The base of the bathhouse must be reliable and durable, but in addition to all the indicators, the heat-saving characteristics are also very important. There is an opinion that it is not necessary to spend time and money on insulating the foundation of a bathhouse, but it is wrong. Of course, steaming more than twice a week is harmful, and you can heat the steam room longer, wasting a large amount of firewood. But when the foundation begins to collapse and the walls begin to give way, it will be too late to think about the problem. You should not be afraid of labor-intensive and expensive work, especially since everything can be done on your own. We will tell our readers how to insulate the foundation of a bathhouse with your own hands using various materials in today’s article.

The foundation of the bathhouse must be insulated, otherwise heat loss will be high and it will take a long time to heat the steam room.

Why is it important to insulate the foundation of a bathhouse?

There are a number of reasons why it is necessary to insulate the foundation of a bathhouse:

- due to the large temperature difference in winter during heating of the bath, condensation forms on the inside of the base, which significantly reduces the service life of the structure;

- the soil under the foundation in the summer heat still remains cool; the foundation only heats up from the outside. Temperature changes cause condensation to form, which will destroy the foundation from the inside all summer long;

- in a bathhouse with an uninsulated foundation, the heat quickly disappears and the steam room has to be heated all the time;

- in winter, soil heaving has a destructive effect on the foundation walls, insulation will soften the pressure;

- a good layer of thermal insulation will protect the structure from mechanical damage.

As a result, due to constant humidity and pressure, the base will slowly begin to collapse.

It is more effective to insulate the foundation from the outside of the structure.

You can insulate the foundation of a bathhouse along the base from the outside, from the inside, or from both sides at once. The last method is the most effective, but labor-intensive and expensive. Since the bathhouse is associated with temperature changes, we do not recommend performing only internal insulation. The foundation will freeze and quickly collapse. Internal thermal insulation can be carried out only in the most extreme cases, when external insulation is not available for some reason. The internal insulation will be effective, but the foundation will remain unprotected.

Once you have decided on the insulation method, you need to choose the right material.

Thermal protection method

You can insulate the foundation in two ways - before and after laying. The first method is used before pouring cement. Insulation materials are laid on the outside of the foundation wall above the ground and underground (if there is a tunnel). The insulation of the underground part of the foundation block in contact with the ground is additionally covered with a protective layer. If the foundation block is shallow, its base is also subject to thermal insulation.

After casting the cement mortar, in addition to finishing the interior with heat-insulating material, a blind area is laid - the outer layer that holds the base. Before filling the blind area, a heat-retaining layer is laid under it.

Often builders use formwork instead of an insulating layer. The structure is mounted not from wood, but from polystyrene foam. Therefore, it does not need to be removed after the concrete solution has dried. It is a good thermal insulation material and does not deteriorate under the influence of environmental factors. Wooden boards, unfortunately, are susceptible to rotting.

The second method is used after the construction of the building. In essence, it is equivalent to insulating the height of the base. The base, as with internal insulation, is protected with a blind area. This method is simpler, more economical, but less effective, since it is applied only to the front side of the foundation.

Which material is best for foundation insulation?

To insulate the foundation of a bathhouse, you can use one of the following insulation materials:

- Mineral wool (glass, stone, etc.) is taken in the form of mats, it is easier to work with.

- Expanded polystyrene or polystyrene foam.

- Bulk materials (expanded clay, sawdust).

The main requirements for insulation materials are: not to absorb moisture and not to deform under soil pressure.

Mineral wool for foundation insulation

Mineral slabs can be used to insulate the foundation, but since they absorb moisture well and are subject to deformation, they are additionally protected with a brick wall or boards. The disadvantages include an unpleasant odor that will appear if the base inside the bath is insulated, and deformation. In addition to all of the above, rodents like to live in mineral wool, which quickly breed and damage the thermal insulation layer.

Scheme for insulating the foundation of a bathhouse with mineral wool.

The advantages include low price, high heat-saving properties, ease of installation.

Bulk insulation

Expanded clay and sawdust were also used by our grandfathers. But the materials have a number of disadvantages:

- absorb moisture well;

- sawdust rots quickly;

- have low heat-saving characteristics.

The only advantages, perhaps, are the low price and availability in any region. Sawdust, in general, can be taken for free at any sawmill.

Polystyrene foam or polystyrene foam

When insulating the foundation, sheet foam is often used. The material retains heat well and is not afraid of moisture. The price of insulation is low; you can buy it at any hardware store. The disadvantages include the low strength of the material. Manufacturers produce extruded foam, but the price is higher.

