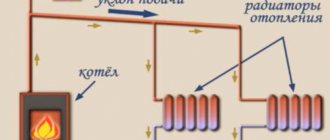

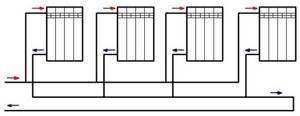

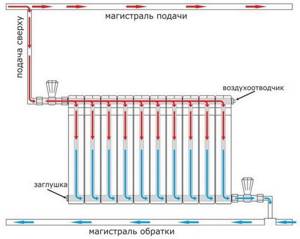

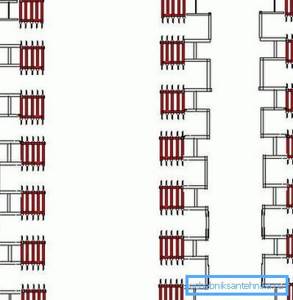

Single-pipe heating system diagram

Single-pipe heating system: vertical and horizontal distribution.

In a single-pipe heating system, the supply of hot coolant (supply) to the radiator and the removal of cooled coolant (return) are carried out through one pipe. All devices relative to the direction of movement of the coolant are connected to each other in series. Therefore, the temperature of the coolant at the inlet of each subsequent radiator along the riser is significantly reduced after heat is removed from the previous radiator. Accordingly, the heat transfer of radiators decreases with distance from the first device.

Such schemes are used mainly in old central heating systems of multi-storey buildings and in autonomous gravity-type systems (natural coolant circulation) in private residential buildings. The main defining disadvantage of a single-pipe system is the impossibility of independently adjusting the heat transfer of each radiator separately.

To eliminate this drawback, it is possible to use a single-pipe circuit with a bypass (a jumper between the supply and return), but in this circuit, the first radiator on the branch will always be the hottest, and the last the coldest.

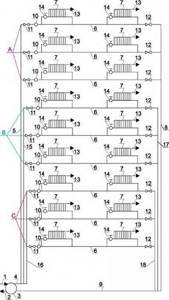

Multi-storey buildings use a vertical single-pipe heating system.

In multi-storey buildings, the use of such a scheme allows saving on the length and cost of supply networks. As a rule, the heating system is made in the form of vertical risers passing through all floors of the building. The heat output of radiators is calculated during system design and cannot be adjusted using radiator valves or other control fittings. Given modern requirements for comfortable indoor conditions, this scheme for connecting water heating devices does not satisfy the requirements of residents of apartments located on different floors, but connected to the same heating system riser. Heat consumers are forced to “endure” overheating or underheating of air temperature during the transitional autumn and spring period.

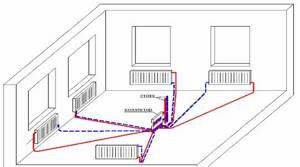

Single-pipe heating in a private house.

In private houses, a single-pipe scheme is used in gravity heating networks, in which hot water circulates due to the differential densities of heated and cooled coolants. Therefore, such systems are called natural. The main advantage of this system is energy independence. When, for example, in the absence of a circulation pump in the system connected to the power supply networks and in the event of power outages, the heating system continues to function.

The main disadvantage of the gravity single-pipe connection scheme is the uneven distribution of coolant temperature across the radiators. The first radiators on the branch will be the hottest, and as you move away from the heat source, the temperature will drop. The metal consumption of gravity systems is always higher than that of forced ones due to the larger diameter of the pipelines.

Video about the installation of a single-pipe heating circuit in an apartment building:

Open and gravitational systems - is it realistic?

No matter what fans of forced circulation say, yes, it’s real. In fact, most professionals take into account, if not constant work on a natural flow, then at least the possibility of maintaining some productivity during a power outage.

The first thing you need to do is to aim at increasing the power of the boiler. Moving heated water against the force of gravity requires energy, and since only heat is used to create a pressure difference, much more of it will be required, and heat losses will naturally increase.

Another issue is the efficiency of the system. For heating large areas, the flow rate of the coolant is important so that it has time to maintain the temperature until the last radiator in the chain. Gravity systems are simply not capable of this, but they again maintain the flow even without a circulation pump, which means that at least the system will not defrost, and part of the house will even remain comfortable warm.

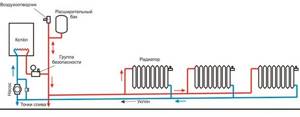

Heating system of a two-story house with natural circulation: 1 - boiler; 2 — open type expansion tank; 3 — feed; 4 — radiators of the second floor; 5 — radiators of the first floor; 6 - return

Acceleration of the flow is achieved by classical methods:

- a fairly steep slope of the pipes;

- absence of sections with a counter-slope;

- increasing the volume of coolant (pipe diameter);

- minimizing turns and narrowing;

- increasing the difference between the top and bottom points.

And yet, it is strongly recommended to abandon systems without forced circulation - they are too uneconomical, and besides, pipes can only be laid openly. Instead of overpaying for wasted fuel year after year, it is better to spend money once and organize uninterrupted power supply to the boiler room.

