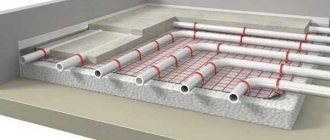

Heating a house or apartment in winter and its costs are of concern to almost everyone. A warm water floor, which you can install yourself, will be a good solution to the problem. Pipes through which hot water circulates are connected to the boiler (or other heating system). The advantages of this system: low energy costs and the ability to independently regulate the temperature in the room. It is very important to choose an economical boiler that is most suitable for specific conditions. The most important indicator will be the thermal power of the heating equipment.

- Boilers for heated floors

- Electric or liquid fuel boiler?

- Boiler selection parameters

- How to calculate the power of a boiler for water heating?

- Requirements for installing a gas boiler

Boilers for heated floors

Boilers are divided into single-circuit and double-circuit boilers.

Single-circuit boilers. Single-circuit boilers in the heating system provide only heating of the coolant (only room heating is possible). To expand the scope of application of single-circuit boilers (providing hot water), additional devices are needed:

- storage boilers (providing hot water supply);

- heat exchangers;

- mixing units for heating circuits;

- and other.

Double-circuit boilers are multi-tasking devices: they provide heating and water heating. The second function is performed by equipping the boiler with a built-in flow-through heat exchanger or a built-in storage boiler.

Variety of boilers by installation type:

- floor-mounted (power up to 120 kW);

- wall-hung (power up to 35 kW).

Wall-mounted boilers (most often these are atmospheric devices) are more convenient from an installation point of view and require lower costs.

A boiler with a closed combustion chamber does not require additional space in the form of a separate room. Wall-mounted boilers are equipped with a circulation pump and other equipment for the boiler room. To put it into operation, it is enough to connect the heating pipeline and hot water pipes to it. Boilers with built-in storage boilers of 100 l are a ready-made mini-boiler room

Types of boilers for warm water floors

To equip a warm water floor, boilers running on gas, electricity, solid or liquid fuel are used. Each type has its own advantages. The most economical are gas ones, and the most autonomous are diesel ones.

Gas boilers. The body of gas boilers can be made of steel or cast iron. Steel units are distinguished by their low weight (about half the weight of cast iron with the same power), small dimensions and good maintainability. Cast iron devices are larger and more expensive. Floor-standing gas boilers of the modern generation are suitable for main gas and liquefied gas. The small dimensions of the wall-mounted gas boiler allow it to be placed in any convenient place, and a power of 7-30 kW is enough for a small cottage.

The diesel boiler runs on diesel fuel and is highly efficient and productive. There are no unpleasant odors during equipment operation. Other advantages of this type of boiler include ease of installation, ease of maintenance and control, high efficiency and low fuel consumption. Thanks to a special operating mode based on a gradual decrease in water temperature in conditions of elevated ambient temperatures, liquid fuel boilers are economical and environmentally friendly.

Solid fuel units for arranging water heated floors will be a completely autonomous source of heat supply. They are considered a good alternative to liquid fuel, gas and other types of heating equipment. Fuel combustion occurs according to the following scheme: firewood laid on a grate is set on fire. After this, the boiler door closes and the smoke exhauster turns on. In the inner chamber of the boiler, the firewood is exposed to high temperatures (250–750°C) without access to oxygen. Charring occurs and wood gas is released, which heats the thermal media. Scope of application of solid fuel boilers: residential and industrial premises, agricultural facilities.

Electric boilers are suitable for residential and non-residential buildings equipped with water underfloor heating. The system is connected to the boiler using special equipment and additional devices. The choice of device power is influenced by the area of the room, its condition and other factors. The most optimal power can be selected in rooms with good thermal insulation of walls and ceilings (for example, in new buildings). If there is good thermal insulation, then the manufacturer considers a power of 12 kW sufficient for heating 150 sq.m.

For the tandem “electric boilers - warm water floors”, manufacturers recommend the following combinations:

- heating area 250-450 sq. m - boiler power 36 kW;

- heating area 220-350 sq. m - boiler power 30 kW;

- heating area 140-300 sq. m - boiler power 12-24 kW;

- heating area up to 70 sq. m - boiler power about 6 kW;

- heating area up to 30 sq. m - boiler power 6 kW.

Pros and cons of heated floors. Find out in our article. About infrared warm field. Find out more right now! How to reduce electricity consumption. Find out in our article.

