A heated towel rail is a necessary attribute of any bathroom, ensuring the comfort of its use; without it it is impossible to imagine a modern apartment or country house. When carrying out construction or repair work yourself or moving the device to another location during reconstruction, it is important to know how to connect a heated towel rail to the heating system.

The task is complicated by the fact that there are different types of heated towel rails and ways to connect them; to choose the best option, it is useful to study the basic diagrams of their location. And studying the correct installation technology will allow you to avoid uneven heating or its absence, airing of the system and leaks, which are a fairly common occurrence among errors when installing the device.

Rice. 1 Heated towel rails for bathrooms - varieties

Connecting a water heated towel rail - features

A heated towel rail is an important attribute that creates increased convenience when using the bathroom, in which it performs the following functions:

- Drying towels that are wet after washing and washing clothes and shoes.

- Heating the bathroom for a comfortable stay in the room after taking a bath or shower.

- Combating dampness affecting finishing materials, electrical sockets and lamps, heating boilers and household appliances.

The heated towel rail is connected to the heating or hot water supply system by parallel or series connection to the pipeline through which hot water flows.

Any heated towel rail has an inlet and outlet pipe with a thread at the end for quick and convenient connection to pipes. In some schemes, the heated towel rail becomes part of the pipeline, placed in the gap in place of the cut section of the pipe. During installation, it is welded to pipes or installed on American-type threaded connections.

Rice. 2 Design and equipment of the ladder heated towel rail

Why does the water heated towel rail not heat up?

An analysis of the situation with malfunctions of heated towel rails (abbreviated as HS) shows that a violation of their thermal efficiency occurs for several reasons:

- incorrect installation;

- unqualified interference in the work of engineering structures;

- general condition of heating and hot water supply systems;

- quality and parameters of coolant supply.

In order for the heated towel rail not only to look good in the interior, but also to provide effective heating, it is necessary to carry out the installation in accordance with the laws of hydrodynamics

As you yourself understand, it is almost impossible to influence the latest circumstances. All that can be done in this case is to try to force utility workers to fulfill their direct responsibilities. But any more or less educated person can check the correct connection and find the “weak link” in the heated towel rail-DHW system chain. But first, let's figure out how a heating device can be powered and find out the reasons for the drop in its thermal power.

Types of heated towel rails

Heated towel rails connected to the pipeline are divided into three main categories:

- Mermen. The main type in all apartment buildings and private buildings, they work on the principle of circulating water through a heated towel rail, and are a piece of curved pipe of various shapes or a ladder with threaded outlet pipes. In old houses, the element was often connected to heating pipes and it functioned only during the heating season; in modern residential high-rise buildings, the heated towel rail is connected to the hot water supply pipeline.

- Electrical. The device is a regular autonomous heating element not connected to water; it can be installed anywhere in the apartment: in the bathroom, in the kitchen, in the loggia. Although this device is a modern development, its use in the household is limited due to high energy consumption and additional financial costs for electricity.

- Combined. Such models combine water and electric heating of the heated towel rail, which is very convenient when connecting it to the heating system. In this case, during the heating season, the heated towel rail operates due to hot water passing through it, and when the heating is turned off, heating occurs due to electricity. This option is less popular due to its higher cost.

Rice. 3 Electric coil - modifications

Operating pressure and other operating conditions of the system

An important point that should be taken into account when purchasing equipment is the pressure in the system where the connection will be made. In high-rise buildings, hot water supply systems are characterized by high pressure, which is why it is necessary to buy a device with a decent safety margin. This is due to the fact that at the time of pressure testing, the pressure rises 1.5 times, and your pipes, unable to withstand such an increase, simply burst, and as a result, the entire apartment is flooded with hot water.

Important! In addition, when connecting the device directly to the riser, you will need to set a shut-off or thermostatic temperature, because otherwise, the likelihood of disrupting water circulation throughout the house will be close to the maximum level.

Main materials of manufacture - comparison of characteristics

The main materials for the manufacture of heated towel rails are stainless steel and brass; in budget options, galvanized steel is used for installation in apartment buildings. When choosing, the buyer often gives preference to the widely advertised stainless steel, which has an aesthetic appearance. To determine which metal is better, their main characteristics should be compared in terms of efficiency as materials for heat exchange devices.

