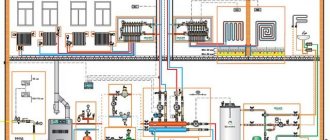

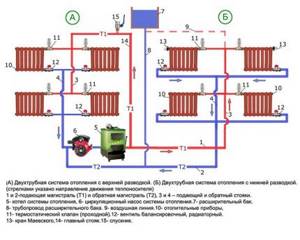

Standard wiring of heating elements in a 2-story house

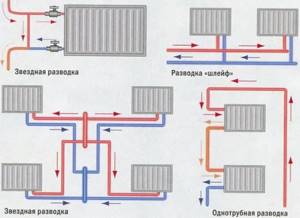

Sample wiring of heating elements

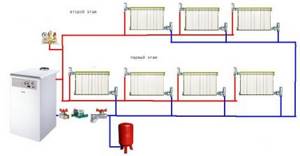

Let's consider a water heating scheme for a standard building with two floors. It provides manual temperature control in each individual room of the house. The system is installed in a standard way: using horizontal placement of two pipes, in which heating radiators are connected to the sides.

It is better to use metal-plastic pipes for the heating system due to their strength and durability. But you can also use polypropylene pipes, which will also be a very effective solution. Metal-plastic pipes do not require special installation skills, and there are almost no blockages or dirt sticking inside them. You can assemble polypropylene pipes yourself; they are light and reliable.

At the system design stage, the required number of corner, adjustable and connecting nodes of the system is calculated, the number and installation locations of taps and plugs are marked. An analysis is carried out of the required number of heating radiators and the number of sections in each of them; the amount of heat given off by the radiator will depend on this in the future. For each heating radiator, mounting brackets are installed, in an amount determined by the dimensions of the radiator.

The diagram contains a designation where in the system it is necessary to install a heating boiler, an expansion tank, and a pump. A heating boiler can operate on various types of fuel, but the most popular are gas, solid fuel or electricity. In new houses and cottages, solid fuel is almost never used due to its low environmental friendliness.

If the heating boiler is small, then you can install it directly in one of the rooms of the house, a storage room, for example, or in the owner’s workshop. In this case, the boiler is hung on the wall so as not to waste space. It is not recommended to install the boiler in bedrooms or rooms such as a library or office. This is due to the fact that the boiler can emit noise during operation, although not loud. Large boilers must be placed in a separate room or even in a separate building.

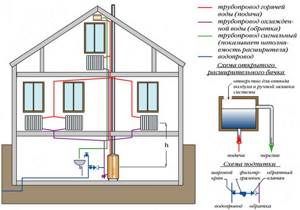

An example of placing a tank in a house

Tank placement: bottom or top.

If your house has a basement and an attic, then you can make a heating system with bottom pipes or bottom pipes at your discretion.

- If the wiring is from the top, then the boiler is placed in the attic and from there hot water is supplied through the riser to all heating radiators.

- If you choose bottom wiring, then the tank is installed in the basement and from there, using a pump, the heated water is distributed through the pipes.

Whatever option you choose, the expansion tank is always installed in the highest place of the house, that is, in the attic. A riser connects it to the heating boiler with bottom wiring.

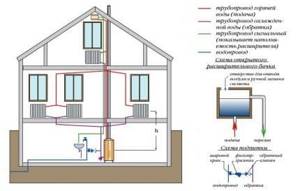

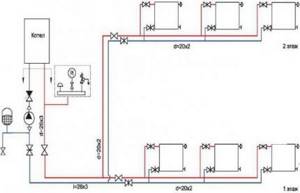

Heating system with one or two pipes

A heating system with one pipe is a ring. Water from the boiler first goes to one floor, then returns back to the tank through another. As a result, the temperature is higher on one floor and lower on the other. To compensate for this phenomenon, larger radiators are installed on the lower floors (where the water is usually not so hot) than on the upper floors. In addition, in a single-pipe system, there is no way to turn off one specific heater. It is necessary to turn off the entire system.

Heating system sample

A system with two pipes is more difficult to install, but it has almost no disadvantages. This system has two pipes: hot and cold. Entering the radiator, hot water cools and pours into the cold pipe. In this case, you can shut off one of the radiators, this will not affect the operation of the others.

Video - heating a house using a boiler

Video - house heating diagram

Video - how to make a warm floor in a house

- Two-pipe heating system for a private house

- Heating scheme for a one-story house - various options

- Single-pipe heating system for a private house

- Heating system of a private house

Heating with heated floors

The main feature of underfloor heating is the installation of one large but low-power “radiator” in the underground space, instead of using a system of standard wall-mounted radiators. This ensures more uniform heat distribution, increases indoor comfort and, with proper implementation of the system, reduces energy costs. However, heated floors are not without their drawbacks. These include:

- long time to warm up a completely cooled room;

- the possibility of condensation due to almost complete isolation from external factors;

- complexity of calculation and installation of the system.

