Pellets and their effectiveness as solid fuel

Pellets are cylindrical granules compressed under high pressure, obtained by processing waste from agriculture (husks of grain seeds, hay or straw) and wood processing (sawdust, chips, shavings or bark). Peat and coal pellets are less popular.

This is what different types of pellets look like.

The calorific value (specific heat of combustion) of pellets is 17.2–19.5 mJ/kg = 4.7–5.4 kW/h, which is significantly higher than, for example, wood, pure peat and even fuel briquettes . Burning 2 tons of pellets provides the same amount of energy as 960 cubic meters of gas, 1000 liters of diesel fuel or 3.2 tons of firewood.

In Russia, the production of pellets of the “Premium” and “Standard” varieties is permitted, which have an insignificant degree of ash content of 0.4–1% and 1.5–3%, respectively.

Reference . Contrary to popular belief, pellets are produced without the addition of synthetic substances: and although there are standards that allow chemicals in the composition, most pellets do not contain binding substances and improvers, and gluing occurs due to lignin released during heating.

The disadvantages include, perhaps, storage conditions - they cannot be left simply under a canopy, but must be stored in a closed room or container.

Advantages and disadvantages

Pros:

- Full autonomy, you can adjust the equipment according to your preferences.

- High efficiency, this parameter reaches 86-93%, which practically coincides with the parameters of gas equipment.

- Low power consumption. A low-power fan and electronics that ensure the operation of the boiler consume about 60-70 watts.

- A small amount of ash. When the boiler operates regularly, cleaning is carried out every 5-7 days. In addition, there are already options on sale with self-cleaning of ash residues.

- Increased heat transfer. Due to their denser structure, the combustion process of pellets is more efficient than that of conventional firewood.

- High degree of fire safety. External metal parts do not heat up, except for those surfaces that are heated according to the technological scheme.

- Automation. Equipment with this function can operate autonomously for up to 5 days.

- Environmentally friendly, when burning pellets, the emission of carbon dioxide into the atmosphere is very small.

- No permits or approvals are required for installation.

Minuses:

- The main drawback is predictably the cost. This limits the distribution of such equipment. In addition, compared to conventional wood, heating with pellets is more expensive. And the dependence of equipment on electric current also does not contribute to its popularization.

- Significant cost of equipment;

- Increased operating cost compared to other solid fuel boilers. The cost of pellets is quite high, despite the low cost of the source material.

- High cost of thermal energy from pellets.

- Pellets require specially equipped storage.

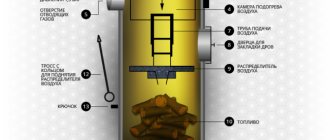

Operating principle of automatic pellet boilers

An automatic pellet boiler is a steel or cast iron heating unit, which, from a design point of view, is the same solid fuel boiler, but with the ability to fully automate the work process, i.e. it can function with minimal human intervention.

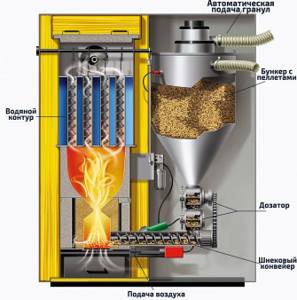

The principle of operation of a pellet boiler is the sequential interaction of 3 separate systems (a bunker for storing reserves, a mechanism transporting pellets into the combustion chamber and the burner itself), combined into a single device by the ACU attachment - a hardware control unit.

Accordingly, the equipment operation process includes 3 stages:

- Supply of pellets from a bunker or from a fuel storage to the combustion chamber.

- Ignition, achieving the required temperature and maintaining combustion.

- Regular cleaning, including removal of ash and carbon deposits from device elements.

The dispenser supplies the required amount of granules into the combustion chamber. The pellets ignited by the burner heat the water circuit. In general, automatic pellet boilers designed for domestic use are very easy to maintain. The main thing is to initially correctly set the appropriate operating mode, so that later you can turn the heating on and off with one button and simply monitor the number of pellets.

Pellet feeding system

The organization of an automatic pellet supply system directly depends on many factors (design features of the heat generator model, availability of free space in the room, financial capabilities, as well as other personal preferences) and can be carried out in several ways:

- bulk (spontaneous) - pellets fall into the burner under their own weight, which can only be realized from the built-in hopper;

- pneumatic (vacuum) – supply occurs using a powerful pump that can suck pellets even from another room (up to 30 meters);

- screw (worm) - the intake of granules is realized through a gear-screw mechanism, which involves the portion supply of new batches;

- conveyor (conveyor) – fuel is supplied via a standard (> 45°) or steeply inclined (< 45°) “endless” belt with blades.

