In heating, water can reach 80-90°C. And if this is still normal for pipes with radiators, then for a heated floor this temperature is too high. To ensure normal standing on the floors, a three-way valve is used. Although it is not installed only for these purposes, it is indispensable in a system with almost any solid fuel boiler. Let's figure out what this mechanism is, what it is needed for and how to choose the right three-way valve for the heating and water supply system.

What is it and why is it needed

This is what a classic three-way valve for a heating system looks like.

As the name suggests, this valve has 3 strokes. You can even call it a tap, since it refers to shut-off and control valves. In appearance it is an ordinary tee, but inside its structure is much more complicated. Roughly speaking, it serves to change the temperature of the water. There are two methods: in the first, the return is mixed with the supply to lower the temperature; the second method, on the contrary, separates the flows, discharging hot water into the return line. This is useful in different cases:

- Warm floor . The return and heating supply are connected to the valve. Since the return is colder, water at a lower temperature is supplied to the floors. At the same time, the temperature of the rest of the heating remains the same.

- Temperature maintenance . For normal operation of almost any heating equipment, it is necessary that the return flow is not 60 degrees colder than the supply. Otherwise, the boiler will not last long. Therefore, the valve takes water from the supply and sends it to the return.

- Condensation protection . For the same reason. If water warmer than the dew point enters the heat exchanger, condensation begins to accumulate on it.

- Overheat protection . Modern boilers are equipped with various sensors. If it is, for example, a simple solid fuel boiler, it will continue to work even if it overheats. The three-way valve solves this problem.

- For piping an indirect heating boiler . To have hot water in the house, you can connect a boiler to the boiler. And then the water will be heated using heating. The three-way tap serves for uninterrupted supply of hot water. It opens when the water temperature in the boiler drops.

- When organizing a bypass . In some cases, it is necessary to direct water along an alternative path - a bypass. For example, for more efficient heating. The easiest way to do this is through a three-way valve. It will open and close at the right time.

But why install a valve when you can simply reduce the temperature? The question seems logical, but in fact, in conventional boilers at low temperatures, the heat exchanger quickly fails. A condensing boiler is better suited for this mode of operation, but their price is much higher. Therefore, it is better and easier to install a three-way valve.

As you can see, there are quite a lot of ways to use it. In some cases, it is used to improve the energy efficiency of the system. In others, it is an indispensable device for connecting equipment.

Thermostatic valve

In modern realities, a thermostatic valve is a prerequisite for modern and reliable equipment in a heating system. The valve temperature is automatically adjusted. The operation of a heating system mixing valve for radiators is to limit the supply level to an individual heating radiator. The valve stem makes movements to open and close the hole. Through this hole, coolant enters the radiator. When the valve with a thermostatic head heats up, the inlet opening is closed, as a result of which the coolant flow rate decreases. The thermostatic valve constantly changes its position. And an important factor is the quality of the materials on which this product is made. The product may fail due to sticking of the rod, as well as significant corrosion and breakthrough of sealing materials. But even if the thermostatic valve fails, you can extend its service life by replacing the thermostatic element.

Heating system valves with thermal heads differ depending on the shape and type of supply to the heating system. They can be angular when connected to radiators from the floor, or they can be straight, which connect the pipes to the battery relative to the wall surface. Axial, mainly when connecting pipes from the wall to the battery. When connecting batteries sideways, a special kit is required. It uses thermostatic heads and valves. Batteries that come with a bottom connection are obviously equipped with valve-type inserts.

Design and principle of operation of a three-way valve in a heating system

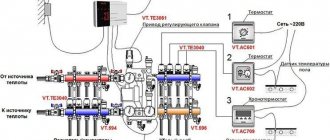

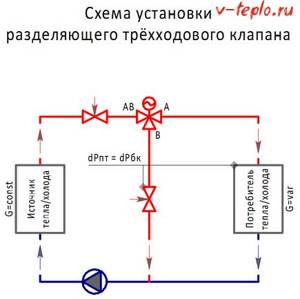

To make it easier for you to understand the principle of operation, I suggest considering this diagram:

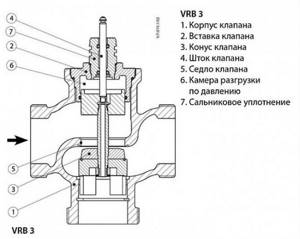

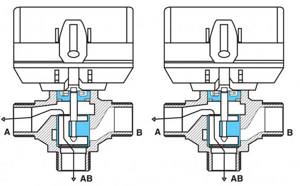

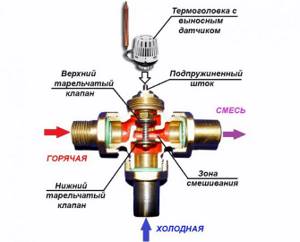

Sectional design of a three-way valve.

