Gas boiler maintenance must be done regularly. During the annual inspection, failures in the operation of automation, the safety of insulating materials, and the tightness of components and pipes are identified. This ensures the safety of the equipment and achieves savings by fine-tuning the gas flow. In this material we will talk about the actions that need to be performed for proper prevention of a gas boiler. Let's look at the example of a wall model. Most often, it is wall-mounted boilers that require detailed maintenance. The following maintenance steps can be defined:

- shutdown of gas, water and electricity

- coolant drain

- turbine maintenance

- cleaning the heat exchanger

- cleaning gas burners and electrodes

- boiler cleaning

- checking the expansion tank

- checking flow sensors and filters

- gas pressure adjustment

- connection and testing

Turbine maintenance

Gas boiler turbine

The exhaust fan ensures proper removal of carbon dioxide, soot and smoke after combustion of the gas mixture. After dismantling the fan, it is worth checking the chimney pipe leading to the street for clogging. The fan must be cleaned of dust and the shafts lubricated. The condensate collector leading to the turbine must be sealed.

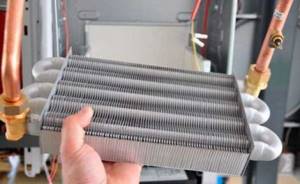

Cleaning the gas burner chamber and heat exchanger

gas boiler burner

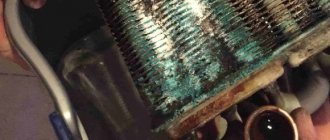

After removing the cover, clean the outer fins of the heat exchanger from combustion products with a coarse brush. A well-cleaned heat exchanger ensures uniform heating of water or other coolant and prevents local overheating.

Using a soft copper brush, you need to remove any remaining soot from the ignition electrodes and ionization sensor, which are located in the chamber, and wipe them with isopropyl alcohol. Finally, you need to check the gap from the electrode to the burner, which should be about 4 mm.

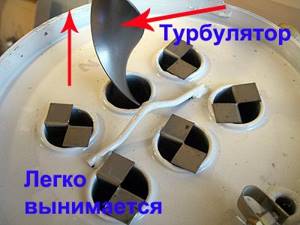

Turbulators for gas boilers AOGV Zhukovsky. Review.

Catalog / Repair instructions for gas boilers AOGV Zhukovsky / General tour of spare parts for gas boilers AOGV with Economy block Turbulators for gas boilers AOGV Zhukovsky. Date of publication: 02/02/2016. Here we will talk about tabulators for gas boilers AOGV. Sometimes these corkscrew-shaped pieces of iron are called turbulators. First, let's understand the terms, and at the same time, raise my IQ a little. Wikipedia and the company Technician SAN present: Name 1. Turbulator - a device or structural element for converting the laminar flow of a medium (for example, liquid or gas) into turbulent one. 2. A turbulator or swirler is an aerodynamic device that is used to improve air flow on aircraft. It is installed on the streamlined surface of an aircraft or to introduce disturbances into the flow around it in order to destabilize it and shift upstream the point of transition from laminar to turbulent flow. The meaning is almost the same, but judging by the name, we still need to contact the Sukhoi Design Bureau with turbulators. And with turbulators - that's for us. Although the meaning is the same. By the way, turbulators can be active or passive. The active ones rotate themselves. Passive ones are simply installed motionless, and with their structural shape they “spin” the hot exhaust gases passing through the boiler. How one “engineer” came up with a turbulator. A guy we know decided to somehow make a small, rotating turbine right under the carburetor, in the intake manifold of a Zhiguli VAZ 2106, that would better prepare the mixture of air and gasoline. I was delighted with this idea that he made the turbulator himself. This thing then fell off and fell into the engine. Then he got tired of getting it out of there. Purpose In AOGV boilers, turbulators are used only to increase the efficiency of heat transfer, i.e. heating the boiler heat exchanger directly by the burner flame. Turbulators are in direct contact with the burner flame and burn out over time. Hence the deterioration of heat exchange, deterioration in boiler heating and, as a rule, a sharp increase in the gas consumed by the boiler. In our opinion, turbulators in AOGV wear out within 5-10 years. Such a large spread is due to the fact that turbulators are directly dependent on the conditions in which temperature conditions our boiler operates. Device For the manufacture of the turbulator, ordinary steel is used. The thickness of the turbulator is 2 mm. The design is rigid, screw. Year of manufacture of the boiler: 2002 The turbulators that the plant offers today are intended for AOGV ZhMZ boilers manufactured after 2002 and to this day. Be careful before ordering! Compare the appearance. Replacement The burnt-out turbulator is much shorter than the new one. Usually they are replaced as a whole set, so as not to have to climb into the boiler again just for the sake of a couple of burnt-out turbulators. The old turbulator is simply taken out and the new one is lowered. At the end of the turbulator there are curved “whiskers” that prevent the turbulator from falling lower, and at the same time we do not confuse the top with the bottom.

