The design of heating and water supply systems provides several options for achieving high device safety. One of the most effective methods for achieving long-term trouble-free operation of domestic and industrial heating installations is a comprehensive method of using safety devices. The method involves a multi-stage, redundant function of system components and the use of devices to prevent emergency situations. One of such devices are compensators for heating pipelines.

Purpose and methods of installation of expansion joints for polypropylene and pipes

The heating system, whether private or multi-storey, is designed taking into account possible risks and unforeseen situations. And if the uncontrolled heating of the coolant in the boiler circuit is compensated by the activation of the emergency valve and the release of liquid into the expansion tank, then with the thermal expansion of the pipes things are a little different.

Like metal pipes, polypropylene pipes are also susceptible to expansion when overheated. And even though these values are small, they cannot be discounted in any way. According to the standard, the coefficient of linear expansion of polypropylene pipes at a temperature difference of 70 degrees is 10.50 mm per 1 linear meter of pipe.

That is, at an air temperature of 20 degrees and a coolant temperature of 90 degrees, an ordinary pipe with a diameter of 20 mm and a length of 1 meter will become 1 cm longer. It is not difficult to imagine that a pipeline made of such pipes 3 meters long will increase by as much as 3 cm. And this is already becoming a big problem for the building's heating system.

In this case, there is only one way out - installing a linear pipe expansion compensator in the pipeline.

The principle of operation of this device is simple - when heated and expanded, the compensator, due to its design and the special materials from which it is made, changes its shape. That is, it is compressed and thus provides compensation for the volume of pipelines that increase in volume. When cooling, when the pipe material is the opposite, the compensator contracts, deforms, expands, and thus ensures the integrity of the pipeline.

What are compensators used for?

It is necessary to understand that heating networks are pipe systems through which thermal energy carriers move. More often it is hot water, less often saturated steam. Therefore, such highways are subject to two main loads and two minor ones. But even small significance often leads to major accidents.

Main problems:

- temperature changes;

- pressure changes.

Under the influence of these two loads, the pipes either expand or contract. Such movements often lead to deformations, and over time to an increase in overloads. The end result is the destruction of the entire system or section, which is equally unpleasant and economically costly.

Two minor loads:

- vibration of pipes from the operation of pumping units;

- own vibration of the highway itself.

If these two components coincide in amplitude, destruction of the pipe structure will quickly occur, especially at the joints of its elements.

To avoid this, compensators are installed in the pipeline. These are a kind of elastic structures (devices) that dampen not only vibration, but also the consequences of expansion and contraction of pipes. In essence, they compensate for the loads acting on the pipeline.

Under the influence of changing temperatures and pressure, pipes not only expand or contract in the transverse plane. There is such a thing as linear expansion of materials. It occurs constantly in the design of heating network pipelines.

This is a serious load that pipes can only withstand with the help of expansion joints. If they are not installed, then first of all the welds and joints of the sections that are carried out with couplings will begin to fail.

Therefore, today the installation of different types of heat compensators in pipelines of heating networks is a mandatory operation that is not discussed. This is the only way to ensure efficient and long-term operation of pipe heating systems.

Compensating device in a pipeline system

What are the dangers of pipe expansion?

A list of what can happen to a pipeline if one of the types of compensators is not installed in it:

- bending of the line, which will negatively affect the speed of movement of hot water, and the supports installed under the pipes will also suffer;

- break in sections at the junction of highway elements;

- the appearance of leaks (this reduces the efficiency of the heating main).

This makes the system short-lived and leads to the need for constant repair work, which affects the cost of the services provided.

Compensators for polypropylene pipes: bellows, U-shaped, Kozlov compensator

Unlike metal pipes, the range of expansion joints for polypropylene pipes is not so large. This is mainly due to the fact that polypropylene is used for water supply and heating systems with low temperature indicators. But this in no way reduces the importance of installing compensators. The second point lies in the features of installation work. For metal fittings, welding, soldering, threaded connections, and flanges are used. But for polypropylene, only soldering. And therefore for this type of pipes the following are used:

- Bellows devices;

- U-shaped inserts;

- Loop type inserts;

- Kozlov compensator.

Compensation products and pipeline

Axial type compensation products are installed in a certain order. At the first stage, they are fixed by welding one end to the pipe. A gap is left between the opposite side and the end of the pipe, which is equal to the length of the pre-made stretch. For the operation of stretching the compensation product, hardware of various shapes (nuts, studs) is used. When installing hinge compensation devices, they are welded in accordance with the installation diagram, while the bolts holding the hinge cheeks are not removed.