Recent studies have noted that, all other factors being equal, a room with a heated floor can be heated to a temperature 2ºC lower than a room with classical heating, and this will not affect human comfort in any way. This fact alone allows you to save up to 10-15% energy.

Today, quite often, heated floors are used for heating a two-story house. The system can act as the main one, but for this it is important to make all the thermal calculations.

Type of bottling

The natural circulation of water in the heating system depends on the principle of supplying coolant from the boiler to the heating devices. There are different contours with bottom and top filling.

Bottom filling makes it possible to avoid the installation of high vertical pipes - communications are laid at floor level. This option is suitable only for single-pipe circuits and is considered ineffective without installing a circulation pump.

Top filling is the best option, since the distribution pipe of a two-pipe system is located under the ceiling and provides an active supply of heated coolant to each radiator, from which cooled water flows into the return pipe located along the floor. For a single-pipe system, top-type filling is also preferable.

Two-pipe heating system with top filling

Single-pipe heating: advantages and disadvantages

Even in a horizontal circuit, pipes can be laid hidden if you use a single-pipe radiator connection scheme. This is the simplest and cheapest option, in which the heating devices form a sequence.

At the same time, only one pipe is used to connect them, moreover, it can be laid at any level (compare with the two-pipe heating diagram of a two-story house, where the supply pipe must be higher than the radiators).

One-pipe and two-pipe wiring

Taking advantage of this opportunity, homeowners often hide heating pipes in the floor structure, as a result of which the interior of the room retains its “pristine” appearance. And if you also install stylish tubular radiators, the design of the room will delight your guests.

However, the single-pipe heating system for a two-story house also has significant disadvantages:

- The coolant arrives at the last batteries of the circuit quite cool. Since gases dissolve in it better when water is cooled, self-airing often occurs in such a system. As a result, air drainage has to be installed on each radiator.

- There is no possibility of independently adjusting the heat transfer power on each device.

- If one of the radiators is repaired, the entire system has to be turned off and drained.

The disadvantages described in points "b" and "c" can be eliminated by connecting the input and output of each battery with a bypass jumper to the control valve.

Methods for supplying coolant to the heating system

When choosing the most suitable heating system option, the homeowner will have to make a decision on the main issue: how to get the coolant to move along the heating circuit. This problem is solved in one of two ways:

- naturally;

- forcibly.

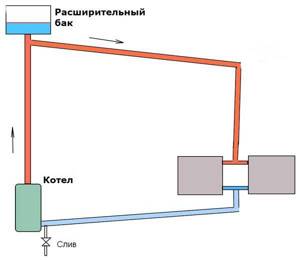

Heating scheme for a private house with natural circulation

As is known, a heated gas or liquid, due to its lower density, is pushed upward by a colder medium. This phenomenon is called convection. If the heating system is properly designed, it can play the role of an engine that will force the coolant to circulate through a closed loop of pipes and radiators.

The most important element of such a scheme is the accelerating manifold - a vertical section of the pipeline running immediately after the boiler. The powerful upward flow that forms here pushes the coolant well through the circuit. In such a system, an open-type expansion tank is used, which is a regular container connected to the top point of the heating circuit.

Heating a two-story house with natural circulation

The presence of a second floor makes it possible to make the accelerating manifold long enough, which, with good insulation of this area, ensures quite decent coolant circulation. However, despite this, even in two-story houses, a scheme with natural movement of the working environment is becoming less and less common. The reason lies in its characteristic disadvantages:

- large diameter pipes are required;

- on horizontal sections of the pipeline it is necessary to maintain a significant slope - 5 - 7 cm per 1 m of length;

- after bypassing the circuit, the coolant temperature drops by more than 25 degrees (a prerequisite for good natural circulation), so the boiler must be operated in high-performance mode, which shortens its service life;

- the maximum length of the pipeline is limited to 30 meters.

Forced method

In two-story houses, a forced circulation scheme is used much more often, if only because the length of the heating circuit in such buildings is, as a rule, more than 30 meters. Here the working medium is pumped by a special pump, which is called a circulation pump. It is installed at the entrance to the boiler, where the coolant is coldest. Since the heating system is closed, the pressure developed by such a pump does not depend on the number of storeys of the building and is determined only by the circuit resistance (hydraulic).

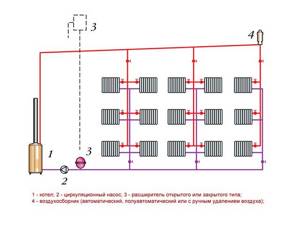

Forced circulation heating circuit

With this scheme, the speed of movement of the coolant increases, so it does not have time to cool down much. This results in a more uniform distribution of heat throughout the entire circuit, as well as the ability to operate the boiler in a gentle mode. In addition, a system with forced circulation is more practical: in spring and autumn, when it is not very cold outside, it can be operated in a low-temperature mode, which could not be achieved with natural circulation of the environment. Horizontal sections of the pipeline are installed with a slope of 0.5 - 1 cm per 1 m.

