The principle of operation of the collector and how to choose it

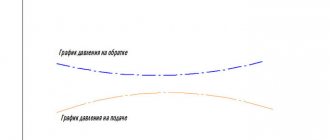

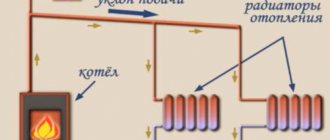

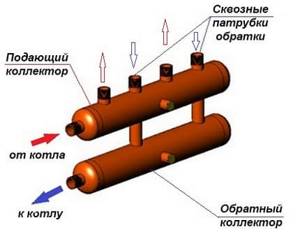

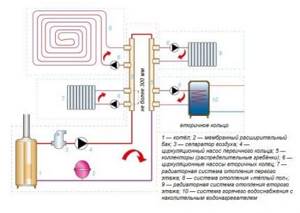

The collector, or “comb”, as it is often called popularly, has at its base two main pipes (supply and return), to which nozzles are connected. Each such pipe has a continuation of the supply or return pipeline, respectively. A pump is installed on the supply manifold to circulate hot water.

A servo drive is mounted on the supply manifold to close the valve. When the water temperature reaches the specified parameters, the temperature sensor, when triggered, activates the servo drive, which presses the valve. The valve, in turn, blocks further water supply until the next moment it is cooled by a certain number of degrees.

After the heat is transferred through the radiator into the room, the water in the reverse circle of the system returns to the boiler, where it is heated again and supplied to the collector for further circulation.

Maintaining the required water pressure on the supply manifold is achieved by installing special regulators. They also regulate the required amount of water.

The choice of the required collector is influenced by the following factors:

- area of premises;

- number of radiators;

Operating principle and types of solar collectors

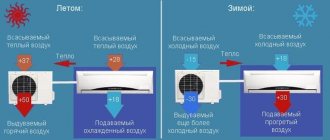

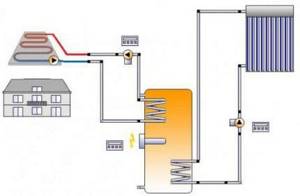

The time has come to say a few words about the design and operating principle of the solar collector. The main element of its design is the adsorber, which is a copper plate with a pipe welded to it. Absorbing the heat of the sun's rays falling on it, the plate (and along with it the pipe) quickly heats up. This heat is transferred to the liquid coolant circulating through the pipe, which in turn transports it further through the system.

The ability of a physical body to absorb or reflect solar rays depends, first of all, on the nature of its surface. For example, a mirror surface perfectly reflects light and heat, but a black surface, on the contrary, absorbs it. That is why a black coating is applied to the copper plate of the adsorber (the simplest option is black paint).

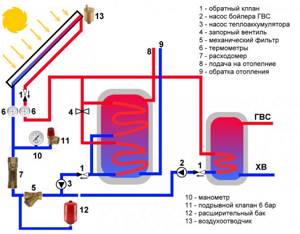

The principle of operation of the solar collector

1. Solar collector.2. Buffer tank.3. Hot water.

4. Cold water.5. Controller.6. Heat exchanger.

7. Pump.8. Hot flow.9. Cold flow.

You can also increase the amount of heat received from the sun by correctly selecting the glass covering the adsorber. Regular glass is not transparent enough. In addition, it glares, reflecting part of the sunlight falling on it. In solar collectors, as a rule, they try to use special glass with a low iron content, which increases its transparency. To reduce the proportion of light reflected by the surface, an anti-reflective coating is applied to the glass. And to prevent dust and moisture from getting inside the collector, which also reduce the throughput of the glass, the housing is made sealed, and sometimes even filled with inert gas.

Despite all these tricks, the efficiency of solar collectors is still far from 100%, which is due to the imperfection of their design. The heated adsorber plate radiates part of the received heat into the environment, heating the air in contact with it. To minimize heat loss, the adsorber must be insulated. The search for an effective way to thermally insulate an adsorber led engineers to the creation of several types of solar collectors, the most common of which are flat and tubular vacuum.

Flat-plate solar collectors

Flat solar collectors.

The design of a flat solar collector is extremely simple: it is a metal box covered with glass on top. Mineral wool is usually used to insulate the bottom and walls of the housing. This option is far from ideal, since heat transfer from the adsorber to the glass through the air inside the box cannot be ruled out. With a large temperature difference between inside and outside the collector, heat loss can be quite significant. As a result, a flat solar collector, which functions perfectly in spring and summer, becomes extremely ineffective in winter.

Design of a flat solar collector

1. Inlet pipe.2. Protective glass.

3. Absorption layer.4. Aluminum frame.

5. Copper tubes.6. Heat insulator.7. Outlet pipe.

Tubular vacuum solar collectors

Tubular vacuum solar collectors.

A vacuum solar collector is a panel consisting of a large number of relatively thin glass tubes. An adsorber is located inside each of them. To prevent heat transfer by gas (air), the tubes are evacuated. It is precisely due to the absence of gas near the adsorbers that vacuum collectors are characterized by low heat loss even in frosty weather.