There is a fairly free gap between the pipe walls and the turbulators. If we shake the new boiler from side to side, we will hear a characteristic ringing sound, as if something was dangling inside. This ringing is produced by the turbulators. Below are some supporting photos.

The turbulator is an extremely useful part, the integrity of which would be a good idea to check once every 5-10 years. Especially if gas consumption increases more and more noticeably over the years.

- Turbulator for AOGV-11.6 and KOV SG 43 JSC Zhukovsky Machine-Building Plant (Russia)

Find out more about the product Price: 200 rubles

- Turbulator for AOGV-17.4, 23.2, 29.1 JSC Zhukovsky Machine-Building Plant (Russia)

Find out more about the product Price: 200 rubles

In order to efficiently clean gas equipment from soot and deposits, you must first of all acquire the necessary set of tools.

Chemical descaling

gas boiler heat exchanger

There are operating conditions (they are indicated at the end of the article) under which it may be necessary to service a gas boiler in the form of cleaning the heat exchanger from scale. In this case, the supply pipes are unscrewed and the entire heat exchanger is dismantled. For chemical cleaning, it must be filled with a solution of hydrochloric acid, which dissolves blockages. After 10-15 minutes, drain and rinse with running water. If during washing there are still difficulties with the passage of water, the cleaning process should be repeated.

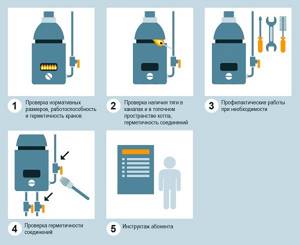

What is included in the list of services

A set of maintenance works for wall-mounted gas boilers.

The list of work carried out by the service depends on the type of boiler room and is regulated by the boiler manufacturer’s instructions.

The list includes:

- equipment inspection;

- installation of the input panel;

- checking the expansion tank;

- identifying the operability of safety devices;

- control of power supply, exhaust and supply ventilation, as well as the chimney;

- replacing filter cartridges and injectors;

- cleaning of mud filtration elements;

- study of the functioning of servos, valves and circulation pumps.

The technician checks the external and internal state of the device, the automation settings and the burner operation algorithm.

Adjusting the pressure of the expansion tank

During the production of a gas boiler, nitrogen is pumped into the expansion tank, but during operation, manufacturers are allowed to pump it with ordinary air. An expansion tank is necessary to compensate for excess pressure that occurs as a result of heating and cooling of the coolant. In addition, it has the function of protecting against water hammer in the heating system.

To completely prevent a gas boiler, you need to measure the pressure in the expansion tank using a pressure gauge. For most wall-mounted boilers, the pressure required for operation is 1 bar. The exact numbers need to be clarified in the documentation for the boiler. In the event that the pressure is insufficient, it is necessary to pump nitrogen or atmospheric air into it using a compressor. In case of excess pressure, it is necessary to bleed off the excess through the valve.

Professional solution to the issue

At first glance, there is nothing complicated in carrying out preventive maintenance measures for boiler units. But you shouldn’t set up and clean a gas boiler yourself. And it's not just a matter of experience.

Such a critical procedure should only be performed by a qualified specialist who has the precise equipment necessary to diagnose faults.

The quality of boiler equipment maintenance directly depends on the professionalism of the technician. Therefore, such work should be entrusted only to professionals with special permission.

In the event of an unforeseen situation, the master will be able to react correctly and quickly, thereby preventing unjustifiably serious, sometimes catastrophic consequences

According to paragraph 6.2 of the current SNiP, servicing of boiler equipment must be carried out by licensed organizations that have their own emergency dispatch service.

Leading manufacturers of gas boilers, in order not to open branded service centers in every region of the country, issue licenses to organizations specializing in the field of maintenance.