Expanded polystyrene also consists of gas bubbles, but the structure of the insulation is more dense. Available in the form of slabs or foam, which is sprayed using special equipment under pressure. The spraying method is considered the most effective, since the heat-insulating layer is sealed. But the price for work starts from 600 rubles/m².

Types of wallpaper

- Paper ones are the most democratic. They are cheap, can be found in any repair store, they come in embossed and smooth. However, they have one significant drawback - they are not durable at all and cannot be repainted often (no more than 5 times during their service life). To increase strength, some craftsmen coat them with a special varnish composition. This adds durability and gloss. However, it exposes all the irregularities of the wall. In addition, to repaint, the varnish will have to be removed, which can lead to very disastrous consequences.

- Vinyl is more durable. Consist of vinyl and foamed PVC. They can withstand up to ten repaints without losing integrity, but are afraid of mechanical damage. On sale you can find this type of wallpaper with an interesting texture - a pattern or imitation. They are well suited for the kitchen or hallway.

- Non-woven ones - created on the basis of a more technologically advanced material than those mentioned above. The composition includes three or even four different layers, which make the material very durable and unpretentious. They are elastic, withstand wet cleaning, as well as repainting up to 15 times. You can also come across negative statements, which mainly boil down to the non-environmental friendliness of this type of coating. The fact is that when heated strongly, non-woven fabric releases a certain amount of formaldehyde vapor. However, if you stick them on the walls of the hallway or hall and do not plan to set them on fire, you have nothing to fear.

- Fiberglass wallpaper is the most expensive and most technologically advanced type of wall covering in our review. It is obtained by processing glass with special additives. The high cost is more than covered by its excellent appearance, environmental friendliness and durability. In addition, they do not burn and do not emit any odors or harmful substances. If you intend to surprise your guests and plan to change the color of the walls often, this is the best option for you.

Liquid wallpaper. To complete the picture of the possibilities of decorating walls in residential premises, this type cannot be ignored. Essentially, it is a dry mixture of various materials, which just needs to be diluted with warm water, spread on the wall and wait until it dries. In terms of painting, they can be compared with paper ones, i.e. They practically cannot be painted and are very afraid of being treated rudely.

How to insulate the foundation of a bathhouse - methods and methods

The method of insulation depends on the design of the foundation and the type of soil on the site. Let's consider the insulation of the most common types of foundations: strip, monolithic, columnar.

Thermal insulation of strip base

Insulating a strip foundation immediately solves two problems:

- the impact of soil heaving is reduced;

- heat loss through the base walls is reduced.

The work is carried out as follows:

- The foundation is cleared of soil along the entire perimeter. We dig a trench with a depth of at least the soil freezing level and a width of 50 cm. The soil freezing level can be found out at the local geocenter; for central Russia the figure is 1.5 m.

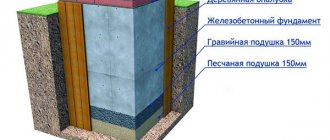

- A sand cushion of 15–20 cm is poured in. It is necessary to moisten and compact the sand as thoroughly as possible. It is better to use coarse sand, it goes less into the soil.

- The foundation is coated with bitumen mastic in 2 layers. The waterproofing is allowed to dry.

- Insulation is being installed. Its thickness is calculated separately for each region; for central Russia, mineral wool is taken 20 cm, polystyrene 15–20 cm. The seams are foamed with polyurethane foam. It’s easier to take foam plastic with L-shaped locking joints, so the seams will be more airtight. The foam is glued to a special adhesive composition and fungal fasteners.

- At the corners, the insulation is laid in a layer 1.5 times thicker, since heat loss is the highest there.

- Expanded polystyrene can simply be covered with sand on the side and compacted. Polystyrene foam and mineral wool must be additionally protected with a 25 cm brick wall. It is simply laid out along the entire perimeter of the base.

- A blind area from the base is made on top at an angle of 15 0 from concrete. The top of the blind area can be decorated with ceramic tiles.

The insulation of the strip foundation is ready. It will retain heat well and is not affected by soil heaving and moisture. Heat loss in the bathhouse will be reduced by 45%.

Scheme of insulation of a strip foundation.

If it is impossible to insulate the foundation from the outside, you can do the work from the inside in a similar way.

Insulation of a monolithic base under a bathhouse

For subsidence and silted soils, a monolithic base for a bathhouse is selected. It is better to lay a monolithic foundation on a layer of hydro- and thermal insulator. But if the work is not completed, you can insulate the finished structure.

Protection of slab-type insulation from liquid concrete is carried out depending on the type of base reinforcement. when the reinforcement is made using wire and metal rods, a PVC film with a thickness of at least 200 microns is laid on top of the thermal insulation. All joints are glued using double-sided tape.