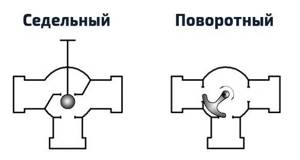

When it is necessary to achieve a certain temperature, the rod rises, opening the duct. This is reminiscent of the operating principle of shut-off valves. And the mechanism itself is called a saddle mechanism. Instead of a rod, a ball or a rotating sector is sometimes used. Exactly the same as in conventional ball valves. This mechanism is called a rotary mechanism. They can be depicted in the diagram as follows:

I’ll talk about what exactly controls the rod or ball a little later. For now, let's look at each type. Let's start with the mixing valves:

As you can see, hot water enters from the left and cold water from below. The rod rises when necessary, allowing the two streams to be mixed.

And this is what the operation of a separating valve looks like. Here, on the contrary, hot water enters from the right, and can exit to the left or down. If the temperature is normal, the rod rises. If higher temperatures are required, the rod is lowered, sending hot water downwards. That is, in the opposite direction.

From the instructions for the VMR type valve from Mut International.

Typically, thermomixing and separation valves do not close completely. But the switches, as you can see, close one of the pipes and open the other. In this case, no mixing or separation occurs.

Cross-section of a typical three-way valve.

Subtleties of installing a thermostatic mixing valve

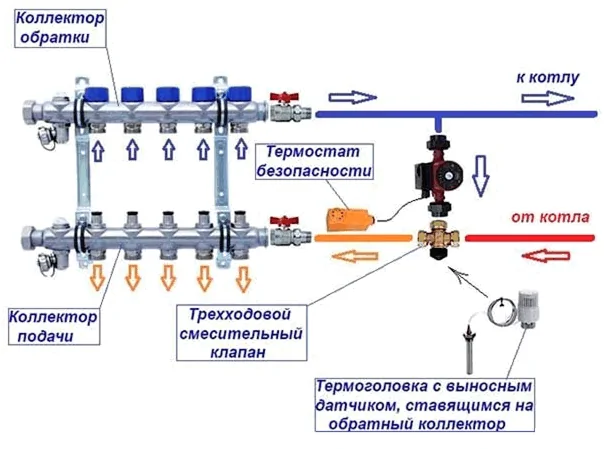

The three-way mixing valve can be installed in heating systems with one or more circuits by placing it in the mixing unit. It is noteworthy that the connection diagram for a three-way valve for a heated floor will not change depending on the number of circuits (read: “How a three-way mixing valve for a heated floor works, types, application”). The only difference is that the system will be equipped with additional parts.

Additional circuits are needed just to connect the warm water floor pipes to the heating. Please note that according to the connection diagram for a heated floor with a three-way valve, it is mounted in front of the pressure pump. This is a prerequisite for the high-quality functioning of the heating system.

When performing tapping work, it is important to ensure that the valve is not clogged with slag or splashes of molten metal left by the welding machine. In addition, the valve must be removable so that it can be checked and, if necessary, replaced.

If you do not have the appropriate skills, it is better to leave the tapping of the control valve to professionals.

How to choose a three-way valve for a private home heating system

Now you know for what purposes certain types of valves are used. But this is not the only selection criterion, because the valves have several ways of regulating the temperature and different throughputs. Yes, and the material of manufacture may differ. Let's look at this in more detail.