You may be interested in information on how to choose a good and reliable gas boiler, discussed in our other article.

In addition to a certificate for performing a specified range of work, such organizations receive full access to technical documentation for equipment produced by the manufacturer, as well as the opportunity to receive new boiler components for warranty replacement. A list of certified companies is usually listed on the manufacturer's website.

When choosing a service organization and drawing up a contract, you should focus on two parameters:

- Certification of the boiler manufacturer, confirmed by the presence of a license to carry out work.

- The location of the service center in the same city or region, which will reduce the response time of the field technician.

In most cases, a service contract is signed before the boiler is fully put into operation. It clearly states the list of future works and the deadlines for their completion.

As a supplement to the contract, a boiler passport is attached, which specifies all the design features of the system, a complete list of its components and elements, as well as the timing of maintenance.

The work offered by service organizations is divided into three types:

- Routine maintenance is regular preventative work carried out to assess the technical condition of the unit, identify and eliminate impending breakdowns, to prepare the unit for the heating season and after its completion before summer inactivity.

- Maintenance upon request of the subscriber - includes measures to identify violations and damage to the system, diagnose the performance of the gas appliance or its individual parts, and eliminate breakdowns and malfunctions.

- Overhaul is a set of measures in the event of a unit breakdown, carried out in the event of emergency situations caused by external factors or as a result of equipment failure.

The regularity of preventive maintenance of equipment depends on the purpose of the installed unit and its design.

A list of mandatory “procedures” for routine maintenance and overhaul, as well as the frequency of their execution, is provided by the manufacturer for each specific model

On average, routine inspections are recommended to be performed 2 times a year. They are carried out both for devices included in the heating circuit and for units of hot water supply systems.

Failure to meet the deadlines for such an important event can lead to serious consequences. Thus, a clogged pipeline can cause a failure of the heating system, and depressurization of a gas pipeline can cause an explosion and fire.

Image gallery

Photo from

Stage 1: General diagnostics of the technical condition of the equipment

Stage 2: Adjusting the column ignition and gas combustion process

Step 3: Checking the tightness of the heat exchanger

Stage 4: Monitoring the condition and performance of the turbine

Cleaning filters

Incoming filtering is necessary. If water is used as a coolant, the flow often contains fine sand, silt, scale, rust or metal shavings. Dirt entering the system can disrupt the operation of the input flow sensor, clog the heat exchanger, etc.

The filter and flow sensor are cleaned using ordinary running water and a brush with hard bristles. Next, before reinstallation, to soften the O-rings that prevent leakage, they need to be treated with silicone grease to achieve a tight connection.

How to clean the fire tube heat exchanger of a single-circuit boiler?

Cleaning floor-standing boilers with a fire tube heat exchanger differs from the same procedure for mounted equipment. Here, to carry out the procedure, the heat exchanger is not removed, but only access to it is provided.

To complete the work you will need the following tools:

- open-end wrenches;

- metal brush;

- hand brush for metal;

- screwdriver;

- natural bristle brush or nylon brush.

The first mandatory action is to turn off the gas supply valve. Next, you need to complete three stages of work - providing access to the heat exchanger, cleaning parts, and assembling the boiler. The disassembly/assembly steps depend on the specific model. How to clean boilers of the MAYAK-12 KS model can be seen in detail in the video.

Gas pressure adjustment

Measuring and adjusting the minimum and maximum gas pressure will not only achieve proper operation of the boiler, but also save money. The exact pressure range is indicated in the instructions. For wall-mounted boilers it is at least 2 mbar. The maximum pressure is 13 minibar.

If there are no errors, start the gas boiler and open the gas valve. Using a differential pressure gauge, we measure the minimum gas pressure in the system. To measure the maximum possible pressure, turn on the boiler in the “chimney sweep” mode and check the pressure in this mode. If necessary, adjust the pressure to the specified values.

What can be repaired without gas workers?

There are several main causes of malfunctions. This is the incorrect operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or low-quality components.

When making repairs yourself, be sure to observe safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can and cannot be repaired on their own.

When repairing gas equipment, the main danger is a possible gas leak. Therefore, it is necessary to carry out all manipulations for installation and dismantling of units and parts of the device with caution. Particular attention should be paid to replacing components related to the fuel supply system.

