Menu:

- Technical characteristics, advantages and disadvantages

- Using corrugation

- Calculations

- Popular questions and answers to them

- Briefly about the cost where to buy

- Installation and fastening

- Welding

- Connection of metal and plastic pipes

- Docking with fittings

- Video

Creating a heating circuit is quite a complex task. To solve this problem, metal pipes are traditionally used. They have excellent performance characteristics. Despite the emergence of polymer analogues, metal structures do not lose their popularity. Because they can withstand high temperatures and have high strength.

Technical characteristics, advantages and disadvantages

The properties of steel products depend on many factors. These include the production method and the characteristics of the steel grade used. Products are divided into welded and seamless. The first type is connected by welding. The second option is produced using special machines.

The key advantages of the products are:

- Availability. The price of metal heating pipes is relatively low.

- High strength. Circuits with a significant internal pressure are constructed exclusively from steel channels.

- Good gas tightness. This indicator for the products in question is very high. It plays a vital role in the construction of the heating circuit.

- Low thermal expansion. Therefore, there is no need to use thick-walled structures to install a heating system.

- Significant thermal conductivity. The metal gives off a significant amount of heat to the environment. Therefore, using steel products it is possible to make a heating system even without the use of radiators.

Metal channels also have disadvantages. They must be taken into account when arranging pipelines.

The disadvantages of the products in question include:

- High electrical conductivity. This imposes certain restrictions when arranging a heating circuit based on an electric boiler.

- Considerable rigidity. Bending structures can only be done by exposure to high temperature. To install the system, you need to use special fittings.

- Heavy weight. This complicates the transportation and installation of structures.

- Low resistance to corrosion processes. To avoid problems caused by oxidation, it is advisable to use galvanized or stainless steel.

Black steel products

There are several types of metal channels.

They can be made from the following types of steel:

- black;

- stainless;

- galvanized.

Products made of black steel were in great demand in the second half of the last century. As a rule, water-gas electric-welded structures were used to create a heating circuit.

Their properties are regulated by the state. standard 3262-75.

Below you can see the table of pipe sizes.

Today, designs with a diameter from six to one hundred and fifty millimeters are popular. There are products with larger cross-sectional sizes.

The key disadvantage of products made of black steel is their poor resistance to corrosion processes. As a result of oxidation, rust flakes and various unwanted deposits appear inside the products. All this negatively affects channel capacity.

The cost of such structures is quite low. But the duration of their operation also leaves much to be desired.

Galvanized products are resistant to rust. Therefore, their service life is significantly longer than that of the previous type of product. Moreover, the zinc layer only slows down the oxidation processes.

Galvanized ducts have more acceptable characteristics for creating heating circuits. They withstand pressure changes and high temperatures. Ideal for creating a central heating circuit. To install autonomous systems based on gas boilers, it would be more reasonable to use structures made of polymer materials.

Galvanizing also has disadvantages. During welding work, the zinc layer is damaged. Therefore, rust will inevitably occur in this place, which will have an extremely negative impact on the operation of the entire system. In addition, galvanized channels have a higher cost than products made of black steel or polymers.

Stainless steel is one of the best options for arranging heating pipelines. Such designs are durable. They are highly resistant to oxidation processes and have a significant safety margin. The disadvantages include the complexity of installing such channels and the high cost.

Steel pipes

Until recently, steel pipes were at the peak of their demand. But today they have been replaced by polymer and PPR pipes. However, they are still used in heating systems and it would not be out of place to mention them.

Advantages of steel pipes:

- Good price-quality ratio

- Small linear expansion

- High strength

Disadvantages of steel pipes

- Labor-intensive installation. Welding machine required

- You cannot hide pipes in the wall. All work is carried out outdoors

- Massive and heavy. Quite difficult for one person to install

Using corrugation

Corrugated stainless steel structures are a good material for arranging heating systems in a private house or apartment. Products can have a diameter from fifteen to thirty-two millimeters. Corrugations with a larger cross-section can be made to order.

The products in question can withstand temperatures over a wide range. Corrugation can be used at temperatures from -40 to +800 degrees. It is obvious that these designs are not applicable in such conditions. Plastic fittings used during installation can withstand temperatures up to one hundred and ten degrees.

Corrugated structures are characterized by high resistance to physical damage and pressure changes. Such products can withstand exposure to up to fifty atmospheres. In this case, the operating pressure is fifteen atmospheres.

Please note that flexible products are completely oxygen impermeable. In this case, the value of the roughness coefficient is only 0.008. If you follow the rules for using these structures, their service life will be at least twenty years.

Using corrugation has a number of advantages.

These include:

- environmental friendliness of products;

- long service life;

- significant length of measured segments, allowing you to create long sections without fittings;

- slight noise;

- low weight;

- ease of installation;

- resistance to mold and fungi;

- excellent smoothness of the internal walls, ensuring high permeability of the channels;

- resistance to temperature and pressure changes;

- high anti-corrosion properties and inertness to chemicals;

- good heat dissipation;

- significant strength;

- ideal design flexibility.