Temperature control method

Let's start with manual adjustment. Here the rod is connected to a valve or handle; under them there are marks, with the help of which the temperature is regulated. This is the simplest and cheapest method, so some consider it more reliable. But I believe that it all depends on the company: if the valve is of high quality, then with automatic adjustment it will work no less than with manual adjustment.

| Advantages | Flaws |

| Low price compared to other types of valves | You have to independently react to all changes in environmental conditions |

| Works without electricity connection | The heating circuit warms up unevenly |

If a thermostat is built into the design, such a valve is called thermostatic. Usually it is configured only once. Then he himself selects the position of the rod based on temperature fluctuations. A heat-sensitive liquid or gas is responsible for this: when the temperature rises, they expand and begin to move the rod. Such valves are either electronic or mechanical. A three-way valve with a thermostat is much more convenient than a manual one, since it operates automatically, but it also costs more.

| Advantages | Flaws |

| Automatic temperature control | High price compared to manual valves |

| Uniform heating of the heating circuit | |

| Mechanical models work without electricity |

Three-way valves with electric drive are considered the most accurate. They have a built-in thermostat, but control occurs using an electronic unit that operates on a servo drive. When the temperature changes, the thermostat sends a signal to the controller. And now he controls the drive, raising or lowering the rod.

| Advantages | Flaws |

| Does not require human participation in temperature control | High price |

| Highest precision of any type of three-way valve | Electricity addiction |

| The highest quality and uniform heating heating | Increased energy consumption compared to electronic thermostatic valves |

I think it's better to go with the middle option. Manual adjustment is inconvenient, and the motorized valve is expensive. And such precision is rarely required in everyday life.

Material of manufacture

The durability of the product depends on the material used to make the case. I want to say right away that sometimes there are valves made of silumin. Although they are much cheaper, I do not recommend paying attention to them. And there are many other reliable materials:

- Black carbon steel valves are durable and relatively inexpensive. Unfortunately, they are susceptible to corrosion, so they are usually plated with nickel or chrome. Stainless steel is also often used, but such products are more expensive.

- Cast iron is strong, durable and does not corrode. But usually these are old-style valves, since more advanced materials are now used.

- The most popular are products made of brass and bronze. These are durable, strong and stainless materials. They cannot be used in industrial conditions where temperatures exceed 200 degrees, but they are ideal for domestic needs. I advise you to choose just such three-way valves; if the material is not indicated in the characteristics, it can always be identified by its characteristic color and texture.

I would also like to say something about ceramics. It is practically not used as a material for the body. But internal parts are often made from it. This is due to the fact that ceramics are not affected by chemicals. And it is also durable.

How to select and connect to the system the most important element - a security group

Temperature range and operating pressure

When choosing a three-way valve, the temperature adjustment range should also be taken into account. For example, a thermomixer for heated floors is usually set to 30-40°C. Although this range is the most comfortable for obtaining hot water. The maximum pressure that the valve can withstand also varies. Some models can withstand up to 16 bar. Although usually in domestic conditions more than 6 bar is not required. In general, the operating pressure values for these devices are regulated by GOST 26349-84.

Other

Of course, do not forget that three-way valves have different diameters of connecting pipes. The most common sizes for domestic use are 1 and ¾ inches. The thread can be internal or external.

The number of liters that passes through the valve per hour depends on the throughput indicators. The choice should be made so that the valve coefficient is slightly higher than the calculation result. For example, if the system flows 2 m³ per hour, a valve with a capacity of 2.5 m³ per hour should be selected.

But the throughput varies depending on whether the valve is fully open or slightly open. The ratio of these indicators is called the dynamic range of regulation. The higher the ratio, the better the throughput is maintained. The best odds are considered to be 100:1, but they are quite rare. The most common indicators are 50:1 or 30:1; valves with such indicators can be safely taken.

Main design features and functions of the device

Having a rough idea of the operating principle of a three-way valve, it is better to study in detail the operation of this mechanism. The name “three-way” defines the main function of the device - water of various origins enters the valve through two inputs:

- hot coolant from the supply pipe connected to the heating device or to the riser of the central heating system;

- cooled water returning after passing through the water circuit.

Mixing with each other in the valve in a certain proportion, the flows exit through the third pipe, having a given temperature. The valve works constantly, since the principle of cyclic operation of heated floors is based on mixing hot water with the cooled coolant: heating - heat transfer - mixing - heat transfer - mixing.

The process of mixing two coolant flows of different temperatures must be constantly monitored, preferably in automatic mode. Otherwise, the intensity of heat exchange between the heated floor and the room air will not be tied to changes in the temperature in the room, and you will have to change the heating temperature of the coolant manually as necessary.