In addition, for greater ease of installation, the above options can be subject to various modifications and can also be combined with each other.

One load of pellets can be enough for a fairly long period - from 2-4 days to 1-3 months, up to the entire heating season (depending on the volume of the built-in or separate bunker). At this time, the ABU controller itself assesses the situation and ensures uninterrupted operation of the heat generator.

Ignition and combustion maintenance

After pressing the start button, the electric ignition system is activated:

- The glow plug (or heating element) ignites the fuel, and the flame sensor turns on.

- The fan pumps air and creates a stable combustion torch.

- The photo sensor detects the presence of a flame and the glow plug is turned off.

- The boiler switches to heating mode and pellets are regularly supplied to the burner.

- When the temperature reaches 60–70 °C, the maintenance mode is activated.

- The volume of incoming air and the pellet supply speed are reduced.

- When the temperature drops (sharp cold snap), heating begins again.

- The burner will periodically turn on/off in the specified mode.

The fully automated pellet boiler is also equipped with a temperature limiter and a coolant overheating sensor. When the supply of a new batch of fuel to the burner is stopped, the system goes into afterburning mode - the fan burns out the residues for 5–10 minutes at full speed.

Stopping work can be done by manually pressing the “Stop” button or (in case of any error) by a software command from the device. Modern GSM modules make life even easier: they synchronize with mobile gadgets and immediately notify about an emergency shutdown, the end of pellets, etc.

Removing ash and carbon deposits

The frequency of servicing heating equipment, i.e. removing carbon deposits and ash remaining from burning pellets, depends on the degree of its equipment:

- model without automatic cleaning – once every 3–10 days;

- model with self-cleaning function – once every 4–6 weeks

That is, the built-in self-cleaning system does not completely eliminate the need for manual cleaning, but only allows you to significantly reduce its frequency.

Automatic ash removal occurs through the transportation of burnt-out residues into a voluminous outer container using a screw conveyor. When stirred, the ash is compacted, which saves space in the ash pan. The drive of this mechanism can operate either from the controller of the boiler itself or autonomously.

Automatic removal of carbon deposits from the burner is carried out using knives - moving parts of the grate. In fact, they simply cut off the charred resin particles and direct them to the ash bin. When it is full, the consumer is given a signal about the need to clean it.

How to choose the right equipment

Even before deciding to purchase a pellet boiler, you should understand a number of points in order to avoid significant financial losses. It so happens that, in a hurry with the purchase, the owner cannot install the purchased equipment or fully operate it.

What to look for before buying

So, before buying, you should understand several nuances.

First , make sure whether it is possible to place the necessary equipment in the building. Usually it is installed on the ground floor, in the basement.

It is necessary to take into account not just the expected dimensions of a particular product, but also the requirements for its installation, for example, there must be gaps of 700 mm or more between the components of the boiler.

Secondly , you need to figure out whether it is possible to store fuel in the required quantity. It is also necessary to pay attention to the convenience of its delivery to the boiler (delivery from the supplier, movement from the storage location to the bunker). And fuel should only be stored in a dry room.

It should be kept in mind that there will be quite a lot of pellets. For example, to heat a house with a relatively small area (100 sq. m), when it is cold, you will need 25 kg of pellets per day

Thirdly , is the power of the electrical network sufficient? Since the control unit, together with the sensors, and the ignition system are powered by electricity, for normal operation, for a short period, they can create a significant load.

This happens during the boiler ignition procedure, when a special heating element raises the temperature in the combustion chamber to an impressive 1000°C so that the pellets ignite.

The line of boilers from the Teplodar company includes combined boilers COOPER PRO, which can be used as both solid fuel and pellet:

Image gallery

Photo from

COOPER PRO 42 with pellet burner APG 42

Boiler processing of wood and coal

Water tube heat exchanger

Automation for organizing boiler operation

Take care of fuel in advance

Also, before purchasing a boiler, you should find out whether there are organizations nearby that supply pellets. There should be several sellers - if there is only one and suddenly ceases to exist, then problems with operation will begin.