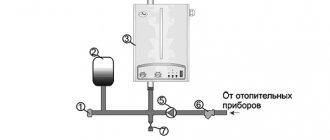

Due to the high pressure developed by the pump, the design of the expansion tank has to be complicated. Here it is closed and consists of two cavities separated by a flexible membrane. One cavity receives an expanding coolant, the other contains compressed air, the pressure of which equalizes the pressure in the system. The closed tank does not have to be located at the highest point of the circuit; it is usually mounted next to the boiler.

Prudent designers leave the accelerating manifold even in systems with forced circulation. In this case, if the power supply is turned off and the pump is subsequently stopped, the system will continue to operate in convection mode.

The best schemes for a two-story house

In each specific case, it is necessary to develop an individual heating project that will ensure efficient and economical operation.

To make the right choice, you should consider the following factors:

- climate and quality of building insulation;

- number and purpose of premises. Is constant and uniform heating required everywhere?

- the stability of the electricity supply and the presence of a generator largely determine the type of circulation;

- individual wishes of the residents - warm floors or walls in individual rooms or throughout the house, etc.;

- layout of the premises - is perimeter wiring feasible;

- design requirements and renovation stage. In many cases, all pipes, and sometimes even heating devices, can be hidden in the floor and walls;

- budget - the estimate for installing heating in one building can differ several times or tens of times.

By answering all these questions and knowing the features of different schemes, you will get an idea of the required option.

Do not chase overly complex schemes: sometimes primitive ones are more reliable and no less effective, and there is no need for fine tuning

Next, we suggest choosing one of the proven effective schemes for connecting heating devices to the boiler and adjusting it in accordance with your layout.

Single-pipe Leningradka - reliable and cheap

This one-pipe scheme is one of the cheapest, simplest and oldest, but relevant and popular to this day. Using only radiators allows for a mixed type of circulation in case of a power outage. To do this, the gas boiler must be non-volatile, all pipes must have a slope of 5 - 10 mm per 1 linear meter.

To make settings easier, you can install thermostats on the supply of each battery and control valves on the battery bypasses. An additional valve on the riser will make it possible to turn off the heating circuit of a separate floor.

Warm floors can be included in the system as a separate, third circuit, or replace radiators on one floor. However, in this case, the division of flows must pass through a thermal mixer or hydraulic arrow so that the floor does not heat up to 70 - 80 ° C in cold weather, like radiators.

Also keep in mind that during a power outage, only the batteries will work, and in a strictly horizontal floor heating circuit the coolant will be idle.

For the effective operation of the Leningradka system, it is necessary to use pipes of different diameters: the supply from the boiler to the division into separate floor contours is the thickest, the floor mains are medium, and the radiator connections are of the smallest diameter

The main limitation when installing such a system concerns the heated area: a house larger than 100 m2 does not warm up with natural coolant circulation. Such a system will only save you from defrosting pipes and rupture of the boiler heat exchanger during a long shutdown, but not from the cold.

In addition, even with forced circulation, such a heating circuit is almost impossible to set up if it includes more than 5 - 7 batteries. That is, for ease of use in a large house, it is necessary to divide the circuit into a larger number of circuits.

You can read more about the arrangement of a single-pipe heating system in Leningradka in this material.

Tichelman loop with forced circulation

As we have already mentioned, this connection scheme ensures the most efficient operation and convenient adjustment of each radiator at a relatively low cost of materials.

The system can cover the entire house with one loop, be divided into 2 circuits by floor, as in the diagram, or be used only for one floor or part of it.

The system is easy to set up and maintain; if necessary, some of the batteries can be disconnected or even removed without stopping the boiler

Modern radiator heating systems are often equipped according to this plan, if it is possible to disguise the pipeline. In addition, devices of different types can be included in one circuit: radiators, convectors, heat curtains.

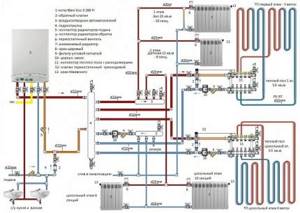

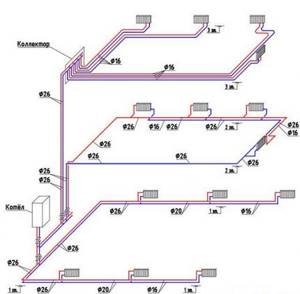

Manifold connection and mixed systems

Using a collector to separate not only heating circuits, but also to individually connect each device is the most modern and easy-to-use solution.

It has a number of advantages:

- beautiful - all pipes are hidden in the floor and walls;

- convenient – adjustment of any device in the manifold cabinet;

- efficient - all devices are supplied with the same hot coolant, but each of them heats exactly as much as you need;

- universal - devices of different types can be connected to one collector, regardless of the layout.