Which boiler should I choose?

Wood-burning

A simplified analogue of a brick stove, the cheapest option for solid fuel equipment. When burning wood, temperatures reach 200⁰. The low power of the boiler does not allow it to work autonomously and drive water through the pipe system.

It is necessary to install a pump in front of the equipment so that it constantly pumps water. This will prevent the boiler from exploding when it boils. The liquid pump will not be able to pump out the resulting vapor.

Constantly pumping water will reduce the pressure. The disadvantage of a wood-burning boiler is that the fuel burns quickly when the temperature is low. It needs to be constantly refilled. Firewood must be dried for a long time.

Boiler equipment

Boiler equipment means a combustion chamber with an exhaust hood and a storage device with a dispenser. Fuel is supplied in certain portions at set intervals. This device allows you to load a solid fuel boiler once a week. To connect an automatic feed device to the combustion chamber, you must have a room with a high ceiling to accommodate it, and the ability to configure and control the automation. Boiler equipment will cost much more than usual. But it saves time on loading the boiler and allows you to leave home for a long time, if there is an emergency power supply.

Pellet solid fuel equipment

The boiler, which uses pallets in its operation, is sold with a connected dosing unit. Compressed firewood comes in the form of portioned briquettes. They just need to be fed into the firebox periodically. Pellet equipment can work independently in a floor heating system for 3–4 days.

Pyrolysis boiler

Inside the pyrolysis boiler, a complex process of decomposition of solid fuel into combustible gases occurs at high temperatures. As a result, the combustion process occurs slowly. Firewood or other material slowly decomposes at the bottom of the chamber. The rest of the fuel lies on top.

Electric or liquid fuel boiler?

To compare two types of boilers, all factors must be taken into account. Despite the cheapness of diesel fuel compared to electricity, an assessment of all costs will show the real picture.

Initial costs for the purchase of equipment and installation costs An electric boiler is a ready-to-use device. A liquid fuel unit will require additional costs for the purchase of a boiler, mounted burner, and fuel storage tank. The difference in consumables is 2.5 times in favor of the electric one.

Installation of an electric boiler will cost several times less, since all the necessary elements for the control and safety of the equipment are built into its body. A liquid fuel device requires the installation of additional devices: a chimney, a fuel tank, and a mounted burner.

Operating Costs Maintenance of an oil boiler requires costs (several hundred dollars per year) for regular maintenance and cleaning. An additional inconvenience is associated with the need for constant orders for fuel delivery. Electric boilers do not require the listed operations.

However, electrical devices also have disadvantages.

- To operate the boiler, several tens of kilowatts of energy are required (1 kW per 10 m2 of area. The ceiling height is up to 3 m, and the room is well insulated). It is not possible to allocate such a volume of electricity in all areas.

- The cost of electricity is high and power outages occur. To protect against frequent power outages, a backup solid fuel boiler is often used.

If water heating is done in a house or apartment within a large city, then electric boilers are the most preferred of all types. This is due to strict environmental requirements and coordination problems.

Having analyzed the situation, we can highlight a number of advantages of electric boilers:

- low cost;

- compactness and light weight;

- easy installation, no chimney required;

- safety (no open flame);

- ease of operation;

- can be installed in any room;

- service is simple;

- environmentally friendly: no emissions and odors;

- silent.

Principle of operation

Electric boiler designs use different operating principles:

- With a heating element, the device has the simplest principle: immersed in water, the heating element heats it, after which the water is directed to the place of use. The traditional, proven method is far from the best, ineffective and costly, but is still used in various devices.

- The electrode type of water heating uses its ability to increase temperature when an electric current passes. The method is safe because in the absence of water the process itself stops - there is no possibility of contact between the electrodes. They have minimal dimensions, smoothly adjustable modes, and are relatively inexpensive.

- The induction method of boiler operation is the most modern. An induction coil, inside of which there is a metal container with a coolant, creates an alternating magnetic field that heats the water. There is no scale from constant very fine vibration (invisible and safe for humans), no maintenance required, no consumables that periodically require replacement.

Boiler selection parameters

Heating installations, depending on their characteristics, provide different thermal efficiencies and are suitable for a certain area and operating conditions.