It is also necessary to pay attention to the fact that it is usually cheaper to buy fuel from the manufacturer. To prevent any accidents, a potential buyer of pellets should familiarize themselves with the sellers' offers before purchasing.

It is advisable to contact them directly and find out all the details - delivery costs, whether the organization will be able to deliver regularly, etc. And for industrial expenses, it is best to sign a supply agreement with the supplier before purchasing.

The bunker can be installed on any side of the boiler - the main thing is that it is convenient to use the equipment

Rules for choosing a pellet boiler

If there are no doubts about the possibility of installation and the provision of fuel, then you can proceed to choosing a boiler. This should be done by calculating the power.

Theoretically, it is not difficult to calculate - all manufacturers indicate this characteristic in their data sheets, and for simplicity they add how many square meters the boiler is ready to heat.

For example, if the description says that the power is 30 kW, then the manufacturer will indicate that his boiler is capable of heating 200-300 square meters. m of premises. But all these are average values, which are of little use for determining exact values.

Also, any person can perform the calculation himself, since it is believed that 1 kW of power is needed for every square meter. The formula is relevant only for buildings with insignificant heat loss. Effective heat-insulating materials were used in their decoration, and the doors and windows also matched them.

Otherwise, it is necessary to calculate heat loss, which only a specialist can do. This will cost money, but it will guarantee that the building will be warm and you won’t have to overpay for it.

Without the necessary calculations, the purchase will be made at random, which is unacceptable, given the cost of purchase and installation

In addition to the rated power, it is worth considering such a moment as its modulation. Although it sounds incomprehensible, everything is simple here - this is the ability of a pellet boiler to operate at conditions below its maximum productivity.

This is true for regions where temperatures are not the coldest for most of the season. Therefore, heating equipment does not need to operate at full capacity, but rather use only 30-40% of it.

If the boiler does not have such an opportunity, then, at first glance, this is not a problem - having reached the highest temperature specified by the user, it will turn off. When it drops to the minimum set level, it will turn on again. But during such switching on/off wear occurs, which significantly reduces the service life of the equipment.

Heat exchangers are made of steel or cast iron. The former give off heat better, are less massive, the latter are more resistant to corrosion

You should also pay attention to dynamic power. The owner may encounter this characteristic rarely, but in unpleasant moments (if the boiler is chosen incorrectly).

To understand dynamic power, it is enough to look at an example: there was a sharp drop in temperature and the boiler began to not cope with heating.

If it has enough opportunities to briefly, but significantly, increase its productivity and quickly bring the temperature to the set point, then the boiler has sufficient dynamic power. If this does not happen, then the specified characteristic is insufficient and it is better not to buy a boiler - it will sometimes make the owners freeze.

How to choose the right equipment model

When the power is determined, you can proceed to choosing a model. At this point, the potential buyer will understand that there are many manufacturers, as well as models. In order not to get confused in this variety, you should decide which boiler to buy from a well-known domestic or foreign manufacturer.

You should only buy equipment from a well-known seller in the country or region who provides service, updates of all software, and repairs of the sold boiler.

The larger the bunker, the greater the autonomy of the equipment. This will allow you to avoid adding fuel longer.

Also, when choosing, you should pay attention to the type of model you like, advantages, versatility, etc.

But in any case you need to check:

- is the boiler certified by Rostechnadzor;

- are there conclusions from independent specialized institutes confirming the high efficiency of the selected equipment and the amount of harmful emissions;

- is there a fire extinguishing system and can the boiler automation prevent a “backfire” when for some reason the flame begins to move from the burner to the hopper;

- what methods are used to prevent overheating of a working boiler.

Since the boiler will operate in different modes, it is worth checking information about efficiency and emissions in all of them. It would also be a good idea to check the noise level and worry about safety.

In addition, you should look at how easily the equipment is programmed, controlled, and whether it has automatic ignition so that all household members can handle it. Cleaning the product from ash should also be simple.

Since the boiler will be connected to other heating equipment, you always need to find out the standards, connection diagram, manufacturer’s requirements in this case, and pipe diameter. The last point is especially relevant if they are already installed or purchased.