If the reinforcement is performed using a welding machine, then a screed no more than 15 cm thick is made of weak concrete mortar or cement on top of the insulation.

Along the walls, the finished structure is insulated similarly to tape.

Thermal insulation of a columnar base for a bathhouse

The most difficult thing to insulate is a columnar foundation. The free space under the bathhouse is ventilated and the floors quickly freeze. Ask how to insulate the foundation of a column-type bathhouse? The following steps:

- A trench 1.5 m deep and at least 50 cm wide is dug along the walls of the bathhouse.

- A sand cushion is poured into the bottom, watered and tamped down.

- A wall of red brick and half a stone is laid on top. The wall should barely reach the bottom of the bathhouse. This gap is foamed with polyurethane foam.

- The wall is coated with bitumen mastic.

- Further, the work is carried out similarly to the insulation of the strip base. During work, the posts must also be covered from the outside with insulation.

The work is labor-intensive and requires free time of at least a week. You will have to work hard, but it will be easier and faster to heat the bathhouse. And the steam room will last longer, which will please your family. And may the steam be light and the procedure useful.

Preparation and calculation

First, you need to draw a diagram of the site in accordance with the scale, designate the area for the installation of a bathhouse and conduct communications to it. The location of the building largely depends on the drainage device. When connecting the water drainage to the central sewer system, the bathhouse can be located anywhere in the summer cottage. If the drain is separate, then it is better to place the building away from bodies of water.

The bathhouse area must be fenced off from outsiders - a fence is needed on the site. The building can be surrounded by hedges. All additional plantings or extensions are also marked on the site plan.

The work begins with cutting off the top layer of soil. Next, the area needs to be leveled. This can be done using special equipment. Changes in height should be avoided - this will complicate the marking and make it impossible to lay the foundation evenly. The marking is made based on the design on paper, so the further arrangement of the base depends on the accuracy of the terrain image.

The outer perimeter of the foundation is marked using a tape measure and a construction angle. The extreme points are marked with pegs through which the cord is pulled. It is necessary to check the perpendicularity of the corners at each stage of marking. To check the accuracy of the placement of marks, measurements of the diagonals of the structure are taken. If the building is rectangular or square, then the diagonal dimensions will be equal.

To accurately place the pegs, you must use special geodetic equipment - a theodolite or level. You should check the length of each side and the degrees of the angles several times. The tensioned cable is the height level of the future foundation. After marking the outline of the building, the area is broken down.

When constructing piles, pegs mark the location of future wells. Their number depends on the area of the bathhouse. The excavation spacing should not exceed two meters. Piles also need to be placed at the junction of the load-bearing wall and partitions. If the number of floors of the future building reaches two or more floors, then the distance between the supports must be reduced. Dense soil allows you to reduce the number of piles, while loose soil does the opposite. The depth of the well depends on the type of soil: in heaving soil, the pile must be lowered 30-50 centimeters lower.

A monolithic foundation can be poured without preliminary calculations - the optimal thickness of the foundation should reach 25 centimeters. Reducing the screed may require additional reinforcement with reinforcement. With a foundation thickness of thirty centimeters or more, a strong structure is obtained, but such construction cannot be called economical. It is customary to cover a substrate of sand and gravel in layers not exceeding ten centimeters in thickness.

The insulation board should not exceed ten centimeters. A concrete base also requires a frame made of reinforcement. According to regulatory documents, for reliable construction, reinforcement should not be less than 0.3 percent of the total mass of the structure. The dimensions of the rods can be calculated with your own hands based on the cross-sectional area of the slab. To save time, craftsmen advise installing a frame made of rods 12-13 millimeters in diameter in two tiers.

Insulated foundation for a bathhouse

Is there a need to insulate the foundation of a bathhouse, how justified is this process, will an insulated foundation reduce heat losses? There are actually a lot of questions about this problem, because in the old days no one was involved in insulating baths. This is all true, but in the old days no one thought about it seriously. A modern approach to the implementation of the construction of any building or structure should go in parallel with issues that relate to thermal insulation. And bathhouses are not in last place in this matter, especially since everything is connected with monetary costs relative to the fuel consumed.

So, experts have calculated that up to 20% of thermal energy is lost through the floor, and accordingly through the foundation. So much for unexpected fuel expenses. What needs to be done to reduce this indicator to nothing? There are two options: insulate the floor and foundation. And since the topic of our article concerns the foundation, let’s talk about how it can be insulated correctly.

Insulation of different types of walls

Owners sometimes insulate the bathhouse from the outside at their own discretion. The procedure is not cheap. If the cost of heat loss exceeds the cost of cladding materials, the work will have to be done.