Knowledge of typical malfunctions of gas boilers and methods for eliminating them allows you to make simple repairs yourself. It is worth remembering that serious repairs can only be carried out by gas workers, but there are procedures available to independent home craftsmen

Boiler manufacturers strongly recommend calling gas service employees to correct problems associated with breakdowns of the gas supply system and built-in electronic devices. An inexperienced person will not be able to independently configure, repair and restore the functions of specific automation in a gas boiler.

There are three main elements in the design of a typical gas boiler:

- Gas burner closed/open type;

- Specific security blocks;

- A heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits served.

If all the components involved in the operation of the boiler are classified according to their functional purpose, then they can be divided into the following groups: control system devices, hydraulic system devices, burner and gas supply unit, smoke exhaust, boiler operation control devices, multi-level safety systems.

Most often, users have the following problems: the boiler emits an unpleasant odor of gas, does not turn on, turns off during operation, does not heat the pipes or smokes

Most of the listed elements cannot be changed or repaired yourself. In case of tampering with the boiler design, its owner loses the right to restore operability at the expense of the manufacturer during the warranty period. But you definitely need to know what and how the craftsmen from the organization with which the contract for servicing the unit and supplying gas are repaired.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is performed in cases where traction is weakened by mechanical manipulation or using chemicals.

- Checking the tightness of water supply connections, gas supply lines, and heating circuit branches.

- Installation of a voltage stabilizer.

We warn you once again that all actions that require removing the casing from the boiler must be performed by a gas service representative.

However, if the guarantee is not important to you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger/heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade water solutions of citric acid (100g/1l) or suitable household chemicals that can dissolve calcium deposits.

- Supercharger fan maintenance. Replace the fuse or the fan itself, check the electrical circuit connected to it, and lubricate the bearings with technical fluid.

- Cleaning the injectors. Clogged nozzles cause a weak burner flame. They need to be periodically cleaned to remove any deposits with fine sandpaper and dirt removed with a rag containing household chemicals.

- Adjusting the pressure in the system.

- Finding a problem due to which the boiler does not turn on.

In order to decide how and how to repair a gas boiler, you need to visually inspect it and, if necessary, carry out a series of diagnostic procedures. Self-repair is possible in cases where the manufacturer’s warranty has already expired.

If you smell gas, you should immediately forget about manual intervention. It is necessary to turn off the gas supply, immediately carry out burst ventilation and call an emergency. The rules for operating gas equipment are described in detail in the following article, the contents of which we strongly recommend that you familiarize yourself with.

The importance of correct gas pressure setting

When the pressure drops below acceptable values, the boiler automation is not able to accurately regulate the heating temperature and operates at maximum values. The electronics opens the maximum pressure and heats the boiler to the required temperature, but due to insufficient pressure, it is impossible to maintain the desired temperature. The automation shuts off the gas and, after reaching the minimum allowed temperature, again heats the boiler to the maximum in the maximum possible mode.

If the gas pressure exceeds the rated values, the flame height is too high. This can lead to premature burnout of the heat exchanger, which is not designed to operate in this mode.

Compare this with normal operating mode, in which the temperature is gradually brought to the required values, and then maintained at a minimum gas flow. In this case, gas consumption decreases due to the smooth dynamics of heating and cooling.

Equipment maintenance in emergency conditions

If an emergency occurs, the problem must be responded to quickly. In most cases, breakdowns occur due to continuous use at maximum power level or low-quality fuel entering the system.

If there is a service agreement, then you need to contact the organization, fill out an application, after which a technician will come and fix the breakdown. The specialist has a set of tools and parts that correspond to the model, since the service center keeps records of gas and diesel boilers.

Sometimes they may not arrive immediately upon request. It is not recommended to use the services of private masters. In order not to encounter poor-quality repairs, you need to use the service of a special company before winter.

Is it necessary to chemically clean the inside of the heat exchanger?

Under normal operating conditions, no. The service life of the heat exchanger is about 6-7 years and after this time it is easier to make a preventive replacement. Annual dismantling and reinstallation will only increase the risks associated with possible destruction of connections and the risk of subsequent fluid leakage.

However, there are reasons why annual chemical cleaning may be worthwhile. This is very hard water that contains too many mineral impurities. A layer of scale builds up too quickly in the heat exchanger. Because of this, difficulties arise associated with insufficient heating of water. During prolonged operation under such conditions, the heat exchanger generally stops passing enough liquid, overheats, burns out, and the boiler fails.