Reviews of household automatic pellet boilers: advantages and disadvantages

Reviews from owners of automatic pellet boilers indicate that this technique has both strengths and weaknesses, or rather, nuances:

| Advantages | Flaws |

| autonomy – equipment with a GSM module can remain unattended for weeks | cost – the price of even the most modest options is 100–120 thousand rubles. |

| versatility - work on wood chips, husks and sawdust | energy dependence , a backup generator is needed for operation |

| Convenience – self-cleaning and auto-feeding minimize manual maintenance | service - many foreign companies simply do not have a representative office in Russia |

| safety – the body does not heat up, which is especially important for children and animals | granule consumption - often real figures differ from theoretical calculations |

| cleanliness - there are no traces of use in the room, i.e. soot, dust and smoke | fuel price - the cost of pellets exceeds the cost of firewood or coal |

Reference . An unexpected increase in pellet consumption is often associated with inadequate quality of the product itself: if they contain foreign impurities or their moisture content is more than 10–12%, then in order to maintain a given regime it becomes necessary to compensate for the loss of heat capacity in quantity.

What to look for when choosing a boiler unit

The efficiency factor (efficiency) is the most important point that is worth paying attention to, since it is it that shows the efficiency of the heating device. Manufacturers usually indicate an efficiency of 85–98%, but in reality it depends on the correct settings, the quality of the granules and design features.

Main characteristics of automatic pellet boilers:

| Burner type | |

| retort (meat grinder) - “omnivorous” vertical burner, but the use of less heat-intensive fuel reduces efficiency | stoker (flare) – horizontally directed burner, efficient, but demanding on fuel quality |

| Heat exchanger material | |

| steel is durable, but (with a thickness of up to 6–8 mm) material subject to burning | cast iron is a durable, but fragile material if used improperly |

| Control system | |

| built-in controller - a control unit located on the boiler controls the processes of loading granules and heating | full automation - options for feeding, ignition, heating, self-cleaning, thermal and photosensor, timer and protection system |

| Maximum power | |

| The boiler power required for heating a house is calculated individually, but in any case it is recommended to buy the device with a small margin of 10–20% | |

| Heating circuit | |

| single-circuit - intended only for heating the space of the house itself | double-circuit – allows you to heat water for sanitary and domestic needs |

Reference . If there are several heating systems, such as radiators, water supply and heated floors, or it is necessary to create climatic zones, then it is better to purchase dual-circuit equipment with additional automation that allows you to control several temperature conditions at the same time.

It is also worth paying attention to equipping the boiler with a device for swirling fuel gases: thanks to it, part of the heat does not go into the chimney, but is transferred as much as possible to the heating system, which increases efficiency, and also prevents ash formation, because The pellets burn out almost completely.

How to choose a room thermostat for a heating boiler and save up to 30% every month

Specifications

The main parameters of the equipment include its power, degree of automation, volume of the loading hopper, and the number of circuits in the heat exchanger.

One of the technical characteristics of the device is also the type of burner, which works in conjunction with electronics and a mechanism for feeding pellets into the firebox. The variety of this unit affects the performance of the unit.

A total of 3 types are used:

- flare;

- volumetric;

- fireplace.

The torch burner is compact, durable and easy to use. The disadvantage is low productivity, which allows this design to be used only in low-power boilers.

Volumetric burners are the most productive and efficient. The devices are supplied to industrial installations and some household units.

Fireplaces are used in small boilers. The disadvantage of this design is its high sensitivity to the quality of the fuel used.

Bunkers are installed in the boiler supply system. The size of this design component depends on the power of the device and the consumption of combustible material.

The best known manufacturers and models: characteristics and prices

When choosing a pellet boiler with automatic feeding, you need to focus not only on the technical characteristics, but also on the manufacturer, since not everyone will be able to ensure timely delivery of replacement parts, as well as provide a specialist for installation, configuration and warranty service.

Therefore, in order not to be left without heating at the wrong moment, it is better to choose a proven model from a company with extensive experience in this field.

ZOTA Pellet-15S

Wear-resistant pellet boiler made in Russia, supporting different types of fuel (pellets, firewood, briquettes). It is designed taking into account operation in harsh winter conditions that imported solid fuel boilers cannot withstand.

Those. parameters : power – 15 kW, bunker volume – 296 l, efficiency – 90%.

Average cost : 150,000–170,000 rubles with standard equipment.

Manufacturer : TPK KrasnoyarskEnergoKomplekt, Russia.

FACI 15

A compact boiler with a twin-screw feeding system ensures high combustion efficiency of almost any crushed biofuel. It is equipped with a retort cast iron burner of the “anti-slag” type, which allows you to reduce the ash content of even low-quality pellets.