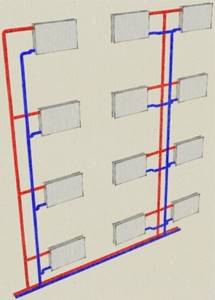

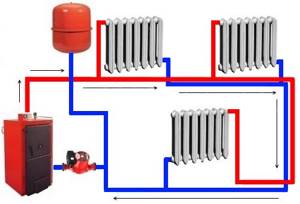

Two-pipe heating system diagram

In two-pipe schemes, the supply of hot coolant to the radiator and the removal of cooled coolant from the radiator are carried out through two different pipelines of the heating systems.

There are several options for two-pipe schemes: classic or standard, associated, fan or beam.

Two-pipe classic wiring

Classic two-pipe heating system wiring diagram.

In the classical scheme, the direction of movement of the coolant in the supply pipeline is opposite to the movement in the return pipeline. This scheme is most common in modern heating systems, both in multi-storey buildings and in private individual ones. The two-pipe circuit allows you to evenly distribute the coolant between radiators without loss of temperature and effectively regulate heat transfer in each room, including automatically through the use of thermostatic valves with installed thermal heads.

Such a device has a two-pipe heating system in a multi-story building.

Associated scheme or “Tichelman loop”

Associated heating wiring diagram.

The associated scheme is a variation of the classical scheme with the difference that the direction of movement of the coolant in the supply and return is the same. This scheme is used in heating systems with long and remote branches. Using a passing circuit allows you to reduce the hydraulic resistance of the branch and distribute the coolant evenly across all radiators.

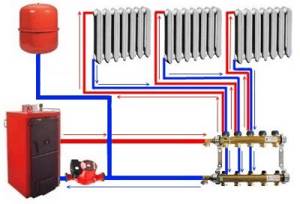

Fan (radial)

A fan or radial scheme is used in multi-storey construction for apartment heating with the possibility of installing a heat meter (heat meter) in each apartment and in private housing construction in systems with floor-to-floor piping. With a fan-shaped scheme in a multi-storey building, a collector is installed on each floor with exits to all apartments of a separate pipeline and an installed heat meter. This allows each apartment owner to account for and pay only for the heat they consume.

Fan or radiant heating system.

In a private house, a fan diagram is used for floor-to-floor distribution of pipelines and for radial connection of each radiator to a common collector, i.e., each radiator has a separate supply and return pipe from the collector. This connection method allows you to distribute the coolant as evenly as possible across the radiators and reduce hydraulic losses of all elements of the heating system.

Note! When distributing pipelines in a fan pattern within one floor, installation is carried out in solid (without breaks or branches) sections of pipes. When using polymer multilayer or copper pipes, all pipelines can be cast into a concrete screed, thereby reducing the likelihood of rupture or leakage at the junction of network elements.

Equipment options, how heat consumption is calculated and payment methods for services

In order to understand how much coolant you consume to heat a house with a large number of apartments, the best option would be to install a house meter. To calculate the payment for consumed heat, readings are taken from the meter. They are divided by the number of apartments in the building and their area. A house meter makes it possible to pay for heat only in the cold season and it is possible to reduce the amount of incoming energy into the heating systems of buildings.

House heat meter

This leads to you saving your finances when favorable living conditions arise. The cost of this type of heating is indicated by local authorities. To install a home meter, first of all, gather the residents for a meeting and decide whether everyone agrees to switch to a different heating method. It is also worth seeking help from specialists to assess the feasibility of a home heating system.

Such a heating system in a five-story building or in a house with fewer or more floors allows heating at certain times of the year and paying bills for actual energy consumption. Such a heating system for Khrushchev houses implies that a meter is installed to control the heat, from which monthly readings are taken. However, this is the most complex heating system for a five-story building for profitable heating. There are a lot of nuances that need to be observed, and there is no guarantee that local authorities will release your home from control.

Heating scheme for a multi-storey building

Types of radiator connections

The main methods of connecting heating system devices are several types:

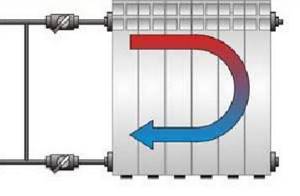

- Lateral (standard) connection;

- Diagonal connection;

- Bottom (saddle) connection.

Side connection

Lateral radiator connection.

Connection from the end of the device - supply and return are located on one side of the radiator. This is the most common and effective connection method; it allows you to remove the maximum amount of heat and use the entire heat transfer of the radiator. As a rule, the supply is at the top and the return is at the bottom. When using a special headset, it is possible to connect from bottom to bottom, this allows you to hide the pipelines as much as possible, but reduces the heat transfer of the radiator by 20 - 30%.

Diagonal connection

Diagonal radiator connection.

Connection diagonally to the radiator - the supply is on one side of the device from the top, the return is on the other side from the bottom. This type of connection is used in cases where the length of a sectional radiator exceeds 12 sections, and a panel radiator is 1200 mm. When installing long radiators with side connections, there is uneven heating of the radiator surface in the part furthest from the pipelines. To ensure that the radiator heats up evenly, a diagonal connection is used.