How often does the boiler need to be serviced? Regularity of prevention

A gas boiler inspection must be carried out at least once a year, before the start of the heating season. Why is regularity necessary when servicing gas boilers? The answer is simple, it is necessary for reliable and uninterrupted provision of hot water. Let's try to figure out what can happen if you don't carry out an annual inspection of your gas boiler.

- Over time, the connections become more and more fragile, the insulating materials exhaust their service life and cannot provide a sufficient degree of sealing. This applies to both coolant and gas.

- Excess dust and fumes on the turbine impeller lead to wear and premature failure.

- Insufficient or excessive pressure in the expansion tank leads to sudden pressure surges, which leads to the destruction of connections, seals and hydraulic units.

- A dirty filter may cause the water supply to stop. Also, poor filtration leads to clogging of thin tubes in the heat exchanger. If dirt gets into the water flow sensor, the boiler will not turn on when the hot water tap is opened.

- Incorrect gas adjustment leads to burnout of the heat exchanger, failure of the Venturi nozzle or excessive gas consumption. Over time, the pressure in the gas pipe changes and only annual pressure adjustment can ensure that the pressure corresponds to the specifications.

Pay attention to your gas boiler, do its maintenance and preventive maintenance, and then it will serve you for a long time

Basic malfunctions and their elimination

After carrying out diagnostic procedures and identifying a specific problem, you need to begin solving it. To do this, you will need some tools and components depending on the situation. Most problems can be easily fixed with a tool that is always at hand.

Before starting work, it is important to disconnect the gas boiler from the electrical network. You also need to shut off the gas supply by turning off the gas tap. Even in cases where repair procedures do not affect parts in contact with gas, the fuel supply must be turned off in accordance with safety regulations.

Volatile boilers quite often break down due to voltage surges. As a result, not only the settings are reset, but also sensitive sensors become unusable

In some cases, it is not possible to estimate approximately the duration of the required repair work. If in such a situation the temperature outside is below zero, then a significant decrease in the temperature in the room is possible. And therefore, the water in the system will freeze.

To prevent ice plugs from forming in the boiler coils, the anti-icing system is never turned off for long periods of time. For example, if the boiler is not used for one or two days, all volatile devices are turned off, except for this function. It is possible to completely disconnect it from the power supply only if the unit is preserved for a long period.

Also, before you begin repairing the boiler and dismantling its internal components, you need to make sure that the working surface of the device has an acceptable temperature. During operation, the casing and appliances of the boiler heat up significantly, and contact with some parts can lead to burns.

Gas boiler does not turn on

Sometimes, when you try to turn on the boiler, you discover that the device simply refuses to work. First of all, you should make sure that the device is connected to the electrical network. Then you need to check whether the switch in the distribution machine is turned on.

If, after inserting the boiler plug into the socket and turning it on, the machine knocks out, then you should remove the plug from the socket. Then you need to inspect the wiring for faults

If it turns out that the device is connected to a working outlet, but still does not start, then you need to disconnect the boiler from the network and carefully remove its protective casing. It is necessary to carefully inspect the internal elements of the boiler for signs of a short circuit. Such signs include the presence of a burning smell and soot on the internal elements.

If there are no signs of a short circuit, then you need to inspect the fuse and the electronic board. If a blown fuse is detected, you need to install a new one, turn on the boiler and check its functionality. Sometimes after replacement the new fuse immediately burns out. This usually indicates that there is a serious problem inside the boiler or a problem with the wiring.

A common problem with electronic boards is that they get wet. It is better to dry it with a regular home hairdryer, then leave it for a couple of days until the moisture has completely evaporated.

Electrical wiring must be checked for correct connection and wiring. You need to make sure there are no exposed wires or short circuits.

If it is found that the fuse is OK, then you need to inspect the varistor. This device protects the boiler from voltage surges. Perhaps there was a serious voltage surge earlier and the varistor exploded. Only a small part of it may remain. To solve this problem, you will need to resolder the varistor using a blowtorch and the required material.

A varistor is a semiconductor resistor. If the voltage rises to too high a level, it redirects it through itself, thereby protecting the device

In cases where the boiler is accurately connected to the electrical network, and the fuse and varistor are in perfect order and after inspection it was not possible to find any visible causes of starting problems, you should call a gas boiler repair specialist. Most likely there is a serious internal problem that will be difficult to fix at home.