If we consider stainless steel, it is almost three times cheaper than brass or copper, can withstand temperatures of more than 450º C, and is slightly susceptible to corrosion in water. Although stainless steel is corrosion-resistant and is not afraid of the effects of solutions of most acids and alkalis, if the alloy is made poorly (violation of technology, structural defects, reduced content of the main alloying additives of chromium), corrosion processes can occur in the structure. The material has high strength and durability, is harmless throughout the entire period of operation, but non-ferrous metals are used much less frequently as parts of plumbing fittings.

Copper-based brass alloys have thermal conductivity 4 times higher than stainless steel, which is the main advantage when using the material as a heat exchanger. Brass has high corrosion resistance (its surface is covered with a protective film of oxides, which serves as a barrier against the penetration of oxygen into the pure metal). Non-ferrous metals, unlike steels, are not subject to electrochemical corrosion; when used, the maximum temperature of the flowing coolant should not exceed 260º C.

Rice. 4 Types of heated towel rails - U-shaped, M-shaped and ladder

What designs are there?

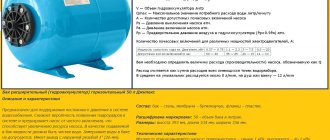

The main diameter of the pipe for a heated towel rail is 32 mm; if the body has a complex structure in the form of a ladder with welded pipe sections, their diameter is about 20 mm. On the market you can find other dimensional parameters of the main pipeline with an outer diameter of 26, 28, 50 mm.

All structures can be divided into two categories: single-pipe U-shaped or M-shaped and multi-pipe, consisting of two pipe sections of large diameter and small cross-section pipes located between them in the form of a ladder.

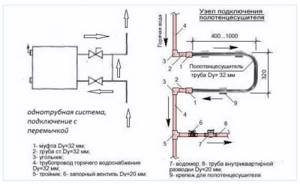

Some models provide for connection using special seals that allow the device to be rotated around its axis; in other modifications, a set of heated towel rails is possible from several fragments connected in series to each other. To connect the heated towel rail to the water riser, use a bottom, side or diagonal connection - this is how the inlet and outlet pipes are located in manufactured models.

Rice. 5 Single-pipe arrangement of a heated towel rail in the system

Principle of operation

Under the modern name of the equipment, there is actually a pipe located in the bathroom of each apartment in a multi-storey building, through which hot water flows. In fact, it is the only source of heating for the room, and can be used for drying things.

Modern, modernized mechanisms are curved pipes in which a liquid of a certain temperature (water, antifreeze) circulates. Such a device can be connected to two systems:

- open type;

- closed type.

In the first case, the equipment is installed directly to the heating pipeline. Due to the fact that oxygen is present in the first option, the formation of corrosive deposits on the inside of the mechanism is possible. This fact must be taken into account when choosing a model. If it is not resistant to corrosion, then this model will not fit into an open type system.

The closed system is built on the principle of complete tightness, so oxygen and other substances that can cause deposits cannot enter it. For such a system, you can select any product.

Product functions

The main purpose of the item is to dry wet towels. However, with the development of technology, the device was subject to modernization and became more practical and functional. Now you can dry not only towels on it, but also other linens, things, etc. In winter, the main task of the mechanism is to heat the room and eliminate dampness, which can cause the formation of fungi and mold.

In addition to practicality, there is also a decorative component. Designed bathroom interiors require that all items be perfect and complement the overall style. That is why on the market you can find models of different colors and shapes, with additional elements in the form of stone inserts, built-in shelves, and glass decors.

Where to connect and where to hang - recommendations

When installing heated towel rails, the following recommendations should be followed:

- The distance from the vertically located riser to the most remote section of the heated towel rail pipeline should not exceed 2 meters - if the device is located at a greater distance, due to the high hydraulic resistance of the resulting loop, water simply will not flow into it. In the bathroom, the heated towel rail is installed by direct connection to the tee adapters of the riser.

- It is more practical to choose more expensive products made from chrome-plated non-ferrous metals - they have four times better thermal conductivity compared to stainless steel and better corrosion resistance.

- To connect the heated towel rail, you should use the installation option using an American connection, which allows you to connect the fittings in a stationary position of the parts without turning around their axis.