Vacuum manifold device

1. Thermal insulation.2. Heat exchanger housing.3. Heat exchanger (collector)

4. Sealed plug.5. Vacuum tube.6. Capacitor.

7. Absorbing plate.8. Heat pipe with working fluid.

Pipe selection

The main point of installing collector wiring is the correct choice of pipes. In the installation of this system, a large number of connections are used, which entails the use of a large number of clamps and fittings. For this purpose, soft, flexible suture metal-plastic or polyethylene pipes are most suitable. Copper pipes are used to exit the pipes from the manifold.

These pipes have the properties of preventing air from entering due to a special coating on the outer surface.

The most optimal pipe diameter is 16 mm. However, you should consult a specialist on this issue.

Purpose of the heating manifold

The absence of a distribution manifold in a water heating system can lead to the fact that water may flow unevenly into different circuits of the system. As a result, you will have a hot floor and cold radiators, or vice versa.

This may occur because several heating system circuits can be connected to one boiler outlet. The liquid flows unevenly through such connections, as a result of which part of the premises will not have enough heat. But the efficiency of the heat supply system depends on the amount of coolant passing through the pipes, the volume and speed of its movement.

pipes coming from the boiler

Some home owners try to solve this problem by installing additional pumps and control valves. But this only complicates the system and does not always lead to uniform distribution of the coolant.

Advantages and disadvantages of the collector system

Due to the emergence of a variety of plastic and polyethylene pipes, the collector heating system has replaced the tee system, due to the following advantages:

- When installing and operating a collector heating system, you can do without highly qualified specialists.

- The efficiency factor (efficiency) increases due to the fact that the coolant delivers heat to the radiators faster and with less losses . This is achieved due to the operation of the circulation pump and the poor thermal conductivity of plastic pipes. These pipes carry heat with the least loss to the radiators, which, thanks to their special design, effectively heat the room.

- Increasing the efficiency of the heating system makes it possible to reduce pipe diameters and boiler power, and also saves fuel.

- Since plastic pipes from heating devices to collectors do not have connectors (joints), they can be walled up in the floors and walls of the house . This gives an aesthetic appearance to the room.

- Makes it possible to heat a house without traditional radiators using heated floors.

- High maintainability. Since it is possible to disconnect any section of the pipeline from the water supply, without interfering with the functionality of the entire heating system.

- Simplicity of design , since there is no need to apply complex mathematical calculations.

- Possibility of adjusting the temperature on each heating device. What creates a certain comfort

The disadvantages of a collector heating system are:

- Airing the system . The air remains in the system after it is filled with coolant, which enters the heating devices horizontally and quickly under the influence of the pump. Air from microscopic bubbles combines and accumulates at the highest points of the radiators.

- High cost due to the presence of a pump, manifolds, shut-off valves and a large number of pipes for moving the coolant.

- Cannot work without circulation pump .

- A special room is required for the manifold cabinet.

- Labor-intensive installation and material consumption.

The nuances of the procedure for de-airing heating radiators are described in this article: https://teplo.guru/sistemy/udalenie-vozduha-i-vozdushnoy-probki.html

From the above it is clear that the collector heating system is considered reliable and comfortable for a low-rise cottage. But the cost of this system is much higher than the tee system .

Positive and negative aspects of the collector circuit

When planning the installation of heating with collector wiring, you should carefully study the technical side of the issue and determine all the positive and negative qualities of this system. Taking these qualities into account when building a house, you will be able to achieve its greatest energy efficiency.

- direct control of each individual radiator of the system;

- a differentiated approach to heat distribution in each room, which makes it possible to effectively maintain the required temperature throughout the house, while saving money;

- ease of operation, the ability to access each component of the system without interfering with the operation of the others;

- aesthetic component, which consists in the possibility of installing the pipeline and auxiliary components of the system in the wall or floor;

- high payback associated with efficient consumption of energy resources.

Negative qualities: high costs at the initial stage of design and installation associated with the need to use pipes and additional components;

As you can see, there are not many disadvantages, they are not significant in comparison with the advantages of the system. Therefore, a collector heating system is rightfully considered the best solution today.

In what cases is a collector heating system acceptable?

There is no standard solution when drawing up a diagram of a collector system, and there are also no generally accepted planning standards. The selection of equipment should be carried out by specialists, taking into account the specific tasks that need to be solved.

The opinion of experts should not be ignored: such a system cannot be recommended for heating in multi-storey buildings.

Heating system options in multi-storey buildings

The problem is that heating in the apartment is provided by the supply of coolant to at least two risers. A prerequisite for the system under consideration is the connection of all radiators to one riser.

Having left one source of heat, you will need to shut off the others, i.e. brew them. The entire load will be concentrated on the left riser, and a closed hydraulic circuit will be formed within a particular apartment.

All radiators located on the upper floors will be cut off from the centralized heating system and no coolant will flow into them. Naturally, residents of the upper floors will express dissatisfaction and will demand the forced restoration of the previous communications.

The only legal option for using collector circuits in an apartment building would be when additional valves were installed during the construction process, allowing the connection of circuits of different configurations.

Advantages of a collector circuit for distributing water supply pipes in an apartment

In apartments, simple water pipe installation is most often performed. There is a pipe coming from the riser. Then, with the help of tees, there are branches from it to plumbing fixtures. At the same time, few people know about another type of pipe routing - manifold. And in vain, because such a system has a number of advantages that need to be discussed.

But first we need to talk about the types of wiring that exist in plumbing today. The first type is tee wiring. In such a system, all consumers are connected from one pipe using tees. It is possible to install shut-off valves in front of each consumer in case of an emergency.