A temperature-sensitive head allows for automatic mixing of hot coolant, regulating the valve capacity depending on the temperatures of the mixed liquids to obtain a given output value.

Depending on the purpose and operating conditions, various types of three-way valves are used.

1. Heating systems

For a heating system with radiators, powered by an autonomous boiler, the simplest type of device is used. They are inexpensive and have a relatively simple design, which allows you to install them yourself. In this case, the mixing volume is adjusted manually.

2. Hot water systems

In hot water supply systems, three-way valves are used to maintain safe water temperatures in the communication system, eliminating the possibility of burns. The design of such devices is also quite simple and understandable. Such devices differ from valves for heating systems by the presence of a special protective block that shuts off hot water if there is no cold water in the water supply.

3. Warm water floors

Devices of this type are the most complex, as they are designed to maintain a given temperature of the coolant in heating circuits in relation to the air temperature in the room. The use of such devices in a mixing unit allows you to regulate the heating intensity of your home automatically,

Layout diagram of the mixing unit and location of the three-way valve in it

Three-way valve model with adjustment scale

For heated floors, the faucet is equipped with an adjustment handle and a measuring scale, which is used to adjust the device.

The best known manufacturers and models: characteristics and prices

Now I want to talk about the most popular and reliable three-way valves to make it easier for you to choose the right model.

TIM

Manufacturer from China. It offers fairly high-quality products for heating and water supply at a relatively low price.

| Photo | Model | Specifications | Peculiarities | Cost, rub. |

| (ZEISSLER) BL3110C04 | Material: brass Temperature range: 35-60 Operating pressure: 2-5 bar Diameter: 1 inch | Mixing, for heating and hot water supply | 2 300-3 000 |

| BL8803 | Material: brass Temperature range: 38-60 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, external connection via American connection | 2 800-3 500 |

| BL8804A | Material: brass Temperature range: 38-60 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, electrically driven | 2 000-2 600 |

Esbe

This Swedish company produces various models of valves and controllers. I believe that the products from this company are of the highest quality. Although expensive.

| Photo | Model | Specifications | Peculiarities | Cost, rub. |

| VTA321 | Material: brass Temperature range: 35-60 Operating pressure: 2-10 bar Diameter: ¾ inch | Mixing, for heating and hot water supply | 6 000-6 500 |

| VTA372 | Material: brass Temperature range: 20-55 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, high throughput | 7 000-8 000 |

| VTC511 | Material: cast iron Temperature range: 60-75 Working pressure: 3-10 bar Diameter: 1 inch | For solid fuel boilers | 8 000-9 000 |

STOUT

Joint production of Russia, Italy, Spain and Germany. The products are perfectly adapted to Russian conditions.

| Photo | Model | Specifications | Peculiarities | Cost, rub. |

| SVM-0120-164325 | Material: brass Temperature range: 20-43 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, for heating and hot water supply | 4 500-5 000 |

| SVM-0125-186520 | Material: brass Temperature range: 30-65 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, for heating | 4 000-4 300 |

| SVM-0120-256025 | Material: brass Temperature range: 35-60 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, high throughput | 5 200-5 800 |

WATTS

One of the largest manufacturers of heating equipment in Europe. Huge range of products.

| Photo | Model | Specifications | Peculiarities | Cost, rub. |

| Aquamix 61C | Material: brass Temperature range: 32-50 Operating pressure: 3-10 bar Diameter: ¾ inch | Mixing, for DHW | 5 200-5 700 |

| Aquamix 63C | Material: brass Temperature range: 25-50 Operating pressure: 1-10 bar Diameter: ¾ inch | Mixing, for heated floors | 5 500-6 000 |

| V3GB Watts Classic | Material: brass Temperature range: 20-50 Operating pressure: 3-10 bar Diameter: 1 inch | Mixing, electrically driven | 12 500-14 000 |

Manufacturers

Preference should be given to mixing valves from manufacturers that have proven themselves well in the market. Such companies include:

- Esbe (Sweden) - occupies a leading position in the quality of products of this type. The valves are reliable, with a warranty period of more than 5 years.

