- balcony, loggia;

- concrete garage floor above the basement, cellar;

- the need to save money, etc.

In the listed cases, internal thermal insulation of ceilings is arranged with strict adherence to technology. We will describe the work procedure in the form of step-by-step instructions, but first you need to find out...

What you need to know before starting work

Where to start?.. The topic is quite extensive, and work related to insulation requires, if not professional, then at least basic knowledge about the materials available on the market, their properties and methods of their use.

If you do the work without having this knowledge, you can, at best, waste time, effort and money, so to speak, in the wind, which is what makes it cold, and at worst, provoke a fire due to neglect of fire safety rules and improper installation of insulation material. Yes, insulation is needed to keep warm, but a fire is clearly too much in every sense.

Now we will look at the most popular materials, and also learn how to insulate a ceiling with a cold attic using common types of insulation. We'll find out what the advantages and possibly disadvantages of each are.

The best way to insulate ceilings

To insulate ceiling structures, 4 groups of materials are used:

- Fibrous - mineral, stone (basalt) and glass wool.

- Bulk – sawdust, clay, expanded clay, vermiculite.

- Polymers made from expanded polystyrene and polyethylene.

- Sprayed - ecowool, polyurethane foam, liquid foam - penoizol.

We will not focus on the last group of insulation materials - liquid mixtures are applied by spraying or filling cavities under pressure, which requires appropriate technological equipment. This kind of ceiling insulation in a private house cannot be done with your own hands - you need to hire specialists from a specialized company and pay for the services.

Application of cellulose ecowool (left) and polyurethane foam (right)

Note. Sprayed materials are the most effective and at the same time expensive. Only insulating polyurethane foam Polynor with a low thermal conductivity coefficient λ = 0.04 W/(m•°C) is applied manually. The price of an aerosol can is 8 USD. That is, the coverage area is 1 m² with a thickness of 50 mm. Thermal resistance of the layer: R = 0.05 / 0.04 = 1.25 m²•°C/W - information will be useful to us for comparison.

Let's take a closer look at each group of building materials, then select suitable insulation for ceilings in various rooms.

Porous-fibrous materials

For thermal insulation of roofs and attics under a cold roof, 3 types of fiber products are used:

- mineral wool on a synthetic binder, thermal conductivity λ = 0.055–0.06 W/(m•°C);

- basalt non-flammable insulation λ = 0.05—0.053 W/(m•°C);

- mineral wool based on glass fiber (otherwise – glass wool) λ = 0.044 W/(m•°C).

Clarification. We present insulation parameters for real operating conditions, taken from regulatory construction documentation. To increase the characteristics of insulators, manufacturers indicate the λ coefficient for the material in a dry state. The lower the thermal conductivity, the better the insulation resists cold.

Above we calculated the thermal resistance R of penoizol with a thickness of 5 cm (1.25 m²•°C/W). Let’s compare the indicator with the characteristics of fibrous materials of similar thickness by performing a short calculation for each (we applied the methodology from SNiP):

- mineral wool - R = 0.05 / 0.055 = 0.9 m²•°C/W;

- stone wool - R = 0.05 / 0.05 = 1 m²•°C/W;

- glass wool - R = 0.05 / 0.044 = 1.14 m²•°C/W.

Conclusion. In terms of thermal insulation properties, fiber insulation is inferior to liquid and foamed polymers. The best result is shown by glass wool, the worst – by ordinary mineral wool insulators. By the way, the values of thermal resistance R are interpreted the other way around: the higher the indicator, the more efficiently insulation of a certain thickness works.

Externally, basalt wool differs from mineral wool in color and corrugated fiber structure

Let us list the other, no less important properties of fiber insulation:

- Cotton wool is produced in rolls, slabs and mats of various densities - from 35 to 200 kg/m³.

- The open-pore structure promotes good vapor permeability of materials.

- Mineral wool absorbs moisture, but with proper ventilation it dries quickly.