A number of models of gas boilers, which are designed to display an error code on the dashboard, do not turn on and do not display an error code at the same time. This problem often manifests itself when the circuit of a temperature sensor installed in a room or outside is broken.

It is necessary to inspect the room sensor; perhaps it is unplugged or its batteries are dead. Then you need to replace the batteries or plug the plug into the socket. If the boiler panel does not show the temperature, then most likely there is a problem with the thermostat and it is advisable to start looking for the problem with it.

Problems with filter and pump

The boiler may not operate properly due to a clogged cold water filter. To clean it, you need to turn off the water supply and remove the filter mesh. Rinse it under running water or replace it with a new one.

The coarse filter of the water supply system provides reliable protection of the boiler system from large foreign particles. If contaminated water flows through the water supply, the filter often becomes clogged.

Boiler users may also encounter problems with the pump. The pump stops pumping water when the rotor is broken or air accumulates inside it. First of all, the serviceability of the rotor is checked. To do this, unscrew the nut from the pump and drain the water. Then you need to insert a flat-head screwdriver into the slot and force the axle to rotate. Sometimes the pump jams or sticks.

If it turns out that the pump is broken, you will need to disassemble it yourself and find out the cause of the failure. Having determined which part has broken, you need to order it from a gas equipment store or from a boiler seller. Pump parts are changed at home or in a workshop.

If air has accumulated in the pump, then it is necessary to open the air vent slightly and wait until the excess air comes out. The air vent is closed with a tight-fitting cap. The process of releasing air is accompanied by a characteristic sound.

The pump is often installed when installing a heating system in private homes. It allows warm water to circulate through a closed circuit and ensures equal heating of all radiators

If the pressure gauge needle is in close proximity to the red zone, then you need to turn on the boiler and heat the water in the system. If, with low heating, the pressure rises strongly in the range from 0.7 to 1.5 bar, then you need to carry out a procedure to add air to the expansion tank.

Air is added after the pressure in the system has been reduced to zero. This is done by opening the tap and draining the water. Then, using a pump or compressor, the pressure in the tank is pumped up to 1.3 bar. After this, you need to bring the pressure in the system to 1.5 bar.

Heat exchanger cleaning procedure

The cause of boiler overheating is often faulty automation or a clogged heat exchanger. If the automation of a gas boiler will most likely have to be repaired by a service center, then the heat exchanger can be cleared of blockages at home. To do this, you need to turn off the boiler and wait until it cools down. Turn off all taps and remove the cover of the device.

All electrical components and parts, the pump and control devices must be tightly covered with plastic film so that water does not accidentally get on them. By opening the tap or valve of the gas boiler, you need to drain the remaining water from it.

Next, you need to dismantle the burner block with the manifold, remove the fan from its seat, disconnecting the fasteners securing it to the combustion chamber. After which the return pipe is disconnected from the heat exchanger.

Water heats up unevenly due to impaired thermal conductivity. This occurs due to the accumulation of a large layer of scale on the walls of the heat exchanger. Uneven heating causes alternating water supply at different temperatures

To remove the heat exchanger, you must first disconnect the overheating sensor, then remove the combustion chamber. To do this, first unscrew three self-tapping screws, after which the camera along with the cap is pulled towards itself. After which the cap is detached from the chamber and the heat exchanger is disconnected.

The heat exchanger itself is first mechanically cleaned using a brush and emery cloth. Then you need to hold the part in a 10% solution of citric acid or household chemicals that dissolves mineral deposits. Soaking in the solution should run for about 10-15 minutes.

Next, the solution is poured into the internal pipeline and kept there for a period of similar length. Afterwards everything is drained and washed thoroughly with running water. Reassembly is carried out in the exact reverse order. In order not to forget the sequence, it is recommended to take a photo of each step on your phone during dismantling.

If you first read the recommendations for cleaning the heat exchanger and the instructions for disassembling the gas boiler, the preventive cleaning process will not take much time

It is recommended to clean the heat exchanger every one and a half to two years.

Solving the problem of poor traction

Boilers with an open combustion chamber sometimes lose draft power. To determine the cause of this malfunction, it is worth looking directly into the combustion chamber. Perhaps it is clogged with soot, soot or decay products. You need to brush and vacuum this part.

