Instructions for selecting and connecting an external thermostat to an electric boiler

Some simple models of electric boilers do not have smooth power adjustment, not to mention wider functionality.

But even with degree-by-degree adjustment, the operation of the automation is based on measuring the temperature of the coolant in the supply and return of the boiler, which is not entirely effective: high accuracy cannot be achieved; high inertia is characteristic, i.e. a rather slow change in air temperature in the house. But the main thing is that in the absence of precise adjustments, a lot of electricity is wasted.

The problem can be solved by installing a special room thermostat (thermostat) for an electric boiler, more expensive models of which measure the air temperature in the room and regulate the boiler operating mode in accordance with it, which is more correct and, most importantly, allows you to save from 10 to 50% of electricity. Moreover, the price of the issue is only 800-1000 rubles for simple mechanical models or 3-5 thousand rubles for more functional programmable thermostats controlled from a phone.

How to connect a room thermostat to a gas boiler?

To install the regulator, you will not need any professional skills or special tools , just understand the installation diagram, follow the instructions of the manufacturer of the gas boiler and regulator, and follow safety precautions for working with electric current. Then the installation can be done independently, without the help of a specialist.

Connection diagram

The diagram of the gas boiler must indicate whether it is possible to connect a thermostat to it. It is important to make sure that the installation of additional equipment is permitted by the manufacturer and will not harm the heating system.

Incorrect installation can lead to breakdown of expensive equipment and loss of warranty.

In the case where the control unit will be installed inside the boiler, find a suitable place for it . If necessary, you can use an installation box.

Important! When connecting a thermostat, to comply with the requirements of the boiler manufacturer !

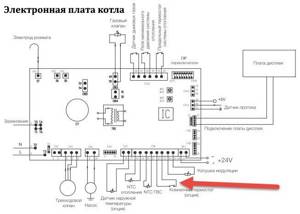

If you study the diagram of the main board of a gas boiler, you will see that there are two contacts on it, connected by a jumper , where the electric current first leaves the board and then returns to it, controlling the switching on and off of the heating boiler. In many modern models, for ease of installation, this jumper is located on a separate terminal block, where the thermostat is simply connected.

Photo 1. Printed circuit board of a gas boiler. The part circled in red shows the possibility of connecting various thermostats.

But on some types of heating equipment you will have to look for the installation location directly on the board. In this case, unscrew the screws that hold the jumper , remove it, and install the wires going to the thermostat in this place.

A correctly connected thermostat passes through itself an electric current going to the boiler from the network, thus controlling the switching on and off of the entire heating system. If the air in the room is heated more than what was set on the regulator during its setting, the device turns off the gas boiler, and when the temperature drops below the specified limit, the heating turns on again and the air in the house is heated.

Materials and tools

To install the thermostat to a gas boiler, no special tools are required. Everything that is necessary to install the device in the heating system is included in the delivery kit .

To install the regulator, you will need technical data sheets for the thermostat and heating boiler to verify electrical connection diagrams, a household screwdriver, a tester to check the presence of voltage in the network, and a set of tools for mounting the device on the wall in a living room.

Choosing a location to install the thermostat

Before starting installation work, select the location for installing the thermostat. Choosing the right room for the device is extremely important , because it is based on the temperature and humidity of the air in this room that the entire heating system in the house will be adjusted.

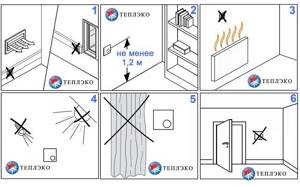

The thermostat must be installed in a residential area, and not in a technical one . Usually choose the coldest room in the whole house, for example, the corner. Installing the device in a boiler room or pantry will lead to incorrect heating operation. Do not hang the regulator near heating radiators or household appliances that emit thermal interference: stoves, heaters. It is not recommended to place the regulator in a draft, near windows, or where it will be exposed to direct sunlight.

The thermostat should be easily accessible and visible so that you can change the temperature settings or replace the batteries at any time.

rules :

- The installation height is no more than one and a half meters above floor level.

- Do not install on an external , cold wall of the house.

- The device must be freely accessible.

- Do not hang near stoves, air conditioners, or windows.

- Do not expose the device to direct sunlight .

What are thermostats for an electric boiler?

Why are they needed and how are they used?

