By basalt chips (backfill) we mean crushed scraps left over from basalt wool. This material is successfully used in filling interwall voids, arranging floors, attics, and roofing. The material is characterized by non-flammability, vapor permeability (not prone to moisture accumulation), noise insulation properties, and natural origin. In addition, the material does not rot.

Material quality

The material is characterized by the following qualities:

- high heat-saving indicators;

- Cold “bridges” are not formed when using this material;

- the ability to insulate surfaces of any thickness;

- convenience in insulating inaccessible or inaccessible places;

- affordable price;

- ease of storage and transportation;

- compact and reliable packaging;

- vapor permeability and noise insulation.

The use of basalt chips allows you to reach and insulate even hard-to-reach parts of the house, floors, ceilings, attics, etc.

The material is supplied to the market in bags, in a loose and free-flowing state. Compared to other options for existing thermal insulation (slag, sawdust, expanded clay and others), the material surpasses them in technical characteristics.

Insulating a house with basalt chips

Backfill is used for insulation of buildings of any type: residential and industrial buildings. The main condition put forward for the implementation of the insulation project is the presence of a minimum gap between the walls up to 4 centimeters thick.

The backfill is fed under the surface layer using a special blowing unit that delivers crumbs under pressure into the cavities formed between the internal and external walls. This allows the result to achieve a “thermos” effect, which helps the house retain heat for a longer period of time, and, therefore, saves on resources previously spent on heating the building.

When choosing the option of insulating a house with basalt chips, it is worth noting that this insulation technology significantly exceeds the thermal insulation performance when using the same foam backfill in almost all respects.

Main advantages of the material

Among the positive qualities are the following:

- raw materials of natural origin (basalt rock melt product), not containing blast furnace slag or additives;

- high fire safety. The material does not burn and, on the contrary, prevents the spread of flame over the surface, due to which it is recognized as a high-quality fire-resistant insulation;

- the fibrous structure of the crumb allows, during pneumatic blowing, to form a layer with a density of 75-80 kg/cube, which is equivalent to the effect of a monolithic slab;

- The main area of application of basalt chips based on mineral wool is insulation of walls, ceilings, attics, and inter-wall spaces.

It is these qualities described above that make home insulation with this kind of material the main and preferred choice of buyers. The consumer mentions in his reviews the high quality of basalt backfill produced by domestic companies and notes the affordable price of the product. This is what makes basalt insulation so popular, because in their choice, a potential buyer is primarily guided by what the person who actually tried the material says.

Advantages of bulk insulation

High-quality home insulation is the basis for a comfortable stay. Therefore, it is important to pay enough attention to the material before choosing insulation. Bulk heat insulators have the following positive characteristics:

- minimal heat loss;

- resistance to sudden temperature changes;

- minimum weight;

- environmental friendliness;

- Fire safety;

- long service life;

- ability to retain heat for a long time;

- ease of installation.

To insulate walls with bulk basalt wool or other bulk insulation, no special tool is required. All work can be done by a home craftsman without the help of professionals.

It is important to pay attention to the manufacturer of thermal insulation materials. A popular Russian company supplying quality products is Ecover.

Advantages of insulation

As a result of using insulation - basalt chips, the client receives the following effect:

- reducing heat loss during the cold season (basalt backfill is up to 25% more effective than foam chips in terms of thermal insulation);

- reducing living space heating costs;

- additional sound insulation;

- high vapor permeability and water-repellent properties, which prevents the accumulation of condensate;

- long service life due to the inorganic composition of the material, which is resistant to rotting and fungal infections.

Features of insulating house walls with basalt backfill

The technology for blowing the interwall space with basalt chips is as follows:

- Preparing the walls. Drill holes with a diameter of up to 45 mm, from 8 to 12 pieces on each wall (the number depends on the area of the surface being treated).

- Blowing out. The process takes place using a special unit. Which, under pressure, injects crushed material into the cavities so that the layer of basalt wool lies evenly, forming a dense, but at the same time loose structure, which contributes to more efficient heat retention in the room.

Please note that work can be carried out even in the cold season. Blowing in inter-wall voids promotes effective gas savings of up to 60%, and this figure depends on the size of the inter-wall air gap, the selected type of material (basalt wool or foam plastic boards), the quantity and quality of heated surfaces.

As the buyers of this material and those who have already tried all the benefits of basalt backfill from their own experience describe in their reviews of basalt chips, insulating walls with this material is profitable, because by paying for high-quality home improvement once, you get a comfortable and warm home for decades.

Everyone wants to save money when building a country house. Therefore, developers are looking for cheaper building materials. For example, instead of expensive mineral wool insulation in the form of slabs, they buy an inexpensive option - the so-called. aspiration of stone wool - crumbs obtained from its waste. Are these savings justified? The answer is in an article based on the real experience of FORUMHOUSE participants.

