Features of a two-story oven

Structures of this kind are characterized by large dimensions and large mass. For a stove that will provide heating simultaneously on two residential floors, a strong and reliable support is required. Accordingly, when laying the foundation, the structure and composition of the soil are taken into account.

The furnace is erected in connection with load-bearing internal walls. In areas where interfloor and ceiling sections adjoin highly heated surfaces of the heating system, fire-resistant elements must be provided.

There are two types of two-tier systems: with one and two fireboxes. The first option for a stove for heating two floors is the simplest and most reliable. At the lower level there are large elements: a hob and a stove bench. On the second floor, at the request of the owner, for example, a fireplace can be installed. This type of design increases the heat transfer surface and improves the quality of heating of rooms.

Description of design and materials

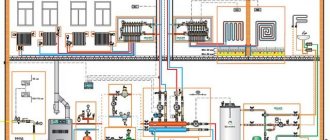

The channel single-turn furnace has one firebox on the ground floor. Dimensions of the building: 89*115 cm. Height – 715 cm. Dimensions of the heating panel on the lower floor are 77*102 cm, on the second floor – 77*95 cm. Heat exchange outlets are provided in the lowering channels of the smoke circulation panels, increasing the heating rate and heat transfer.

For masonry you will need the following materials and stove equipment:

- 1900 pieces of red ceramic bricks,

- 170 pieces of fireclay bricks,

- 2.1 m3 of red stove clay,

- 0.2 m3 refractory clay,

- 2.3 m3 of mountain sand,

- grate (40*40 cm),

- steel sheet (50*70 cm),

- firebox door (35*35 cm),

- blower door (13*12 cm),

- 5 cleaning doors (13.5*12 cm),

- 2 valves (13*26 cm).

Two-story stove with one firebox

The quality of home heating during the cold period depends on the location and design of the heating system. A single-furnace two-tier stove is less durable than a two-furnace stove due to higher thermal and other loads. At the same time, it is easier to construct and maintain: you do not have to bring firewood and coal to the second floor.

This type of structure is installed in the center of the living area and by analogy with stoves for two rooms in a wooden house. This arrangement ensures the most stable and uniform heating of all rooms.

Such heating structures have the following features:

- On the second floor there are separate vertical channels equipped with dampers. This allows you to regulate the temperature on the floors.

- This system ensures delineation of the paths of movement of combustion products and prevents their rapid cooling with the formation of condensation.

- For normal heating of the house, the size of the designed firebox must accommodate a sufficient amount of firewood, which is laid vertically.

With this arrangement of logs, the combustion area significantly increases, which increases heat transfer. Hot gases rise through the ascending channel and, at the height of the second floor ceiling, are divided into two streams into the corresponding chimneys.

How does stove heating work in a two-story house?

Any stove is heavy, so it should be located next to solid internal walls, which will make it possible to balance its operation. If the total estimated weight of the stove is no more than 700 kilograms, then it can be installed directly on the floor, but only if it initially has high strength. If the total weight of the stove is too large, then it becomes necessary to lay a foundation. The foundation must be laid to a depth of at least one meter.

If stove heating in the house is the main one, then a separate stove must be installed on each floor. In general, it would be best to design and calculate the stove masonry before building the house. A stove installed on the second floor should be located directly above the stove, which is located on the floor below. This is done to reduce the load on the floor between floors. In addition, reinforced concrete slabs are often used to provide greater reliability and rigidity.

Construction of a two-story oven with a hob

A modern two-story stove with one firebox, in addition to the main heating function, provides the ability to prepare simple dishes, heat food and heat water for household needs. For these purposes, it is equipped with a hob with a massive cast-iron plate - monolithic or with two round holes. The latter are equipped with a composite lid in the form of a set of overlapping rings of decreasing diameter.

When developing a design for a stove intended for heating a two-story house, the following are taken into account:

- Tying the heating system to the internal main walls allows not only to reduce the load on the structure of the house, but also to balance the operation of the stove.

- Furnaces weighing up to 700 kg do not require a complex foundation.

