The most common method of heating cottages and country houses is with natural gas. However, firewood as a type of fuel is also often used, mainly for heating a country house. Typically, this option is resorted to if the region is not gasified and will not be gasified in the near future, or if the cost of connecting to the gas main is unreasonably high. Heating a dacha with wood is also popular in areas where large forests are located and firewood is easily available.

Scope of use of wood heating

Heating a dacha with wood can be done in two ways - using a stove and using a solid fuel boiler.

| Monday | Open 24 hours |

| Tuesday | Open 24 hours |

| Wednesday | Open 24 hours |

| Thursday | Open 24 hours |

| Friday | Open 24 hours |

| Saturday | Open 24 hours Now open |

| Sunday | Open 24 hours |

Heating using a solid fuel boiler

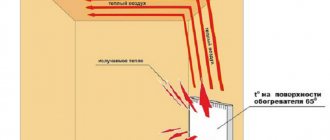

The second method of heating a country house with wood is to use a full-fledged heating system with a solid fuel boiler as heating equipment. At the same time, there are different boilers for each type of solid fuel; it is necessary to purchase a wood-burning boiler, and not a pellet or peat boiler.

It is necessary to place dry firewood into the combustion chamber of the boiler from time to time. When they are burned, heat is released, which heats up the coolant. Combustion is regulated by opening and closing the damper. The more air enters the combustion chamber, the more intense the combustion process.

Buy or make it yourself

Of course, Russian craftsmen are capable of much. However, the final result will be significantly lower compared to purchased structures. And while it is more or less simple to build a stove for low-power heating of a house, it is hardly possible to create a powerful long-burning unit. As a result, your costs will be significant (search for materials, time, worries, damage in case of an unsuccessful experiment), and you will not be able to obtain sufficient heating. It is advisable to spend money once on solid equipment and enjoy everyday comfort for many years.

The most expensive modifications are long-burning ones, but the costs are still paid off handsomely. The myth that prices are too high can be easily dispelled by starting to use a modern unit in practice.

Do-it-yourself homemade wood-burning boilers and stoves will not provide the high power and high user safety that factory-made products are capable of.

Disadvantages and risks when operating homemade boilers:

- short service life;

- inability to ensure long-term combustion;

- low efficiency;

- overheating of the case (hence burns from accidental touches).

How much do wood-burning boilers and wood-burning stoves with water heating cost? Focus on prices in the region of 58-65 thousand rubles. at a power of 20-24 kW. The most positive reviews are addressed to such models as Protherm DLO 30, Dakon DOR F 24, Buderus Logano G221 and a number of others. Please note that prices are always slightly higher.

One of the most important stages in the construction of a private house is the choice of heating. To create a heating system, you first need to decide on a boiler. At the moment, the market offers a huge range of products from domestic and foreign manufacturers. Therefore, in order to buy a boiler that will best fit into your home, you need to correctly navigate the huge variety of products.

Since the price of heating increases every year, people began to seriously think about the possibility of using alternative heating methods.

Economical wood-burning boilers for heating a private home today have taken a leading position in the heating appliance market, because such boilers produce a large amount of heat with minimal use of wood.

Wood is not the only fuel.

An economical long-burning boiler has many advantages:

- High level of efficiency;

- Complete independence of the boiler from external communications;

- Inexpensive fuel (compared to gas);

- Possibility to choose fuel.

About company

For many years, he has been installing heating and water supply for country houses, cottages, and dachas in Moscow and the Moscow region. Her motto is “Fast! Qualitatively! Reliable! This company employs experienced and qualified specialists (we do not use the services of guest workers) who are able to quickly design and install a wood-burning dacha heating that will work properly for a long time.

A dacha is a country house where we strive to move our family in the summer, take a break from the noise of city life, and breathe in the fresh, clean air of the forests. Enjoy the peace, quiet, and escape the hustle and bustle of the big city. It’s nice to go out into the yard in the morning and take a deep breath of the clear country air, hear the birds singing and the chirping of crickets. A sudden change in weather can lead to colder temperatures, especially in early spring or autumn. Increasingly, people prefer to live outside the city and come to the metropolis to work. In these conditions, heating a dacha can be an important element of a comfortable life.

What heating systems are used according to wiring methods

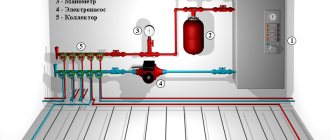

In private homes, water heating network pipelines are carried out in the following options:

- Vertical system with bottom wiring. This option involves laying pipes through the basement or, at a minimum, in a concrete floor screed.

- Vertical system with top wiring. The hot water supply line is installed in the attic of the house or in the ceiling space of the interior.