- Before installation, it is better to replace the cheap rubber gaskets in the American union nut, which at constant high temperatures quickly lose their plasticity, with higher-quality fluoroplastic ones; you can install silicone and paronite rings or use a sandwich of soft and hard rings.

- If the heated towel rail is part of a common building riser of an old design, to replace it and carry out preventive maintenance, install a bypass and connect the device through ball valves, which are also secured using fittings.

- When connecting a heated towel rail to fittings, it does not hurt to maintain electrochemical compatibility, that is, to join products from the same material. A common mistake is contact between steel and brass, which creates a galvanic couple with accelerated corrosion.

- To seal the seal, it is more practical to use flax tow or plumbing thread; it is better to avoid using Fum tape - it is often cut with threads and assembled in the channel in parts, allowing water to penetrate between sections.

- If the heated towel rail is connected in a line parallel to the riser, it is useful to install shut-off ball valves in front of its inlet and outlet pipes for the convenience of carrying out preventive and repair work in the unit.

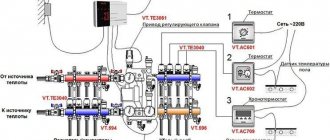

Rice. 6 Installing a heated towel rail in the bathroom - assembly diagram

Technology for connecting a heated towel rail

It is clear that connecting a heated towel rail to the heating system is a bad option; in private homes it is installed in the hot water supply pipeline, for which many use modern plastic pipes to supply water. The pipeline can be placed in any convenient place, the liner can be made from sections of pipes not only of the same type, but also from any material used for hot water.

If the work is carried out in an apartment building, when repairing a bathroom, the riser located in the basement of two pipelines of the forward and return lines will have to be closed; the material of the old risers is always steel; if they were replaced, in most cases polypropylene was used.

When the pipe is steel, you can weld an outlet threaded fitting to it, cut it with further cutting of external or internal threads to connect adapter tees, or attach a clamp with a branch - all methods are quite complicated except for the last one, but this option is not very reliable. There is another modern innovative option for connecting transition fittings to a steel pipe, which will be discussed below.

If there is a polypropylene riser, a section is cut out of it and two tees are soldered in to connect pipes or the heated towel rail itself.

Rice. 12 Connecting a heated towel rail through the threads on the pipes

Option for connecting heated towel rails to hot water

This option is characterized by the fact that heated towel rails are installed in a hot water recirculation circuit, which operates continuously year-round. This is the most economical option, since it does not require additional equipment and operating costs. A special feature of this option is the significant limitation of the heated towel rail models used. They should only be made of stainless steel and designed for installation on water. The appearance of such models is various variations on the theme of “ladders” and “coils”. Accordingly, their power is low (usually around 150-200 W) and heating a room with them without additional radiators is problematic. True, leading manufacturers of design radiators and heated towel rails (for example, Zehnder) have more powerful stainless steel models that are suitable for heating bathrooms up to 12-18 square meters. (of course, taking into account the installation of heated floors in them).

Advantages:

do not require additional costs, work all year round. It is possible to provide heating without radiators in bathrooms with an area of up to 12-18 square meters.

Flaws:

Only stainless steel heated towel rails can be used. Providing heating for large bathrooms is problematic.

| Important. It must be remembered that only stainless steel heated towel rails can be used for hot water. |

If an economical option for selling heated towel rails is important to you, use the option for recirculating hot water supply;

The appearance of the heated towel rail is extremely important for you, which must be combined with the interior of the bathroom - your choice is a separate circuit for heated towel rails;

You have hot water heated towel rails, but want to get rid of the radiator in the bathroom - install a heated floor in it and select a powerful stainless steel heated towel rail of a designer model.

Important components of the bathroom are, in addition to the bath itself, a sink, a shower and a mirror, and many other things, including a heated towel rail. This is an extremely convenient device that not only makes wet towels and linen dry, but also prevents dampness. In a word, it serves as a kind of heating system for a given room. And if it is better to entrust the installation of a bathtub or sink to professionals, then you can do the installation and connection of a heated towel rail yourself. The main thing is to know how it's done.