- What is bulk stone wool insulation in bags?

- How much does rock wool aspiration cost?

- How to insulate a house with stone wool chips

- Advantages and disadvantages of bulk stone wool from industrial waste

Insulating a house with basalt wool chips, or myths and reality about aspiration

Everyone wants to save money when building a country house. Therefore, developers are looking for cheaper building materials. For example, instead of expensive mineral wool insulation in the form of slabs, they buy an inexpensive option - the so-called. aspiration of stone wool - crumbs obtained from its waste. Are these savings justified? The answer is in an article based on the real experience of FORUMHOUSE participants.

- What is bulk stone wool insulation in bags?

- How much does rock wool aspiration cost?

- How to insulate a house with stone wool chips

- Advantages and disadvantages of bulk stone wool from industrial waste

Features and cost of stone wool aspiration

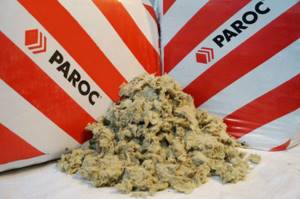

To understand the pros and cons of basalt wool chips, you need to understand what kind of material it is. Aspiration of mineral wool is a waste product. For example, from a factory where stone wool slabs or sandwich panels are produced. The trimmings are crushed and poured into bags with a volume of 0.2 - 0.3 m³ or big bags with a capacity of 500 - 1000 liters.

The physical properties of thermal insulation directly affect the scope of its application and the specifics of the work. Manufacturers and sellers of aspiration recommend placing crumbs only on horizontal surfaces so that they do not slide down over time, for example, in a wall. By compacting, you can increase the density of the laid insulation. The main thing here is not to overdo it. If you fanatically compact the poured basalt chips, you can achieve a packing density of 100 or more kg/m³. But, the worse the thermal insulation properties of this material will be.

Insulation with mineral wool chips: pros and cons

Aspiration of mineral wool is simply crumbs, waste from the production of this popular insulation. It is also called basalt chips or bulk wool. At any factory, when producing sandwich panels or stone wool slabs, waste and trimmings remain in any case. They are crushed and sold in bags with a volume of 0.02–0.3 m 3 or in big bags with a capacity of up to 1000 liters. The density of bulk insulation crumbs is 35–55 kg/m 3 .

Important! The thermal conductivity coefficient of aspiration is the same as that of ordinary mineral wool in rolls or slabs - 0.041–0.042 W/(m °C) with a density above 40 kg/m 3 and normal humidity. Other properties are also similar. The crumb does not burn, it also needs to be protected from moisture and condensation.

The advantages of using mineral wool chips are obvious:

- It's very inexpensive. One cubic meter of crumbs will cost approximately 600 rubles, while the price of the same volume of stone wool in the form of slabs will be at least 1,500 rubles. The savings are obvious. In addition, if you find a company that does not pack and sell waste from its insulation production, you can generally get aspiration for free - pick up.

- Bags of crumbs weigh very little and are easy to carry and transport.

- The installation process itself is simple.

- There are no cold bridges, the crumbs can be poured, blown out, compacted in all hard-to-reach places.

- The thermal insulation properties are high, no worse than those of stone wool in slabs.

But there are also many disadvantages to insulating a house with mineral wool chips:

- During the installation of bulk insulation there will be a lot of dust; you need to work only in a respirator and safety glasses.

- We need hydro-, steam- and wind-proof films, and special requirements are imposed on the tightness of their seams; the protection must be as reliable as possible. Crumbs absorb moisture faster than mineral slabs.

- There is a risk of buying low-quality material, substandard, which the manufacturer hastened to get rid of.

- There is a risk of not filling all the voids in hard-to-reach places, for example, in walls or under roof slopes. As a result, cold bridges will remain.

- It is difficult to say what will happen to the insulation in 10 and 20 years, as there are no reviews yet about such a long service life of mineral wool aspiration.

In general, the process of using stone wool chips is similar to laying ecowool, which the portal Rmnt.ru wrote about in detail. It is advisable to use dry blowing, when aspiration is applied to the surface under pressure and immediately pressed. In addition, this method of insulation is suitable for walls and partitions, when mineral wool chips need to be compacted inside.

Important! In the process of laying basalt chips, you can overdo it with compaction. If the layer turns out to be very dense, up to 100 kg/m3, then the thermal insulation properties of the material will decrease. Tamping up to 65 kg/m 3 is optimal.

According to user reviews, stone wool chips are well suited for insulating horizontal surfaces: floors, attics, ceilings between floors. It is more difficult with walls, although blowing using a special apparatus allows you to solve the problem of compacting crumbs between the walls.