Models with a closed combustion chamber are equipped with coaxial chimneys, which have the following disadvantages. In the cold winter, drops of water fall from the outer pipe into the inner one, and there the water freezes and turns into an icicle.

Ice in the space between the pipes blocks air access to the gas boiler and, therefore, reduces the supply of fresh air required for combustion. To solve this problem, the street part of the chimney is insulated or holes are drilled in the outer pipe to drain condensate.

There are situations when foreign objects and waste get into the chimney. In such cases, you need to carefully dismantle the pipe and clean it of excess contents. Problems with a gas boiler occur when the coaxial chimney becomes excessively clogged. Soot needs to be cleaned out at certain intervals. Then the boiler will work long and efficiently.

It is worth noting that the accumulation of soot in a gas boiler is a rather rare occurrence. Gas does not emit too much soot when burned. Therefore, the manufacturer usually recommends chimney cleaning every two or three years.

A pipe cleaner is quite easy to make yourself. However, it can also be purchased in stores at a reasonable price.

Cleaning the chimney is carried out as follows. It is necessary to turn off the boiler, turn off the gas and water supplies and wait until it cools down. Remove the external protection of the boiler and disconnect the chimney pipe from it. Cleaning can be done mechanically or chemically.

It is convenient to clean the lower part of the chimney pipe directly adjacent to the boiler with a long-handled metal brush and then use a brush. After this, you can use chemical solutions. After cleaning the inside, you need to start cleaning the outer outlet of the pipe.

There are several ways to clean the chimney with your own hands while on the roof. Most often, a special metal brush is used on a rope with a weight attached to it. In this case, the circumference of the cleaning tool must correspond to the circumference of the chimney.

Alternately lowering and raising the mechanism, the pipe walls are cleaned. The soot falls down and needs to be shaken out, removed or vacuumed from the inside of the chimney.

You can also clean the chimney using a powerful vacuum cleaner specially designed for similar procedures. This device has pockets for drawing in waste. And the hose is long enough to clean the entire chimney.

In special cases, it is worth calling a chimney sweep who has a vacuum unit designed for cleaning chimneys. This expensive device will completely clean the chimney of contaminants without damaging the system.

When cleaning the chimney and other elements of the boiler, be sure to wear a mask on your face. It will protect the owner from inhaling soot and getting harmful microelements into the lungs

If you do not solve the problem of weak traction in a timely manner, you may encounter a number of negative consequences:

- Carbon monoxide entering the premises and causing harm to the health of residents;

- Soot accumulations increase the risk of fire;

- Due to carbon deposits on the boiler walls, heat loss and gas consumption increase.

Possible problems indicate that it is necessary to regularly carry out preventive cleaning of the gas device.

Replacing components and eliminating leaks

If leaks and water leaks are detected at the gas boiler connection points, the water supply should be shut off. Then, using a wrench, you need to unscrew the connection, remove the remaining tow and check the threads for damage. After which you need to apply a new layer of tow or FUM tape and screw the pipes tightly.

If, as a result of the inspection, it is discovered that the water pipe is damaged, then you need to replace it yourself or call a plumber.

The use of FUM tape, plumbing thread, liquid or anaerobic sealant protects pipe connections from leaks. Before re-screwing the pipes, you must thoroughly clean the threads from foreign elements.

If you detect the smell of gas in the air, turn off the lights and all sources of fire. Open the window and ventilate the room. You can check the location of the leak using a soap solution. After applying it, a soap bubble appears on the pipe. Gas leaks are eliminated in the same way as on a water pipe.

Sometimes after diagnostics it turns out that it is necessary to replace the burner in a gas boiler. You can replace the burner yourself, but you should install exactly the same burner model. It is necessary to disconnect all communications, and when dismantling, be sure to remember the correct location of all elements connected to the burner.

If the boiler refuses to maintain the set temperature, then a broken sensor is usually to blame. Temperature sensors can be surface-mounted or submersible. Overlays are easily mounted on pipes and replaced without difficulty. When installing an immersion sensor, you need to drain the water from the boiler and, after installing the sensor, seal the thread.

In order to maximize the safety of your own space and eliminate the possibility of excess toxins due to the operation of gas equipment, it is recommended to use a carbon monoxide detector at home. The principle of its operation, selection and installation rules are described in the article we recommend.