The temperature regulator is a wired or wireless control panel that is mounted on the wall in any convenient place.

There are both simple mechanical models, the functionality of which is smooth degree-by-degree temperature control (especially important for electric boilers with mediocre 3- or 6-step power control), and automatic programmable models with an information display, which allow you to configure more than 50 parameters of the boiler operation and program them change for the next day or even week.

Automatic thermostats allow you to adjust the operation of the boiler once and up to a whole or even several heating seasons.

In general, room thermostats for electric boilers perform the following functions:

Existing types

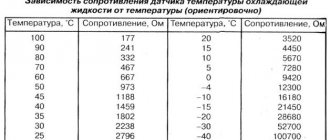

The settings specified on the thermostat take precedence over the settings of the electric boiler itself. The operating principle of the device depends on the type of temperature sensor used in it:

1. Mechanical thermostats

The simplest models, the operating principle of which is based on the operation of membrane and capillary temperature sensors. They use substances placed in a capsule that expand significantly at the slightest increase in temperature. When the expanding substance reaches the maximum temperature threshold, it puts pressure on the relay membrane, as a result of which the contacts open, and the thermostat sends a signal about a partial or complete reduction in the power of the electric boiler.

The main disadvantages of such thermostats are simple functionality, limited to turning a round rotator to set the desired temperature, and a high error - up to 3-4°C.

2. Electromechanical

They have a more complex design based on the use of special metal plates as a heat-sensitive element, which produce a micro-discharge when heated to a certain temperature. The micro-discharge activates an electromagnetic relay that controls a mechanical valve. In general, electromechanical thermostats have +- the same functionality, but a much smaller error; their cost is 20-40% higher.

3. Electronic

The most modern and multifunctional devices, equipped with electrical boards (automation), often with remote sensors: both internal and external (street). Capable of maintaining or changing the operating mode of an electric boiler without human intervention. Allow a minimum error of up to 0.5-0.7 degrees. We recommend paying attention to electronic thermostats due to their functionality and cost-effectiveness.

The automation of modern models is capable of maintaining the most economical mode of operation of the electric boiler, constantly adjusting its operation in accordance with the temperature in the working room, which completely prevents unnecessary energy consumption. After all, reducing the temperature by 1°C is up to 5% savings.

Types of thermostats for boilers

The main difference between thermostats is different types of temperature-sensitive sensors. Some are installed on the heating pipe, others inside it, and others are mounted on the wall. Some are designed to measure air temperature, and the second - coolant.

The choice of thermostat model depends on:

- boiler type;

- heating system wiring diagrams;

- availability of free space;

- required functionality.

Many modern boilers are pre-designed to connect thermostats to them. Moreover, the manufacturer of boiler equipment immediately writes down all the nuances of this installation in the technical data sheet.

If an electronic thermostat model is selected, then it is best to give preference to the most efficient one - the one recommended by the boiler developer

Ideally, the thermostat should regulate the operation of the heating device itself, that is, the supply of fuel to it. This is the most efficient connection scheme in terms of fuel economy. In this case, the energy carrier will be burned exactly as much as the heat required.

But such a thermostat can only be installed on a gas or electric heating unit. If the boiler is solid fuel, then a thermostat with a mechanical valve, which is mounted on the pipe, will help regulate the room temperature.

Regulators installed on batteries are designed to shut off the water supply if the temperature in the room or coolant is too high. In this case, the boiler stops working a little later, when its own temperature sensor inside is activated, preventing overheating of the equipment.

Group #1: mechanical

The operation of a mechanical temperature sensor is based on a change in the characteristics of a material when its temperature changes. This is an easy-to-use, budget-friendly, fairly effective and completely power-independent option. It is designed for installation on pipes of a water heating system to regulate the flow of coolant.

A classic example of a mechanical thermostat is a device with a needle valve (constipation) and a thermal bellows head

The following substances are used in mechanical thermostats as a substance that responds to temperature changes:

- gas;

- liquid.

When the liquid is heated, the gases expand, which leads to their pressure on the shut-off valve stem. When the temperature drops, they compress, the constipation is returned by a spring, and the heated water again flows through the pipes into the heating radiators.