How to insulate a wooden bathhouse from the outside

Thick walls made of timber or logs. There is no point in insulating them from the outside. Wood itself is the insulation material, plus the internal thermal insulation of the bathhouse. Walls made of timber or logs are insulated by sealing cracks. Caulk the gaps between the crowns with flax, eliminate cracks near the frames of windows and doors.

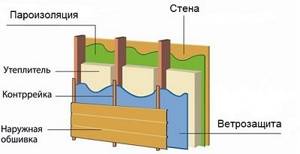

If a wooden bathhouse is made of boards or the walls are made of thin beams or logs, a ventilated façade is installed outside. Polystyrene foam and expanded polystyrene cannot be used even in this technology. The boards do not allow moisture to pass through. For this reason, they do not combine well with wood. Wooden walls will begin to rot from the vapors accumulated under the insulation. It is better to install basalt wool in a ventilated façade.

Advice! If the log house is warm but unsightly, the outside of the bathhouse can be lined with a ventilated façade without thermal insulation. Only steam and waterproofing and sheathing are attached under the panels.

Insulation of a frame bath

A special feature of frame buildings is the presence of insulation inside the walls. There is no need for additional costs for external insulation. For beauty, you can install a ventilated façade without thermal insulation. Only if the insulation inside the frame has become unusable, then a full-fledged ventilated façade with basalt slabs is installed on the outside.

Insulation of a brick bath

For a bathhouse made of brick, cinder block, foam block and other similar materials, it is advisable to insulate the outside. Preference here is given to “wet facade” technologies. Such insulation is cheaper. Budget thermal insulation is polystyrene foam. Expanded polystyrene or basalt slabs will cost a little more. The thermal insulation on top is covered with decorative plaster and painted with facade paint.

When the budget allows, the outside walls are insulated using the “ventilated facade” technology. If for a wooden bath you can only use basalt wool, then here you can lay foam or expanded polystyrene slabs between the sheathing. It is only important to seal all joints and cracks with polyurethane foam to avoid the formation of cold bridges.

Materials for thermal insulation of foundations

Of course, we need to start with insulation. What can be used today to insulate the foundations of a bathhouse? In principle, the range of models is not that large, because the foundation is not floors or walls; the operating conditions are completely different here. Namely: large vertical and horizontal loads, high temperature changes, negative effects of the soil in terms of chemical and mechanical influence.

Therefore, experts offer several interesting options for insulating the foundation of a bathhouse.

- Expanded polystyrene boards.

- Foam glass blocks.

- Brickwork with a lining made of expanded clay, polystyrene foam balls, perlite.

Many may wonder what is mineral wool or glass wool. No one has canceled them, but, as practice shows, more effective insulation materials have appeared that can better withstand the loads below the ground. This mainly concerns moisture. Therefore, anyone who is going to insulate the foundation of a bathhouse should choose the simplest and cheapest option - installing polystyrene foam boards.

How to select the components of a concrete mixture?

We have already found out that the active components in the solution formula are cement and water, which makes it work. Only the grade of cement should not be confused with the grades of concrete, since these are completely different parameters. M of Portland cement means a value indicating the strength of the cement mortar. Therefore, regardless of what kind of concrete is needed for the construction of the future foundation, cement is taken with the marking M400 or M500.

Most often, Portland cement is used to independently mix concrete for the foundation. A pozzolanic analogue can be used if there is no base, as it shrinks greatly in the open air. The slag version perfectly resists ground moisture, but is pleased with frost resistance.

Since the foundation is a predominantly reinforced structure, crushed stone with a fraction of up to 40 mm is needed to mix concrete according to construction requirements. The optimal choice is crushed granite gravel, its rough edges optimize traction. Crushed limestone is not suitable for aggressive groundwater. You need river or sea sand, but in the absence of it on sale nearby, quarry sand will do. The sand must be sifted and washed. The inclusion of clay and organic inclusions of more than 5% is unacceptable.

You don’t need distilled water for mixing, but you don’t need to scoop it out of a stagnant lake of mud either. There should be no biological impurities, oils, or salts in it at all. Typically, concrete producers use potable water. The amount of water is approximately equal to half the mass of cement.

How to insulate the foundation of a bathhouse

So, we will assume that the foundation has been laid, now we can move on to its insulation. Let's consider the option of external thermal insulation, especially if this is an effective means if the bathhouse is already in operation, that is, built, and it has just been decided to carry out insulation.

In order for you to understand the layout of the heat-insulating material, you need to understand the photo below, which shows all the structural elements of the bathhouse, as well as the heat-insulating layer.