Heating devices

It is obvious that the design of the heating system must include not only a heat source, but also heating devices. Which batteries are best for a budget-conscious homeowner?

First, let's think about the conditions under which the radiator will operate in an autonomous system.

Operating temperature is usually in the range of 50 - 80 degrees. Working pressure does not exceed 2.5 atmospheres. Water hammer is excluded - unless, of course, you fill the circuit by opening the valves sharply and to capacity.

If so, you can safely opt for aluminum sectional radiators - beautiful, cheap and with excellent heat transfer.

Aluminum sectional radiators.

As we have already found out, extreme pressure and high temperature are not expected in the autonomous circuit. If so, you can save on pipes: we will choose inexpensive, lightweight and durable polypropylene.

Since this material has a high coefficient of thermal expansion, we will have to:

- Select pipes with reinforcement. A layer of aluminum foil will noticeably reduce elongation when heated.

- Provide long straight bottling areas with compensators - ring or U-shaped bends.

The U-shaped compensators are clearly visible in the photo.

How to conduct heating yourself using polypropylene?

A low-temperature soldering iron is used to weld pipes with fittings. The melted surfaces are fixed in the working position and after 10 - 40 seconds (depending on the size) they become a single whole.

Important point: aluminum foil must be removed from the welding field by stripping (shaver). It will weaken the connection, and in the future may cause delamination of the pipe.

Cleaning polypropylene with a hand shaver.

What pipe diameters should I choose?

- For bottling a small (no more than 150 m2 per floor) house - with an outer diameter of 25 mm.

- For connections to radiators - with a diameter of 20 mm.

Classification

Let's start with an overview of the properties that distinguish different schemes.

Serial and radial wiring

In the first case, radiators are mounted to a common pipeline. Serial wiring does not mean that each radiator breaks the main distribution. On the contrary, very often a bypass is installed between its inserts, which allows you to regulate the temperature regime of the heating device independently of the others.

Important: when installing any throttling valve, a bypass is required. Otherwise, we will begin to regulate the permeability not of the radiator supply, but of the entire circuit.

Radial (collector) wiring means that combs with throttles or valves are mounted on the supply and return pipelines, from which the coolant is distributed through a pair of connections to each heating device. The disadvantage of this solution is obvious: the pipe flow increases many times over.

- Temperature control is made very convenient. From one point, the owner of a house or apartment can regulate the heat output of each radiator.

- Each pair of pipes leading from the collector serves only one heating device. If so, you can get by with a smaller pipe diameter, which, in turn, allows you to lay the liner in the screed or the space between the subfloor joists. The pipes will not remain visible and spoil the design of the room.

One-pipe and two-pipe schemes

The difference between them is easier to explain with examples.

A typical one-pipe heating system is Leningradka, a simple wiring system consisting of a filling ring laid around the perimeter of the house. Heating devices break it or, more correctly, are connected in parallel.

What does this heating implementation provide?

- Cheapness. It is clear that one pipe will cost less than two.

- Exceptional fault tolerance. While the coolant is circulating in the circuit, stopping its movement in a separate heating device and defrosting it is impossible in principle.

The price of these qualities is a wide range of temperatures on radiators that are as close as possible to the heat source and as far away from it as possible. However, heat transfer can be easily leveled by using chokes or varying the number of battery sections. In addition, the contour must be continuous: the door or panoramic window will have to be outlined with pouring from below or from above.

In the case of two-pipe heating, we install two independent bottlings - supply and return. Each radiator is a jumper between them.

Important: balancing two-pipe heating with chokes is mandatory. Otherwise, the entire volume of coolant will flow through nearby heating devices; distant ones can be unfrozen. There were precedents.

Dead-end and passing schemes

In a dead-end distribution, the supply bottling reaches the farthest point of the circuit, after which the coolant returns to the starting point along the return line, moving in the opposite direction to the original direction.

However, if the heating circuit encircles the perimeter of the entire house or apartment, the coolant can return to its starting point and continue moving in the same direction. In this case, the scheme is called passing.

Of course, division according to this criterion is possible only for two-pipe circuits.

Top and bottom filling

A typical scheme for five-story Soviet-built buildings is when in a two-pipe heating system both filling points are located below, in the basement. Each pair of risers connected on the upper floor serves as a jumper between them. This is the so-called bottom filling.

A nuance: by bottling, professionals mean both the direction of movement of the coolant and the pipe through which it moves to the risers.

In houses with top filling, the supply pipeline is placed in the attic. EACH riser serves as a jumper between the supply and return pipelines.

Which scheme is better? It's hard to say for sure.

- With bottom filling, all shut-off valves and threaded connections are located in the basement. Leaks will not flood apartments.

- On the other hand, starting circulation in the heating system becomes much more complicated. After all, the jumpers between the paired risers become airy; and they are located in apartments, access to which is often problematic.

In the case of top filling, all air pockets are forced into the expansion tank located at the top point of the supply pipeline, from where the air is released through a valve or automatic air vent.

Natural and forced circulation

Let's imagine a closed volume filled with water. Now let’s place any type of heating element in it. What will happen to the liquid?