- The stove, which is designed as the main source of heat in a two-story house, is a single system that runs through the entire building and is linked to the load-bearing elements.

When laying a stove, both one- and two-tier, a refractory clay mortar should be used. This will significantly increase the degree of resistance of the furnace design to high temperatures. Brickwork with the formation of vaults ensures high reliability and durability.

Selection of coolant and method of transporting thermal energy

The most rational solution in two-story houses, in which there are a large number of rooms and there is an overlap between floors, is the implementation of water heating. With a complex building configuration, in the vast majority of cases, there is no alternative to such heating. The system is a looped structure of pipes through which coolant flows, and heat is transferred through radiators or air heaters.

Also, heating using a heated floor can be installed as an additional or sole source of heat. Its operating principle is similar to heating using radiators.

The choice of coolant is extremely important

The use of heated floors powered by electricity throughout the entire house is a theoretically feasible option. However, a number of problems arise in its implementation. Firstly, from an economic point of view, heating organized in this way is not always profitable. Secondly, there is a possibility that it is technically impossible to carry out the task of air heating.

Warm floor

Air can be used as a coolant in multi-level houses. In this case, it is necessary to solve the problem of its transportation. To implement such a project, it becomes necessary to create a system of channels in the space of the building, as well as equip them with fans to force air flow. Only in this way can organized heating ensure the delivery of heat to remote rooms and rooms located on the second floor.

Materials and tools used for constructing a two-story stove

The construction of such a complex structure requires specific knowledge, skills and experience. To build a functional and efficient stove on 2 floors in a private house, you will need the following materials:

- refractory and ordinary solid brick (red);

- fire-resistant fireclay clay;

- quarry sand, sifted and washed;

- cement grade not lower than 500;

- cast iron doors: large - for the firebox, small - for the blower;

- grate bars from 4 to 10 pieces depending on the size of the firebox;

- cast iron plate, solid or with holes;

- views and dampers to block flows in chimneys.

- equal-flanged metal corner with a side of 50-60 mm;

- tin cap for installation above the chimney pipe on the roof;

- steel wire;

- asbestos sheets.

To build a stove that will heat both floors of a private house at the same time, you will need the following tools and accessories:

- concrete mixer or containers for preparing solutions - large and small;

- equipment: bayonet and scoop shovels, buckets for water and solution;

- tools: mason's hammer, trowel, electric drill with an attachment for mixing solutions, level and plumb line.

The required amount of materials is calculated based on the design dimensions of the furnace with a small margin of 5-10%. Thus, some of the bricks, even from an experienced craftsman, become unusable as a result of splitting during the laying process; some turn out to be defective from the very beginning.

Features of stove heating systems

It is necessary to understand that stove heating is a rather complex system that requires taking into account many nuances. If the craftsmen make one mistake or another, the owner of the house will have to pay. Below we will dwell on common problems that arise due to improper construction of the stove structure.

What are the advantages of heating a private house with wood, peat or coal? It should immediately be noted that they differ in autonomy. The oven can be built anywhere. She does not need access to communications. In some areas this is the only option available.

If there is no gas main at the location of the house, an alternative heating option may be a stove, which can be completely autonomous. Such heating is a classic option for organizing heating in a wooden house.

Undoubtedly, stove heating of a private house also has disadvantages. Firewood can be bought anywhere, but it needs to be stored somewhere. A small closet is clearly not suitable. A separate building will have to be erected. What can we say about space for flammable materials if the stove itself takes up a lot of space? In addition, to warm up a room with this device, you will have to spend a lot of time.

The stove takes up a lot of space in a wooden house. The larger it is, the warmer it is. In other words, it will be truly cozy in a large cottage. For example, it would be advisable to heat a wooden house using a stove if the building has enough space to accommodate it.

The low efficiency of this equipment often becomes the reason for searching for another way to maintain a comfortable temperature in the home. As a rule, the alternative is gas boilers, which we have already mentioned above.

Despite this, many still build such heating systems. Perhaps this is due not only to its good consumer properties, but also to the fact that the stove creates a special comfort that is difficult to put into words. You can only feel it. In addition, food cooked in it acquires a unique taste.