- Basalt fiber is considered non-flammable because it can withstand temperatures of 600-700 °C. Ordinary mineral wool slabs also do not burn, but are destroyed by strong heat. Glass wool begins to melt at 250 degrees.

- Insulation materials do not have high strength; they are attached with glue or using a frame.

Fiberglass wool contains tiny glass particles and is therefore not suitable for indoor use. The well-known manufacturer of roofing insulation, Izover, recommends covering the outside of attic floors with glass wool.

The structure of glass wool - the fibers form many air layers

Other mineral insulation materials use a synthetic binder containing formaldehyde. Under certain conditions, these substances can be released and mixed with the air. For internal insulation, mineral wool must be well insulated from the living space using film, drywall, and so on.

Bulk insulation materials

All backfill materials are of natural origin and therefore environmentally friendly. The following insulation materials are used to insulate ceilings:

- expanded clay;

- small shavings, sawdust;

- clay;

- vermiculite gravel.

Reference. Vermiculite is much more expensive than expanded clay, so it is used quite rarely. Clay in its pure form is also not used - it is usually mixed with reeds or sawdust.

The main disadvantage of natural insulation materials is their low efficiency compared to mineral and polymer products. Example: the thermal conductivity of expanded clay gravel with a density of 200 kg/m³ is 0.11 W/(m•°C). Thermal resistance R of a 50 mm layer will be only 0.05 / 0.11 = 0.45 m²•°C/W. The indicators of high-density expanded clay, sawdust and clay are even lower.

Vermiculite (left) and expanded clay gravel (right)

Briefly about the properties of building materials:

- All bulk insulation materials allow water vapor to pass through well.

- The flammability of clay, expanded clay and vermiculite gravel is practically zero. Sawdust or reeds mixed with clay mortar also successfully resist fire.

- Long service life (excluding wood chips).

The low price of natural insulation is a relative concept. To create a thermal insulation layer comparable to 5 cm thick mineral wool, you need to fill expanded clay to a height of 100 mm, that is, spend twice as much.

Characteristics of polymer thermal insulation

To begin with, we will give a list of materials used with an indication of the thermal conductivity characteristics in operating mode:

- foam plastic with a density of 15...35 kg/m³, λ = 0.045–0.041 W/(m•°C);

- extruded polystyrene foam EPS, density - 20...40 kg/m³, λ = 0.039-0.037 W/(m•°C);

- foamed polyethylene 30…50 kg/m³, λ = 0.044–0.042 W/(m•°C).

Reference. Extruded polystyrene foam is often called Penoplex after the popular brand. Products made from polyethylene foam are known by the names “Penofol”, “Izolon” and “Tepofol”.

For comparison with fiber insulators, we determine the thermal resistance of polymers 50 mm thick:

- polystyrene foam 25 kg/m³ - R = 0.05 / 0.043 = 1.16 m²•°C/W;

- “Penoplex” - R = 0.05 / 0.038 = 1.32 m²•°C/W;

- “Penofol” - R = 0.05 / 0.042 = 1.19 m²•°C/W.

It is noticeable that the thermal insulation properties of polymer insulation exceed those of mineral and basalt wool. The leader is extruded polystyrene, whose results are comparable only to polyurethane foam applied by machine.

The rest of the properties look like this:

- Thanks to the closed air pores, insulation materials practically do not allow moisture to pass through. The exception is foam plastics, which have a meager vapor permeability of 0.05 mg/(m•h•Pa). Mineral wool indicators are 0.4...0.6 mg/(m•h•Pa).

- All polymers are flammable, no matter what sellers and manufacturers claim.

- Polystyrene-based materials are highly durable and are produced in slabs.

- Foamed polyethylene has a soft and flexible structure and is sold in rolls. To reflect the infrared heat flow, the surface of the insulation is covered with aluminum foil.

In terms of availability, foam plastic is the leader - its price is comparable to natural materials. The “extruder” is sold at the price of basalt non-combustible wool or even more expensive.

Useful fact. A polymer stretch ceiling, which forms an air gap under the ceiling, can be a good insulator. This cavity cannot be called airtight, but there are very few ways for warm air to penetrate.