- Power. The required parameter is determined by the area of the heated room and the level of its thermal insulation. The manufacturer indicates the area for which the boiler is designed, provided that the building is well insulated. If heat losses are unknown, then it is necessary to choose a boiler whose power is designed to heat an area 25% larger than the actual one. It is not advisable to purchase equipment with excess power, as the device will overheat and break down. If the boiler is installed in an unheated room, it is necessary to involve a heating specialist to calculate the power.

- Possibility of power control. Gas installations may or may not be equipped with a power control system. To adjust the operation of the equipment, automatic mode or manual control can be used. Automatic control systems are more economical. In this case, the user only sets the necessary parameters, and the automation ensures the accuracy and smooth supply of the gas mixture to the burner. Also, when using automation, the frequency of complete shutdown of the burner is reduced, thereby increasing the service life of the equipment.

- Energy dependence. The use of electronics in the control system of electric pumps for forced circulation increases the performance of the boiler, but at the same time depends on the stability of the energy supply and reduces its autonomy.

- Type of water heating. If it is necessary for a boiler (including an industrial gas device) to provide not only a heating function, but also to heat water for domestic needs, it is necessary to choose a dual-circuit model that heats water in flow-through mode. If greater productivity is needed, then you need to go with the cumulative option. Boilers can be built into the boiler or autonomous and connected to the installation. Remote models can have a very large volume (several hundred liters), while built-in ones are limited by the dimensions of the boiler.

Advantages and disadvantages of the system

Typically, a heated TP heating system is easy to install and very cost-effective. It does not interfere with the residents, as it is built into the floor.

Does not require significant maintenance and free space on the wall under the window for the radiator. Such heating does not require high heating temperatures, which makes the system ideal for condensing boilers.

The radiated heat from the heated floor is distributed evenly throughout the room, so the person feels comfortable in it.

With traditional heating, warm air rises to the ceiling, thereby heating only the upper part of the room, leaving the lower part cold. This is very uncomfortable for residents of the first floor, especially when the room has a tiled floor.

A warm floor heats the house evenly, removing cold spots that are typical for radiator heating. Heat is transferred directly to the human body, so even if the room temperature is below +18 C, he will still feel the heat, unlike radiators. The TP system allows the use of any heating source, even a self-made boiler for heated floors.

The system has its drawbacks, which you need to know before making a heated floor. The most significant is the inertia of heating. It takes no more than 30 minutes to warm up a wooden floor, while a concrete floor takes one to several hours to warm up, depending on the depth of the installed pipe systems.

It is impossible to install heated floors over the entire area; the location of floor units and utility networks must be taken into account. During maintenance and repairs, the owner will have to remove the existing covering to access the heating cables or pipes.

How to calculate the power of a boiler for water heating?

It is necessary to calculate the required power of heating equipment to select the correct boiler. The approximate required power for heating a country house is calculated based on the following data: to heat 10 m2. area, 1 kW of power is required, that is, it is assumed that the specific power is 100 W/m2.

The calculation is quite rough, and it is suitable for a brick house with low heat loss: the building must be well insulated, the ceilings must be no more than 3 meters high, metal-plastic windows with double glazing.

To increase the life of the heating system and thermal reserve, it is necessary that the coolant temperature be at the level of 65–75°C. To do this, the boiler power (under ideal conditions) is increased by 20–25%.

Any additional load requires an increase in power. In the case of providing hot water using a storage boiler, it is necessary to add another 30-40%. If in the future it is planned to expand the heated area, install a heated water floor, or a heated water pool, then the boiler must be purchased immediately with a capacity designed for further changes.

If a heated floor is planned as an element that complements radiator heating and increases living comfort, then its heat output is considered to be no higher than 50 W/m2.

Device

The design of electric boilers largely depends on the type of construction, so you should consider them in order

- Boilers with heating elements as a heater. The heat exchanger, inside of which there is a heating element, when turned on, it begins to heat the water. In essence, the principle of a conventional boiler is used. The system is simple and most vulnerable from the point of view of many processes that destroy and weaken the functionality. With a high efficiency of the heating element, equal to almost 100%, over time, scale will inevitably form on it, which significantly reduces heat transfer. The service life of the heating element, declared by the manufacturers, is 10 thousand hours, which in itself is not very long, but in practice, not every heater reaches this value - the coil burns out. Heating elements cannot be repaired.