Foundation structure

The supporting structure must be massive enough to support the weight of a two-tier heating system. A large two-story oven creates a significant load on the foundation, the construction of which takes into account the following requirements:

- Loose sandy and sandy loam soils must be compacted before laying the foundation. The depth of the foundation is at least 1 m; a sand and crushed stone cushion must be poured and waterproofing done.

- In width and length, the base should be at least 50 mm larger than the stove, the height should be level with the floor of the first floor or 50-70 mm above it.

- The distance from the foundation of the house to the foundation of the stove must be at least 500 mm; the gap between them is filled with sand and carefully compacted.

Pouring the base for the stove cannot be done at the same time as laying the supporting structure of the house, this can lead to uneven shrinkage. After completing the foundation work, it is necessary to leave it alone for a month and a half until the cement is completely mineralized. The side walls of the base are insulated with roofing felt to protect it from the destructive effects of moisture.

Advantages of stove-type heating

Stove heating, which can be used to equip a two-story house, may also be the only possible solution, since a cottage located outside the city may not have electricity or a gas pipeline. In addition, heating a two-story house with a stove is quite cheap; you will only need to buy coal or firewood.

However, such heating also has some disadvantages, including the significant weight of the heating system, as well as its dimensions. Heating and all its benefits can be started to be used a long time after the start of heating, since the stoves are inertial: they heat up for a long time, but cool down just as long. When heating a house, the stove can lose quite a lot of heat, which escapes through the chimney. The efficiency of stove heating is low and is only 25 percent, which means that before the stove begins its immediate duties, it will warm up the walls.

Laying a two-tier stove and its main elements

A waterproofing layer is laid on the upper surface of the matured foundation. When building any stove - a fireplace for two adjacent rooms or a two-tier one - the first row of single bricks is laid without mortar. Accuracy is ensured by applying markings directly on the roofing felt.

The construction of a heating structure is carried out according to a pre-designed scheme, which provides for all its main elements:

- blower;

- a firebox that can accommodate a sufficient number of logs;

- hob for cooking;

- chimney channels;

- views and screens;

- inspection hatches;

- bed;

- chimney pipe.

When laying the stove, a solution of refractory clay and sand is used, the consistency of thick sour cream. After drying, it does not crack or fall out. The prepared masonry mixture is used within an hour and a half; when thickening, adding water is not allowed.

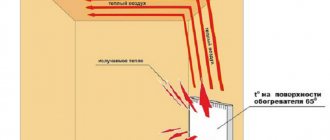

Air heating

In this category we include all methods of heating without the mediation of a coolant - water, oil, antifreeze and any others. The air in the room is heated through direct contact with the heating element.

Buleryan

The stove is a firebox surrounded by thick pipes with open ends up and down. The pipes heat up and provide convective mixing of the air in the room.

Directing them in different directions speeds up the process. If it is necessary to heat several isolated rooms from the buleryan, air ducts with natural or forced circulation are installed.

Advantages:

- Existing furnaces ensure almost complete combustion of fuel due to the fact that they provide long-term smoldering with a limited supply of oxygen. This ensures efficiency that is unattainable for traditional stoves.

- Buleryan does not take up much space and does not require its own premises. A stove for heating two floors can easily fit in the living room or dining room. There will be no soot or odors.

- Installing air ducts will cost less than installing a water heating system. Although, taking into account the necessary thermal insulation, not by much.

Flaws:

- It is almost impossible to lay air ducts after finishing the final renovation without spoiling the aesthetics of the room. The heating plan for a two-story house - both the heat source and the wiring - will have to be thought out in advance.

- Any stove heating of a two-story house is associated with the need to store reserves of firewood, coal, pellets or peat briquettes.

In the photo there is a buleryan stove in the living room.

Brick oven

An ordinary Russian stove usually has very impressive dimensions.

It occupies up to a third of the house’s area and is quite capable of heating several rooms. It is clear, however, that two-story heating stoves are somewhat more complex structures.