When heated, water, in full accordance with the laws of physics, will expand and reduce its density. After which it will be forced out by the surrounding colder and denser masses into the upper part of the vessel.

It is this effect that underlies the operation of a gravity heating system. How is it structured?

- After the boiler, the filling rises vertically, forming an accelerating manifold. An air vent is mounted at its top point (in the case of an open system without excess pressure - an open-type expansion tank).

- The rest of the contour runs with a slight constant slope along the contour of the house. The cooling water makes its way through the bottling by gravity, giving off heat to the heating devices. Having reached the boiler, it is reheated - and then in a circle.

This scheme is fault-tolerant and non-volatile, but has a number of disadvantages:

- The pressure in the gravitational circuit is small, and to ensure circulation it is necessary to minimize the hydraulic resistance of the filling by increasing its diameter. This means a lot of expenses and... please come up with your own antonym for the word “aesthetics”.

- A pipe laid not level, but with a slope, also does not add sophistication to the design of the room.

- Finally, a system with natural circulation warms up the house for a very long time and, after warming up, has a large temperature spread at the beginning and end of the circuit.

Forced circulation in autonomous circuits is provided by a low-power circulation pump. In houses connected to central heating, it is not needed: the pressure difference between the supply and return pipelines of the heating main is usually at least 2 kgf/cm2.

An interesting solution is a circuit built like a gravitational one, but with a pump built into it. Moreover, the latter does not break the main contour, but cuts parallel to it. Between the taps, the bottling is equipped with a valve or check valve (exclusively ball valve, which has minimal hydraulic resistance and does not require a large differential to operate).

The proposed scheme can operate in two modes:

- When electricity is available, the pump ensures fast and uniform heating of all heating devices. In this case, the bypass is closed (by a valve or an activated check valve).

- Without electricity, the bypass opens, after which the system continues to operate with natural circulation.

Main types of water heating wiring

Today, there are several main options for piping around the house when using water heating:

Single-pipe. The so-called “Leningradka”, in which one pipe connects all the heaters in the house in the direction of flow of the coolant. This scheme is chosen for its simplicity, minimal financial (the price of highways is generally lower) and labor costs.

But at the same time, the heating of the radiators is uneven, and it is impossible to regulate the temperature in each of the batteries;

- Two-pipe

. The heating radiators are connected by two pipes laid parallel to the movement of water in the system. The advantages include the ability to quickly adjust the temperature, quick and uniform heating of rooms, accessibility; - Manifold pipe arrangement

. It has its own supply and return pipelines, connected together using special distribution manifolds. Features: beautiful appearance, full control over all batteries in the house from the distribution cabinet.

The main advantages of water heating of a cottage

As you can see in the photos and videos of country houses on our website, water heating schemes are used quite often in our country.

There are simply a huge number of reasons for such wide distribution:

- Possibility of performing installation work on heating a house at any stage of construction. In addition, even in a finished house, water heating can be installed without any problems;

- The water itself has excellent qualities if used as a coolant. High thermal conductivity, availability and low cost, along with unique heat capacity, make water the best choice;

- Versatility, the ability to use different types of fuel to heat the coolant in a heating circuit;

- A large selection of pipe routing options for water heating schemes. You can choose a certain type depending on a lot of parameters, starting from the area of the cottage and ending with financial capabilities;

- A variety of equipment for arranging home heating;

- Accurate and quick adjustment of air temperature in each room of a private house. This is ensured by the installation of special equipment, namely thermostats and shut-off valves.

Equipment

So, we are going to install water heating with our own hands. What main elements will our scheme include?

Boiler

Domestic gas heating boilers are the cheapest to operate. In the Moscow region, the cost of heating a 200 m2 house with main gas does not exceed 3,000 rubles per month.

Boilers can be volatile (with electronic ignition) and non-volatile (using piezo ignition and a pilot burner). The former are noticeably more economical - the pilot burner consumes up to 20% of the total amount of gas.

In second place in terms of efficiency are solid fuel boilers. Coal and firewood will be an excellent solution where there is no main gas. However, using solid fuel requires frequent loading: you will have to light the boiler at least twice a day.

There are, however, a number of ways to solve this problem.

- Gas-generating solid fuel boilers split the fuel combustion process into two stages. Initially, it smolders with limited air access, forming flammable pyrolysis gas; then this gas is burned in its own furnace. A gas generator boiler is capable of operating on one load not for 2-5, but for 8-12 hours.

- Top-burning devices use the smoldering of a thin top layer of coal or wood. A coal boiler can operate for up to 5 days without maintenance or cleaning.

- A simple and universal solution is to use a heat accumulator (a thermally insulated container with a volume of 300-2000 liters). Working at full power, the boiler heats the water in the tank after lighting. Over the next few hours, the accumulated thermal energy is gradually released to the heating devices.

Finally, solar and electric boilers differ little in heating costs. They provide the maximum cost per kilowatt-hour of heat. In addition, it is not possible to provide the power required for heating with electricity everywhere.

Pipes

Their choice is determined by whether we are talking about central or autonomous heating.

The optimal material for central heating is steel pipes of several types.