- An electrode boiler works on the principle of heating water between two electrodes under voltage. There is a container - a heat exchanger, inside which an electric current is passed through the water column from one contact to another. There is a saving of about 40% of energy, since there is no need to heat anything - the temperature of the water changes depending on the course of the physical process. The inconvenience is that only special compounds can be used as a coolant, which eliminates the possibility of heating household water.

- The induction type of heater is the most advanced and economical of all currently used types of electric boilers. There is an inductor. It plays the role of the primary winding. Secondary (like a short-circuited turn) - heat exchanger housing. When current is passed through the primary winding, the secondary winding is inducted, causing it to heat up and give off heat to the water inside. Since the heating area is maximum, the boiler’s operating efficiency is very high.

Requirements for installing a gas boiler

Premises requirements:

- A separate non-residential premises is required for the boiler room.

- The ceiling height in the room is at least 2.2 m.

- Room volume based on 7.5 m3 per boiler.

- The floor area per boiler is 4 m2.

- Doorway width from 80 cm.

- The size of the window is determined by the calculation: for every 10 m2 of area - a window measuring 0.3 m2.

- There must be a hole for air flow (8 cm2 per 1 kW of boiler power).

- The boiler must be installed at a distance of at least 0.1 m from walls that are plastered or the wall decoration is made of non-combustible materials.

- Installation of devices near fire-resistant walls is permitted if they are insulated with roofing steel laid on an asbestos sheet with a thickness of at least 0.3 cm.

Communication requirements

- Characteristics of the electrical network: single-phase current, voltage 220 V, current 20 A. An individual circuit breaker is installed. Grounding is provided.

- A shut-off unit is installed on the gas main, one for each boiler.

- Water supply and the possibility of connecting it to the heating and hot water supply (DHW) systems of the building.

- The sewerage system provides emergency drainage from the water supply and boiler systems.

- Communication parameters (gas pressure in the gas main, water pressure, etc.) must comply with state standards.

Description of the electric boiler

A water heating boiler, powered by electricity, is an insulated container of a certain volume. Polyurethane foam is used as a thermal insulation material. The container is protected from the outside by a stainless steel casing.

The inner surface is covered with glass enamel or made of steel, onto which enamel with the addition of titanium is applied. The coating can withstand high temperatures, does not react with water salts, and does not corrode.

The boiler has outlets for cold and hot water. Water heaters to which a heating system can be connected are equipped with outlet pipes for the coolant, which flows through a pipe system to the radiators or to the floor line, and returns through the cold circuit back to the boiler. The coolant is discharged through the hot water intake pipe.

There is a heating element inside the container. This could be a heating element, an electrode or an induction coil. These devices are connected to a 220 V network. Depending on the heating source, there are some modifications of boilers.

- heating elements; This is the most common equipment for heating water. The coolant is brought to a certain temperature using a heating element. It is installed on the bottom surface of the firebox. To prevent scale from forming on the heating element, it is placed in a metal tube. Additional protection is a magnesium anode.

- Electrode boilers; a metal rod acts as an electrode. It is the cathode. Current is supplied to it. The boiler body acts as an anode. When the system is turned on, the ions begin to change their polarity and are attracted either to the rod or to the walls of the boiler. The chaotic movement of charged particles releases energy, which contributes to an increase in water temperature.

- The coolant can be heated using an induction coil, in the center of which there is a metal rod; Electric current is supplied to the coil. An electromagnetic field is formed around it and around the rod; vortex flows are created that heat the coolant.

If an electric boiler is used only for heating water, which is intended for household needs, then choose a low-power horizontal unit. It is easy to install on the wall. Vertical, high-power equipment is designed for a water heating system. They are installed on the floor or on the wall.

The main manufacturers of heating equipment are Buderus, Logamax, Kospel EKCO, Aton Electro, Galan, Barsky Machine-Building Plant. The equipment is selected depending on the capacity, operating power, and the number of water circuits. For underfloor heating, units with 2 circuits are purchased.

You can assemble an electric boiler for underfloor heating yourself. A stainless steel barrel is chosen as a container. From the outside it is insulated with mineral wool.

A metal rod is installed in the barrel, to which electricity is connected. A hole is made at the bottom side for the cold water pipe. A pipe leads from it to the central water supply. The hot circuit is output from the upper side.

The equipment is equipped with automation, a thermostat and a sensor, and grounding is provided. The top cover is made removable.