The insulation layer should be at least 15–20 centimeters. If you decide to do everything yourself, then first of all you will need work gloves and other protection. Having poured out a layer of crumbs, it needs to be compacted with something; often homeowners simply use sticks and other improvised means. They are compacted so that the insulation layer is springy and not too dense. The top is covered with wind protection.

In general, we repeat, the technology is similar to the use of other bulk insulation. The process is quite labor-intensive if you work manually, but it does not present any particular difficulties.

We note: using mineral wool chips as insulation really allows for significant savings. It’s inexpensive, you can do everything yourself, and the thermal insulation performance is good. However, you need to choose high-quality material, follow installation technology, avoid the formation of voids, and be sure to use vapor barrier membranes.

Insulating a house with bulk basalt insulation in the form of crumbs

Although the price for aspiration is attractive, for most developers basalt chips are a “pig in a poke.” It's not clear how to work with it. Doesn't it track over time? Won't it get damp? Will fine dust from mineral wool waste cause allergies? And most importantly, won’t such a cronyism lead to a crapfall?

I was looking for insulation and came across aspiration. The price is tempting - 500 rubles. for 1 cubic The consistency of the crumb is similar to ecowool. I am looking for reviews from real users on this thermal insulation. Has anyone already insulated a frame house with such crumbs? I want to insulate walls and ceilings. By the way, I asked the crumb sellers if it was possible to blow it out. They say no. The vacuum cleaner will not pull it due to its weight.

It seems to me that saving will cost you more. This is production waste! Noname product. Who will give it a guarantee of quality and compliance with all declared characteristics? It is better to buy ordinary stone wool slabs and not bother with the installation of aspiration.

I think crumbs should not be poured into the walls, but the ceilings and floors are fine.

I insulated the frame with stone wool chips. He poured it into the corners of the walls. To prevent the thermal insulation from settling, I tamped it with a stick, but without fanaticism! According to my calculations, the density came out to 100 kg/m³.

The portal participant acted like this:

- I covered the aspiration with gloved hands.

- I poured 5-9 liters of mineral wool crumbs at a time.

- The insulation was pushed through with a stick.

- I compacted it, or rather compacted it, not to a solid state, but so that the insulation was slightly springy.

- The insulation was poured in layers - a layer, a tamper, the next layer.

I insulated a frame house using aspiration. I laid it in the walls, on the roof and in the ceilings. I compacted everything. Nothing has settled. The “box” turned out to be very warm. Now I save on heating.

And I insulated the ceiling of a cold attic with stone wool chips. The thickness of the insulation is 20 cm. I poured it onto the rough ceiling, which I made from a solid sheathing with an inch board. On the room side there is a vapor barrier. On top of the insulation there is a dense wind barrier. I really liked the material. He cost me free of charge - he took the waste from the production of sandwich panels. The crumb is also good at filling hard-to-reach places - junctions of rafters and joists. The downside is that it is difficult to lift the bags to the second floor. The material is very dusty. After installation, be sure to cover it with a windbreak, otherwise you will suffocate from dust!

And I blew out the aspiration like ecowool. Density approximately 60-65 kg/m³. There is no shrinkage.

I was captivated by the low price of stone wool chips and the ability to insulate “narrow” places with a continuous layer to prevent “cold bridges.” I compacted it myself. It's simple. The 15 cm thick insulation layer turned out to be very dense. There is a lot of dust, but I worked in a respirator. I was more tired of having to reload the insulation from big bags into 200 liter bags and carry them upstairs.

The experience of a portal participant with the nickname Dekagon is interesting. He insulated his unusual frame yurt house with mineral wool chips.

Bulk insulation basalt chips

Each person, when building his house or after, in one way or another thinks about its insulation. We all know that today the market for thermal insulation materials offers us a huge selection and assortment.

By type of material, polystyrene foam and mineral wool are widely used. Polystyrene foam and its derivatives are well known to everyone, and we will not consider it in this article. As for mineral wool, this is a collective name that includes the most common materials: glass wool or quartz wool (base sand or glass) and stone wool or basalt wool (base natural stone basalt). We will not compare the characteristics; there are plenty of them on the Internet. Basically, these insulation materials are presented on the market in slabs and in rolls (mats), but there is another type of mineral wool insulation, about which little is known, but which can save the budget on insulation by up to 300 - 400%! Do you agree that this figure is significant? And now we are talking about bulk mineral wool insulation. What is bulk insulation? Let's figure it out.

So, let's begin. Why are bulk mineral wool insulation materials little known to buyers? The answer is simple: bulk insulation is a production waste. In any production in any industry there is waste, and bulk insulation, namely mineral wool, is a waste from the production of mineral wool and sandwich panels. A reasonable question: how can you insulate your home with industrial waste? I agree, it doesn’t sound very good, but let’s take a closer look.