Those. parameters : power – 15 kW, bunker volume – 352 l, efficiency – 92%.

Average cost : 130,000–150,000 rubles with standard equipment.

Manufacturer : FACI-RUS LLC (FACI Caldaie), Russia-Italy.

Teplodar Kupper OK-9 with APG 25 burner

A universal boiler equipped with an APG 25 pellet burner is also suitable for conventional solid fuels, including wood and coal. The simple combined design is easy to modify; if desired, you can switch to a gas burner.

Those. parameters : power – 9 kW, bunker volume – 200 l, efficiency – 68–95%.

Average cost : 80,000–110,000 rubles including a torch burner.

Manufacturer : Teplodar LLC, Russia.

Biopellet P-15

A boiler with an original but well-thought-out design, which is easy to assemble and maintain even by an untrained specialist. It is unpretentious to the quality of pellets; you can burn both white and gray varieties without the risk of the burner stopping due to contamination.

Those. parameters : power – 15 kW, bunker volume – 200 l, efficiency – 92%.

Average cost : 160,000–180,000 rubles with standard equipment.

Manufacturer : Dozatech LLC, Russia.

START-50-GR

A powerful, domestically assembled boiler with an impressively sized hopper and imported components (automation and burner). Known for its high reliability and durability, thanks to cast iron parts (burner, boiler door, grates) and a durable heat exchanger made of 6 mm thick steel.

Those. parameters : power – 50 kW, bunker volume – 400 l, efficiency – 95%.

Average cost : 230,000–250,000 rubles with standard equipment.

Manufacturer : LLC Heating boilers "START", Russia.

Calculation of the minimum required power

The simplest way to calculate the required boiler power ( N ) is using the formula:

N =S×W beats /10

- , where S is the heated area of the house, taking into account all residential and domestic premises;

- W beat – power required to heat 10 m2 (according to the climate).

In central Russia, a moderately insulated room with a ceiling height of 2.5–2.7 m and an area of 10 m2 can be fully heated with a power of 1.1 kW.

Thus, the minimum required power of a pellet boiler for heating a house of 10x15 m will be calculated using the formula 150 m2x1.1 kW/10=16.5 kW.

Installation standards and requirements

Installation of long-burning boilers with automatic loading of pellets is carried out taking into account existing fire safety rules (FSR):

- placement in a separate room - boiler room (basement or annex);

- covering the floor in the room with the boiler exclusively from non-flammable material;

- a room without high humidity, equipped with a ventilation system;

- the minimum distance from the boiler to the pellet storage place is at least 1 m;

- fireproof partition between the external fuel storage and the boiler;

- organization of the chimney in accordance with the building codes SP and SNiP.

Despite the fact that before installing a pellet boiler you do not need to contact any regulatory authorities (for approval and examination), as practice shows, it is quite difficult to independently install and connect weather-sensitive equipment, so it is better to entrust these matters to professionals.

How much fuel will you need for the heating season?

Pellet consumption ( Mx of time is calculated using the formula:

M x =X/ fuel heat capacity

, where X is heat loss during the heating season, determined by the formula:

X = S×D×24×0.9×70

- , where S is the heated area of the house, taking into account all residential and domestic premises;

- D – duration of the heating season;

- 24 – number of boiler operating hours per day;

- 0.7 – boiler operating coefficient;

- 70 – average heat loss per hour (for a typical residential building).

For the calculation, you can take a house of 150 m2 from the previous example. If you heat it for about 6 months (175 days) a year, then the heat loss will be X = 150 × 175 × 24 × 0.7 × 70 = 30870 kW for the entire season or 177 kW per day. Accordingly, the consumption of pellets for the same period will be equal to M1=30870/5=6174 kg (season) and M2=177/5=36 kg (day).

Heating costs per month are calculated by multiplying the average daily consumption of pellets by the number of days and the price of pellets per 1 kg, i.e. 36×30×8.5=9180 rubles.

Consumption and calculations of fuel pellets per 100 m²

It is worth considering that wood pellet material is a packaging product, packed in bags of a certain volume. Therefore, it is not difficult to calculate what the pellet consumption will be for 1 kW, 1 m². There is no need to interpret weight into volume, because pellet manufacturers always register goods in kg, and the unit of heat measurement is kW. High-quality fuel material has an exceptional ability to generate heat, so when burning 1 kg of wood pellets, about 5 kW of energy is generated.