Tips for choosing

A review and comparison of the characteristics of insulating materials showed that each group of insulators has strengths and weaknesses that limit their scope of application. For example, flammable polymers cannot be used to insulate the interfloor ceilings of wooden houses - fire regulations prohibit it. You should not ignore the requirement - with the help of insulation, the fire will easily spread to the next floor.

Reference. When installing wooden ceilings, regulations require treating the load-bearing beams with a fire-resistant compound and using non-combustible insulators. If you follow these instructions, then in the event of a fire the ceiling will last 30-60 minutes until it completely collapses. Here is the answer to the question whether it is possible to insulate a wooden ceiling with foam plastic.

Based on experience in construction and other regulatory requirements, we will give the following recommendations for choosing thermal insulation:

- It is better to insulate wooden floors from the attic side with basalt wool, expanded clay, vermiculite or a mixture of clay and sawdust.

- Ceilings in bathhouses (especially steam rooms) must be insulated with environmentally friendly materials. Here the choice is small - the same expanded clay, sawdust, vermiculite gravel, natural moss. No polymers or mineral wool; strong heating will cause the release of harmful substances.

- The ceilings of attic rooms are lined from the inside with dense basalt fiber; glass wool is not applicable.

- Concrete monolithic coatings are usually insulated with foam plastic or expanded polystyrene. In a country house - from the roof, on the balcony of a high-rise building or in the basement of a garage - from the inside.

- It is more correct to insulate flat reinforced concrete roofs with polymers from the outside, before installing a built-up bitumen roof. If this is not possible, Penoplex can be hemmed from below without any problems, but in compliance with the technology.

- It is advisable to use foiled polyethylene foam as an additional insulating layer. Find out how to properly insulate a ceiling with Izolon and Penofol from a separate guide.

Practice shows that it is better not to combine wood and vapor-tight building materials. The polymer, tightly adjacent to the beam, blocks the access of air, the wood does not “breathe”. If steam begins to condense at the joint and has nowhere to escape, the tree will turn black and rot.

The author of the video is clearly exaggerating and exaggerating the problem, but the situation shown is, of course, unacceptable. There is only one way out - when using polymers, you need to ensure contact of wood with air, which is not easy to implement technically.

Bulk insulation

Bulk insulation is made from polymers, wood derivatives, cellulose, clay rocks, resin and even stone. For obvious reasons, it is possible to insulate the ceiling with bulk materials only from the attic side, and for some types, for example, ecowool, a compressor will be required. The main positive quality of bulk thermal insulation is its high penetrating ability. The weak point is considered to be shrinkage, which is characteristic of all insulation materials of this group.

Expanded clay

The most common and relatively inexpensive bulk insulation. For its manufacture, ordinary baked clay is used. The result is a lightweight (about 400 kg per m3), moisture-resistant product. Depending on the size of the fraction, expanded clay is produced in the form of crushed stone, sand or gravel. In terms of thermal insulation properties, they are the same - the difference is in size and density.

Note! Expanded clay is resistant to moisture, absorbs it very slowly, but once saturated, it releases it even more slowly, which affects its thermal insulation properties.

Expanded clay costs significantly less than other bulk insulation materials of synthetic origin or ecowool, and has relatively low thermal conductivity (from 0.9 to 0.17 W/mK). It does not harbor rodents, does not grow mold, is chemically neutral, durable and does not contain toxins. When laying, you can mix it with sawdust, but then it is necessary to increase the insulation layer, since sawdust has greater thermal conductivity. The price of expanded clay is 2000 rubles per m3 or 150 rubles per bag (30 kg).

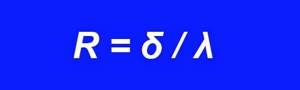

How to calculate the thickness of thermal insulation

We will show the determination of the thickness of the insulating layer using examples. Let's take as a basis the formula for calculating thermal resistance (in previous sections we already used it to compare the efficiency of different materials):

- R – heat transfer resistance of the insulating “pie”, m²•°C/W;

- δ – insulation thickness, m;

- λ – coefficient of thermal conductivity of the material, W/(m•°C).