They are dismantled after checking the length of the gaps between the joints and tightening the fasteners

Gland-type expansion joints require alignment with the pipes being joined. Displacement of the axes during installation is unacceptable, otherwise moving parts may jam or failure of the compensating device packing may occur. The guides that are installed on the pipes inhabit it, and thus the pipes are centered in different planes.

Compensators for polypropylene pipes and methods of their installation in the heating system

Each of the presented types of devices has found wide application in assembling heating and hot water supply pipelines made of polypropylene pipes. A certain methodology for using devices for installation in systems has already been developed, and experienced designers will tell you how and how to choose a device for installation.

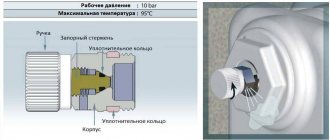

Bellows devices

This type of compensator is intended for installation in particularly critical systems. This is due to the design of the device - its base consists of stainless steel corrugation. The outer part is made of high quality aluminum. The main purpose is high-temperature pipelines and high-pressure pipelines. They are used to work with saturated water steam, water heated to 90-95 degrees, and pressure up to 16 bar.

For metal networks, bellows with a flange type of connection are used; for polypropylene, the main type of connection is a coupling with a metal threaded insert on one side, and on the other side, a standard soldering socket.

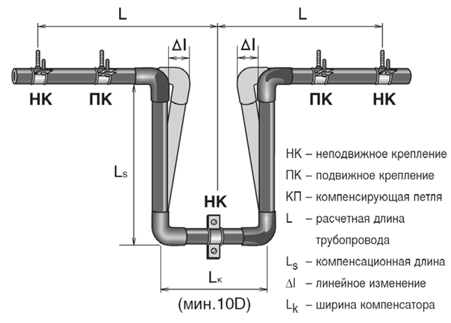

U-shaped inserts

A simple but at the same time effective way to protect the pipeline using an insert made of ordinary polypropylene pipes and angles. The essence of the method is to assemble a structure resembling the letter “P”. The right and left sides are made from pipe sections of 30-50 cm. The jumper at the bottom can be 15-20 cm. This insert is made into a horizontal pipeline. When horizontal pipes heat and expand, they compress the vertical sections without damaging the integrity of the entire structure.

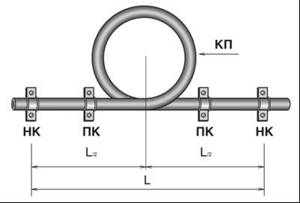

Loop type insert

For installation of large sections of pipelines there is a special loop-type insert. This is a ready-to-use element made in the form of a loop. Inserted into the system using conventional couplings. The principle of operation is reminiscent of the action of a spring - when the connected segments expand, the loop contracts, and when cooled, it expands. In this case, neither the integrity nor the throughput of the pipeline is compromised.

Kozlov compensator

This device is a bellows that is specially designed for installation in pipelines with a diameter of 20 and 25 mm. The device has polypropylene inserts on both sides, so there will be no difficulties with installing this device. There is an aluminum corrugation inside the device. The device is capable of ensuring deformation of the main pipe up to 25-63 mm. The guaranteed number of compression-release cycles is 50,000.

All presented heating pipeline compensators are axial type devices, that is, they work best when they are inserted into a flat vertical or horizontal section.

For other types of installation, such as offset or Z-shaped sections or for angular turns, modified U-shaped and hinged expansion joints are used.

Protection of pipeline systems from excessive loads

Protecting pipeline systems from excessive loads begins at the design stage. Designers and constructors calculate it in such a way that its components (pipes) have the ability to freely change their length with temperature changes, while the system and its components should not experience additional loads.

In other words, pipeline systems, of course, correctly designed, have the opportunity to change their linear dimensions, but only within the limits of permissible loads and without the use of special equipment, called self-compensation.

It (self-compensation) can be realized only because pipelines consist not only of straight sections; as a rule, turns or bends are placed between the support points.

These design elements are turns or bends and help compensate for variations in length. It is directly related to the elasticity of the structure in the straight section; the other part is compensated by the characteristics of the metal used to produce the pipes.

But it is not always possible to include the possibility of self-compensation in the project or it is impossible to use it in full, then devices called compensators are installed in the pipeline system.

Our company has mastered serial production of the following types of compensation products:

- bellows;

- lens PGVU;

- lens OST;

- omental;

- tissue.

How to select and install a compensator for polypropylene pipes

For heating systems in an apartment or house, polypropylene pipes with a diameter of 20 or 25 mm are usually used. It is considered irrational to use pipes of larger diameter, especially if a boiler with a circulation pump is installed. Therefore, most often the simplest and most reliable circuits and devices are chosen for installation.