The main disadvantage of this solution is the high cost of both materials and installation. You will need much more pipes than for any other connection scheme, and laying communications in the floor, especially if the concrete screed has already been poured, will cost a lot.

It is also worth considering that such a connection completely eliminates the possibility of natural circulation.

For ease of connection and maintenance, pipes of different colors are sometimes used, red and blue for supply and return

In two-story houses, as a rule, one collector is installed in the center of each floor, but with a large number of heating devices and collectors there may be more. For underfloor heating systems, separate collectors are used, with a lower coolant temperature.

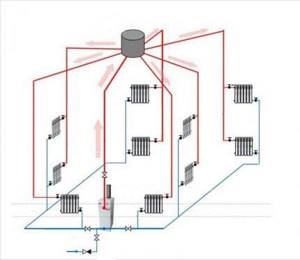

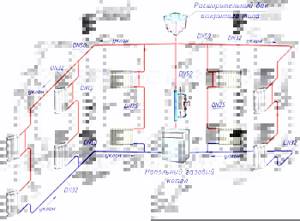

Vertical gravity scheme

In addition to the standard options described, there are also more exotic ones, such as a vertical two-pipe with natural circulation. Perhaps this is the best solution for a two-story house in which the lights are often turned off.

Due to the fact that water circulates more easily in a vertical system than in a horizontal one, and the large expansion tank under the roof acts as a collector, the most efficient and uniform heating is ensured, even without the use of a pump.

When arranging such a system, it is very important to use pipes of different diameters, depending on how many radiators they serve.

The hot water supply pipe to the expansion tank and the return line should be the thickest; The supply risers supplying the 2nd floor are slightly thinner, their lower part on the 1st floor is of even smaller diameter, and the radiator connection pipes have the smallest cross-section.

Types of forced circulation of coolant in heating

The use of forced circulation heating schemes in two-story houses is used due to the length of the system lines (more than 30 m). This method is carried out using a circulation pump that pumps the liquid from the circuit. It is mounted at the inlet of the heating device, where the coolant temperature is lowest.

In a closed circuit, the degree of pressure that the pump develops does not depend on the number of floors and area of the building. The speed of the water flow becomes greater, so when passing through the pipeline lines the coolant does not cool down much. This contributes to a more uniform distribution of heat throughout the system and the use of the heat generator in a gentle mode.

The expansion tank can be located not only at the highest point of the system, but also near the boiler. To perfect the circuit, the designers introduced an accelerating collector into it. Now, if the power goes out and the pump stops, the system will continue to operate in convection mode.

- with one pipe;

- two;

- collector

You can install each one yourself or invite specialists.

One-pipe circuit option

Shut-off valves are also installed at the entrance to the battery, which serves to regulate the temperature in the room, as well as necessary when replacing equipment. A valve is installed on top of the radiator to bleed air.

Valve for batteries

To increase the uniformity of heat distribution, radiators are installed along the bypass line. If you do not use this scheme, then you will need to select batteries of different capacities, taking into account the loss of coolant, that is, the further from the boiler, the more sections.

The use of shut-off valves is not necessary, but without them the maneuverability of the entire heating system is reduced. If necessary, you will not be able to disconnect the second or first floor from the network to save fuel.

To avoid uneven distribution of the coolant, circuits with two pipes are used.

- dead end;

- passing;

- collector

Options for dead-end and passing circuits

The associated option makes it easy to control the heat level, but it is necessary to increase the length of the pipeline.

The most effective is the collector circuit, which allows a separate pipe to be connected to each radiator. Heat flows evenly. There is one disadvantage - the high cost of the equipment, as the amount of consumables increases.

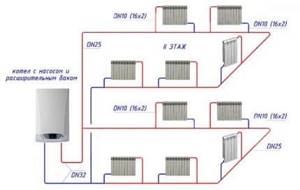

Scheme of collector horizontal heating

There are also vertical options for supplying the coolant, which are found with lower and upper wiring. In the first case, the drain with the supply of coolant passes through the floors, in the second, the riser goes up from the boiler to the attic, where pipes are routed to the heating elements.

Vertical scheme

Two-story houses can have a very different area, ranging from several tens to hundreds of square meters. They also differ in the location of the rooms, the presence of extensions and heated verandas, and their position to the cardinal points. Based on these and many other factors, you should decide on natural or forced coolant circulation.

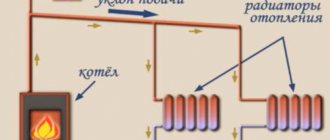

A simple diagram of coolant circulation in a private house with a heating system with natural circulation.

Heating schemes with natural coolant circulation are distinguished by their simplicity. Here, the coolant moves through the pipes on its own, without the help of a circulation pump - under the influence of heat it rises, enters the pipes, is distributed among the radiators, cools down and enters the return pipe to return to the boiler. That is, the coolant moves by gravity, obeying the laws of physics.