Bends from steel hot water riser for heated towel rails

When installing a heated towel rail in multi-apartment residential buildings, the main problem is connecting to a steel riser pipeline, and several methods are considered:

Welding. To connect a directly installed heated towel rail to the pipeline, two holes are cut in the pipe and a threaded fitting is welded. The method requires a welding machine or gas torch, as well as the presence of a gas welding specialist; difficulties may arise in the case of an old pipeline with thin walls, which the device will burn through, making welding difficult or impossible.

Thread cutting. With this technique, the steel pipeline is cut, a thread is cut into the surface of the pipe using a die, and then the adapter tees are screwed on from steel to polypropylene. Then they connect to the riser sections of soldered polypropylene pipe with threaded fittings at the end, which are laid in the wall grooves.

In addition to complexity and labor-intensiveness, the method has significant drawbacks: it is rarely possible to cut a thread when placing the pipeline at a short distance from the wall; moreover, old steel pipes have thin walls, and additional weakening often leads to their breakage.

Rice. 13 Example of a clamp connection in a private house

Clamps. The method is quite simple and is carried out in the following way: a large diameter hole is drilled in the pipeline and a composite clamp with a sealing rubber gasket and a threaded outlet of the required diameter is installed at this point, both halves are connected using bolts.

The method is quite simple and does not involve large costs, it is easy to implement with your own hands, the disadvantages are a rubber gasket that is not intended for long-term work with hot pipes (it is better to use fluoroplastic) and the possibility of moving the assembly down when loosening the bolts.

Gebo couplings. Gebo cast iron couplings are compression fittings that are securely and tightly connected to the pipe through a slotted metal ring (cracker) and an O-ring. To connect, a section of pipe is cut out, Gebo tees with bends of the required diameter and a pipe section between them are inserted at the top and bottom. The connection is very reliable and surpasses the above technologies in practicality of use, working in nodes for 10 years or more.

Rice. 14 Gebo couplings

Do-it-yourself preparatory work

When carrying out work on installing a heated towel rail with your own hands in a metal riser, depending on the chosen method, you will need different tools. To install the clamps, you need a drill with a metal drill and a hexagon of the required diameter; if the pipe is cut to attach the Gebo coupling, you will need a grinder with a metal disc to trim the riser and adjust the size of the pipe section between the couplings.

To fix the fasteners, you need a hammer drill with a concrete drill with a diameter of 6 mm. and dowels with screws.

To properly connect such a device, you will need a building level - it is recommended to connect the lower pipes to the heated towel rail with a slight slope to ensure spontaneous drainage of water from the heated towel rail pipeline in the absence of coolant (especially important when connecting the unit to the heating system).

Before carrying out work, disconnect the riser from the water supply to the heated towel rail pipeline and prepare two containers for continuously draining water from the system.

Rice. 16 Examples of installing an old heated towel rail in a single-pipe and two-pipe system

Connection to the hot water supply system

To connect a heated towel rail to a riser located at a great distance, polypropylene pipes are used - compared to metal plastic and cross-linked polyethylene, they are produced in a large diameter, which is necessary to reduce hydraulic losses. The connection is made using a pipe soldering iron; the necessary fittings are soldered at the ends. The heated towel rail is connected in the following sequence:

- After completing the plastering work, mark the connection points on the wall where the heated towel rail is installed, make markings and knock out grooves in the wall through which the pipes will pass. Install the plastic pipeline by soldering, leaving the threaded fittings protruding from the wall so that the later laid tiles are flush with them.

- Temporarily screw the heated towel rail on, level it and fix it on the wall using telescopic fasteners on the body, then cover the pipes with gypsum binding solution, after the plaster has dried, remove the device, and screw plugs into the fittings.

Rice. 17 DIY installation of a heated towel rail - main steps

- Further work is carried out upon completion of finishing work on laying tiles. The manufacturer produces heated towel rails with a different set of components; American ones are often found that are screwed onto the outlet pipes of the device with a special key. For sealing, it is better to use flax tow complete with a special paste.

- After placing the American on the outlet pipes, the device is screwed to the pipes through eccentric adapter couplings, which are connected and sealed with flax - this allows you to adjust the position of the pipes in the absence of alignment.

- Then unscrew the telescopic fasteners on the pipe walls of the heated towel rail until it makes contact with the wall, mark the holes for the fasteners with a marker, after which the device is removed.