Battery thermostats are characterized by low sensitivity and large adjustment errors. They only work when the temperature rises by 2 degrees or more. Plus, over time, the bellows filler loses its characteristics, the numbers on the knob for setting the required temperature parameters and the actual degrees begin to diverge.

These thermostats are quite large in size. The vast majority of them are designed to measure the temperature of the water in the batteries, and not the air in the room. It is often difficult to precisely adjust them the way the home owner wants.

Group #2: electromechanical

These thermostats operate on principles similar to their purely mechanical counterparts. Only a metal plate is used here as a heat-sensitive element.

When heated, it bends and closes the contact, and when cooled, it returns to its original position and opens the circuit. And through this circuit a signal is sent to the burner control unit.

The electromechanical thermostat requires power supply; it controls the valves or burners in the boiler that regulate the flow of coolant using electrical signals.

Another option for an electromechanical thermostat is a device with a sensor in the form of two plates made of different metals. In this case, the heat-sensitive element is installed directly into the firebox of the solid fuel boiler.

At high temperatures, a potential difference occurs between the plates, affecting the electromagnetic relay. The contacts in the latter alternately open and close. As a result, air injection into the combustion chamber is turned on/off.

Group #3: electronic

This type of thermostats for hot water boilers belongs to the energy-dependent category. Such devices have a remote temperature sensor that monitors the room temperature and a full-fledged control unit with a display.

For electric boilers, such thermostats are a mandatory addition. Without them, electric heaters will work without stopping, heating the air or coolant too much.

In the vast majority of cases, boilers and boilers operating on electricity are equipped with thermostats at the factory.

An electronic thermostat has two main elements:

- Temperature sensor.

- Microcontroller.

The first measures the temperature, and the second controls it and issues signals to increase/decrease the supply of thermal energy to the room. The sensor can send an analog or digital signal to the controller. In the first case, the thermostat’s capabilities are similar to its mechanical counterpart, only it greatly exceeds it in the accuracy of temperature measurements.

Digital thermostats are the pinnacle of development of these devices. They allow you to regulate heat supply according to a preset algorithm. Plus, you can connect many more sensors to them, located both in rooms and outside.

Many electronic thermostats have remote control capabilities via infrared or cellular. This allows you to regulate the room temperature not only using the remote control in the room, but also from any point outside it.

For example, while still leaving work, you can send a signal to heat the room air to comfortable parameters, and when you arrive the house will delight you with comfort and warmth.

Electronic devices designed to automatically adjust the qualitative and quantitative characteristics of the coolant are a mandatory component of heating systems in smart homes. We recommend that you familiarize yourself with their device.

How to choose a room thermostat for an electric boiler

Mounting and connection method

According to the technique of fastening and connecting to the electric boiler, wired and wireless devices are distinguished.

Wired thermostats can still be installed in any room, can have any functionality, but require a wired connection directly to the electric boiler. Their cost is lower, and in most cases the connection wire is included.

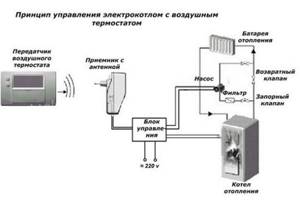

Wireless temperature controllers consist of a control panel and a radio signal receiver connected to the electric boiler by wire. The advantages are obvious: when placing the thermostat in a room remote from the installation site of the electric boiler, there is no need to lay an additional electrical wire through the entire house.

According to practice, a radio signal with a frequency of 433 or 868 MHz intended for household appliances does not affect other electronics in the house and is transmitted without problems through any walls at a distance of 20 and even 30 meters. The disadvantage is the need for additional power for the control panel, usually 2 standard AA batteries.

Functionality

Standard simple models only have an on/off switch and a rotator (or “+” “-“ buttons) to set the temperature.

For significant savings, it is better to choose a more expensive programmable thermostat, which will pay for itself in the first few months of use. With its help, you can reduce the room temperature to 15-16°C when everyone has gone to work, or to 18-19°C at night. It is enough to set up several electric boiler operating patterns once, the duration of which can range from 8 hours to 7 days.

In addition, programmable models, in addition to the built-in temperature sensor, are often equipped with additional remote ones, including those for heated floors.