Scheme of a closed two-pipe heating system for a two-story house with forced circulation

- More uniform heating of the entire household;

- Significantly large length of horizontal sections (depending on the power of the pump used, it can reach several hundred meters);

- Possibility of more efficient connection of radiators (for example, in a diagonal pattern);

- Possibility of installing additional fittings and bends without the risk of pressure dropping below the minimum limit.

Thus, in modern two-story houses it is best to use heating systems with forced circulation. It is also possible to install a bypass, which will help you choose between forced or natural circulation in order to select the most optimal option. We make a choice towards coercive systems as more effective.

https://www.youtube.com/watch?v=olrD9qxCAhM

Forced circulation has a couple of disadvantages - the need to purchase a circulation pump and the increased noise level associated with its operation.

The practical magic of the Tichelman scheme

It is generally accepted that in a two-pipe heating system, the heat distribution between radiators due to the parallel connection is absolutely even.

This is not entirely true. First of all, let's understand that the hydraulic resistance of a pipeline is proportional to its length.

In a conventional two-pipe system, the path through the first radiator is the shortest for the coolant, and through the last - the longest.

Accordingly, in the first case, the medium has to overcome the minimum hydraulic resistance, and in the second - the maximum. It is clear that the liquid flows, figuratively speaking, more readily through the radiators closest to the boiler than through those further away.

To balance the system, it is proposed to start the “return” from the outlet pipe of the first radiator, then route it to the last, simultaneously connecting other radiators. And only after the connection from the last radiator is the return line directed to the boiler. This is Tichelman's scheme.

Thus, moving through any radiator, the coolant will travel a path of the same length with equal hydraulic resistance. In this case, the volumes of medium flowing through each device, as well as heat transfer, will become equal.

Heating a two-story house can be realized by using different systems: single-pipe, two-pipe, horizontal or vertical. A do-it-yourself heating diagram for a 2-story private house will help you do all the installation work correctly.

What kind of heating system is called Leningradka, you will find out here.

And in this topic https://microklimat.pro/sistemy-otopleniya/montazh-sistem-otopleniya/chastnyx-domov-svoimi-rukami.html we will consider do-it-yourself heating systems for private houses: water, steam, collector and other options. Overview of each heating type.

Two-pipe heating system for a 2-story house

Truly comfortable living conditions can only be achieved by installing a two-pipe heating system. Its design allows you to regulate the temperature in individual rooms and save energy resources.

How does a two-way circuit work?

Unlike a single-pipe circuit, a two-pipe circuit consists of a pair of lines with different purposes: one of them supplies coolant, the second returns it back. The radiators are connected not in series order, but in parallel. One circuit, with heated coolant, extends from the riser to the radiators of both floors, the second is mounted to the boiler outlet and is also distributed to both floors.

Radiators are equipped with thermostatic valves that allow you to set a comfortable temperature. If desired, you can reduce the heating intensity partially or completely block the flow of water into the device.

Some devices are fundamentally embedded in the return line, for example, a membrane tank that regulates pressure, a circulation pump and a safety valve are traditionally installed in front of the boiler

In modern 2-story houses, two-pipe structures are used, since they are much more efficient than single-pipe ones:

- reduce pressure loss;

- do not require a powerful pump;

- keep the coolant temperature the same for each radiator;

- allow you to use many different thermal devices within one system (for example, radiators, convectors and “warm floors”);

- make it possible to repair and replace parts without compromising overall functionality.

The main disadvantage is the difficulty of self-installation - during assembly, consultation and supervision of professionals is required.

Successful solutions for installing a two-pipe system

There are many incarnations of various schemes, but when drawing up a project you should start from individual requirements.

The simplest diagram for arranging a heating system in a 2-story house. It is characterized by the following points: 2 circuits for heating and hot water production, liquid coolant, forced circulation (+)

A number of universal schemes are suitable for providing heat to houses of various sizes and number of floors.

Detailed diagram of two-pipe wiring for a one-story house with a fully equipped basement. The problem of thermal insulation of the floor in the basement was solved by connecting a water-based “warm floor” system

If you install additional equipment, such as a membrane tank, the capabilities of the heating system will expand.

A and B – two variants of the wiring device, upper and lower type. Additional equipment: expansion tank, Mayevsky taps, overhead line (+)

The following diagram combines the three most popular wiring diagrams.

Level 1 – dead-end wiring with parallel installation of both circuits; Level 2 – counter wiring, characterized by two-way radiator connection; 3 – collector wiring with improved balancing

All of the above schemes are suitable for heating a 2-story building.

Pipes used for water heating

If you use steel pipes, you need to take into account its disadvantage - low corrosion resistance. Their stainless steel and galvanized pipes do not have this drawback. When installing, it is best to use threaded connections. At this time, metal pipes are used quite rarely when constructing a heating wiring diagram for a two-story house.

As one of the most reliable options for heating a 2-story house, the scheme uses copper pipes; they can withstand the highest temperatures, as well as high pressure.