Collector wiring. This system has clear advantages over the tee system. A shut-off valve is installed at the entrance of the water supply to the apartment. The difference is that each device has a separately supplied pipe. In this case, all valves are concentrated in one place.

Sometimes you can find a mixed system. This means that it contains elements of tee wiring and collector wiring. For example, water can be supplied to the washbasin and bathtub from the collector (that is, a separate pipe for each consumer), and the toilet and bidet are connected via tee wiring.

The feasibility of installing a collector system

Recently, collector heating systems have also begun to be used in the construction of multi-storey apartment buildings using wall-mounted boilers.

But it is impossible to install a collector heating system in an apartment of old multi-storey buildings, because a tee heating system is already working there. For the collector system to operate, it is necessary to close the hydraulic circuit, which is necessary to create coolant circulation in the system. If a closed hydraulic circuit is created in one apartment, then other apartments will be cut off from the heating system .

The collector heating system also cannot be used in areas with unstable power supply, since when the circulation pump stops, the water will freeze and the pipes will fail. But the situation can be somewhat improved by using non-freezing liquid for the heating system.

How I installed the collector wiring with my own hands.

1.

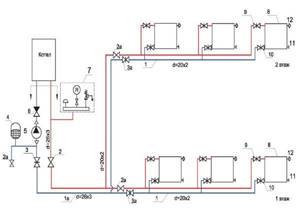

I decided to install a gas floor-standing boiler in the basement of my house.

The boiler was installed on a concrete screed five centimeters thick.

2.

For the installation of the main pipelines I used a metal pipe with a diameter of 32 mm.

3.

A closed expansion tank was installed on the supply pipe.

4.

A circulation pump was installed on the return pipe.

Installing taps on both sides of the pump will allow you to change the device without draining the coolant.

Creating forced circulation in the heating system is mandatory. Forced circulation improves the efficiency of heating the coolant, and also simplifies the system and makes it more compact.

5.

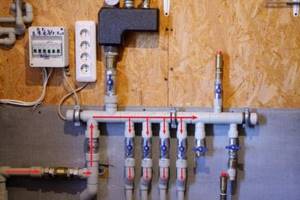

We install collectors (distribution “combs”) on the main pipelines.

The combs are positioned so that the lengths to each heating device on the floor are approximately equal.

For example, if the distance from the collector to one radiator is 10 times greater than to the other, then the coolant pressure drop on the extended segment will be much higher than on the short one. The system is doomed to imbalance.

However, a difference of 2 times is not considered unacceptable.

6.

Each collector outlet has its own shut-off valve - a ball valve.

This allows, if necessary, to disconnect any radiator from the entire system without in any way affecting the operation of other heating devices. Each circuit is essentially an independent heating system.

It’s very convenient – I couldn’t be more pleased!

7.

I secured both collectors to a vertically placed metal corner.

8.

The wiring to the rooms was mounted along the basement ceiling using a metal pipe with a diameter of 15 mm.

9.

The rays of the circuits were connected to the collectors with a metal-plastic pipe.

10.

I installed a tap on the return pipe, through which I recharge the entire system.

11.

I punched holes in the floor slabs through which the pipes are connected directly to the heating devices.

12.

He connected the heating radiators to the risers of the circuits with a metal-plastic pipe.

This is my second winter using heating with manifold wiring. The system did not cause any serious failures, but we had to “fight” the formation of air in the system. There will be a separate article about this.

Types of collectors in heating systems

Collector installations used in the design of closed circulation heating systems come in three varieties.

Depending on the purpose of the design, the following are available on the market: radiator and solar systems, as well as devices equipped with a hydraulic arrow.

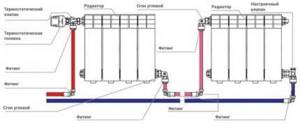

Type #1 - radiator collector heating

Whatever type of heating is designed in the house, radiators are always present in it. Therefore, collectors that distribute coolant flows directly to batteries installed in rooms are the most popular type.

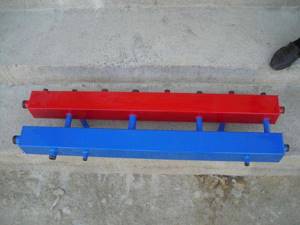

The distribution unit consists of two interconnected combs: the first directs the coolant to the appliances installed in the rooms, the second takes it back to the boiler

Collectors used for radiator heating, depending on the architectural and interior features of the room, can be connected in various ways.

According to the connection method, the radiator heating system can be made in any of the following versions:

- top connection;

- bottom connection;

- side installation;

- leading diagonally.

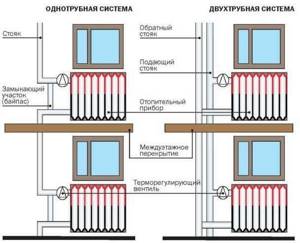

Comparison of collector and other types of wiring

You can choose one of 3 common pipe routing methods:

single-pipe heating - ideal for heating a small private house. In this case, all radiators are connected in series, which means that the last battery in the chain works less efficiently than the first. But the cost of such a scheme is minimal;

Single pipe heating system

with 2-pipe heating, the wiring diagram can be represented as 2 parallel circuits, one supplies hot coolant to heating devices, the second removes cooled coolant to the boiler. This heating method can be considered the most common;

Example of a two-pipe heating system

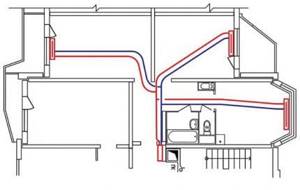

The collector wiring differs from the listed analogues in that each radiator is supplied with coolant individually. That is, a collector is installed in the room (its design is discussed later in the article), and from it a supply and discharge pipeline goes to each battery. This affects the cost and complexity of installation, but all the work can still be done with your own hands.