- Black steel is cheap but susceptible to corrosion. In addition, steel risers and connections require a lot of time and effort for installation. Connections are most often made by welding.

- Galvanized steel is protected from corrosion by a zinc layer; It would be correct to assemble a galvanized liner ONLY on threads. Welding breaks the protective coating, including inside the pipe.

- Finally, a wonderful material is corrugated stainless steel. The pipes are connected using compression fittings with silicone seals and are easy to bend.

Why steel? Because in the central heating system you are not protected from exceeding the design temperature and water hammer. It is better to overpay when installing heating, and not when eliminating the consequences of a dirty boiling water leak.

But autonomous heating means that all parameters are constant and under your control. Hence the choice of materials:

- Metal-plastic with press fittings.

Important: it is better not to use compression fittings with union nuts on heating and hot water. After several heating and cooling cycles, they begin to leak.

- Polypropylene. Preferably reinforced: reinforcement not only increases the tensile strength of the pipe, but also reduces its thermal expansion.

- Cross-linked polyethylene. In addition to strength, these pipes have another advantage: they are flexible and are supplied in coils up to 500 meters long, which is useful for radial distribution with laying pipes in a screed.

Heating devices

And here it is worth separating central and autonomous heating.

In central heating systems, it is better to use steel tubular radiators, steel convectors and bimetallic radiators. Aluminum is not desirable.

And not only from the point of view of strength: the instructions for the use of aluminum radiators specifically stipulate the ability of this metal to accelerate destruction in combination with copper water supply. Metals form a galvanic couple.

Since you can’t know what your neighbors’ eyeliners are made of, it’s better not to take risks.

But for autonomous heating, aluminum radiators are undoubtedly the best choice.

Safety

- Expansion tank. It accommodates excess coolant during its expansion accompanying heating.

- Safety valve - additional insurance against circuit overflow. The valve is activated and releases excess coolant when its pressure reaches a preset threshold value.

- A pressure gauge or thermomanometer is installed for visual monitoring of parameters.

- An automatic air vent or a manual air vent is mounted at the highest points of the circuits and in air pockets.

Installation

It’s worth saying right away that installing such systems with your own hands is a risky business. The problem is that designing horizontal systems requires serious calculations. Only a competent engineer can make such calculations and correctly design the entire structure.

In addition, installation, debugging and launch of such a system will require the work of experienced specialists familiar with modern technology, plumbing standards and regulations, which are just beginning to be introduced in this country.

You can, of course, find a lot of tips and guidelines for installing horizontal heating systems, but there is no guarantee that such instructions will not lead to an ineffective configuration.

The fact that a particular scheme works for one person does not mean that the same scheme will work for you. This requires an individual approach.

Also, do not forget that the commissioning of accounting equipment requires the participation of government specialists who will confirm the compliance of this equipment with standards.

Advice! If you decide to install such heating yourself, we recommend that you watch the video on our website. You will also need a serious theoretical basis and experience working with plumbing.

It would also be a good idea to find someone who already has similar experience and ask about all the intricacies of the upcoming work.

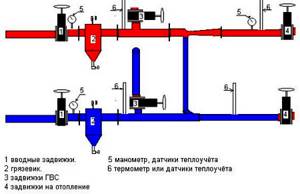

House heating scheme

It was already mentioned above that most modern houses in cities are heated using a centralized heating system. That is, there is a thermal station in which (in most cases using coal) heating boilers heat the water to a very high temperature. Most often it is more than 100 degrees Celsius!

Therefore, in order to avoid boiling and evaporation of water, the pressure in the pipes is very high - about 10 kgf.

Water is supplied to all buildings connected to the heating main. When connecting a house to a heating plant, inlet valves are installed to control the process of supplying hot water to it. A heating unit is also connected to them, as well as a number of specialized equipment.

heating unit operation diagram

Water can be supplied both from top to bottom and from bottom to top (when using a single-pipe system, which will be discussed below), depending on how the heating risers are located, or simultaneously to all apartments (with a two-pipe system).

Hot water, entering the heating radiators, heats them to the required temperature, ensuring its required level in each room. The dimensions of radiators depend both on the size of the room and on its purpose. Of course, the larger the radiators, the warmer it will be where they are installed.

Leningradka in a two-story house

Most classical schemes are applicable to multi-story buildings and the single-pipe system is no exception. The supply riser rises from the first floor to the second. This pipe has the largest diameter, equivalent to the boiler pipes. The supply runs under all the radiators and after the last one is conventionally considered the return line. Since the pipe usually goes around the perimeter of the house, it is extended to the supply and lowered to the boiler in a common technical channel.

Another option is to lower the pipe to the first floor and run it in the same way below all the radiators and close it back into the boiler. For such a connection, high boiler power and high flow rate are required, otherwise the temperature at 8-10 radiators will no longer be high enough. Therefore, it is optimal to make a floor-by-floor pipe distribution with the organization of two circulation circuits. If you want a clean Leningrad, think about a way to limit the flow in proportion to the distance of the radiators from the boiler, but remember that a single-pipe system always has a shorter wing length.