In general, there are almost no standards in the field of designing brick kilns. The specific implementation depends on the size of the room, the location of the stove, the imagination of the stove maker, or, alternatively, the order of a ready-made solution found on the Internet that was invented by someone else.

A typical two-story heating stove has a firebox located below and a cap or duct chimney that makes several turns on the second floor.

Execution options can be varied. For example, it is enough to place a cast-iron stove on the firebox, laying an asbestos cord under it to isolate the room from combustion products - and you will get a heating and cooking stove on two floors.

The stove can be placed in the middle of the room or in the corner; finally, if desired, you can even organize water heating of a two-story house with natural circulation by simply placing a coil in the firebox.

Dignity:

In the absence of gas, stove heating is the cheapest heating method. A brick stove pleases its owners with its great thermal inertia: it is usually heated once a day for 2-3 hours, and the rest of the time it releases the accumulated heat.

Flaws:

- Again, you will need a supply of fuel, which will take up a fair amount of space in the yard.

- Folding a stove so that condensation does not seep through the masonry, so that the stove does not crack and smoke into the room is an art that is gradually being lost.

If you are not afraid of experiments, you can try to do this work yourself; but in the absence of any experience, it is better to be prepared for various surprises.

Gas convectors

Another way in which you can do air heating of a private two-story house with minimal time and money is by installing gas convectors.

Each device is a closed burner with air intake from the street and combustion products discharged there through a coaxial pipe. The heat exchanger heats the air in the room. The devices can operate from both main gas and bottled gas.

2163d27d9b0f7a448f842769831b5843.jpe 6abc3571ae8d0fcb3349ee3d83cd8e79.jpe 70d1ae7f8983b60d60e7b2d69c801397.jpe 81fa333c2bc668042adc3 d10b0c088ea.jpe

Advantages:

- Full autonomy of heating for each room in the house.

- Low project cost. The price of each convector is 4-8 thousand rubles. Considering that you do not need a boiler and wiring from it, this will mean significant savings.

Flaws:

- Unfortunately, mains gas is not available everywhere.

- Installation of convectors is possible only on the external wall of the house.

- Drilling wide holes for a coaxial pipe in, for example, reinforced concrete is still a pleasure.

- look here.

Step-by-step instructions for building a two-story stove

The laying of a two-tier heating system in a cottage or private house is carried out at positive temperatures. Experienced stove makers prefer to work when it is warm and dry outside, but not hot. This avoids uneven setting and drying of the solution.

The construction of a two-tier furnace is carried out in the following order:

- On top of the first row laid dry (without mortar), the second row is laid with mortar. A blower door is installed on the front side and temporarily secured with wire.

- When forming the blower part, the latter is made smaller than the combustion part, and recesses are provided in the brick for laying grate bars.

- In the fourth row, the firebox door is mounted in the same way as the blower door.

- The walls of the combustion chamber are created by rows of fireclay bricks, starting from the 4th to the 8th inclusive.

- Higher up, the stove narrows - in this part there are smoke exhaust channels, which make up the rows of bricks from the 16th to the 20th.

- Above this structure, starting from the 21st row, an expansion is made up to the ceiling.

On the second floor, the masonry levels are numbered first. Up to the 26th row inclusive, construction is carried out following the classic “stove-chimney” scheme.

During the construction process, a kind of “labyrinth” is created, consisting of long horizontal channels. They are connected to each other by short vertical ones. Above them, starting from the 31st row, a chimney pipe is formed, which passes through the ceiling, the attic and goes out onto the roof.