One of the pipe layout options

Of course, this does not have the best effect on the cost of installation work and materials. The total length of the pipes in this case will be maximum, and the collector also costs money (especially if the model chosen is not from the latest manufacturer with thermostats).

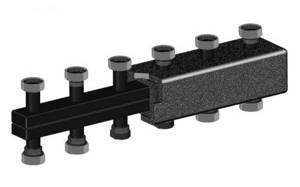

Modifications of distributor combs

Today, there are many types of collectors for heating systems on the equipment market.

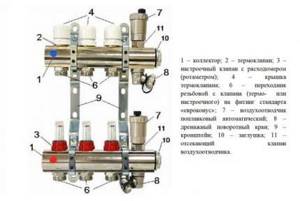

Manufacturers offer both connecting links of the simplest design, the design of which does not provide for the presence of auxiliary fittings for regulating the equipment, and manifold blocks with a full set of built-in elements.

A collector block that includes all the necessary functional elements to create conditions for uninterrupted and high-performance operation of the heating system

The simple-to-use devices are brass models with one-inch branches, equipped with two connecting holes on the sides.

On the return collector, such devices have plugs, instead of which, in the case of “expanding” the system, additional devices can always be installed.

Intermediate assemblies that are more complex in design are equipped with ball valves. For each outlet they provide for the installation of shut-off control valves. Sophisticated, expensive models can be equipped with:

- flow meters , the main purpose of which is to regulate the flow of coolant in each loop;

- temperature sensors designed to monitor the temperature of each heating device;

- automatic air release valves

- electronic valves and mixers aimed at maintaining the programmed temperature.

The number of circuits, depending on the connected consumers, can vary from 2 to 10 pieces.

Regardless of the complexity and versatility of the equipment, materials that are resistant to external factors are used in the manufacture of manifold block combs

If we take the manufacturing material as a basis, then intermediate prefabricated collectors are:

- Brass - characterized by high performance parameters at an affordable price.

- Stainless steel structures are extremely durable. They can withstand high pressure with ease.

- Polypropylene - models made of polymer materials, although they have a low price, are inferior in all characteristics to their metal “brothers”.

Models made of metal are treated with anti-corrosion compounds and covered with thermal insulation to extend their service life and improve performance parameters.

Separating structures made of polymers are used in the construction of systems heated by boilers with a power of 13 to 35 kW

Parts of the device can be cast or equipped with collet clamps, allowing connection to metal-plastic pipes.

But experts do not advise choosing combs with collet clamps, since they often “sin” by leaking coolant at the valve connection points. This occurs due to rapid failure of the seal. And it is not always possible to replace it.

Collectors are used in single- and two-pipe heating schemes. In single-pipe systems, one comb supplies the heated coolant and receives the cooled one

We manufacture a distribution manifold

We calculate the material required for the manufacture of the collector. The easiest way to do this is in Excel spreadsheets. At the same time, in this program you can calculate the cost of materials required for the manufacture of the device. We purchase the necessary starting material and prepare tools for self-production.

preparing tools

The starting materials for the main parts of the collector will be regular or square pipes. We make the necessary markings on them using calipers, a ruler and a core.

We make the necessary markings

Using a gas cutter, we make holes for the pipes.

make holes for pipes

We insert the pipes (pipe sections with threads) into the seats.

Insert the pipes

We fix the pipes by welding. First, rough it out, and then scald it around the entire perimeter.

We fix the pipes by welding

We also weld brackets to the body for wall mounting.

We weld the brackets to the body

We clean the welding areas from scale and rust.

Cleaning the weld areas

We treat the entire structure with a degreasing compound and cover it with paint and varnish.

treated with a degreasing compound, coated with paint and varnish

The paint completely sets in two to three days and we have a self-made distribution manifold at our disposal. Now all that remains is to install it in place and connect all the incoming and outgoing circuits to it.

ready-made homemade distribution manifold

A system with a distribution manifold will work much more efficiently than a simple pile of heating pipes

In order to catch all the nuances of making a distribution manifold yourself and the scope of its application, we recommend that you watch the training video.

Manifold wiring for heated floors

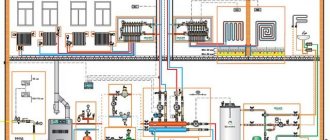

Installation of a heated floor using collector wiring is carried out similarly to a conventional water floor. You can install a heat transfer element under the floor covering and then connect it to the collector. Practice shows: it is possible to combine a collector for floor heating together with heating through radiators, but this should not be done. Multi-temperature systems.

It is worth remembering about thermal regulation: heated floors have less heat transfer, radiators have more.

The collector heating system today is the most efficient, economical, and quickly pays for itself. It is convenient, simple, and visually invisible, which makes living where it is installed as comfortable as possible.