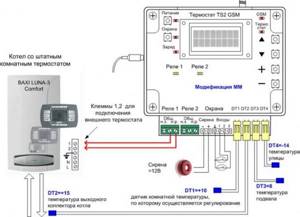

Availability of Wi-Fi or GSM module

The built-in GSM module allows you to receive notifications via SMS messages about the operation of the heating system or about an emergency situation that has occurred, which you can immediately solve. This way the coolant will not freeze during a long absence of the owners.

The best known manufacturers and models: characteristics and prices

Cewal RQ-10

One of the simplest and most budget-friendly mechanical thermostats from an Italian manufacturer. Despite its low cost, it is known for its build quality and reliability. The instructions for the device provide a schematic and detailed description of the installation and connection algorithm. The only drawback is the large hysteresis - up to 1.5-2.5 degrees, which is typical for all mechanical thermostats.

Cost: 800-1,150 rub.

SKAT Teplocom TS-2AA/8A

A more advanced thermostat with an error of up to 1°C. It has a micro-display for indicating temperature, powered by 2 AA batteries (enough for 10-15 months). It features an economical night mode with automatic temperature reduction by 4°C and frost protection.

Cost: 1,450-1,600 rubles.

Danfoss ECtemp Next Plus

One of the best thermostats for an electric heating boiler in terms of price-quality-functionality. It is a modern electronic programmable thermostat with a stylish design and wide functionality. In addition to the built-in one, it has an external wired temperature sensor for heated floors, which allows control separately from the air temperature in the room. Wide functionality, programming and the presence of ready-made modes (“night”, “away”, etc.) allow for maximum energy savings.

It is also distinguished by its safety: it has protection against overheating and freezing, child locking, and monitoring the health of temperature sensors. According to installation practice and owner reviews, there were no cases of malfunction. To avoid malfunction, during installation it is necessary to accurately fit into the grooves of the plug connector.

Cost: 3,420-3,900 rubles.

TEPLOLUX MCS-350

A modern multifunctional premium thermostat with a built-in Wi-Fi module and the ability to control using a special application for a smartphone. It features one of the most extensive functionality, an informative touch screen (with automatic locking) and a stylish design. The kit includes both built-in and remote temperature sensors for simultaneous or separate control. Additionally, you can connect up to 32 temperature sensors.

There are template energy-saving operating modes and weekly programming, as well as energy consumption statistics. The connection must be made via a modular contactor.

Cost: 5,900-6,200 rubles.

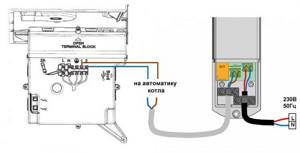

Correct connection of the thermostat to the electric boiler

When choosing an installation location, it is necessary to take into account that:

Connection instructions using the example of a mechanical Cewal RQ-10:

Modern thermostats are powered by AA batteries, but they may also need to be connected to an electrical outlet according to the diagram below:

Connection diagrams and a detailed algorithm are described in the instructions for each thermostat. However, each case is individual and requires certain basic knowledge and skills. Therefore, the traditional advice is to contact specialists in case of difficulties and difficulties.

Source

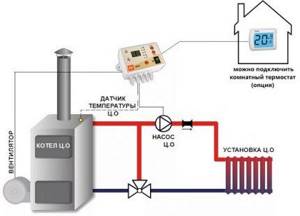

Connecting the thermostat to the boiler. Simple principles

Connecting the thermostat to the boiler is practically nothing complicated, and therefore does not require calling a specialist. You just need to understand the principle of operation of the thermostat, and connecting any thermostat to any gas boiler will no longer be a problem for you. And it doesn’t matter what kind of boiler you have: Baxi, Bosch, Protherm, Ariston or another. The principle is the same everywhere. We will talk about this in our material.

Connecting a room thermostat to a gas boiler: steps of the procedure

Before connecting the thermostat to the boiler, it is important to remember that:

- equipment cannot be covered with panels or fabric, or decorated with stickers;

- nothing should interfere with the thermostat; do not install it next to a heater, fireplace, fan, hood, or furniture;

- Place the device out of the reach of children and pets.

Now about how to connect a thermostat to a gas boiler:

- carefully read the instructions that each thermostat should have;

- stop the heating system at home;

- The heater has a special place for connecting the regulator, and the connection diagram is also located there. Usually this place is located on the lintel;

- remove the jumper;

- install the regulator;

- turn on the heating system, the device will start working together with it.