The essence of the calculation: using the standard thermal resistance specified for your region of residence, calculate the thickness of the insulation, knowing the characteristic λ. The R value is determined according to the scheme given in the regulatory documents; a map with indicators for the Russian Federation is shown in the photo.

Similar maps can be found in regulatory documents of other CIS countries

Example 1. It is necessary to calculate the insulation of a summer house with an attic located in the Moscow region. We find the characteristics R for Moscow, choose the indicator 4.7 m²•°C/W (for coatings), take the coefficient λ of basalt wool equal to 0.05 W/(m•°C) and calculate the thickness: δ = 4.7 x 0.05 = 0.235 m ≈ 240 mm .

Example 2. We determine the thickness of the insulating layer of Penoplex for a concrete floor, location - Cherepovets. The algorithm is like this:

- We find on the Internet or reference literature the thermal conductivity of reinforced concrete λ = 2.04 W/(m•°C) and find out the thermal stability of a standard 220 mm floor slab: R = 0.22 / 2.04 = 0.1 m²•°C/W.

- Using the schematic map, we find the standard value of R for Cherepovets, take the overlap indicator - 4.26 m²•°C/W (the figure is highlighted in green).

- We subtract the found plate resistance from the required heat transfer value: 4.26 - 0.1 = 4.16 m²•°C/W.

- We calculate the thickness of polystyrene foam insulation λ = 0.037 W/(m•°C): δ = 4.16 x 0.037 = 0.154 m ≈ 160 mm.

Comment. The algorithm does not take into account the heat resistance of interior finishing and attic floors, so it gives the result with a small margin. If we take away the resistance of the flooring boards and plasterboard ceiling lining, the thickness of the EPS will decrease to 135 mm.

We insulate the ceiling with mineral wool

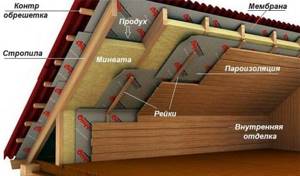

As mentioned above, mineral wool is used to insulate wooden floors and ceilings of attic rooms. To prevent the material from becoming saturated with moisture and losing heat resistance, 3 conditions must be met:

- protect the cotton wool from the entry of water vapor from inside the premises;

- ensure ventilation of the outer surface so that the resulting moisture is evaporated from the thickness of the insulation;

- the vapor permeability of the materials used in the “pie” should increase towards a colder room or street, as shown in the diagram.

Slab or rolled mineral wool is located in the space between the ceiling beams, as shown in the insulation diagram. When laying thermal insulation with your own hands, follow the following procedure:

- Roll out a vapor barrier film from the bottom of the beams, laying adjacent sheets with an overlap of 100 mm wide. Make an overlap on the walls 10-15 cm wide. Carefully tape the joints with tape.

The right photo shows the option of moisture insulation with foamed polyethylene with a reflective layer of foil - Glue the film overlaps to the walls of the structures with silicone sealant. The goal is to cut off room moisture from entering the attic.

- Work is being carried out from the cold roof side. Therefore, first make a rough padding of the ceiling, where the cotton wool will subsequently lie.

- Lay mineral wool boards as shown in the photo. The rolled material is carefully trimmed and placed between the joists; creasing the cotton wool is unacceptable.

- Lay waterproofing sheets on top of the insulation - a diffusion membrane that allows moisture to pass in only one direction - outward. Overlap 10 cm and glue the joints.

- Arbitrarily lay attic floors from edged boards across the joists. It is not necessary to make a continuous flooring.

Important point. A ventilation duct must be provided between the surface of the wool and the waterproofing. Thanks to the air gap, moisture is removed from the insulation.

Sometimes builders lay the first moisture-proofing film on top of the rough ceiling boards, going around each beam. We do not recommend using this approach - a vapor barrier will block the access of air to the log wood, and from below it will remain open for saturation with steam. Then it is clear - the tree will begin to rot.