- Valtec is a Russian-Italian company; its mixing taps have good characteristics at an affordable price. Warranty - 7 years.

- Honeywell (America) - the priority of mixers from this company is considered to be convenient and uncomplicated installation. They are reliable, but expensive.

However, it should be remembered that even high-quality products if installed incorrectly will not ensure correct operation of the system.

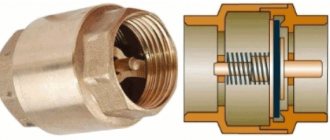

Rules for installing fittings

Typically, the manufacturer indicates the movement of water flow with arrows on the body of a three-way valve. Using these guidelines, you can determine the type of valve. Connection to the system occurs as indicated by the arrows. The installation location should be convenient for subsequent adjustments or replacement in case of malfunction. Both return and supply are suitable for this. But read the instructions carefully, since not all valves can be installed for supply.

Since most of the valves inside are made of ceramic, they do not handle dirty water well. Therefore, it is better to install a filter in front of the valve. If this is not done, the device may become clogged. In some cases, it is enough to clean it, but sometimes even this does not save. Therefore, you should not skimp on filters.

The electric drive should not be located at the bottom, and mechanical thermostatic mixers are also not recommended to be installed this way, only vertically. But I can say from my own experience that in some cases this is possible. And reviews from some owners confirm this.

Conclusions and useful video on the topic

Below is a useful video for your reference, which demonstrates the disassembly of a device that regulates heat flows in a gas boiler. Moreover, the practice of disassembling it yourself is given.

The distribution device described in the video is equipped with a hydraulic rod drive. Familiarization with this repair practice will help you understand how to check devices of a similar type and repair if there are defects.

Thus, a three-way valve for a domestic gas boiler can be tested in almost any design, regardless of individual design. The main point is to correctly determine which drive the gas boiler switchgear is used with. Information on this issue can be obtained from the documentation for the equipment or by relying on the drive demonstration examples in this article.

Do you have useful information on the topic discussed above and want to share it with other users? Write your remarks and comments in the block below, add photos, leave your recommendations - the feedback form is located below.

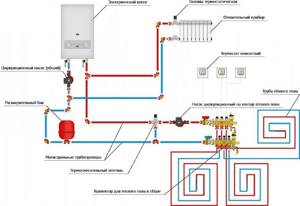

Layout diagrams of a three-way valve in a heating system

The simplest scheme in a system with a solid fuel boiler. Purpose: protection against condensation and overheating, maintaining the temperature in the heating circuit.

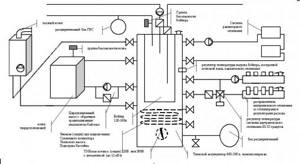

Heating scheme with electric boiler and heated floors. Hydrocollectors are used to distribute heated floors into several circuits.

Use in piping using an indirect heating boiler, which allows organizing hot water supply with a single-circuit boiler.

Advantages and disadvantages of three-way valves with thermostat and electric drive

Valves of this type are the most successful options for such shut-off valves. Their main advantages include:

- quick response of the heating system to changes made;

- ease of adjustment of the operating mode;

- Possibility of temperature control within a small range.

The disadvantages include certain requirements for the order of installation work. If these requirements are not met, the device will not operate correctly.

Temperature can be adjusted over a fairly wide range

How to check a three-way valve for functionality

First of all, an external inspection should be carried out: there should be no cracks in the plastic and metal casing. As for the regulator, it should turn smoothly in all directions. To check the thermal head, it needs to be heated. For example, a hair dryer. In this case, the rod should move in accordance with the indicators. If the valve has an electric drive installed, you can check its functionality using a tester, but to do this you will have to disassemble the electric drive.

Conclusion

Three-way valves only resemble a tee in appearance. Their design is much more complex, and their applications are quite diverse. Choose a valve responsibly; consider only models from well-known, reputable manufacturers; fortunately, there are plenty of them. And then this small but very important device will work for many years without causing problems.

Boiler room equipment

How to install a dividing valve with your own hands

Providing quantitative regulation by changing fluid flow rates is the main function performed by such a three-way valve. Its operating principle is extremely simple and was discussed above. It is used where it is possible to bypass liquid to the “return”, but stopping circulation, on the contrary, is not allowed.