Despite the reliability of the bellows expansion joint, its installation is very difficult for small-diameter pipes. It is much easier to use a U-shaped junction or loop for this. But Kozlov’s compensator became a real find today. It is easy to install, and according to its characteristics it is perfect for hidden installation, because its outer diameter is not much larger than the diameter of the heating pipes.

U-shaped expansion joints are most often installed on horizontal sections. The loop compensator has proven itself to be excellent for vertical installation. It is the loop type that is most often used when installing water pipes.

The Kozlov compensator can be installed regardless of position; it is equally convenient for both horizontal and vertical installation.

Features of installation of lens compensation devices

When installing lens compensators, it is necessary to monitor the location of drainage devices; these can be fittings or taps. In addition, the guide glass must be installed along the axis of movement of the moving working medium.

It is advisable to install lens compensation devices in pipes, assemblies or blocks before they are installed in the position specified in the design documentation. During transportation and storage of the finished lens compensation device, it is necessary to ensure the safety of the product. For this purpose, special devices are used, they are called rigidity. After installation of the finished product, they must be removed.

During the assembly of pipelines located in a vertical plane, installers must weld brackets that are installed parallel to the compensator and cut off upon completion of work.

Before installation, lens expansion devices must be stretched to half their thermal deformation capacity.

These products can also be stretched during installation, after welding or assembly on flanges. In addition, all stationary supports, hanging devices, etc. must be installed.

In this case, stretching of the expansion joints is carried out by pulling it to the nearest, specially prepared joint.

Compression of the product is carried out after it is finally connected to the pipeline, until it is secured to stationary supports. To manipulate the compensation device, use a device that includes two clamps and elongated pins.

When installing several expansion joints in a pipeline system, designers are required to provide for the presence of stationary supports located behind the product being installed. This approach makes it possible to prevent deflection of a pipeline line under load. This approach will ensure uniform deformation of all compensation products installed in this area. The thing is that each lens compensator has its own rigidity parameters.

For lens compensators, they are sometimes called wavy ones, before installation it is necessary to check the construction length, then set the gap, which should correspond to the preliminary load (stretching).

What is important to know when selecting expansion joints for polypropylene pipes?

When starting to calculate system parameters and select equipment, it is important to remember the following rules:

- The diameter of the heating system pipes must correspond to the diameter of the expansion joints;

- They are installed in the places specified in the heating system design, therefore, before selecting components, it is necessary to assess the possibility of installing it in the specified location;

- Compensators for heating pipelines should provide a margin of another 10-15% from the calculated expansion coefficient.

Calculation of compensators is carried out according to the formula:

X=LxTxK

L – length of the straight section of the pipeline; T – heating temperature of the coolant fluid relative to the initial temperature in the room; K – coefficient of thermal elongation.

The result obtained will mean the indicator of linear expansion of the straight section of the pipeline.

Selection rules

The choice of compensator for a pipeline for any purpose is based on an analysis of the specific characteristics of different types of models. Basic parameters (starting points of the search) - pressure in the system, temperature range, flow of the working fluid, pipe material. In addition, before making a decision, you should consider the following:

- the longest life cycle is for stuffing box options, this is one of the reasons that made stuffing box devices popular for overhauls of complex systems and repairs of heating supply networks;

- there is a direct connection between the smoothness of the mirror and the service life of the filling (models with a smoother mirror have a longer service life of the filling);

- in networks where there is a high probability of minor equipment damage, you should not use multi-layer expansion joints (with minimal deformation they lose the tightness of the chambers/channels);

- One of the weak points of the structure is the corrugation; it is easily damaged during loading/unloading and transportation, therefore its integrity must be checked before acceptance.

Installation of expansion joints for polypropylene pipes

Compensators for heating pipelines are installed during system assembly or repair. During work, the coolant from the system must be drained.

The algorithm for installing the U-shaped compensator structure is as follows:

- The necessary materials and tools are prepared;

- The installation site is measured and it is determined in what position the structure will be installed;

- A marker on the pipeline marks the place where the expansion joint is inserted;

- A pipe section is cut according to the width of the insertion section;

- 90 degree corners are attached to the segment on both sides, the position of the bends is one-sided;

- Next, pipe sections are attached to the bends;

- Angles are attached to the ends of the segments for connection to the pipeline;

- The final stage is connecting the compensator to the pipeline.

The resulting structure must be secured to the wall with mounting clips. For fastening, points are selected in the middle of the U-shaped branch and 10-15 cm from the points of insertion into the main line on both sides of the insertion.