Here, number 1 is the foundation, number 2 is the wall of the bathhouse, and number 3 is the floor of the structure. 4 and 5 are thermal insulation. Number six is a protective coating, 7 is a cushion under the blind area, 8 is the blind area itself, 9 is a sand and gravel mixture (SGM), 10 is a drainage system and 11 is a heat-insulating material laid under the floor base.

Once again, pay attention to the picture showing thermal insulation. Please note that the insulation layers are located both vertically and horizontally. The horizontally laid layer is laid to a certain depth, which is due to the fact that it prevents the depth of seasonal freezing of the soil. After all, the heaving of the soil will depend on this, negatively affecting the quality of the structure itself.

Since we are talking about thermal insulation, it would be appropriate to talk about the thickness of the thermal insulation layer, its laying depth and horizontal laying. In this case, all these quantities are plotted on the drawing under different letter signs. They directly depend on the so-called frost index (MI). Its unit of measurement is degrees C*hour. There are special tables in which the relationship between the IM and the dimensional parameters of the insulating layer is shown accurately. We will not present all the relationships, we will show only two:

- MI is equal to 20000, the thickness of the vertical layer will be equal to 70 mm. With this index there is no need to install horizontal thermal insulation.

- MI is equal to 70000, the thickness of the vertical layer is 140 mm, the thickness of the horizontal layer is 80-90 mm, the width of the horizontal layer is 1.2-1.5 m.

There is an opinion that by laying thermal insulation under the blind area, you can solve the problem of the thickness of the layer being laid. The opinion is completely wrong, because in addition to vertically directed cold, the foundation is mainly affected by lateral cold. This, on the contrary, will lead to an increase in the thermal insulation layer, which is laid under the blind area.

Insulation of the foundation from the outside

Now let's move on to the process of insulating the foundation of the bathhouse. If the bathhouse is operational, then first of all you will have to dig a trench along the foundation. Its width should make it easy to descend into it and carry out thermal insulation processes.

- Add sand or gravel to the bottom of the trench, 10-15 cm thick.

- The concrete screed is poured.

- After drying, the screed and foundation are waterproofed with bitumen mastic. Waterproofing is applied with a roller and brush.

- Expanded polystyrene boards are installed. They can be glued to the same waterproofing until it dries, or secured with special mushroom-shaped screws made of plastic.

- After which protective measures are taken. For example, you can cover an insulated foundation with brickwork (half a brick), install plastic panels, siding, and so on.

If the insulation of the bathhouse foundation is carried out with the installation of a horizontal layer, then you will have to dig a wide trench in accordance with the above tables, where the ratio of the size of the layer to the IM is established. Here you will also need to make a backfill of sand or gravel, pour a screed and carry out waterproofing measures. After which the trench is dug.

A prerequisite for insulating the foundation of a bathhouse is the construction of a blind area.

- Firstly, this device protects the foundation from natural precipitation. The length of the blind area is usually within one meter, so water drainage is guaranteed.

- Secondly, this concrete device creates a certain thermal protective barrier if insulation is placed under it.

The angle of inclination of the blind area is 2-3%.

Insulation from the inside

Is there a need to insulate the foundation from the inside if insulation is done from the outside? Of course, there is no such need. It’s just that this process is easier to carry out if there is an unheated basement under the bathhouse floor. That is, you don’t have to dig a trench and do all the processes described above from the outside. After all, as practice shows, this is quite difficult and involves a large amount of excavation work.

Therefore, it is recommended, if possible, to insulate the bathhouse foundations from the inside. But here you can use a large list of insulation materials. In principle, the insulation process itself is carried out using the same technology, except for excavation work and pouring screed.

- Waterproofing is being carried out.

- Thermal insulation material is laid and secured.

- Protective finish.

A prerequisite is insulation of the basement floor under the bathhouse. For which you can use perlite or expanded clay, a layer of which is filled with a concrete screed.

Practical recommendations

You can determine what brand of concrete is needed for the foundation of a bathhouse without weighing and complex calculations. The method is based on meeting the conditions under which the most durable material is obtained. The cementitious emulsion should fill all the free space between the solid fractions of the mixture.

To do this, take a measuring container and a 10 liter bucket. The sand and gravel mixture is poured into a bucket and filled with water, measuring the volume using a measuring cup. When the water rises to the surface of the mixture, record the measured volume of water. This will be the volume of cement that needs to be added to the solution.

If you managed to pour 2 liters of water into the bucket with the filler, then to obtain concrete, mix a bucket of sand-gravel mixture and 2-liter measures of cement. The cement-mixture proportion will be 1/5. Water is added to the dry mixture in portions until a plastic mass is formed.