Radiators are connected to two points of one pipe without breaking. The greater the difference between the cross-section of the main pipe and the outlet, the less heat loss will be and the longer the line length. This connection allows you to turn the radiator into bypass mode and locally regulate the flow without affecting the overall operating mode - an impossible task for a classic single-pipe circuit.

Development of a heating system project

The heating device, starting from the inlet system and ending with heating radiators, is created immediately after the skeleton of an apartment building is built. Of course, by this time the heating project for an apartment building must be developed, tested and approved.

And it is at the first stage that a number of difficulties often arise, as with any other very complex and important work. In general, the heating system of an apartment building is complex.

Specialists need to calculate the optimal thickness of all pipes that will be used during installation, the dimensions of radiators and much more.

The power of your heating system can depend on the strength of the wind in your area, the material from which the building is constructed, the thickness of the walls, the size of the rooms and many other factors. Even two identical apartments, one of which is located on the corner of the building, and the other in its center, require a different approach.

After all, a strong wind in the winter season cools the outer walls quite quickly, which means that the heat loss of a corner apartment will be much higher.

Therefore, they need to be compensated by installing larger heating radiators. Only experienced specialists who know exactly how all the equipment is designed and how it works can take into account all the nuances and select the optimal solutions.

A beginner who decides to calculate the heating system in an apartment building will be doomed to failure from the very beginning. And this will not only lead to a significant overexpenditure of resources, but will also put the lives of the inhabitants of the house in danger.

Aesthetics and comfort

The aesthetic side of the issue also plays an important role. Increasingly, consumers are placing increased demands on the interior of their home. Designer renovations have come into fashion, implying that the interior matches a certain style.

At the same time, not every style is able to accommodate “scoop” risers in every room, and leaking pipes can turn expensive repairs into a pitiful sight quickly enough.

The horizontal arrangement of the distribution pipes allows you to hide them in the floor screed, which significantly increases the visual appeal of the room and the possibilities of interior decoration.

The horizontal arrangement of the distribution pipes allows you to hide them in the floor screed, which significantly increases the visual appeal of the room and the possibilities of interior decoration.

In addition, modern people no longer want to put up with conditions and adapt to the climate. When investing in real estate, the buyer wants to get housing that is comfortable in all respects.

In winter, the temperature regime is especially changeable: after severe frosts, sharp warming may occur, and the temperature increases several times. Naturally, if the radiators heat up as before, the apartment will become hot.

You will have to open the windows and create drafts, and the question arises: why pay for heat when it is unnecessary? Horizontal systems allow you to regulate the temperature of each individual apartment, and radial systems allow you to regulate the temperature of each individual room.

Advice! Using heat meters allows you to take into account only the heat you need and avoid paying for an overheated room.

Why choose such a system?

Two-pipe water heating is gradually replacing traditional single-pipe designs, since its advantages are obvious and very significant:

- Each of the radiators included in the system receives a coolant with a certain temperature, and it is the same for all.

- Ability to make adjustments for each battery. If desired, the owner can install a thermostat on each of the heating devices, which will allow him to obtain the desired temperature in the room. At the same time, the heat transfer of the remaining radiators in the building will remain the same.

- Relatively small pressure losses in the system. This makes it possible to use an economical circulation pump of relatively low power to operate the system.

- If one or even several radiators fail, the system can continue to operate. The presence of shut-off valves on the supply pipes allows for repair and installation work to be carried out without stopping it.

- Possibility of installation in a building of any number of floors and area. You just need to choose the optimal type of two-pipe system.

The disadvantages of such systems usually include the complexity of installation and higher cost, compared to single-pipe structures. This is due to the double number of pipes that have to be installed.

However, it must be taken into account that to install a two-pipe system, pipes and components of small diameter are used, which provides certain cost savings. As a result, the cost of the system is not much higher than that of a single-pipe analogue, but it provides much more advantages.

One of the significant advantages of a two-pipe heating system is the ability to effectively regulate the room temperature

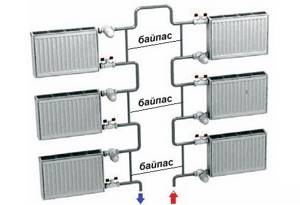

Bypass sections in single-pipe systems with horizontal and vertical distribution

In heating systems with vertical and horizontal pipe distribution, short bypass sections are used.

Bypass sections in a single-pipe heating system

Without going deeply into theory, I will inform you that the bypass pipe should have a smaller diameter compared to the rest of the supply pipe. Or, throttling equipment is installed on the bypass section - special valves (3-way thermostat valves, single-pipe thermostat valves with an adjustable bypass).

Unfortunately, such valves can only be used in single-pipe heating systems.

Pros and cons of a 2-pipe system

The advantages of such heating include the following points:

- The system is more reliable and less vulnerable to defrosting;

- Parallel connection principle, providing greater heat output;

- Possibility of extension, both vertically and horizontally, which is especially convenient when expanding living space (extension of residential premises);

- Possibility of manual temperature control for each room.

The disadvantages include the following:

- Higher cost;

- Installation is somewhat more complicated;

- More consumables (pipes) will be required.