Devices

The list of instruments and materials required for the construction of this furnace is given in table. 2. Its design is not particularly complicated, but requires quite high qualifications and accuracy from the performer

Particular attention should be paid to the quality of the masonry not only of the firebox and external walls of the stove, but also of the internal chimney channels, since communication between the stove’s smoke circulations not provided for by the design can lead to its inoperability

TABLE 1

CHARACTERISTICS OF A TWO-STORY HEATING OVEN WITH SINGLE FUEL

Dimensions of the furnace in plan: fuel section……………………………………..890×1150 mm panel of the 1st floor……………………………………… 770×1020 mm shield of the Nth floor………………………………………. 770×950 mm Furnace height*…………………………………………………………………………………………………………7150 mm Heat-dissipating surface……… …………………………………………………………………………………..20.0 m2 Average heat transfer with a single firing of the furnace per day………………………. 5500 kcal/hour Total daily heat transfer…………………………………………………………..~ 132000 kcal Amount of fuel burned per day (dry firewood)………………… …………………………59 kg Heat transfer time after one fire ……………………………………………………24 hours * The full height of the stove is indicated for the ceiling height 3.4 m. It can be changed by reducing or increasing the number of rows in the masonry from 26 to 46 and from 60 to 82 rows.

TABLE 2 LIST OF DEVICES AND MATERIALS

Solid red brick (selected)……………………………………………………….1900 pcs. Fireproof bricks…………………………………………………………………………………………………………170 pcs. Red clay…………………………………………………………………………………………………………….2.1 m3 Fire-resistant clay………… …………………………………………………………………………………0.2 m3 Sand……………………………………………………… ……………………………………………………………………………………2.3 m3 Fire door 350×350 mm……………………………… ………………………………………………1 PC. Blower door 135×120 mm……………………………………………………………………………………….1 pcs. Cleaning doors 135×120 mm……………………………………………………………………………………………….5 pcs. Furnace valves 130×260 mm……………………………………………………………………………………………….2 pcs. Pre-furnace sheet 500×700 mm……………………………………………………………………………………1 pc. Grate 400×400 mm………………………………………………………………………………………..1 pc.

1. 2. 3. 4. 5. 6. 7.

Heating a two-story cottage with a stove is quite simple, and such a system will not require any special treatment. The only condition that must be observed when using any stove: regular heating. Stove heating of a two-story house is very convenient to use, but the price for this ease will be the complexity of installation, therefore, before constructing a stove heating system, it is necessary to draw up an accurate and specific work plan.

Stove heating can operate autonomously, and in this case there will be no shortage of fuel. True, you should always take into account the fact that the stove occupies a fairly large area, and you need to think about this in advance. In addition, being an excellent decorative element of the house, the operating temperature of the stove is practically impossible to adjust, which is why there is an uneven distribution of thermal energy.

Two-tier stove for main and additional heating of the house

The presence of a two-tier heating structure provides your cottage with the highest level of autonomy. Such a stove for two rooms, located one above the other, can create comfortable conditions throughout the entire country house. Its rear walls are also well heated, which helps maintain the necessary microclimate in two or even four adjacent rooms.

Depending on the layout of the house, a two-story heating furnace can be used as the main system. However, recently, due to the widespread laying of gas mains and the allocation of sufficient electrical power, this structure is increasingly becoming an additional facility.

A brick two-tier stove, decorated with tiles or special ceramic tiles, becomes the central decorative element of many designer interiors.

How to choose a stove for heating two floors

First of all, when choosing possible options for heating devices for a mansion, you need to decide on the type of fuel that you plan to use for heating. A stove for a two-story house with traditional fuel for this region will allow you to become completely energy independent. Now you won’t have to count cubic meters of gas or kilowatts, and the stove itself will make it possible to comfortably spend the entire heating season.

A two-story stove makes it possible to provide a room with heat at the lowest cost. And even with a certain comfort - the firebox of such a structure is located below, on the first floor. This means that there is no need to constantly carry bundles of firewood or buckets of coal to the second floor. And maintaining a comfortable temperature now becomes much easier - for both the first and second floors you can set your own heating mode by simply closing the damper.

A project is selected for construction depending on the volume of the room and the individual preferences of the owners, it can be:

- Two-story oven with hob;

- Stove-fireplace with open firebox;

- Stove with firebox on two sides;

- A building for burning wood, coal or other types of solid fuel.

When deciding on the type of furnace to build, it is important to remember that such a structure has a large mass, and therefore requires a solid foundation that can withstand a load of several hundred kilograms.