Types of thermostats

Thermostats fall into two main categories: mechanical, which are simpler in design and cheaper, and electronic, which are more intuitive and functional.

Mechanical thermostats are adjusted using a rotary temperature control wheel and an on/off button. The error of such a thermostat is usually 1-1.5 degrees. The thermostat operates using a special gas, the volume of which changes when the room temperature deviates from the set norm. When the temperature increases or decreases, the mechanical thermostat opens or closes the contacts, thereby turning on or off the burner in the boiler.

Electric thermostats are a little more complicated, but easy to use. Usually they have a display and several function buttons, with the help of which the temperature is regulated. At the same time, on many models you can also set different temperature conditions for day and night, thereby creating a comfortable temperature for sleep. This feature is also useful for work areas after work hours. This allows you to reduce gas costs.

The choice of one of the options depends entirely on your needs and boiler model. Some manufacturers of gas equipment recommend using mechanical thermostats for their equipment, since they do not support high-tech electronic ones. Therefore, before purchasing a thermostat and connecting it to the boiler, it is imperative that you familiarize yourself with the technical characteristics of your boiler and its compatibility with various devices.

How does a heating thermostat work?

A conventional heating system with water as a coolant consists of heating equipment or a connection point to a centralized network, internal wiring pipes and radiators.

To regulate the volume of heat coming from it into the rooms, you have to either constantly monitor the boiler or regularly close/open the valves on the radiators.

At the same time, the inertia of such a system does not allow maintaining the desired temperature throughout the day at the set level. If you put more firewood into the stove or supply gas to the boiler, the coolant in the pipes will heat up more, and it will also release more heat through the radiators.

This is good at low temperatures outside. But with sudden warming outside, the heat in the house becomes unbearable. The fuel is already in the firebox, and the water has already heated up, there is no way to get rid of the heat. Plus the boiler continues to work.

Without a thermostat in the system, you have to turn it off manually. You can, of course, open the windows for ventilation and let out the heat, but then the fuel bills for your home boiler room will definitely ruin you. The conclusion suggests itself: a heating thermostat simplifies living and makes it as comfortable as possible.

A thermostat (temperature regulator) is a device for monitoring the temperature in a heated room and increasing/decreasing the heat supply to it

The thermostat for the heating system consists of:

- temperature-sensitive sensor (element);

- tuning unit;

- control module;

- electromagnetic relay or mechanical valve.

In the simplest models there is no control unit. Everything happens due to pure mechanics and changes in the physical properties of the temperature-sensitive element.

These thermostats do not require power supply. In terms of efficiency and accuracy of system adjustment, they are inferior to electronic devices, but they are non-volatile. If there are problems with the voltage in the network, they will definitely not stop working.

The operating principle of the thermostat is as follows:

- Using the control unit, the desired temperature is set.

- When the required parameters are reached, the sensor is triggered, which leads to the boiler turning off or the shut-off valve in the heating pipes closing.

- After the air temperature in the room drops, the boiler equipment or heaters turn back on.

The electronic control module allows you to set not just one temperature indicator, but several for each time of day separately. Plus, if such a unit is available, it is possible to install an additional temperature sensor outside and link the functioning of the thermostat to the data from it.

Depending on the type of device, the thermostat is connected directly to the boiler to regulate its operation or at the inlet to the radiator to control the volume of coolant supply

The simplest thermostat is a shut-off valve with a temperature sensor, located on a pipe near the battery. When the desired temperature is reached, the thermostatic valve closes and reduces the coolant flow. And when the room air cools, it opens again, resulting in an increase in the volume of incoming heat.

More complex and advanced models require wireless sensors and control units. All communication between individual elements occurs through a radio channel. In this case, wires are not laid, which has a positive effect on the aesthetic side of placing such thermostats in the room.

Remote thermostats and choosing a location for their installation

A significant advantage in favor of electronic models can be the presence of remote thermostats. In this case, adjustment occurs using a separate panel, which can be placed in any place convenient for you. The choice of location for a remote thermostat in any building should be guided by safety and comfort parameters. It is better to place the thermostat out of the reach of children; it is also worth considering factors that can damage the device.

Currently, electronic thermostats with a Wi-FI module are also produced. Data from thermostats can be transferred directly to your smartphone using special applications created by developers. Using such applications, you can adjust the temperature remotely. Such models will fit perfectly into the “smart home” system.