- Using a one-pipe system. Connection diagrams. The main feature of a single-pipe heating circuit is the sequential connection of heating radiators to the hot water supply pipe. In this case, there is a difference in the thermal heating of the radiator batteries located at the beginning and end of the heating line. Therefore, single-pipe wiring is used to heat rooms with an area of no more than 40 m2. It is advisable to use a vertical single-pipe scheme in low-rise buildings.

Two-pipe heating system. In this case, two pipes are simultaneously connected to each radiator: for supplying hot water and for returning cooled coolant. Pipelines are laid in parallel lines at a short distance from each other.

Note: Two-pipe wiring allows you to individually regulate the temperature in each room without compromising the rest of the rooms.

Radiant heating distribution

A radiant or collector heating network involves connecting each radiator directly to a heat source (collector). This connection diagram simplifies the replacement of a failed heating device without stopping the entire heating system. Sometimes the collector is called the term “comb”, although this name is more often found in the description of the technological process of heating water in industrial enterprises and boiler houses. Due to its dimensions, the distribution manifold takes up a lot of space and to disguise it in private homes they use a small cabinet or a built-in niche with a door.

Scheme "Leningradka"

In private houses with a small area, a single-pipe pipeline layout is most often used. This model is easy to install and requires lower costs compared to other pipeline laying schemes.

However, if one of the radiators breaks down, you have to stop the heating line, drain the water from the entire wing of the line, and only then fix the breakdown.

To level out this drawback and not leave the house without heating in the winter cold, a single-pipe installation scheme called “Leningradka” is used. In this case, it is planned to install heating radiators of different capacities and use bypass bypasses. The pipe lining connects the inlet and outlet openings of the radiators in parallel, and if one of the heating elements fails, it can be easily disconnected and replaced.

Heating the cottage with wood

In a country rich in forests, wood heating is the most popular and inexpensive. The main disadvantage in this case is the need to constantly maintain the temperature in the boiler for comfortable living in the house. When planning to heat your dacha, it is worth considering installing a combination boiler that operates on several energy sources. You can install a boiler that runs on solid fuel with a possible transition to liquid or electricity.

If you visit your dacha exclusively in the summer, you can install a fireplace in it. This will not only allow you to heat the room at night or during a sharp cold snap, but will also add an additional romantic touch to the design of the dacha. It’s wonderful to sit by an open fire, listen to the crackling of logs, and watch the flames dance. Such a pastime is a great way to relieve the stress of a busy day. Heating a dacha with wood is more of an aesthetic nature than a practical one, if you do not plan to live in it for a long time, but are coming only for a short time to relax.

Build process

The process of creating a boiler includes several stages. When manufacturing each element, it is worth taking into account the special operating conditions of the product being manufactured.

Air supply device

We cut a section from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the firebox. We weld a bolt to the bottom. From a steel sheet we cut out a circle with the same diameter as the pipe or larger. We drill a hole in the circle large enough to pass the bolt welded to the pipe. We connect the circle and the air duct pipe by tightening the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed by a freely moving metal circle. During operation, this will allow you to regulate the intensity of firewood combustion and, consequently, the temperature in the room.

Using a grinder and a metal disc, we make vertical slits approximately 10 mm thick in the pipe. Through them, air will flow into the combustion chamber.

Housing (firebox)

The body will require a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a thick-walled steel cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

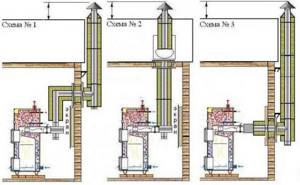

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which the exhaust gases will be removed.

The length of the pipe is selected depending on design considerations.

Connecting the housing and the air supply device

We cut a hole in the bottom of the housing with a diameter equal to the diameter of the air supply pipe. We insert the pipe inside the body so that the air vent extends beyond the bottom.

The air supply pipe should end a few centimeters before the start of the chimney.

Heat Dissipation Disc

We cut out a circle from a metal sheet 10 mm thick, the size of which is slightly smaller than the diameter of the body. We weld a handle made of reinforcement or steel wire to it.

This will greatly simplify the subsequent operation of the boiler.

Convection hood

We make a cylinder from sheet steel or cut a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the firebox (body). You can use a pipe with a diameter of 500 mm. We connect the convection casing and firebox together.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the firebox, if the gap is large enough. With a smaller gap, you can weld the casing to the firebox around the entire perimeter.

From a steel sheet we cut out a circle with the same diameter as the firebox or a little larger. We weld the handles to it using electrodes, wire or other available means.

Considering that the handles can become very hot during operation of the boiler, it is worth providing special protection made of material with low thermal conductivity.

To ensure long burning, we weld the legs to the bottom. Their height should be sufficient to raise the wood-burning boiler at least 25 cm above the floor level. To do this, you can use various rolled products (channels, angles).

Congratulations, you have made your own wood-burning boiler. You can start heating your home. To do this, just load the wood and light it by opening the lid and heat dissipation disk.