Copper pipes are connected using high-temperature soldering with “silver-containing” solder. If desired, they can be hidden in the walls of the house, which is very convenient and aesthetically pleasing. The disadvantage of such pipes is their high price, but this is the only disadvantage; such pipes are very reliable and recommended, since if they are installed correctly, they will last for several generations of home owners, and there will be no need to replace or repair them. Such pipes are very reliable and high quality.

Heating from copper pipes

Polymer pipes have advantages: they are easy to install, which can be done even by a person without special education, which can save money; no sediment is deposited on the inner surface, which means they will not clog quickly; quite resistant to corrosion. Such pipes are installed using threaded or press connections; welding is not used. Disadvantage: the coefficient of thermal expansion is quite high, which can lead to leakage.

Heating system of a two-story house. We are looking for the best option

Polymer heating pipes and fittings

When heating projects for a private two-story house are drawn up, it is necessary to think about which pipes are most suitable for a given building, taking into account emergency and alternative heating. Of course, a lot depends on the material factor, but it’s still better not to skimp on heating, because it determines how you will live in the winter: whether you will freeze, or enjoy life in warmth and comfort.

Experts advise choosing a copper pipeline; it will serve its owners faithfully for several generations. It may cost more, but it is reliable.

Dual-circuit battery wiring

A two-pipe heating system differs from a single-pipe heating system by dividing it into two pipes - supply and return of coolant. It ensures uniform heating of all rooms. This type of wiring is used in most new houses.

Principle of operation

In a two-pipe scheme, water from the boiler flows to the radiators through the supply pipe (main).

Near each radiator, the supply line has a connecting inlet pipe through which the coolant enters the battery. The supply line ends near the last radiator.

In addition to the inlet pipe, each radiator has an outlet pipe. He connects it to the return pipe. The return line starts from the first battery and ends at the entrance to the boiler.

Thus, heated water enters the radiators evenly and at the same temperature. From each radiator, water is discharged into the return pipe, where it is collected and supplied to the boiler for subsequent heating. Thanks to this movement of the coolant, all rooms in the room are heated equally.

What is the difference

A two-pipe heating system includes elements of a single-pipe system and additional devices. In addition to the boiler, radiators, supply and return water collection pipes (the so-called return), the two-pipe circuit also includes a circulation pump.

The large length of the lines, the presence of corners and turns in the supply pipes complicate the movement of the coolant. Therefore, its forced circulation by an electric pump is necessary.

Photo 1. Circulation pump model 32-40, voltage 220 Volts, China.

Also, in a two-pipe scheme there are more taps that regulate the water supply and its quantity. Such a tap is installed in front of each radiator - at the inlet and outlet.

Classification by location

In a horizontal two-pipe system, pipes connect the radiators horizontally. This scheme works for heating a one-story house or one floor of a multi-story cottage.

In a vertical two-pipe system, pipes connect radiators located one above the other in one “riser”. However, there are differences from the single-pipe vertical scheme. Here, thanks to the presence of a supply and return pipe, vertical heating can use batteries of any width - multi-section ones (since the supply and return risers can be removed from each other). Therefore, the efficiency of two-pipe vertical heating is higher.

Reference! It is desirable that batteries of rooms located one above the other have the same number of sections. This makes it easier to lay a vertical return pipe.

Bottom and top harness: which is more effective?

The term “lower” and “upper” piping refers to the method of connecting batteries to the heating system. With the lower piping, the incoming water enters the battery through the lower pipe.

If it also comes out of the radiator at the bottom, then the efficiency of the radiator will be reduced by 20-22%.

If the outlet pipe is located at the top, the efficiency of the radiator will be reduced by 10-15%. In any case, with lower water supply to the batteries, the heating efficiency decreases.

With the top piping (supply), the incoming pipe is connected to the radiator in the upper part. In this case, the movement of the coolant is organized more efficiently, the battery will work at 97-100% (97% - if the inlet and outlet pipes are located on one side of the radiator, and 100% - if the inlet pipe is on one side from above, and the outlet pipe is on the other side from below ).

Advantages and disadvantages

Advantages:

- Suitable for organizing heating of large private houses, in which case a circulation pump must be installed into the system.

- Heats all rooms on the floor or in the riser evenly.

Flaws:

- It is more expensive than a single-pipe system, since it requires twice as many materials - pipes between the boiler and radiators, as well as connecting devices, taps, and valves.

- The electric circulation pump makes the operation of the system dependent on the availability of electricity.

Important! An increase in the number of pipes and the amount of coolant in the system leads to an increase in hydrodynamic resistance and does not allow water to move by gravity. Forced circulation and a running circulation pump are required

Natural circulation scheme

To understand the principle of operation of the gravity system, study the typical diagram used in two-story private houses. Combined wiring is implemented here: the supply and return of coolant occurs through two horizontal lines, connected by single-pipe vertical risers with radiators.