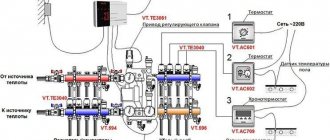

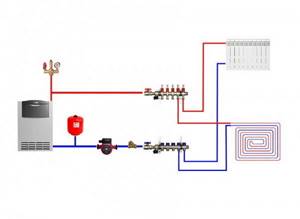

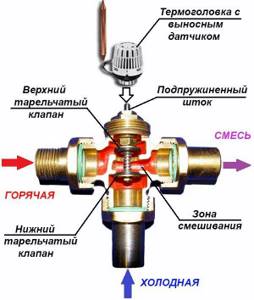

Three-way valve circuit

In the vast majority of houses, this combined underfloor heating system is installed.

It includes:

presence of heating radiators with heating up to 70-80C

separate TP circuit with an average water temperature of 40C

The main question here is how to get a flow of water for heated floors from the 80 degrees going to the batteries at half the temperature.

The problem is solved using a three-way thermostatic valve.

It is mounted on the supply pipe. At the same time, do not forget to install a circulation pump after it.

Colder water is taken from the return of the heated floor. Mixing with hot water coming from the boiler, the coolant acquires the lower temperature necessary for underfloor heating.

The disadvantage of this scheme is that you will not be able to accurately limit and regulate the flow of cooled water from the return. What does this mean?

The fact is that both water that is too cool and, vice versa, water that is overheated beyond normal will periodically enter the pipes of heated floors.

An unprincipled person may not notice this, however, these temperature differences are present in this circuit, and there is no escape from them. Of course, time periods of supply of hot and unheated coolant can be compensated by the thermal inertia of the screed concrete.

But this is all relative. You can never accurately calculate the optimal thickness with such heating.

The advantages of such a combined scheme with a three-way valve:

easy installation

affordable price of equipment

This installation method justifies itself if you have a small apartment or house. And you don’t suffer from excessive demands for super-comfortable living conditions.

Direct connection diagram

You have a boiler, after which all safety fittings + a circulation pump are installed. In some wall-mounted boiler versions, the pump is initially built into its body.

For floor-standing units you will have to install it separately. From this boiler, the water is first directed to the distribution manifold, and then disperses through the loops. After which, having completed the passage, it returns through the return line to the heat generator.

With this scheme, the boiler is directly adjusted to the desired temperature of the TPs themselves. You don't have any additional radiators or radiators here.

What are the main features worth paying attention to here? Firstly, with such a direct connection, it is advisable to install a condensing boiler. In such schemes, operation at relatively low temperatures for the condenser is quite optimal

In this mode it will achieve its highest efficiency

In such schemes, operation at relatively low temperatures is quite optimal for the condenser. In this mode it will achieve its highest efficiency.

If you use a regular gas boiler, you will soon say goodbye to your heat exchanger.

The second nuance concerns solid fuel boilers. When you have it installed, for direct connection to heated floors, you will also need a buffer tank.

It is needed to limit the temperature. It is very difficult to directly regulate the temperature with solid fuel boilers.

Operating principle

The electric boiler tank contains a coolant, an air vent, an expansion tank and a pump for circulating the coolant. There are also heating elements - either electronic or water. At the inlet there is a safety group: a sensor indicating the pressure level and a safety valve. A sensor is a must: if it is not there, at some point (in the absence of movement) the coolant will begin to overheat and the heating elements will burn out.

The principle of operation is simple: the heated liquid enters the boiler, it warms up, and when the set temperature is reached, the coolant flows into pipes laid on the floor.

A gas boiler may have an open or closed combustion chamber . Closed models are purchased more often than others, as they are safer. They consist of:

- fan;

- coaxial chimney;

- primary heat exchanger;

- modeling burner;

- expansion tank;

- gas fittings;

- pump providing circulation;

- hydraulic module;

- plastic heat exchanger (secondary).

All nodes are located in separate housings, in addition, the system has several outlets - for gas, water outlet (hot and cold) and 2 outlets for dispensing (return).

The scheme is as follows: cold liquid flows through a pipe into the heating element, and from there into the heating system. The security group monitors the process and promptly responds to problems by shutting off the gas. The gas also enters the burners first through this group, and the processed gas goes into the chimney (if there is a fan there, the process will go faster).

Attention

If the combustion chamber is open, it is necessary to equip the chimney pipe with sufficient height for natural ventilation.