Bulk insulation is obtained by cutting or crushing slabs of the most common mineral wool insulation materials. The manufacturer, due to the high cost of waste disposal, packages it in bags and sells it as bulk cotton wool. You can purchase bulk insulation where there are the production facilities mentioned above. Such insulation is no different from classic insulation, but costs 3-4 times less. Of course, every manufacturer could package it in branded packaging and sell it as a product, but many don’t do this, perhaps they don’t want to reduce sales of finished products, or maybe they just don’t want to bother, because this requires significant costs and a serious advertising campaign. Although, there are manufacturers who have brought production waste to the market as a finished product, for example the Paroc company and its bulk/blown wool, the IZOVER company with its KV-050 bulk wool.

In our region - the Samara region, the main manufacturer of bulk insulation is. In the Samara region, bulk insulation is better known as basalt chips. Basalt chips are made from stone wool based on basalt. And we will compare it with other insulation materials, since we have experience working with it.

So, let's compare and find out the corduroys and disadvantages of basalt chips compared to other insulation materials. We will compare basalt chips with famous insulation materials, such as TechnoNIKOL, Rockwool, Baswool.

Comparison of bulk insulation (basalt chips) with other insulation materials

| Parameter | Rockwool | TechnoNIKOL Rocklight | Baswool Ecorock | Basalt chips |

| Flammability | NG (non-flammable) | NG (non-flammable) | NG (non-flammable) | NG (non-flammable) |

| Decomposition period | 50 years | 50 years | 50 years | 50 years |

| Thermal conductivity | 0.041 W/(mK) | 0.041 W/(mK) | 0.038 W/(mK) | 0.042 W/(mK) |

| Water absorption | no more than 2% | no more than 2% | no more than 2% | no more than 2% |

| Density | 25 kg/m3 | 28 kg/m3 | 25-35 kg/m3 | 35-100 kg/m3 |

| Application | Any surfaces | Any surfaces | Any surfaces | Horizontal only |

| Ease of installation | Easily | Easily | Easily | Easily |

| Safety | Safe | Safe | Safe | Safe |

| Material | Basalt | Basalt | Basalt | Basalt |

| Price in our store | 1445 RUR/m3 | 1736 RUR/m3 | 1640 RUR/m3 | 600 rub./m3 |

So, we see that basalt chips are basically similar to classic insulation materials, but have a serious drawback, namely, they can only be used on horizontal surfaces. But there is also a plus that significantly outweighs the minus - the price. Yes, of course, the price is “delicious” and someone may ask a question: if this is waste, then perhaps it is not safe for humans, but the fact that bulk insulation may imply its high volatility and harm to health? We agree, it's a good question. Here the guys from Agidel LLC, who are manufacturers of Baswool insulation, did the work for us. They also generate this waste and they also sell it. Baswool took care of the safety issue and sent the bulk insulation for examination. The results of the examination indicate the safety of such materials and allow their use in civil engineering. You can view the results in person by following the link below.

conclusions

In the article we talked about the key points for using stone wool aspiration. Let's summarize what has been said. So, the advantages of mineral wool crumbs:

- low price;

- light weight;

- ease of installation;

- obtaining a continuous layer of insulation without the formation of “cold bridges”;

- high thermal insulation properties;

- the possibility of insulating hard-to-reach places - “pockets” in walls, ceilings, etc.

Disadvantages of insulation obtained from stone wool production waste:

- thermal insulation is very dusty;

- increased requirements for the tightness of seams and junctions of steam-hydro- and windproof films;

- there is a risk of running into outright substandard behavior;

- installation should be carried out using personal protective equipment - goggles, respirator, mask, thick clothing;

- if you overdo it with tamping, you can compact the crumbs beyond the norm, which will lead to a decrease in its thermal insulation properties;

- great influence of the so-called “human factor”, workers can be lazy and leave uncompacted voids in the walls;

- It is difficult to predict how the insulation will behave in the long term, for example, whether it will become damp or whether it will settle in 10-15-20 years .

We recommend a topic that describes in detail the use of mineral wool aspiration - Decagon, or the path from the sphere to the coaxial yurt.

- Insulation of a private house: basic knowledge. We are looking for universal insulation for all occasions based on the experience of FORUMHOUSE users.

- How private houses are built in Europe: the article answers the question why in countries with a milder climate than in Russia, cottages are insulated with a layer of thermal insulation 30-40 cm thick.

- Step-by-step insulation of a timber house with stone wool: how to perform a thermal engineering calculation of the walls of a timber house, and why it is impossible to insulate a wooden house with a vapor-opaque material.