Now that the technology for calculating and installing linear expansion compensators is clear, there is no big problem in doing all the necessary work yourself and assembling the device yourself.

What it is?

When the temperature of the liquid in a plastic pipeline changes, a process of linear deformation occurs. This can cause sagging, which will eventually lead to cracks. To compensate for the expansion of polypropylene that occurs during temperature or pressure surges, you need to install a special PP compensator.

The compensator is a simple part that has a high degree of flexibility. Visually it resembles a loop, but there are products similar to a piece of corrugation. Often, such parts are supplied with fittings for mounting them on the pipeline.

What is it needed for

When installing pipeline systems, a natural question may certainly arise: why do you need a compensator for polypropylene pipelines?

The polypropylene expansion joint is presented in the form of a special connecting type design. It often has the shape of a loop.

The purpose of the polypropylene compensator is to provide compensation for the linear expansion of the pipeline. The device prevents excessive exposure of the internal walls of the pipeline to factors such as high temperature and excessive pressure.

Thus, installing expansion joints on polypropylene pipes ensures optimal stabilization of the entire aquifer.

Despite the fairly low cost and relative simplicity of design, this device significantly increases the service life of pipelines.

The compensator, due to the simplicity of its design, allows installation on almost any straight section of pipelines. It ensures a high degree of reliability of the entire system.

Design Features

Loop expansion joints for polypropylene pipelines are often made using static polypropylene.

Modern products are manufactured using a special injection molding method. Often this part is sold in two color variations - white and gray.

The polypropylene compensator, due to the simplicity of its design and relatively low weight, can be easily installed on a water supply system.

PVC pipe connection

Correct installation of this product does not require the use of special tools or seals.

Thermal compensators for polypropylene pipes are widely used in all types of pipelines.

By installing this product, you thereby significantly increase its strength and protection against ruptures.

This is especially true for those places where joints and junctions are located. Often a compensator for polypropylene is mounted in the middle of the pipe. This may be an area located between two fixed supports.

In addition, expansion joints effectively protect the pipeline from excessive stretching or sudden displacement.

This can happen when the temperature of the working medium inside the pipe rises sharply, or when a water hammer occurs.

The device is widely used for a number of systems. This:

- systems and pipelines for cold water supply;

- systems providing hot water where expansion is unavoidable;

- heating systems.

It effectively fulfills its restrictive function in cases of unauthorized reduction of pipes made of polypropylene.

The device is mounted on the highways of buildings with various purposes. It can be:

- Country and multi-apartment residential buildings;

- Commercial and administrative buildings;

- All types of industrial premises.

Advantages and disadvantages

This part takes on the most important function for any pipeline - ensuring structural integrity. This makes her indispensable. The product is good because:

- Effectively helps stabilize internal pressure on pipes;

- Produces cutoff of so-called vortex flows;

- Promotes quick and convenient fastening (welding) with the main main pipe;

- It has a high degree of reliability due to its manufacture from high-quality materials;

- It has a very long working life and service life exceeding 50 years;

- When installed correctly, it ensures perfect tightness.

No significant deficiencies in the design, structure or operation of these products have been identified. The only, and perhaps the most significant disadvantage is the possibility of combination only with those pipes that are made of polypropylene.

Types and differences

Today, several main types of expansion joints are produced that are mounted on polypropylene water supply:

Loop compensator

- Bellows axial products of the KSO and OPN brands. Installation and subsequent integration of such products is extremely simple and straightforward. This is due to the presence of special fastening guide units. They are presented in the form of firmly fixed supports, which greatly simplifies their installation.

- Shift compensators brand KSS. Designed to effectively provide compensation in two areas simultaneously. They are located parallel to the central axis of the highway. In addition, the design is equipped with one or two corrugations, which are made of stainless steel. The elements are connected to each other by means of connecting fittings.

- Rotating elements of the PCB. They are used to eliminate the consequences of linear expansion. It occurs on those sections of the pipeline where there are bends. The device rigidly fixes the angle and can follow the contours of the highway at an angle of 90 degrees.

- Universal types of KSU products. They have three operating stroke modes - angular, transverse and axial. Often, such an element is used in cases where it is necessary to install a short main line with a large number of branches.

- Rubber flanged bellows expansion joints are actively being introduced into the structure of those water pipelines where water hammer often occurs. These devices can compensate for minor inaccuracies associated with the curvature of the central axis of the water main.

How to choose?

Before you purchase a compensator, there are a few important guidelines to consider.

First of all, before purchasing, you need to correctly take into account the diameter of the product itself and the diameter of the pipe on which it will be mounted.