Bottlings

Depending on their placement, there are two heating distribution schemes.

Lower

Bottom filling, or a heating system with bottom wiring, is used in most modern buildings. Both the feed and return bottling stations are located in the basement. The risers are connected in pairs by jumpers located in the apartment on the top floor or in the attic; At the top point of each jumper there is an air vent (Maevsky valve).

Any riser is a bridge between bottlings. The inevitable imbalance between the risers closest to the elevator unit and those farthest from it is compensated by the difference in the permeability and size of the pipes. Let us present the usual values of remote control for a heating circuit serving the entrance to a modern ten-story building.

| Plot | DU pipes |

| Spills near the elevator unit | 50 |

| Spills at end risers | 40 |

| Risers | 20-25 |

What specific advantages does bottom routing of heating pipes provide?

- All shut-off valves on paired risers are concentrated in one place. There is no need to go up to the attic to turn it off.

- Discharging coolant into a technical basement during repairs does not pose any problems.

But: often basements are used for storage or utility rooms of stores. In this case, you yourself realize that there is no need to talk about any advantage: you will have to dump the risers through a hose into the sewer.

The main drawback of the lower wiring of heating systems is the complexity of starting them after the reset is complete. In order for circulation to begin through all risers, it is necessary to bleed off the air space. At the same time, not all residents of the upper apartments can do this; We should not forget about empty premises.

Upper

Top filling, or heating with a top supply distribution, is completely and predictably different in that the filling supply thread is placed in the attic. The return remains in the basement. Any riser is a separate element, free from other risers.

In the attic, in addition to bottling the supply, in this case there are:

- Shut-off risers from the valve supply.

- Plugs for relieving them (more correctly, for sucking in air necessary to completely dry a group of heating devices).

- Expansion tank. Regardless of the name, it does not compensate for the increase in coolant volume during heating (the system is not autonomous, but connected to the heating main). A tank located at the top point of the filling bottling, laid with a minimum slope, helps to collect air, which is removed from there through the relief valve.

This heating system wiring scheme was widely used until approximately the 80s of the last century.

How does it look against the background of the bottom bottling?

- The main trouble here is the complexity of resetting the launch of a separate riser. To dry it completely you need:

- Close the attic valve.

- Close the valve in the basement and unscrew the plug.

- Unscrew the plug in the attic.

It’s curious: a whole house heating system with an upper supply distribution is reset and started much more easily, especially if the discharge from the heating expansion tank is routed to the elevator unit. Alas: dumping a house is associated with the loss of a huge amount of coolant, which is undesirable from the standpoint of saving thermal energy.

- The main advantage of top filling is that starting it up is extremely simple and does not depend on the residents of the house. It is enough just to slowly (so that there is no water hammer) open the house valves on the supply and return, after which all that remains is to dump the air space from the expansion tank.

Features of autonomous heating

In heating systems powered by a boiler, the weak point is the heat exchanger. It is rare that boilers are equipped with heat exchangers capable of withstanding more than 5 - 7 Atm. Since the permissible value is considered based on the least stable element, the limit of the permissible value of the heat exchanger will thus be the pressure standard in a private house. As a rule, this is 1 – 3 Atm.

If an open expansion tank is installed and there is no circulation pump, there is nothing to worry about! The pressure will never exceed the static minimum. But low blood pressure is also not good. Heating efficiency here is low, so such a system is increasingly being abandoned.

If the expander is closed and the pumps are running, you need to monitor the pressure using a pressure gauge (it is recommended to install a safety group in the autonomous heating system, which includes a safety valve, an air vent and a pressure gauge).

Autonomous heating in the apartment from the boiler

What can lower blood pressure:

- A leak. If a connection is dripping somewhere or the faucet is leaking, this is a leak that needs to be corrected.

- Air vents can also leak.

- Decrease in water temperature. Colder water expands less, and so does pressure.

- Damage to the expansion tank membrane. It may initially be incorrectly calculated, break through, or crack and stretch. After all, the volume of the expander chamber should be a tenth of the total volume of water in the pipes.

- Air in the system. At first, after the new coolant is poured in, high performance is not expected from it, since all the air should gradually come out. If the problem returns again, perhaps air pockets have accumulated again and you need to bleed it from the radiators (noise inside the pipes will also indicate the problem).

- Don't worry if the pressure is low after installing new aluminum batteries. Chemical reactions with the release of hydrogen will take place, and the system will work “perfectly.”

- Failure of the boiler heat exchanger. This threatens serious repairs that must be carried out by service technicians.

The pressure increases less frequently and basically all the reasons come down to overheating:

- Stoker's mistakes. Water may boil if the amount of fuel exceeds the required temperature (it is not too cold outside).

- Blockage. At any stage, in any filter and connection, a blockage can form that does not allow the flow to circulate normally. As a result, the pressure will be excessive before the blockage, and then there will be a sharp drop.

- Narrowing of the lumens. Over time, scale deposits narrow the clearance in the pipes so much that circulation no longer proceeds at all as expected. The solution is to use soft water for pipes and clean the pipes in the summer.

What should be the GOST and SNiP standards for apartment buildings?