Note! This connection scheme has gained wide popularity in water and air heating units that are connected from individual boiler houses.

In order to link hydraulic circuits, it is necessary that the consumer's pressure losses be equal to the losses at the balancer valve in the bypass. The diagram presented here is intended for installation on those pipelines in which there is excessive pressure. In this case, the liquid moves due to the strong pressure generated by a circulation pump.

Drive types and selection criteria

By type of drive, the models are:

- Mechanical , the separator is installed manually. To monitor temperature indicators, a thermometer is installed on each incoming pipe.

- Automatic , the movement of the membrane depends on the temperature and is carried out independently.

The drive can be:

- Thermostatic , in which the sensitive element expands under the influence of temperature and begins to put pressure on the valve stem, mixing cold flows with hot ones.

- Electrical , in which signals are supplied from the control unit.

- Cap type , the tap is controlled by pressing the head on the drive rod; the drive is applicable when installing a floor heating system.

The best option is cast iron, copper.

When choosing, take into account:

- Media consumption.

- Strapping diagram.

- Operating parameters.

Flow and temperature must be indicated in the design documentation; if it is not available, the optimal water heating temperature is indicated in the passport, usually not higher than 50 degrees. Flow is taken into account when selecting a valve based on its capacity.

The type of drive must correspond to the wiring diagram. A thermostatic valve has a simpler scheme, in which water circulates through the third pipe to the first, the boiler heats it, and only after that the coolant begins to warm up. Having heated up to the required temperature, out of three possible ones, the tap opens flows of cold water from the second pipe, replacement occurs, cold water leaves, hot water enters the tank with a heat accumulator.

The piping scheme is more complicated when an external controller is installed on the crane. In this case, dual-drive and dual-circuit mixers will be required. The first circuit is installed next to the heat source and is thermostatic. The second drive is electric, controlled by the controller by sending sensor signals, the faucet maintains the temperature of the coolant.

An important criterion when choosing a device is the range of set temperatures ; products, as a rule, in this case have a thermostatic drive in the piping of hot water boilers and underfloor heating systems. The range of taps depends on the purpose of the products, ranging from 20-43 grams, 35-60 grams and above. It is advised to stick to the second option when purchasing.

When installing the piping, it is worth asking how the tap is checked. If the product is new, it is not difficult to check it; the minimum temperature in the range is set in the third pipe, hot water is poured. After 15 - 20 minutes, the pipe should turn off the tap.

Strapping diagram:

Design

Most often, taps are made of the following materials:

- cast iron;

- brass;

- stainless steel.

Brass models are the most common because the metal is cheap, yet lightweight and durable. Stainless steel is used in more expensive models. Cast iron valves are used on high-performance systems with large diameter pipes.

Externally, a three-way valve resembles a tee with a valve or tap installed at the intersection of three pipes. There are two types:

- rod;

- ball

Rod models have a central chamber with dividing walls and two outlets. A rod with a rubber or ball valve moves between the taps. When the position of the rod changes, the water flow is redistributed between the outlet pipes.

The advantage of rod valves is the accuracy of regulation and high reliability. However, you should be careful when choosing it. The diameter of the nozzles and the radius of the saddle may be significantly smaller than the diameter of the external connection of the faucet nozzles. This can lead to a decrease in the efficiency of the heating system and an increase in the load on the circulation pump.

In spherical models, the flow is divided by a ball or cylinder with a through hole. The ball rotates in a chamber with Teflon gaskets. This design allows you to accurately and quickly adjust the system, however, in terms of reliability, ball models are inferior to valve models. The short life is explained by the appearance of plaque or scale on the surface of the ball and the Teflon seal, which impairs the tightness.

Job

The principle of operation of the valve is to mix water flows with different temperatures. Why do you need to do this?

Without going into technical details, we can answer this way: to extend the life of the heating boiler and make it more economical.

A three-way valve mixes heated water with cooled water after passing through the heating devices and directs it back to the boiler for heating. Everyone can answer the question of which water to heat faster and easier - cold or hot.

Simultaneously with mixing, the valve also separates the flows. There is a natural desire to automate the management process itself. For this purpose, the valve is equipped with a temperature sensor with a thermostat. In this case, an electric drive works best here. The quality of functioning of the entire heating system depends on the drive device.