Feed and return manifold comb device

Combs are one of the main elements of the collector circuit; their main function is to distribute the coolant flow along the heating circuits. The element has a different design for lines of connected radiators and heated floors, the maximum number of involved circuits per collector does not exceed 12.

In relation to the diameters of the outlet fittings, the comb has a large cross-section (1.1 1/2 inches versus 3/4) and is connected to the main line through an end connection with elements of plumbing fittings. Typically, the pipeline is connected to the outlet fittings using compression fittings (Eurocones) - this method can be used to connect pipes made of cross-linked and heat-resistant polyethylene, metal-plastic, most often used in manifold heating systems. Combs are made of stainless steel, brass, plastic, some modifications are assembled from individual links.

Selection of system components

When designing heating, it is best to purchase factory-made distribution units.

Thanks to the diversity of the range, it will not be difficult to select a comb for certain heating parameters, thereby ensuring the accuracy and reliability of the system.

On sale you can find ready-made manifold blocks that combine supply and return units, as well as thermostatic valves and automatic air vents

The key parameters when choosing pipes for heating circuits are corrosion resistance, heat resistance and high burst strength. In addition, the pipes must have the necessary flexibility so that they can be laid at any angle.

When choosing products, preference should be given to pipes produced in coils. The use of one-piece products will allow you to avoid connections in the wiring, which is especially important for closed installation methods inside the screed.

Pipes for private cottage systems

When designing heating in private houses, it is worth focusing on the fact that the pressure in the system is about 1.5 atmospheres, and the coolant temperature can reach:

- for radiators – 50-70 degrees;

- for heated floors – 30-40 degrees.

For autonomous heating systems with their predictable parameters, it is not at all necessary to purchase stainless corrugated pipes. Many owners limit themselves to purchasing pipes made of cross-linked polyethylene marked “PEX”.

Polyethylene pipes for heating circuits are available for sale in 200-meter coils; they are able to withstand pressure up to 10 kgf/kV.cm and operate at temperatures within 95 °C

Such pipes are joined using tension fittings, so that inextricable connections can be obtained.

In addition to high performance parameters, the main advantage of cross-linked polyethylene is the mechanical memory of the material. Therefore, if you forcefully stretch the edge of the pipe and insert a fitting into the resulting gap, it will tightly surround it, ensuring a strong connection.

When using metal-plastic pipes, the connection is made using union fittings with crimp nuts. And this already turns out to be a detachable connection, which, according to SNiP, cannot be “solidified”.

You may also find information about which pipes are best to choose for heating, discussed here.

Pipes for apartment buildings

If the collector system is installed in an apartment building, then it is worth considering that the operating pressure in it is 10-15 atmospheres, and the coolant temperature can reach about 100-120 °C. It should be remembered that collector heating is only possible on the ground floor.

The best option for installing the system in an apartment building is the use of corrugated pipes made of stainless steel.

A clear example of this is the products of the Korean company Kofulso. Pipes of this brand are capable of operating at a working pressure of 15 atmospheres and withstand temperatures of about 110 °C. The collapse pressure of Kofulso pipes reaches 210 kgf/sq.cm.

Due to the excellent flexibility of the pipe, in which the bending radius is equal to its diameter, the products are convenient to use when laying “warm floors”

Assembling pipeline connections using such elements is not difficult. The pipe is simply inserted into the fitting and secured by screwing on a nut, which compresses the corrugated metal surface with an elastic silicone seal.

Which material to choose?

To select a suitable collector system, it is necessary to decide on the material from which the combs and heating circuits will be made.

- The stainless steel collector body is reliable and durable, but it is also the most expensive of the entire line of models. This comb will last almost forever, withstanding changes in pressure and temperature. It is not economically feasible to install it in a city apartment. But it is perfect for installing a collector heating system for an apartment building.

- The most popular among consumers are brass combs. Possessing high performance qualities, their cost belongs to the budget class of models.

- When installing a collector heating system, you should not skimp on materials, so polypropylene combs, which have a low safety margin, are not in demand, despite their affordable price. In addition, with certain skills, you can independently assemble a decent manifold from plastic pipes and tees.

When choosing a distribution comb housing, we must not forget about the requirements for the pipes through which the coolant circulates in the system. There are also nuances and features here.

- The most important thing is that the pipe is sold in coils. The main difference between a collector heating system is the absence of connections during wiring.

- High thermal strength, anti-corrosion coating, long-term service - these qualities also attract buyers in the first place.

- The flexibility of the material also matters. The laying of pipes from the collector to the heating devices has an arbitrary geometry, and the underfloor heating system uses a serpentine or spiral circuit.

Corrugated stainless steel pipes meet the necessary requirements, but are not very popular due to their high cost. But plastic pipes have the best price-quality ratio and are used everywhere.

For the heating system in the apartment, he recommends using pipes made of cross-linked polyethylene. They are, of course, more expensive than cast iron or ordinary polyethylene pipes, but they are still quite affordable, although you will also have to spend money on the appropriate fittings. Installation is carried out using special hand tools. At the same time, it is very, very important not to damage the protective layer. We can say that the longevity of the pipeline will depend on care during operation, which is why it makes sense to entrust the installation to certified craftsmen.

System installation features

The collector heating system of a private house should be installed during the construction stage. After all, after laying or pouring the finished floor, installing such a system will become economically infeasible. The only solution to the problem in this case will be an open method of wiring installation.