Principle of operation

Let's move on to analyzing the principle of operation of a gas boiler directly, without a connected thermostat. Let's say your boiler is currently set to 60 degrees Celsius. As soon as the burner lights up, the temperature begins to tend to the preset value (in our case, 60 degrees). After reaching this temperature, the burner turns off, and the pump that cools the coolant in the heating system continues to work, and the water temperature drops.

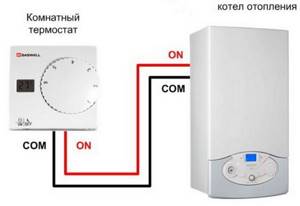

It is also worth understanding what is happening in the boiler electronics at this time. While the boiler is heating up, a certain signal passes unhindered from point A to point B along a closed circuit. As soon as the temperature reaches the required values, the circuit opens and the burner goes out. The network is disconnected by nothing more than a piece of wire, the so-called jumper. A relay thermostat, in its essence, is also such a jumper, only it works not based on the water temperature, but taking into account the air temperature in the room.

Connection diagrams

All methods of connecting a thermostat to a heating system are divided into three connection options:

- Directly to the boiler.

- To the circulation pump.

- On the pipe supplying coolant to the radiator.

The first two schemes eliminate the deterioration in the throughput of the heating pipeline. No additional locks are placed in it, and the hydraulic resistance of the entire system does not change. The thermostat here only controls the operation of the pump or boiler; it “does not come into contact” with water.

When installing a thermostat on a battery or a common pipe with several radiators, the hydraulic resistance, on the contrary, increases. Even when fully open, the thermostat valve slightly slows down the flow of coolant.

Ideally, the boiler piping project should be carried out immediately, taking into account all thermostatic and other devices.

Thermostats should only be installed into existing heating pipelines as a last resort; maximum efficiency from their use can only be achieved if they are included in the system at the design stage

If the water heating system in the house is made according to a single-pipe scheme, then it is better to immediately abandon the third option. When the temperature sensor is triggered, the valve will immediately shut off the entire radiator line in several rooms, and then you can immediately forget about comfort in rooms far from the boiler.

The thermostat should be connected to the radiator input via a bypass. So, when triggered, it will redirect the coolant flow bypassing the battery. In this case, the water will return uncooled back to the boiler. The latter will stop heating it, thereby reducing the consumption of gas fuel or electricity.

When installing a thermostat air temperature sensor, you must adhere to certain rules, otherwise, under the influence of neighboring devices or objects, it will trigger falsely.

The temperature sensor must be mounted:

- in a place where there is no direct sunlight;

- away from cold bridges, drafts and rising heat flows from radiators;

- so that it is not covered by decorative screens or curtains;

- at a height from the floor within 1.2–1.5 meters.

If the sensor is installed incorrectly, the thermostat will produce false signals. This can lead to overheating not only of the air in the room, but also of the coolant in the system. And in the second case, it won’t be long before there are problems with the boiler.

Connection diagram

Almost all thermostats existing on the modern market are relay. This means that they operate via a relay that opens and closes contacts based on a temperature preset by the user. As a theoretically connected thermostat, we will use an electric relay-type thermostat with dry contacts. Dry contacts are a term that means that in any state, closed or open, there is no voltage across the contacts.

To connect to the boiler, there are terminals on the thermostat; you need to connect the open and common ports. If they are not indicated in the manual for your specific model, you just need to ring the contacts with a tester. Next, we need to make sure that the thermostat can be connected to the boiler. Usually this is indicated directly in the technical documentation; if there is none, then the information can be easily found in any of the search engines.

The found electronic circuit diagram of the board indicates the location of the very jumper into which the thermostat will be connected to the boiler. Depending on the boiler model, you will have to unscrew several bolts to get to the required part. The block can be installed either on the control board or taken out separately. Connecting the thermostat for any of these options will be no different.