Reference. There are other ways to organize gravity flow on two floors, for example, by dividing the risers directly from the expansion tank with pipes of a smaller diameter. The circuit is material-intensive, looks like a spider, and installation will cause a lot of trouble.

How gravity heating of a two-story house works:

- The specific gravity of the water heated by the boiler becomes smaller. The colder and heavier coolant begins to displace hot water upward and take its place in the heat exchanger.

- The heated coolant moves along a vertical collector and is distributed along horizontal lines laid with a slope towards the radiators. The current speed is low - about 0.1-0.2 m/s.

- Dividing through the risers, the water enters the radiators, where it successfully releases heat and cools. Under the influence of gravity, it returns to the boiler through a return manifold, which collects coolant from the remaining risers.

- The increase in water volume is compensated by an expansion tank installed at the highest point. Typically, the insulated container is located in the attic of the building.

In modern designs, gravity systems are equipped with pumps that accelerate circulation and heating of rooms. The pumping unit is placed on a bypass parallel to the supply line and operates when electricity is available. When the light is turned off, the pump is inactive, and the coolant circulates due to gravity.

Scope of application and disadvantages of gravity feeding

The purpose of the gravity circuit is to supply heat to homes without connection to electricity, which is important in remote regions with frequent power outages. The network of gravity pipelines and batteries can work together with any energy-independent boiler or stove (previously they said steam) heating.

Let's look at the negative aspects of using gravity:

- due to the low flow rate, it is necessary to increase the coolant flow by using large-diameter pipes, otherwise the radiators will not warm up;

- in order to “spur” natural circulation, horizontal sections are laid with a slope of 2-3 mm per 1 m of the highway;

- healthy pipes running under the ceiling of the second floor and above the floor of the first floor spoil the appearance of the rooms, which is noticeable in the photo;

Due to the too large distance from the ceilings, it is very difficult to hide the pipe behind the cladding - automatic control of air temperature is difficult - for batteries you need to buy only full-bore thermostatic valves that do not interfere with the convective circulation of the coolant;

- the scheme is unable to work with heated floors in a 3-story building;

- An increased volume of water in the heating network implies prolonged heating and high fuel consumption.

Comment. The last negative point does not play a special role - the energy spent on heat production will not go anywhere. It will return as the pipelines cool.

To fulfill requirement No. 1 (see the first section) in conditions of unreliable power supply, the owner of a two-story private house will have to bear the costs of materials - pipes of increased diameter and cladding for the manufacture of decorative boxes. The remaining disadvantages are not critical - slow heating is eliminated by installing a circulation pump, lack of efficiency - by installing special thermal heads on radiators and insulating pipes.

Watch this video on YouTube

Design Tips

If you have taken the development of a gravity heating scheme into your own hands, be sure to consider the following recommendations:

- The minimum diameter of the vertical section coming from the boiler is 50 mm (meaning the internal size of the nominal diameter of the pipe).

- The horizontal distributing and collecting manifold can be reduced to 40 mm, before the last batteries - to 32 mm.

- A slope of 2-3 mm per 1 linear line of the pipeline is made towards the radiators on the supply and the boiler on the return.

Even large pipes can be laid hidden (pictured on the right). On the left is a typical installation with open communications - The inlet pipe of the heat generator should be located below the radiators on the first floor, taking into account the slope of the return line. It may be necessary to make a small pit in the boiler room to install a heat source.

- On the connections to heating devices on the second floor, it is better to install a direct bypass of small diameter (15 mm).

- Try to place the upper distribution manifold in the attic so as not to run under the ceilings of the rooms.

- Use an open-type expansion tank with an overflow pipe leading outside and not into the sewer. This makes it easier to monitor when the container is overfilled. The system will not work with a membrane tank.

Important point. Don’t forget to carefully insulate all elements of the gravity circuit located in the attic of a two-story house so as not to heat up the cold roof.

The calculation and design of gravity heating in a cottage with a complex layout should be entrusted to specialists. And lastly: lines Ø50 mm or more will have to be made of steel pipes, copper or cross-linked polyethylene. The maximum size of metal-plastic is 40 mm, and the diameter of polypropylene will be simply menacing due to the thickness of the walls.

Expansion tanks, open and closed systems

Single-pipe open type heating system with forced circulation. The expansion tank should be at the highest point.

When creating heating in a two-story private house with your own hands, you need to think about the location of the expansion tank. If you plan to create an open system, then the tank is installed at the highest point of the heating system. Most often it stands on the tops of vertical sections - this ensures effective removal of air bubbles. Sometimes it is also installed on the return pipe, but this scheme does not ensure air removal and forces the installation of additional pipes.

In closed heating systems the following are used:

- Sealed expansion tanks;

- Air vents;

- Safety valves;

- Thermomanometers.