Installation of distribution comb

On the floors of houses with horizontal heating distribution, to accommodate the collector, circulation pump and control equipment, you will need to install a closed box - a collector cabinet.

A closed box will protect equipment and shut-off valves from external mechanical influence and give the room a more aesthetic appearance

The manifold cabinet is installed in separate niches of rooms protected from moisture. Most often, a place is allocated for this in the hallway, dressing room or pantry.

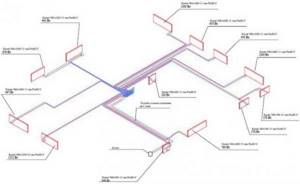

When designing the heating of a two-story building, it will be necessary to install two collector groups: on the first and second levels. Additional distribution units will ensure approximately the same length of the circuit.

As an option, you can take as a basis a scheme in which the first group will be responsible for the distribution of heat along individual circuits, and the second will act as a key component in arranging a “warm” floor.

The heated coolant from the room with the boiler flows through the main lines to the collectors installed floor-by-floor

The number of collector inputs and outputs is always equal to the number of heating elements located on the floor: radiators or underfloor heating rings. For each room, a separate branch is laid, which, by combining several heating devices, will implement a passing or dead-end circuit.

To reduce the cost of connecting radiators, a “pass-through” circuit is used.

In a “pass-through” scheme, the thermal valve is installed only on the first circuit of the radiator; due to which the water flow is regulated on all devices connected in series behind it

With a “pass-through” system, several devices connected in series will be perceived as one element.

Pipeline laying options

When collecting pipes, the most commonly used method is laying pipes in a concrete screed. Its thickness varies between 50-80 mm, which is quite enough to “monolithize” the intra-house wiring of the heating system.

But according to SNiP, only unbreakable connections are allowed to be laid in concrete.

Any radiator or convector is connected to the collector through two pipes: “supply” and “return”, so the pipes are laid in the floor screed in pairs

For this purpose, metal-plastic pipes with a diameter of 16 mm are often used. Due to the fact that they bend easily, it is convenient to lay the pipeline under the floor.

When planning to fill metal-plastic pipes with concrete screed after pressure testing of the system, it is necessary to first wrap them with thermal insulation.

Such a layer will minimize the risk of pipe damage due to thermal expansion, since in this case they will “rub” not against the concrete, but against the insulation.

When laying pipes in a screed, connections in accordance with the requirements of SNiP must be left accessible, placing them above the floor level for this purpose

Plywood is laid on top of the screed, which is covered with a finishing floor covering: linoleum or parquet.

Pipes can also be connected to radiators from the side or from above, for example: in the space of a false ceiling.

Some craftsmen prefer to lay pipes externally, placing them along the walls and hiding them behind decorative skirting boards. But this method of installation entails an inevitable increase in the length of the pipeline.

It is not recommended to lay the pipeline through doorways. This can lead to the fact that when installing the threshold of an interior door, the pipe will be damaged at the time of drilling.

If the pipeline needs to be laid through a wall, in order to prevent its damage due to shrinkage of the building, the hole in the wall should be equipped with a sleeve.

A separate shut-off valve is installed on each hydraulic circuit coming from the distribution comb.

To be able to bleed the air accumulated in the system, install:

- on the distribution unit - air release valves;

- on radiators (accumulates at the highest points) - Mayevsky taps.

Types of collectors

Manifold for radiator heating

The collector is designed for a closed circulation heating system. The device comes in several modifications.

Radiator manifolds

The water device is placed on the battery and promotes uniform distribution of water in each section. It can be connected at the top, side, bottom or inserted diagonally. If you have an apartment, a bottom installation would be optimal - the contours are hidden under the baseboard or floor covering.

A private house is equipped with radiator distributors on each floor. They are placed in the center of the wiring, hidden in niches or special cabinets. If the same number of rings is not supplied to the collector devices, an individual circulation pump is used for each outlet.

The radiator type of mechanisms has several connection features:

- branches of the distribution unit form separate circuits with shut-off valves;

- for heated floors, copper or polypropylene pipes are used;

- the connection is made using one-piece fittings;

- valves are installed to regulate the amount of coolant;

- the circulation sediment is located in the intermediate unit at the entrance to the return pipe;

- the number of pipes depends on the number of rooms connected to one comb.

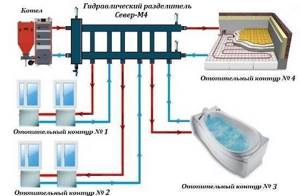

Thermohydraulic distributor

Hydroarrow

The hydraulic arrow is used in a productive or branched heat supply system, to which multi-storey buildings are connected. On one side of the link-link there is a circuit for a heating boiler, on the second - heating radiators or heated floors.

The distribution hydraulic manifold provides:

- elimination of sudden changes in water temperature;

- increasing operational resources in the system;

- saving fuel and electricity;

- maintaining a constant volume of water in the reservoir through mixing and secondary circulation;

- compensation of secondary circuit coolant costs;

- separation of the boiler hydraulic circuit from the secondary wiring;

- maintaining the temperature balance of heating communications.

Solar collector devices

Solar collector diagram

In regions without autonomous water supply or non-gasified areas, heating can be realized using solar collectors. Structurally, the devices are designed like greenhouses capable of accumulating solar energy. The coolant circulates naturally - circulation flows are created by fans of the absorber plate.