In a solid fuel boiler, the scheme is identical: the wood burns, the unit heats the liquid, and the sediment sends it into the pipes on the floor.

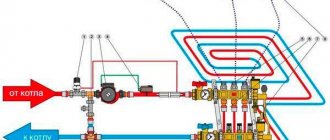

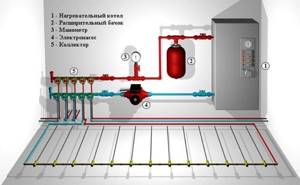

Connection technology

The simplest diagram is to connect the supply and return to the boiler from the collector unit. This option applies to typical single-circuit boilers. The main task here is to adhere to the appropriate output paths of the equipment.

To introduce a double-circuit boiler into the system, in addition to connecting the supply and return, you need to connect the same flows from the water supply. You should also install smoke removal elements, a gas supply pipe and turbocharger units. Each pipeline is equipped with a ball valve so that the flow can be quickly shut off.

Compiling a set of components

- a gas boiler;

- circulation pump;

- connecting fittings in tandem with shut-off valves;

- small diameter pipelines that will be installed in the subfloor;

- the main pipeline through which the coolant will be transported to residential premises;

- collector;

- thermostat, automation and sensors.

For a heated floor system from a gas boiler, you will need a circulation pump

A water heated floor can be assembled using copper, metal-plastic, polypropylene or PEX pipes. The latter are products made from cross-linked polyethylene; thanks to the modernized molecular structure, the material has increased strength.

The durability and high thermal conductivity of copper pipes make them indispensable in the installation of heated floors; this is an expensive but effective solution. The flexibility of polypropylene pipes may not be sufficient for the correct formation of turns. Metal-plastic products are well protected from damage; the inner aluminum layer provides high thermal conductivity.

Basic installation sequence

The following manipulations are performed as preparatory work:

- Boiler installation. The device is mounted according to the instructions on the wall or floor.

- Assembling a heated floor circuit. The formation of the top layer of concrete screed begins only after the functionality of the units has been checked, after treating the contours with compressed air.

- Connection of underfloor heating outlets with a pump-collector unit.

How the boiler is connected:

- The main pipelines are connected to the corresponding outlets of the boiler and mixing unit using copper, metal-plastic, polyethylene pipes and fittings. To supply gas, a corrugated stainless steel pipe is installed.

- Checking the connection comes down to a visual examination of the nodes and docking points, and a test run.

Installed underfloor heating system from a gas boiler

Each pipeline must be equipped with an emergency shutdown capability to minimize the consequences of emergency situations.

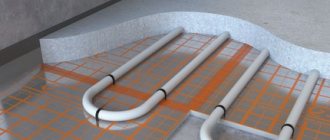

Choosing a floor pipe

TIM PEX pipe for floor contour, cross-linked PE

For a heated floor system (directly for heating), three types of materials, more precisely pipes, are used:

- Copper.

- Cross-linked polyethylene (PE).

- Metal-plastic.

Metal plastic (the same cross-linked polyethylene).

But, I’ll say right away that copper is very expensive, so we won’t even discuss such contours, all that remains is cross-linked PE and metal plastic. Although, in essence, both PE and metal plastic are made from the same polyethylene armored with aluminum foil or EVOH, only we are accustomed to distinguishing them by color and calling them differently.

Based on many years of experience in installing heating and heating systems of various types, I can say that it is best to buy pipes that are usually called metal-plastic. They are usually white, while cross-linked PE is pink, red or grey-blue. The armored layer in the first case is made of aluminum foil (has excellent thermal conductivity), and in the second case, it is an EVOH layer (an efficient new generation material).

So why did I begin to give preference to metal-plastic? Everything is very simple and there are good reasons for this:

- cross-linked PE pipes have the same thermal conductivity as metal plastic, but are much more expensive;

- thanks to the aluminum armor, a concrete screed can be poured onto the metal plastic without filling the tubes with water, while PE can be deformed under such pressure (flattened).

Recommendation. When buying polystyrene foam pipes, you need to choose a seamless pipe - it is more reliable. If the seller cannot provide a certificate for the product, then check it yourself. To do this, cut a piece 7-10 mm long from the coil and try to disassemble it into layers. If you managed to do this without difficulty, then the product is of low quality.

Characteristics of gas models

Modern modifications of gas boilers must be equipped with electronic controls that regulate temperature parameters, ensuring the safe operation of the system.