Sealed tanks are hollow metal structures with a flexible internal partition. This partition bends and takes on part of the coolant that expanded when heated. The heating system remains completely sealed. Air is removed through a special air vent, and if excess pressure is detected, it will be relieved via a safety valve.

Open heating systems do not require the installation of air vents and safety valves, but they do require the installation of a tank at the very top. As for closed systems, here the tank is placed near the heating boiler, along with a “safety group”. As a result, the cost of creating heating in a two-story private house increases, but residents have the opportunity to create heating with a non-freezing coolant.

In open heating systems, the use of coolants other than water is quite problematic. Therefore, we opt for closed systems, the installation of which will not cause huge additional costs.

Possible complications during installation

As long as the diameter of the heating pipes is the same and the radiators are located at the same height, problems usually do not arise during installation and after it.

Problems may arise if the installation order is not followed:

- Poor soldering of polypropylene pipes will lead to a narrowing of the pipe diameter.

- Installing radiators made of different materials and different capacities will disrupt the balance of the system.

- Lack of balancing valves to equalize hydraulic pressure.

- Location of a highway branch with a height difference.

- Incorrect pump selection. The pressure must be at least 0.2 kgf/cm2.

- The use of pipes of different diameters can lead to imbalance of the system and difficulty in passing the coolant.

An associated double-circuit heating system is recommended for heating in one-story houses. Does not require complex calculations, balancing or special installation methods. The cost of such a system is more expensive than a traditional one, but this is compensated by durability and ease of operation. In addition, the home owner can install such a system independently, without using complex engineering solutions, tools and materials.

Heating of cottages - types of systems and equipment requirements

The choice of heating scheme is influenced mainly by the area of the heated premises, that is, the total length of the pipeline. The main task of any heating system is to uniformly heat the premises along the entire length of the pipeline. If in small one-story houses it is not difficult to organize such a system, then in cottages with two levels, serious calculations must be made to solve the same problem.

Any heating system consists of the main elements:

- a boiler or furnace that can operate on any type of fuel;

- pipeline;

- radiators;

- hydraulic equipment – pumps, taps, sensors;

- expansion tank.

Heating system elements

Systems with installation of a circulation pump

Any heating scheme for a 2-story private house must ensure constant circulation of coolant throughout the system. At the same time, the efficiency and speed of heating the premises directly depends on the level of hydraulic pressure in the pipes. Obviously, the simplest solution to this problem is a circulation pump.

Pumping schemes are good because with the help of a small and economical pump, the specified pressure is ensured in the system, and hot water will be delivered to any point in the circuit, regardless of its location. The energy consumption of such a device ranges from 25 to 50 W per hour. Even with daily continuous operation, the meter will generate no more than 40 kW per month, which does not significantly affect the consumption of the family budget. This scheme has a serious drawback - it does not work in the event of a power outage. Unfortunately, such situations are not uncommon in Russia, so in winter it is necessary to have at your disposal a source of alternative power so as not to be left without heat at all.

Circulation pump

Systems based on natural circulation

Knowing the basics of thermodynamics, you can develop a heating scheme such that a pump is not needed at all. This scheme is based on the ability of a heated liquid to rise upward. A boiler or furnace located at the ground floor level heats the water; this water rushes upward, starting the process of movement of the coolant through a closed pipeline system.

In systems without circulation pumps, it is impossible to provide high pressure, because its level depends on the temperature of the liquid. For this reason, natural circulation systems have their own characteristics:

- in order to reduce resistance, the diameter of the pipes must be at least 32 mm, the same applies to the tubes of working radiators;

- the maximum height of the water pipe through which hot water rises and enters the heating circuit should be no more than 6 meters, that is, systems with natural circulation can efficiently heat no more than two floors;

- the wiring diagram should be as simple as possible, but if the length of the pipes is large, it makes sense to make two circuits;

- Without the use of a pump, floor heating systems will not work, so its circuit must be connected separately.

Schematic diagram of heating with natural circulation

The procedure for arranging two-pipe heating in a two-story cottage

A heating circuit of this type requires the presence of the following elements:

- heating boiler;

- auto air hub;

- radiators in the required quantity;

- valves – balancing, thermostatic, safety;

- circulation pump;

- expansion tank;

- valves;

- supply and return collectors (with a collector circuit);

- supply and discharge pipes;

- measuring equipment - for example, a thermomanometer.

Installation algorithm:

Choose the most suitable scheme. Order schematic drawings and calculation of the amount of required materials from the design office. Install the heating boiler in a suitable room with good ventilation and fire-resistant coating of surfaces

If the boiler is electric, these precautions are not necessary. Install an expansion tank, connected, if necessary, to the distribution manifold. Equip the system with measuring and control devices. Connect inlet and outlet pipes to all radiators. Connect a circulation pump to the return circuit (the device works better at low temperatures). Visually assess the quality of work and conduct tests.

If the calculations were carried out correctly and the assembly was carried out with due care, the heating system will last a long time, without interruptions in operation.