The sun's rays are received by a distributor in the form of a flat box. The black heat-receiving plate accumulates heat flows and transfers them to the heat carrier, which uses air flow or water. Innovative systems work in the direction of the sun's movement.

Solar installations are expensive, and even in the southern regions they are used as an auxiliary heating device.

Distributor for radiant heating system

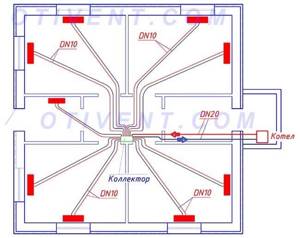

Let us remind you: radial wiring provides for an individual two-pipe connection of each radiator to a common distribution manifold located in a convenient location (usually closer to the center of the building).

An example of radiant heating distribution in a one-story house

To install the collector unit, the following combs are used:

- factory for TP (described above), made of stainless steel, brass or plastic;

- factory for water supply with built-in shut-off valves, made of polypropylene or metal;

- homemade manifolds twisted from brass fittings and polypropylene tees.

The type of comb you choose depends on your budget and radiator system requirements. If each battery is equipped with its own balancing valve and thermal head, then a clean manifold without valves and flow meters is sufficient. Leave the air and water discharge module.

Advice. If you have a limited budget, you can choose an inexpensive water supply manifold with taps, shown in the photo. Many homeowners do this and balance the system with radiator valves.

If you want to automate the heating operation and place all adjustments in a manifold cabinet, buy a comb for underfloor heating. Install all accessories - rotameters, valves with servo drives, air vents, room regulators. A mixer is still not needed; the coolant is supplied to the batteries directly from the boiler room.

The video below shows a combined heating manifold that distributes heat to radiator wiring and floor circuits. Both parts of the comb are installed in parallel. Please note that the master used water distributors to distribute the coolant.

Heating collector device

It is easy to understand if we consider the simplest modification of the product.

As can be seen from the figure, only 2 heating circuits can be connected to such a collector.

More complex options. For example, into 3 separate “threads”.

The disadvantage of such distributors is the impossibility of adjusting the supply of coolant to each circuit. Therefore, for a residential building, which has a number of different types of rooms in which it is necessary to maintain different temperatures, it is advisable to use more advanced modifications of the collector. The figures show some options for such an engineering solution.

The photo below shows a manifold with built-in flow meters.

Installation nuances

The technology for attaching the collector to the wall is quite simple: the TC and radial distribution comb are suspended on mounting brackets, the loops are connected with Eurocone fittings. Pipes going to the top of the collector (usually the “return”) are passed under the bottom.

Advice. No one is forcing you to mount the distributor on brackets. If necessary, the tubes can be spread apart and mounted separately on the wall. The collector box is used in residential areas; when installing the collector in the boiler room, the cabinet is not needed.

Let's briefly list the main points:

- The size of the comb is selected according to the diameter of the pipes used in the heating loops - Ø16 or Ø20 mm. Accordingly, we take a ¾ or 1 inch distributor. The material of the product does not matter; in terms of price/quality ratio, stainless steel wins.

- If the number of comb outlets exceeds 12, assemble a collector assembly of 2 sections. When installing accessories, winding materials are not used, since the parts are equipped with rubber seals.

- A heavier common house collector is suspended on hooks, reinforced brackets, or installed on the floor. Pumps, pipes and other piping elements must not load the distributor with their own weight.

- The hottest coolant receives an indirect heating boiler. The coil and circulation pump of the water heater are connected to the comb directly, usually from the end.

- The radiator heating and TP branches are connected to the manifold through mixing units with three-way valves. A separate pump is installed on each line, selected for pressure and performance.

A heavy coplanar comb can be installed on the floor - weld metal supports

Important point. The mixing unit for heated floors can be installed in the boiler room, near the main comb. Then water at the required temperature will flow to the TP distributor.

Collector Stanilova

Engineer Stanislav Stanilov presented the world with the most versatile solar collector design. The main idea of using the device he developed is to obtain thermal energy by creating a greenhouse effect inside the collector.

Collector design

The design of this collector is very simple. Essentially, this is a solar collector made of steel pipes welded into a radiator, which is placed in a wooden container protected by thermal insulation. Mineral wool, polystyrene foam, and polystyrene can be used as thermal insulation materials.

A galvanized metal sheet is placed at the bottom of the box, on which the radiator is mounted. Both the sheet and the radiator are painted black, and the box itself is covered with white paint. Of course, the container is covered with a glass lid, which is well sealed.

Materials and parts for manufacturing

To build such a homemade solar collector for heating a house you will need:

- glass that will serve as a lid. Its size will depend on the dimensions of the box. For good efficiency, it is better to select glass measuring 1700 mm by 700 mm;

- glass frame - you can weld it yourself from corners or put together from wooden planks;

- board for the box. Here you can use any boards, even from dismantling old furniture or plank floors;

- rental corner;

- coupling;

- pipes for radiator assembly;

- clamps for attaching the radiator;

- galvanized iron sheet;

- radiator inlet and outlet pipes;

- tank with a volume of 200−300 liters;

- aqua chamber;

- thermal insulation (sheets of polystyrene foam, expanded polystyrene, mineral wool, ecowool).