We do the insulation of the bathhouse foundation with our own hands

The bathhouse soars, the bathhouse rules, the bathhouse will correct a hundred ailments. This is how a popular proverb characterizes the bathhouse eloquently. Indeed, this is an inexhaustible reservoir of health and vital energy.

Bathhouse layout diagram.

Therefore, those who have the opportunity to build such a wonderful structure on their own site are truly lucky. However, having a bathhouse is one thing, but building it with your own hands is a completely different matter.

And first of all, because the structure must be strong, durable, and most importantly, capable of retaining heat for a long time. To do this, you need, at a minimum, to know the specifics of construction work and the ability to select the right materials.

But any knowledge and skills fade into the background when solving issues related to heat conservation. This means that you will have to insulate the walls, floor, and ceiling.

From this chain one cannot exclude such an important element of the entire bath structure as its foundation. It serves as the foundation of the structure, so high-quality insulation of the foundation will significantly reduce heat losses and save on fuel.

Why do you need a warm foundation?

Comparison of the characteristics of thermal insulation materials.

Quite often you can hear the opinion that insulating a bathhouse and its foundation is a waste of effort and money. This work is undoubtedly very labor-intensive and painstaking, so some believe that it is better to spend more firewood once a week in order to properly warm the floors and create a comfortable temperature regime than to properly insulate the bathhouse.

But the premature destruction of the foundation and walls will very quickly make itself known and force one to admit the fallacy of this judgment.

In the warm season, the uninsulated foundation becomes covered with condensation. Air heated by the sun from the street penetrates under the foundation, where it meets a cold wall, cooled by damp soil.

The moisture in the air condenses and falls on the concrete base in the form of dew.

Why is this necessary?

Due to the fact that it is completely inconvenient to insulate an already finished building, the process of thermal insulation begins at the construction stage. The first step is to carry out all the internal work - insulation from the inside of the walls, roof, foundation and floors. We will share how to insulate a wooden bathhouse from the outside.

First of all, of course, the foundation is insulated, then the floors. After this, they move on to the walls of the bathhouse. They need to be treated especially carefully, since the walls account for the largest area of the entire room. Let’s not ignore the insulation of a wooden bathhouse from the outside.

If the insulation of the bathhouse from the inside is carried out incorrectly or is completely absent, this threatens the owner of the premises with large material costs for energy resources.

This is explained by the fact that a bathhouse without an internal insulating layer is simply not capable of retaining heat.

No less important is the process of thermal insulation of the ceiling and roof of the bathhouse, since, according to the well-known laws of physics, hot air rushes upward and thus can leave the bathhouse if there is no insulation layer.

Only after all this do they move on to external insulation. Is it necessary? Absolutely yes.

External insulation is necessary to ensure that the high temperature in the bathhouse is maintained for as long as possible.

In addition, the bathhouse is usually used no more than once or twice a week, which means that most of the time the walls of the bathhouse are exposed to temperature changes and precipitation.

Insulating a bathhouse from the inside solves this problem, as it eliminates contact between the walls of the bathhouse and cold air, and also protects against precipitation.

Important! Due to the fact that insulating a bathhouse from the inside eliminates direct contact of the structure with cold air and precipitation, the service life of the structure increases significantly.

The sequence of work, as well as the type of insulation material, directly depend on the material of the walls.

If the structure of the bathhouse consists of logs, you just need to carefully seal all the cracks and holes, since wood has the lowest thermal conductivity. The main thing is that the thickness of the wood is suitable.

When timber is used as a material for the construction of bath structures, it is most often necessary to insulate the walls from the outside.

The material and complexity of the upcoming work can be determined only after the thickness of the timber itself becomes known, as well as the climate of the region in which it is planned to build the bathhouse.

External insulation of a bathhouse is only necessary for structures made of building blocks or concrete, since their thermal conductivity is quite high.

In order to do without insulation, the wall thickness must be at least eighty centimeters, and this is completely unprofitable from a financial point of view.

Therefore, external insulation of a bathhouse made of blocks is necessary under any circumstances.

Installation of insulation

As a result, the inside of the foundation remains wet all summer. Over time, the wet surface first becomes covered with mucus, then with mold. And after a few years, the foundation, and perhaps also the walls, will require major repairs.

Scheme of foundation insulation using expanded clay.

In winter, with the onset of cold weather, the situation looks even more depressing. An uninsulated foundation becomes absolutely defenseless against buoyant forces, under the influence of which it swells, warps and quickly collapses, the consequences of which can threaten the entire structure. And then even repair work will not be able to correct the situation.