How to lay mineral wool on the ceiling if the thickness of one layer is not enough. In such cases, a second tier of heat-insulating slabs is made, shifted by 30-50 cm relative to the first row. If the height of the load-bearing beams is not enough to organize ventilation, a frame of sheathing beams is built up, then a 2nd layer of insulation and waterproofing is installed.

The device for additional sheathing is shown on the left when the height of the beams is not enough

The insulation scheme for the attic floor is very similar to the thermal insulation of a wooden floor:

- A counter-lattice is provided on the roof, the diffusion membrane is rolled out from above along the rafters. If there is no external frame, the waterproofing can be attached from the inside, going around each rafter leg and shooting the edges of the sheets with a stapler.

- The insulation is placed between the rafters at random. If the width allows, we lay the slabs in 2 layers with bandaging, otherwise we install a horizontal counter-lattice.

- We nail the vapor barrier to the rafters through slats, where the interior trim from gypsum plasterboard or lining is subsequently attached.

Reminder. When working with glass wool or basalt fiber, do not forget to wear a respirator and gloves, the material is very dusty and irritates the skin. How to insulate a wooden covering without mistakes, watch the video:

It is extremely undesirable to insulate concrete ceilings with cotton wool from the inside, especially in wet rooms - the kitchen and bathroom. The porous material will harden and lose its properties if effective ventilation is not provided. Another thing is to attach mineral wool in the space behind the suspended ceiling, where water vapor almost does not penetrate.

Roll insulation

All insulators of this type have one strong point - the absence of joints in length, which as a result reduces heat loss. There is also a general drawback - roll insulation cannot be dense, like polystyrene foam, for example, since it is supplied rolled up.

Foiled mineral wool

The thermal insulation and other properties of rolled mineral wool are similar to their slab counterparts, the main differences being the length of the mat and the foil coating. The foil layer on one side of the insulation reflects infrared radiation, further preventing heat loss. The aluminum film prevents moisture-sensitive cotton wool from getting wet.

Foil-coated isolon (penofol)

A relatively new insulation material, which is based on porous polyethylene, and one of the sides is covered with aluminum foil or a special metallized film. It is most often used indoors, including for ceiling insulation. Penofol does not come in thicker than 10 mm, which, together with the polyethylene base, does not significantly prevent heat loss.

In rooms with low levels of infrared radiation it does not give much effect, therefore it is often used in combination with other insulation materials, for example, mineral wool.

Self-adhesive options are available, making installation much easier. When insulating with foil materials, you cannot completely cover the reflective layer, as the reflection effect will disappear. To prevent this from happening, you need to leave a ventilation gap of 15-20 mm.

Expanded polystyrene cladding technology

Polymers are usually used to insulate reinforced concrete floors and ceilings, on both sides. To insulate the structure from the inside, the surface needs to be prepared - seal the joints of the plates, level with mortar and carefully treat with a primer.

The second stage of internal thermal insulation is the installation of a subsystem of wooden bars or metal profiles. The frame plays the role of a platform for finishing - plasterboard, suspended ceiling, and so on. Polystyrene boards are attached directly to the concrete surface using an adhesive mixture and umbrella dowels.

Reference. When performing thermal insulation of balconies and loggias with extruded polystyrene, craftsmen often do without a subsystem - they glue or screw the slabs to the ceiling in a continuous layer. The slats for the internal cladding are attached to the concrete floor through the insulation with special screws - dowels.

How to insulate a reinforced concrete ceiling in a private house from the inside:

- After preparing the surface and assembling the frame (or not), prepare the adhesive mortar mixture according to the instructions on the container.

- Apply glue to the foam board and press it to the surface, hold it for a while. Attach the next element end-to-end with the previous one, make the adjacent row with a shift relative to the first.

- When the mixture hardens, additionally secure the polymer boards with dowels in the form of umbrellas. It is advisable to blow out the joints with polyurethane foam.