Stages of work

Stages of making a Stanilov collector with your own hands:

- A container is made from boards, the bottom of which is reinforced with beams.

- A heat insulator is placed at the bottom. The base must be especially carefully insulated to avoid heat leakage from the heat exchanger.

- Afterwards, a galvanized plate is placed at the bottom of the box and a radiator is installed, which is welded from pipes, and secured with steel clamps.

- The radiator and the sheet underneath are painted black, and the box is painted white or silver.

- The water tank should be installed under the collector in a warm room. Between the water tank and the collector you need to install thermal insulation to keep the pipes warm. The tank can be placed in a large barrel into which expanded clay, sand, sawdust, etc. can be poured. and thus insulate.

- An aqua chamber must be installed above the tank to create pressure in the network.

- Do-it-yourself solar collector installation should be done on the south side of the roof.

- After all the elements of the system are ready and installed, you need to connect them into a network with half-inch pipes, which must be well insulated in order to reduce heat loss.

- It would be a good idea to build a controller for the solar collector with your own hands, since factory devices do not last long.

Main manufacturers

Some people pay little attention to this aspect. Confident that the design is simple, they do not think about the fact that over time, water supply collectors fail. Each of them will need repair or replacement. The only question is how soon this will happen, and how often problems will arise. Now there are several “whales” on the plumbing market:

- Far (Italy).

Despite the fact that the products of this company can be classified as a budget segment, the quality is very acceptable. The products are reliable, easy to use, unpretentious, and durable.

- Rehau (Germany).

The price of this product is higher, but the consistent German quality allows you to use the products of this company for a long time. The brass from which the structural elements are made can withstand aggressive environments, does not rust or rot.

- Tiemme (Italy).

The products belong to the middle price segment, which has made them popular among professionals, developers, and contractors. Low cost combined with reliability are the main characteristics of collectors of this brand.

- Luxor (Italian).

The main advantage is the use of innovative technologies in production. Each product is tested for functionality before leaving the assembly line. Material: brass.

- UNI-FITT (Italian).

The company produces a full range of components with which you can install a supply or heating system. The range is constantly expanding, and now there are more than 1000 items.

It's easy to get confused about manufacturers and models. To make the right choice, there are a number of recommendations that guide professionals.

Selecting a distribution manifold

Using a distribution manifold is convenient and practical and has a number of advantages. To choose the right distribution manifold, you need to know in advance which heating devices will be connected to it; this determines what additional devices you will need and the type of manifold itself.

It is better to choose manufacturers who have proven themselves in the market, study customer reviews of the products, and consult with several sellers on the topic of the same collector.

Whatever your capabilities, you must remember that the price of a high-quality distribution manifold and its components cannot be low.

Finally about homemade collectors

Above in the text we mentioned budget options for combs - tap, polypropylene and homemade. Such distributors can be used without problems in radiator beam circuits. To balance and regulate the flow, a balance valve and a faucet with a thermal head are installed on each battery. The collector is equipped with “air vents” + drain taps.

If you put the indicated combs on the TP, you will encounter the following nuances:

- the distributor cannot be equipped with rotameters;

- without flow meters it is difficult to balance circuits of different lengths;

- Factory plastic manifolds have shut-off valves, which means there is nothing to regulate the flow;

- combs assembled from polypropylene or brass tees have many joints;

- It's worth noting that homemade distributors don't look too good.

A self-made underfloor heating manifold can still be brought to perfection. We assemble the distributor from tees, and on the return connections we mount thermostatic radiator valves with RTL-type thermal heads, as shown in the photo.

Making a solar collector for alternative heating in your home

Recently, the interest of ordinary people in renewable energy sources has increased. Because of this, many homeowners are looking to buy a solar collector for home heating, which converts the sun's energy to heat water. But the decision to buy a solar collector for heating in a store is not always rational. The cost of the finished device is far from budget, so such a purchase can hit the family budget hard.

To avoid expenses, you can make a solar vacuum collector for heating yourself. Various solar collectors for home heating, reviews of which are positive, have the following design details:

- container for storing heated water;

- heat exchanger;

- device for collecting solar energy;

- insulating layer.

The materials from which the collector can be made are very diverse. There are known technologies for the independent production of solar collectors from polypropylene, ordinary garden hoses, window frames, plastic bottles, old refrigeration units and other available materials. The collector assembly diagram directly depends on the type of material chosen, so it is worth studying after the owner has decided on the concept of the collector.

Self-made vacuum solar collectors for home heating, the price of which in the store is $200 or more, can be used as full-fledged heating sources.

Vacuum solar collectors have a number of advantages:

- energy efficiency;

- environmental friendliness;

- autonomy;

- availability.

It is not difficult to make traditional distribution or solar collectors for heating your home with your own hands. This does not require large material costs, complex technological equipment or solid experience. However, these hand-made devices will greatly optimize the home heating system and will help the owner create a reliable, efficient and uniform source of heating for his home.

- How to fill water into an open and closed heating system?

- Popular floor-standing gas boiler made in Russia

- How to properly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes for malfunctions

Recommended reading

Heating thermostat - operating principle of different types How to make an expansion tank for heating with your own hands? Bypass in a heating system - what is it and why is it necessary? Expansion tank for closed heating: device and principle of operation

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement will result in legal liability. Contacts