These indicators must match. It must be remembered that the most common diameter of plastic pipes is from 20 to 40 mm. For systems located in apartments and private houses, the most acceptable diameter is 20 mm.

The heating system cannot be installed without compensators

Remember that using the flange mounting method, the compensator is attached not to the line, but to the counter flange.

Based on this, preference is given to a flange compensator. This product will provide a reliable, sealed, and at the same time detachable connection.

In the event that an emergency occurs, it will be possible to quickly replace the element immediately.

Due to the simplicity of the design, the price of the expansion joint for polypropylene pipes is quite reasonable. It fluctuates within the following limits.

Bellows compensator, KSO:

- Working pressure: 16 atm;

- Total length: 250 mm;

- Pipe diameter: 21.5 mm;

- Price: 3-4 $.

Shear compensator, KSS:

- Working pressure: 12 atm;

- Total length: 170 mm;

- Pipe diameter: 18 mm;

- Price: 2-3 $.

Flange compensator, rubber:

- Working pressure: 18 atm;

- Total length: 295 mm;

- Pipe diameter: 20 mm;

- Price: 1-2.5 $.

Which to choose

Compensators must ensure a reduction in loads occurring in the longitudinal and transverse directions, as well as at an angle to the axis of the pipeline when removing the pipe.

L-shaped, U-shaped, ring compensators and snake-shaped devices are sections of a pipeline (made of the same polypropylene, or similar in characteristics, but with greater elasticity and elasticity of materials), which are given the appropriate shape.

They are mounted in the same way as sections of the main highway (how many layers of FUM tape need to be wound is written here).

Fittings are included in the design to obtain the shape (for example, for U-shaped expansion joints) or the desired characteristics are achieved without using them.

The range of devices that compensate for thermal expansion using other materials is much wider.

These include:

- axial bellows compensators KSO and surge arrester.

These devices are designed to compensate for pipe deformation in a direction coinciding with its axis.

An elastic structure is used as a working element - a bellows made of corrugated sanitary rubber or thin stainless steel.

Practical note! Devices of the surge arrester type are characterized by ease of installation due to the presence in the design of fastening units that serve as supports during pipeline installation;

- shear compensators KS. The devices are designed to compensate for deformations in a direction that does not coincide with the pipe axis, and, accordingly, have degrees of freedom in both (vertical and horizontal) planes.

The design of expansion joints includes one or two corrugated bellows.

When using a two-part device, the reliability of the connection of the bellows is achieved through the use of connecting reinforcement;

- rotary compensators KSP. The function of these devices is to compensate for the linear expansion of both sections of the pipe at the turning points of the pipeline.

They are used where, according to the laying conditions, the angle of rotation of the pipeline must remain unchanged;

- universal compensators KSU.

The devices allow you to compensate for all types of pipeline deviations that occur due to thermal expansion.

Accordingly, the working stroke of these devices is designed for axial, transverse and angular deviations.

The design features of these devices dictate their use on short sections of highways or in places where the use of other types of bellows compensating devices, for some reason, is limited or impossible;

- rubber bellows elements KR (flange). These compensators are used to compensate for the deviation of the axis of pipelines.

In addition, the devices act as dampers and are capable of absorbing water hammer in the serviced section of the highway.

In addition to their functional purpose, compensators are divided according to the installation method.

For polypropylene pipelines, welded and flanged expansion joints are used.

The welding method uses a traditional installation method for polypropylene pipes using welding equipment (which tool is needed is written here).

This connection method imposes mandatory conditions for the selection of compensators:

- identical diameter,

- wall thickness,

- internal section of the compensating device and pipeline section.

Installation of the compensating device is carried out by connecting the flanges on the compensator and the pipeline.

The advantage of this method is to obtain a detachable connection that is easy to maintain and repair.

The main disadvantage is the increased complexity of installation and a greater number of technological operations.

Attention! Installing a metal flange on a polypropylene pipeline is not an easy task. Therefore, it is better to entrust its implementation to specialists with relevant experience.

Therefore, it is better to entrust its implementation to specialists with relevant experience.

For your information! Under certain conditions, the use of bellows expansion joints, in addition to combating thermal expansion, solves the problem of eliminating eddy fluid flows in the pipeline, which increases the safety of its operation.

Effective operation of compensating devices is possible only if the rules for their installation are observed.

Sources

- https://trubanet.ru/truby-dlya-otopleniya/kompensatory-dlya-polipropilenovykh-trub-silfonnye-p-obraznye-kompensator-kozlova.html

- https://HomeBuild2.ru/truby/kompensator-dlya-polipropilenovih.html

- https://ru-canalizator.com/santehnika/s-oborudovanie/kompensator.html