The right photo shows an option for installing EPS together with a suspended ceiling frame under gypsum plasterboard - Cover the ceiling with a vapor barrier, ensuring overlaps and taping joints. The film or “Penofol” is aimed at the subsystem with a stapler.

- Place the edges of the film on the walls and glue them with construction sealant. Install the sheathing slats and move on to finishing.

Advice. You should not screw Penoplex to the ceiling without glue. Firstly, there will be gaps under the insulation, and secondly, the surface needs to be perfectly leveled. Otherwise, differences of 1-3 mm will appear at the joints of the plates.

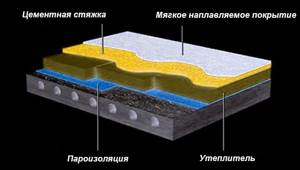

External insulation of reinforced concrete slabs with polymer materials is used on flat roofs and used attics. The “pie” on the roof is formed like this:

- The prepared surface is covered with a vapor barrier film according to all the rules.

- Expanded polystyrene is placed tightly on top and fixed to the ceiling.

- A cement screed is poured, which acts as waterproofing and a solid foundation so that you can walk on the roof.

- A built-up roofing felt waterproofing with weather vanes is installed to remove air and water vapor from under the “pie”.

The technology for installing polystyrene insulators from below to the ceiling is demonstrated in detail in the video:

Of course, you can insulate reinforced concrete from the inside with mineral wool, and the ceiling of a log house with expanded polystyrene. Then take additional measures: very carefully isolate the mineral wool from the room, and blow polyurethane foam between the polymer and the wood - it allows air to pass through and prevents rotting.

Basic materials

Among all the materials that can be used in the case of insulating a concrete ceiling from the inside of an apartment, several of the most popular stand out. Each has its own characteristics.

Styrofoam. It retains heat well, but it also has a drawback - it is quite fragile, and you need to be careful when installing it. In addition, the foam structure may be too bulky for an apartment. However, insulating the ceiling with foam plastic from inside the apartment is quite popular.

Polystyrene. Also, like polystyrene foam, it can be fragile. It is much thinner and will take away less height from the walls. Installation can be one of the simplest - the slabs are simply glued to the concrete base. The same can be done with foam boards. The cost of both of these materials is quite low.

Mineral wool. In terms of cost, it can be even cheaper than polystyrene with foam. However, to achieve good heat saving performance, a sufficiently thick layer is required. In addition, to install this insulation, you will need to assemble a frame, inside of which it will be laid.

Foam tiles. Oddly enough, even such a thin layer of decorative finishing material will help retain some heat. There will be two advantages here - the ceiling will become more beautiful, and the thermal insulation will improve. In terms of cost, these tiles are very affordable.

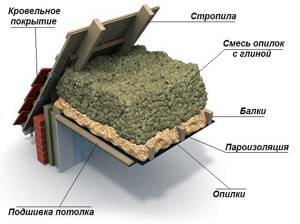

Finally, about backfilling the attic

The use of bulk materials is the simplest option for insulating the ceiling of a country house, although not the most effective. Thermal insulation is carried out on top of the ceiling in various ways:

- The space between the beams is filled with expanded clay, sawdust or vermiculite crushed stone to the maximum possible height. Flooring boards are laid on top.

- Wood shavings and sawdust are mixed with pre-soaked clay. The space between the joists is filled with the solution.

- A sawdust concrete screed is made - the waste is mixed with cement and sand in a ratio of 5: 1: 1.

If you have a concrete auger mixer at your disposal, you can prepare a more modern insulation for the ceiling - polystyrene concrete. The cement-sand mortar is mixed with polystyrene balls and laid on the ceiling in a layer of 200-300 mm. There is no need to lay the flooring - the monolith has sufficient strength.

Note. There is a mistake in the video - there is no need to place the film under bulk materials. Water vapor (especially in a bathhouse) should freely escape through the expanded clay or sawdust concrete to the outside, and the wood should dry thoroughly.