- Using a self-tapping screw or any sharp object, a small depression is punched into the tile to prevent the drill from sliding on its smooth surface, after which a hole is made in the tile in the drilling mode. Then switch the tool to perforation mode and drill a hole of the required depth in the concrete; upon completion of the work, hammer in the dowels with a rubber hammer to avoid damaging the tiles.

- Finally, install the heated towel rail in place using an adjustable wrench, if necessary, replacing the low-quality American rubber gasket with a fluoroplastic one, screw the mount with self-tapping screws to the dowels using a Phillips screwdriver or screwdriver.

When carrying out work, one important rule should be observed - place a rag under the adjustable wrench or insulate its jaws to avoid scratches on the chrome-plated clamping nuts.

Rice. 18 Models of heated towel rails with complex shapes

How to connect a heated towel rail to the heating system

In a private house, there are no problems connecting to the heating riser - this can be done at any convenient time by draining the coolant from the system; in an apartment building you will have to wait until the end of the heating season.

When carrying out installation work in a multi-storey building in the absence of coolant, the functionality and tightness of the unit cannot be checked before turning on the heating, so it is better to install the heated towel rail with the bypass and shut-off valves at the inlet and outlet turned on.

Materials for work

In private homes, water heated towel rails are mainly installed, which are connected directly to the heating system.

When connecting the device, you must use the following materials:

- shut-off valves;

- fittings – couplings, bends, bends;

- air vent valve;

- mounting tow or tape;

- fastening elements - dowels, brackets, bolts, screws.

Experts recommend installing a bypass on the heated towel rail, which is a piece of pipe with tees at the edges. In this case, ball valves are mounted at the ends of the dryer.

How to connect heated towel rails with complex shapes

The main difference between the operation of a heated towel rail made from a large number of elements and a simple one is its high hydraulic resistance, which leads to the fact that the volume of passing coolant will be less and, accordingly, the device will not be sufficiently warmed up. In this case, you should reduce the diameter of the jumper, if present, or abandon the bypass altogether and remove all shut-off valves, connecting the heated towel rail in series to the riser pipeline.

If a highly branched heated towel rail is located at a large distance from the riser and you do not want to remove the bypass, you should choose the diameter of the supply pipes equal to or greater than the cross-section of the riser.

Rice. 19 Combined heated towel rails

A little about installing a combined heated towel rail

A combined heated towel rail is a rather rare guest on the construction market, although its installation in a heating system is quite effective. During the heating season, the heated towel rail will be hot due to flowing hot water; if the heating is turned off, the coolant in the circuit will be heated by the built-in heating element.

Structurally, the device is made in the form of a conventional heated towel rail with the difference that one of the fittings at the bottom (the bottom connection is mainly used) is made in the form of a tee, into the lower outlet of which a heating element with a thermostat is screwed. The combined model is connected in the same way as its water counterparts - from below, from the side or diagonally, the thermostat is always located at the bottom, in the design the outlets are assembled with the possibility of right or left connection.

Rice. 20 Installing a heated towel rail in a combined type bathroom

Option for heated towel rails on a separate heating circuit

This option involves organizing a separate circuit in the boiler room with a pump and pump group, which is intended only for heating heated towel rails. This circuit is closed, like any heating circuit. For this reason, it is possible to install any models of water heated towel rails on a separate circuit, including designer ones, the choice of which is very large. Among the designer heated towel rails, there is a wide range of powerful models that can easily replace other heating devices in bathrooms and showers. That is, in this case, the bathroom can be heated with a heated towel rail - without the use of heating radiators.

Accordingly, organizing a separate circuit for heated towel rails is the most expensive option, since it requires the installation of additional equipment (outlet on the manifold, pump group, pump, boiler room automation), the operation of which will increase operating costs.

Advantages: the ability to use designer models of water heated towel rails, the implementation of bathroom heating without the use of radiators. The operation of heated towel rails is ensured constantly, all year round.

Disadvantages: additional costs for equipment and operation.

| Important to consider. When selecting a heated towel rail model for heating a bathroom, its power should be calculated for a supply temperature of +60 degrees C, while heating radiators are calculated for a supply of +80 degrees C. |