Taking into account the importance of the problem, its solution should be started at the stage of design and construction of the foundation of the bathhouse. Fortunately, the modern market offers a wide selection of heat-insulating materials produced using advanced technologies.

Their main advantage is their small thickness and excellent heat-saving properties. Therefore, if you wish, spending very little money and without resorting to the help of specialists, you can insulate the foundation of a bathhouse yourself.

Arguments in favor of insulating the bathhouse foundation

It is known that almost a quarter of the total heat loss of a bathhouse is lost through the foundation.

Its freezing leads to premature aging and destruction of the waterproofing coating. At the same time, insulating the foundation allows you to:

- reduce heat loss and heating costs;

- maintain an optimal and stable air temperature inside the bath;

- prevent the formation of condensation on the inner surface of the foundation;

- protect waterproofing from mechanical stress and damage, and increase its service life

Advantages of extruded polystyrene foam

Scheme of thermal insulation of the foundation with polystyrene foam.

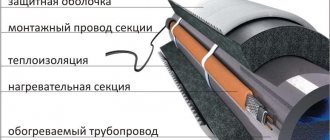

The properties of the raw materials and the closed-cell structure of extruded polystyrene foam prevent the penetration of moisture into the slab, due to which the service life of the insulation is at least 40 years.

Excellent technical characteristics make it indispensable for thermal insulation of baths.

At the same time, this material is less likely to be damaged by rodents than conventional granulated polystyrene foam.

Today, foundation insulation with extruded polystyrene foam is the most rational and gives the best effect. The use of other materials is usually more expensive and less effective.

Insulation of the foundation from the outside

In the process of preparing the foundation for pouring, the formwork and trench for it are made wider than the calculated value by the thickness of one or two polystyrene sheets, the insulation of which gives the best result.

In this case, the density of the material must be at least 35 kg/m³, and the thickness must be more than 10 cm. The insulation is attached to the foundation.

After removing the formwork, it does not require additional mechanical protection. The part of the foundation that rises above ground level is finished with decorative stone or tiles directly on top of the insulation.

Outside

Today, penoplex is the most popular for thermal insulation of walls in rooms for any purpose. Next, we’ll find out which insulation for outside bath walls is better.

It does not allow water to pass through, is resistant to temperature changes, durable and has low thermal conductivity.

Next, about insulating the walls of a bathhouse from the outside with your own hands.

This is why penoplex is considered one of the best synthetic materials.

To insulate walls made of logs and logs, natural materials are most often used; in turn, for a frame or bathhouse made of blocks, penoplex is ideal.

Attention! Penoplex has average fire resistance, and during combustion it releases toxic substances. That is why it is unacceptable to use it for internal insulation of a bathhouse.

Let's look at the process of insulating a bathhouse from the outside step by step:

- The first step is to clean the walls of any kind of contamination, such as paint residues, dust or dirt;

- Next, the surface of the wall should be coated with a primer in two layers;

- When the applied layers have dried, the vapor barrier layer can be fixed;

- Next, glue is applied to the foam sheet; the thickness of the insulation layer should be at least 7 cm;

- The sheet is attached to the wall and additionally secured with “fungi”;

- After the wall surface is completely covered with the first layer of insulation, you can proceed to arranging the second layer. To do this, the foam sheets must be placed in such a way as to overlap the seams of the first layer;

- When the glue is completely dry, you can begin sealing the gaps with sealant or foam;

- Next, you should strengthen the structure with a fiberglass mesh attached on top of the second layer with glue;

- The final stage is plastering the walls, as well as further finishing.

Don't forget about wind protection.

To protect the walls and the thermal insulation itself from precipitation, wind and condensation, waterproof, windproof membranes are used.

This protects the wall and thermal insulation.

They are laid on the outside of the insulating layer directly under the building's cladding and secured using a construction stapler.

Insulation of the foundation from the inside

Scheme of horizontal insulation of the foundation.

If for some reason problems arise with insulating the bathhouse foundation from the outside, you can insulate it from the inside. True, most experts do not recommend doing this, because in winter this can lead to increased freezing of the foundation walls.

Thus, by protecting the heat remaining inside, through the external defenseless part, you give them over to the power of frost. Increased soil heaving will certainly lead to accelerated destruction of the foundation.

In this regard, it is not necessary to insulate the internal part without insulating the external part.

If there is nothing else left but to insulate the foundation from the inside, then at least first check the ability of the walls to accumulate condensation moisture. Attaching the thermal insulation from the inside is done in exactly the same way as with the external device.