Consequently, to obtain 1 kW of heat in a room, you will need to burn about 200 grams of pellets. It will not be difficult to determine the average consumption of granular fuel per 1 m², given that for every 1 m² you need 100 kW of thermal energy, subject to the permissible conditions of a ceiling height of 3 m. 100 W of thermal energy is obtained by burning 20 grams of fuel.

This calculation will be relevant if the efficiency of the pellet boiler system reaches 100%, which is not possible in reality.

The efficiency of heat generators is also indicated by higher rates, but will reach barely 85%. It turns out that when burning 1 kg of pellets in a fuel tank, no more than 4.25 kW will be released (5 × 0.85 = 4.25). You can also calculate the values the other way around. Another point is that heating 1 m² will require 100 W of heat if the ambient temperature is low enough and constant for 5 days. With average data, energy consumption for the entire heating season is almost 2 times less, which means the specific heat transfer per 1 m² is 50 W. The consumption of pellet fuel in a boiler installation for 1 hour is an incorrect calculation, and the final indicator is too small and inconvenient for calculations. It would be ideal to calculate the weight of fuel for 1 day.

What is the consumption of pellets per day? Per month?

Considering Watt as a unit of measurement of power per 1 hour, heating 1 m² per day requires 50 W (50 × 24 = 1200). In this case, you will need to consume 0.28 kg of pellets per day. With data on the specific gravity of the fuel, it is possible to clearly define the financial parameters regarding the use of the average weight of wood pellets for the entire season:

- 28 kg will be consumed per day (0.28×100=28);

- in a month it will take 840 kg (28×30).

Based on the calculations, it turns out that 8.4 kg of fuel material will have to be spent to heat 1 m² with pellets.

On the other hand, reviews and comments from users of this type of room heating on various Internet resources indicate that pellet consumption in cold weather is up to 550 kg. If these indicators are recalculated per square area, then the result is 5.5 kg/m². All this indicates that the figure of 840 kg per month is too exaggerated and does not correspond to reality.

Based on the obtained parameters, we can draw the following conclusions about the consumption of pellets for heating a house, depending on the area:

- 100 m² - 840 kg of fuel will be required when heating a poorly insulated room, 550 kg - with good thermal insulation;

- 150 m² – 1260 kg and 825 kg according to the first point;

- 200m² – 1680 kg and 1100 kg.

Price

Cost of pellet boilers with automatic fuel supply:

| Model name | power, kWt | Average price, rub. |

| ZOTA Pellet-15 S | 15 | 153 000 |

| FACI 15 | 15 | 146 000 |

| Cooper OK-9 + APG 25 | 9 | 101 000 |

| Biopellet P-15 | 15 | 171 000 |

| START-50-GR | 50 | 242 000 |

| ACV ECO Comfort 25 | 25 | 217 000 |

| Kiturami KRP-20 A | 30 | 236 000 |

Furnace structure

A long-burning pellet boiler has 3 main units: a combustion unit, a convective unit with a heat exchanger, and an ash pan.

Additionally, the composition includes an automatic fuel supply device, consisting of:

- fuel storage bunkers;

- an auger that carries out batch movement of pellets into the combustion chamber;

- a gearbox driving a screw device;

- fan for pumping air that supports combustion.

The pellet boiler uses an automatic energy combustion control unit and a controller that ignites the burner and regulates the fuel supply. It controls the temperature according to the unit’s operating scheme chosen by the owner.

Where to buy a pellet boiler with automatic feed?

In Moscow

- Hermes , st. Bulatnikovskaya 20, off. 17 from 9:00 to 18:00, tel. +7(495)384–19–66;

- Stoves -Fireplaces , st. Yubileinaya 4-A from 9:00 to 18:00, tel. +7(495)215–56–94.

In St. Petersburg

- TechnoDom , Stachek Ave. 57 from 10:00 to 19:00, tel. +7(812)671–00–88;

- TeploTorg , st. Yakornaya 10 from 9:30 to 18:00, tel. +7(812)612–40–02.

And in conclusion: an automatic pellet boiler, despite the fact that it is, of course, easier to maintain than many other options (for example, coal, wood, pyrolysis), still requires attention - both in terms of cleaning and in terms of purchased fuel. These factors should be considered before purchasing.

Pellet boilersAutomatic feedSolid fuel boilers