Useful recommendations for choosing and installing a thermostat on a boiler

In order for the equipment to really be useful, you need to select and operate the unit correctly:

- experts say: the heater and thermostat must be from the same manufacturer. Then there will be no problems during the work process. If your thermostat is made by another company, carefully read the instructions before purchasing. The passport usually indicates which boilers of which companies the equipment will not interact with;

- if the house or apartment is small in size, purchase simple wired thermostats. If the home is very large and has many rooms, then the best option is a wireless programmable device;

- Not only a thermostat will help you save on electricity bills and fuel, but also proper insulation of the room - replacing old windows with sealed plastic ones; insulation of the attic, roof, chimney, entrance metal door, ceilings;

- There is no need to check the device daily, check it once every 2-3 months. If you find that the unit does not cope well with the duties entrusted to it, do not try to disassemble and repair it yourself, take it to the store under warranty;

- Do not wet, cool or overheat the thermostat on purpose. The precision instrument will quickly become unusable;

- When connecting the thermostat to a gas boiler, clean the heater from dust and dirt and turn it off for a while.

How to connect a thermostat to a boiler, including an old one, without terminals...

An ordinary room thermostat brings great convenience to home heating. This is a small device, usually placed on the wall, in a key place where we want to measure the temperature and use its value to control home heating. For example, on the wall in the center of the house in the hallway, or in the kitchen on the outer wall, where it gets cold the fastest...

As soon as the air temperature at the location of the device has decreased to the set value, say, +21 degrees, the thermostat turns on the boiler... The boiler will turn off when the air heats up to the shutdown temperature, for example, +24 degrees.

But how does a thermostat manage to control the boiler?, and how to properly connect the thermostat to the boiler for this to happen?

How does a room thermostat work?

Any room thermostat, mechanical or electronic, with radio transmission or wired, or programmable, which we call a room programmer, works very simply, on the principle of a one-button switch - “circuit open or connected” - “On / Off”.

A contact is connected in it when the temperature reaches the switching threshold, and the boiler control circuit becomes closed. When heating has occurred, the contact opens and the boiler stops.

What kind of thermostats are there?

How a regular thermostat is connected to an automated boiler

Modern boilers are usually equipped with a terminal block with two terminals for connecting an external control device that operates on the “On-Off” principle. More often these terminals are designated as TA.

Initially, they are connected by a jumper, while the circuit between them is closed, the boiler always receives the “On” command. If the jumper is removed, the boiler will turn off.

In the thermostat itself, not everything is so clear; different manufacturers have terminals numbered as 1,2,3 or ABS. You need to connect a pair to those contacts that close when the device is triggered by temperature. If you can’t find this out from the instructions, all that remains is to call the closed contacts with an ohmmeter...

Temperature regulator for a heating boiler: from types of heaters to types of thermostats

One heater is required to heat the house. He can be:

- electrical;

- gas;

- operating on other fuels (liquid, solid).

Which type should I choose? It all depends on the specific situation, resource prices in the region. For one it is cheaper to heat the liquid inside the boiler using electricity, for another - with wood, for another - with gas.

Not all units are equipped with temperature regulators for the boiler. Although this thing is really useful - it allows you to configure the heater according to the user's requirements. With it you can set:

- equipment shutdown time;

- intervals for resting the unit;

- supplying fuel to heat the liquid inside;

- time to turn on the device.

For different types of boilers there are different temperature sensors. They may resemble a dial with a disk, a shutter, or an electronic scoreboard.

The touch thermostat for the boiler is easy to use, but costs about 1 thousand rubles more than other similar equipment

By type, temperature sensors for boilers are divided into:

- to the central ones;

- radiator;

- indoor

Central ones are used in apartment buildings or private buildings and are installed in boiler rooms. It is advisable to install indoor ones on the walls of apartments. Radiators are attached to batteries to regulate heating.

The principle of operation is this: a person sets a certain temperature at which it is comfortable for him to be in the room, for example, +25 degrees Celsius. If the thermometer shows a value below +25 degrees, the thermostat starts working, starting the heater. As soon as the air warms up to the set value, the thermostat turns off the heater. It turns out that the heating device does not work 24 hours a day, but functions only when it is really necessary. Hence the savings on fuel.

The thermostat stops not only the heater, but also the electric pump that pumps liquid through the pipes. This way the user saves on electricity bills.

The thermostat for the boiler stops not only the heater itself, but also the electric pump, helping the user save

Important: the thermostat does not measure the temperature of the pipes themselves, but rather the air, which cools more slowly than the radiators. Therefore, the heater works less often than without connecting the thermostat to the boiler.