The documents stipulate the ranges that provide heating for the building. The indicators are calculated to maintain a temperature of about 20 °C with a humidity of about 40%.

To achieve them, a project is being developed at the pre-construction stage. There are three operating pressure values:

- 2-4 atm for houses up to 5 floors;

- 5-7 for 6-9;

- 12 and above for 10-story and large buildings.

Factors determining indications

Modern houses are equipped with elevators that divide the network into parts. Their goal is to mix streams of water of different temperatures. They are equipped with regulators that control the nozzles. This affects the determination of pressure: a partially closed unit changes the indicator.

The following factors also hinder the achievement of the values specified in GOST:

- The power of devices installed in a building rarely matches the calculations carried out before starting work.

- Equipment condition. It wears out during use.

- Pipeline diameter. Sometimes, during repairs, a section of the piping is replaced by choosing a different size, which leads to a drop in pressure.

- Location of the apartment: the further away from the main line and the boiler, the greater the chance of a decrease in readings.

Checking the norm in multi-storey buildings

This is carried out using pressure gauges at three points:

- on the supply, near the boiler, as well as on the return at a similar point;

- near all used equipment: pumps, filters, regulators, etc.;

- on the highway near the boiler room and at the branch to the house.

Requirements for indicators are determined by GOST and SNiP.

Natural circulation scheme

To understand the principle of operation of the gravity system, study the typical diagram used in two-story private houses. Combined wiring is implemented here: the supply and return of coolant occurs through two horizontal lines, connected by single-pipe vertical risers with radiators.

How gravity heating of a two-story house works:

- The specific gravity of the water heated by the boiler becomes smaller. The colder and heavier coolant begins to displace hot water upward and take its place in the heat exchanger.

- The heated coolant moves along a vertical collector and is distributed along horizontal lines laid with a slope towards the radiators. The current speed is low - about 0.1-0.2 m/s.

- Dividing through the risers, the water enters the radiators, where it successfully releases heat and cools. Under the influence of gravity, it returns to the boiler through a return manifold, which collects coolant from the remaining risers.

- The increase in water volume is compensated by an expansion tank installed at the highest point. Typically, the insulated container is located in the attic of the building.

Schematic diagram of gravity distribution with a circulation pump

In modern designs, gravity systems are equipped with pumps that accelerate circulation and heating of rooms. The pumping unit is placed on a bypass parallel to the supply line and operates when electricity is available. When the light is turned off, the pump is inactive, and the coolant circulates due to gravity.

Scope of application and disadvantages of gravity feeding

The purpose of the gravity circuit is to supply heat to homes without connection to electricity, which is important in remote regions with frequent power outages. The network of gravity pipelines and batteries can work together with any energy-independent boiler or stove (previously they said steam) heating.

Let's look at the negative aspects of using gravity:

- due to the low flow rate, it is necessary to increase the coolant flow by using large-diameter pipes, otherwise the radiators will not warm up;

- in order to “spur” natural circulation, horizontal sections are laid with a slope of 2-3 mm per 1 m of the highway;

- healthy pipes running under the ceiling of the second floor and above the floor of the first floor spoil the appearance of the rooms, which is noticeable in the photo;

- automatic control of air temperature is difficult - for batteries you need to buy only full-bore thermostatic valves that do not interfere with the convective circulation of the coolant;

- the scheme is unable to work with heated floors in a 3-story building;

- An increased volume of water in the heating network implies prolonged heating and high fuel consumption.

To fulfill requirement No. 1 (see the first section) in conditions of unreliable power supply, the owner of a two-story private house will have to bear the costs of materials - pipes of increased diameter and cladding for the manufacture of decorative boxes. The remaining disadvantages are not critical - slow heating is eliminated by installing a circulation pump, lack of efficiency - by installing special thermal heads on radiators and insulating pipes.

Design Tips

If you have taken the development of a gravity heating scheme into your own hands, be sure to consider the following recommendations:

- The minimum diameter of the vertical section coming from the boiler is 50 mm (meaning the internal size of the nominal diameter of the pipe).

- The horizontal distributing and collecting manifold can be reduced to 40 mm, before the last batteries - to 32 mm.

- A slope of 2-3 mm per 1 linear line of the pipeline is made towards the radiators on the supply and the boiler on the return.

- The inlet pipe of the heat generator should be located below the radiators on the first floor, taking into account the slope of the return line. It may be necessary to make a small pit in the boiler room to install a heat source.

- On the connections to heating devices on the second floor, it is better to install a direct bypass of small diameter (15 mm).

- Try to place the upper distribution manifold in the attic so as not to run under the ceilings of the rooms.

- Use an open-type expansion tank with an overflow pipe leading outside and not into the sewer. This makes it easier to monitor when the container is overfilled. The system will not work with a membrane tank.

The calculation and design of gravity heating in a cottage with a complex layout should be entrusted to specialists. And lastly: lines Ø50 mm or more will have to be made of steel pipes, copper or cross-linked polyethylene. The maximum size of metal-plastic is 40 mm, and the diameter of polypropylene will be simply menacing due to the thickness of the walls.