In order for the automation and circular pump for a warm water floor to work in the event of a power outage, it is advisable to stock up on a local source. Car batteries will provide several hours of operation. In situations where there is a risk of frequent power outages for several days, you will have to purchase a diesel generator.

Compared to the electric model, the gas boiler is a model of efficiency. Its condensation type is especially effective, receiving integrated heat from fuel combustion (explicit energy) and from steam condensation (latent thermal energy).

The principle of operation of the boiler is based on the circulation of the coolant through the exchanger, during which it is heated by the flue gases produced when the fuel burns. During the transfer of thermal energy, the gases are cooled, and at a certain temperature condensation is formed, causing the appearance of additional heat. This feature significantly increases the efficiency of heating equipment.

Gas boilers function flawlessly under conditions of uninterrupted gas supply, without requiring special routine maintenance techniques. In designs that provide an electronic mechanism for igniting the boiler, the operation of the burner is regulated in accordance with the specified temperature values with the removal of all harmful combustion products through forced ventilation. Boilers with piezo ignition, operating automatically, also stop the flow of gas if the flame goes out, but combustion is restored manually.

Related article: Flexible floor profile: installation and how to use

Gas valve (automatic) EUROSIT 630 (boiler). Mariupol

Gas valve (automatic) EUROSIT 630 (boiler)

Multifunctional gas supply regulator with modulating thermostat and function of complete modulating shutdown of the main burner

Multifunctional gas supply regulator with a modulating thermostat and the function of complete modulating shutdown of the main burner - 630 EUROSIT is a non-volatile device and is available in various designs and is intended for use in boilers and other gas-consuming equipment that requires precise temperature control, with a power of up to 24 kW.

Control knob with positions for off, ignition and temperature selection (MS).

Thermoelectric flame protection system with blocking of gas supply to the main burner after switching off (GM).

Device for setting maximum gas flow (RQ), pressure regulator (PR).

Minimum gas flow adjustment screw (by pass).

Modulating thermostat with the function of completely switching off the main burner (TH).

Gas outlet to the pilot burner with gas flow adjustment screw (RQ).

Inlet filter and pilot burner filter (FL).

Connections for measuring gas flow.

Gas supply, optionally, from below or from the side.

Connection from central heating

According to the legislation of the Russian Federation, the Republic of Belarus, Ukraine and other countries of the former USSR, unauthorized intervention in the centralized heat supply system is prohibited. Simply put, for connecting additional heating devices and heated floors, you face a large fine and an order to dismantle the extra heaters.

Note. Similar measures and responsibility are provided for connecting the transformer substations to the centralized hot water supply (DHW) network.

How is an unauthorized connection from centralized heating detected:

- neighboring apartments receive less heat, residents begin to write complaints, a commission from the management company identifies your modernization;

- due to pressure surges or poor-quality installation, a breakthrough and flooding of the lower apartment occurs; Leaking connection inside a concrete monolith

- responsible persons note a large difference in the readings of common house and apartment heat energy meters;

- if you connect the heated floor circuits in series with the batteries, the hydraulic resistance of the entire branch increases, the flow decreases, and the apartments along this riser become colder.

Some “cunning people” advise connecting the TP loops through a plate heat exchanger in order to isolate the circuits from the central heating. The catch: the hydraulic resistance of the network will not increase and a pipe break will not cause serious flooding, but the amount of heat removed will still increase.

How to do underfloor heating legally:

- Contact the heating supply organization with an application and obtain permission.

- Together with the permit, obtain technical specifications for installation and connection of floor circuits.

- Develop and approve the project.

- Install the system yourself and put it into operation.

It must be admitted that the vast majority of applicants are rejected at the application stage. An exception is made for dwellings in new buildings with individual connection of apartment heating to distribution risers. But if you decide, at your own peril and risk, to embed heating circuits into the heating network, proceed to study the next section.

Suitable boiler room

According to the standards, heating equipment using gaseous fuel must be installed in an autonomous room with ventilation and a chimney. The size of the room for floor fixtures must be selected based on 4 square meters. m of area with equipment power up to 30 kW. It must also have a volume of at least 8 m3.

In the absence of free space, there are gas boilers that are mounted on the wall and have relatively small dimensions. Operational efficiency will be ensured by correct power calculation. Wall elements can be installed in any room that has an exhaust shaft and an equipped chimney.