Features of insulation technology

The foundation is insulated to a certain depth, the value of which is usually equal to the level of soil freezing in the coldest period of the year. The place for the heat insulator is prepared in advance, already at the stage of constructing the foundation itself. In this case, the formwork - the frame, which is subsequently filled with the foundation, is made wider by the thickness of the polystyrene foam layer. After pouring the foundation and removing the formwork, the heat insulator is attached from the outside to the concrete or cement base of the building, and the area protruding above ground level is finished with finishing material directly along the surface of the insulation.

Usually, before laying the insulator on the foundation, a layer of waterproofing is fixed - a polyethylene or foil film that protects the foundation of the building from the damaging effects of external moisture. This layer also serves as additional thermal insulation and protection of the foundation from mechanical damage. All seams between sheets of polystyrene foam and waterproofing are sealed using metallized tape. This problem can also be solved by laying the insulation overlapping or in two layers, with the second layer covering all the seams and joints of the previous one.

Expanded clay insulation can be used to seal areas around pipes or cables. In addition, insulation of the foundation, carried out by combining several materials, has recently gained particular popularity. The peculiarity of this modern method is the installation of the base of the building on pillars with a conical extension at the base. This significantly increases the stability of the structure, while a ventilated space remains under the foundation, which can be covered with expanded clay. Otherwise, thermal insulation is carried out according to the same rules.

The foundation of any structure serves as the basis for its strength and durability. For a bath, in addition to its main purpose, the foundation also retains the heat that is created inside the room. A fairly common misconception is that it makes no sense to insulate the foundation of a bathhouse due to the economic inexpediency of this work. Since staying in the bathhouse is periodic, it is easier to heat it thoroughly once or twice a week, even if you spend more firewood on it, than to carry out expensive and very labor-intensive work associated with insulating the foundation. But the possible premature destruction of the uninsulated foundation, and then the walls, will soon show the inconsistency of such reasoning. This article will tell you how to insulate the foundation of a bathhouse.

Insulation of the foundation with a slight depth

When laying a foundation above the freezing line of the soil, you need to keep in mind that very soon heaving forces will begin to manifest themselves, very often leading to deformation of the structure.

You can reduce the depth of freezing under the foundation by insulating the soil around the perimeter of the bathhouse under the blind area. Thanks to this, it is possible to maintain the frost line in the backfill, gravel or sand cushion.

In this case, extruded polystyrene foam is laid with a blind area slope of 2%. The perimeter thermal insulation made from it must have a width no less than the freezing depth of the soil.

At the same time, the thickness of the horizontal thermal insulation should be no less than the thickness of the vertical thermal insulation of a conventional foundation.

Foundation slab

When insulating the foundation slab, thermal insulation boards are laid on top of the waterproofing.

When reinforcing a monolithic foundation slab in a bathhouse using knitted reinforcement, a polyethylene film having a thickness of 200 microns or more is used to protect the insulation from liquid concrete.

When performing reinforcement work using welding, a protective screed is made on top of a film of cement-sand mortar or low-grade cement. In this case, the film sheets are laid on double-sided tape with an overlap of 130-150 mm.

Only in this way can you save the foundation from freezing and premature destruction. Take care of it today, otherwise tomorrow may be too late!

Insulation at altitude

After the bathhouse has been built and is already being prepared for commissioning, and perhaps is welcoming its first steamers, it is necessary to take care of insulating the base and blind area. This will prevent heat leakage through these structures, and will also prevent the harmful effects of frost heaving forces. The algorithm of work in the case of insulating the base partially repeats the process of thermal insulation of the foundation. Before you begin, you need to make sure that the surface is smooth and clean. In case of differences and unevenness, leveling compounds should be used.

The same XPS boards are used for insulation. They are strong, durable, and retain heat excellently. In addition, some brands, such as TECHNOPLEX, have a special L-edge. This lock allows you to connect the slabs groove to groove, thus forming a single thermal insulation layer.

When choosing XPS for a plinth, you also need to look at the type of surface. If plaster is chosen as a decorative finish, then the slab must be milled on both sides. If you have time and effort, this can be done manually using a hacksaw. An alternative option is to buy factory milled XPS board. Such slabs can be distinguished by the FAS index in the name. After gluing and doweling the XPS boards, the surface is plastered using standard technology

Another modern and quick finishing method is using bitumen facade tiles. In this case, it is possible to use slabs milled on one side - the one that will be facing and fixed on the plinth. The insulation boards are fixed using adhesive foam or polymer-cement compounds, and then additionally doweled.

The bitumen façade tiles themselves are attached with a plastic screw fastener “Screw R16” directly to the XPS slabs, which serve as a flat and durable base. You can handle these jobs on your own, just know how to use a screwdriver.