Thanks to its excellent technical characteristics, corrugation is widely used in heating systems. However, it is worth remembering the disadvantages of the type of steel pipes under consideration. These include:

- the need to provide protection from electrochemical corrosion processes;

- the thinness of the design and its poor resistance to physical influences (you need to install a special protective box);

- high heat transfer rates;

- the ability to accumulate dirt in the recesses between the ribs of the corrugation;

- significant cost.

Criteria for choosing pipes for heating a private house.

Before you start choosing pipes, you should ask yourself a few questions:

- How the pipeline system will be installed - on the surface or inside.

- What will be the power of the generated pressure?

- The heating system will be autonomous or centralized.

- The circulation within the system will be forced or gravity.

- What maximum temperatures are possible?

- Equipment configuration.

After taking into account all of the above factors, you can begin to select pipe materials that are most suitable for your conditions.

Calculations

To create a heating system, you need to calculate the required power of the pipes. The reliability of the system will depend on this. It is important that during the winter season all rooms in a private house or apartment are heated evenly. This can be achieved by installing channels of sufficient diameter. To find out the required section size you need to use the following formula: D = sqrt ((314∙Q)/ (V∙DT)).

Below you will find out what these variables mean:

- sqrt – square root;

- DT is the temperature difference between the inlet and outlet;

- V is the speed of the carrier;

- Q—heat flow;

- D – internal diameter indicator.

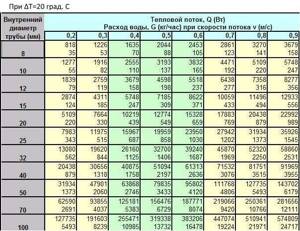

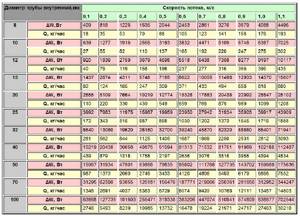

To simplify the calculations, you can use the corresponding table. It will save time .

How to calculate the cross-section of pipes for heat supply

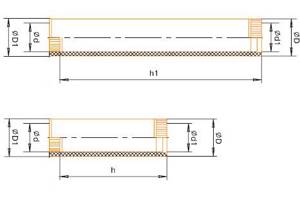

Before you begin to determine the diameter of the pipeline, it is worth understanding in detail the very concept of “diameter”. When applied to heating pipes, it is customary to talk about several interpretations of this term:

- External diameter. A parameter required when designing a system. It is made up of the internal diameter and wall thickness.

- Inner diameter. Determines the throughput of the pipeline.

- The nominal value of the pipe bore. An indicator used for labeling plastic products.

It is important! Marking of steel and cast iron pipes is established according to the internal section, copper and metal-plastic pipes - according to the external one.

Quite often, pipe diameters are indicated in inches. Converting them into millimeters that are more familiar to us is simple - one inch contains 25.4 mm.

Calculation of system thermal power

For small standard heating systems it is quite possible to do without complex calculations. Here it will be enough to follow a few simple rules:

- For circuits with natural circulation, the optimal pipe diameter will be 30-40 mm.

- In systems with forced circulation of coolant, pipes of a smaller diameter should be preferred. This will ensure optimal fluid flow speed and pressure.

If accurate calculations are required, you can call on ready-made special programs to help, or make calculations using formulas. First of all, the thermal power of the system is determined: Q = (V*∆t*K)*860.

- Q – thermal power, kW/h,

- V – volume of heated room, m3,

- ∆t – average temperature difference indoors and outdoors, ⁰С,

- K – heat loss coefficient,

- 860 – constant correction factor for converting calculated indicators into kW/h format.

All multipliers can be easily calculated with a reasonable degree of reliability. Only the determination of the K coefficient may raise some questions.

Its value depends on the level of thermal insulation of the house or room for which calculations are being made.

The numbers could be like this:

- K=3-4. A building with a minimum level of thermal insulation.

- K=2-2.9. Facade facing with brick.

- K=1-1.9. Average level of thermal insulation.

- K=0.6-0.9. High-quality insulation with modern materials.

We recommend that you read: How to repair hot water pipes using cold welding

After determining the thermal power of the heating system, you will need to use a special table to determine the diameter of the pipes.

Tables may vary depending on the type of pipe (polypropylene, steel, cast iron, copper, etc.) and even the manufacturer. It is more correct to take these tables directly from the websites of manufacturers. Most often, the table indicates the thermal power and the expected temperature delta. At the intersection of these parameters, the required pipe diameter will be indicated.

If you cannot find a table for a specific type of pipe, you can use the table of correspondence between different types of pipelines.

Here, for each pipe diameter (meaning the internal diameter), corresponding models made from other materials are described. Of course, there will be some error, but for small heating systems it is quite acceptable.

Speed of fluid movement in the system

The speed of movement of the coolant through the heating system determines the uniform distribution of thermal energy across all radiators or radiators.

The diameter of the pipe, meanwhile, has a direct impact on the speed of movement of the liquid - the smaller the cross-sectional area of the pipeline, the higher the speed (all other things being equal) the coolant will move through it.

When determining the diameter of the pipes, it is worth choosing the speed value so that it falls within the range:

- On the one hand, the water flow rate should not be too high. This, of course, will increase the efficiency of the system, but will invariably be accompanied by additional noise.

- On the other hand, at speeds below 0.3 m/s there will be large heat losses. In addition, low pressure will make air vents and Mayevsky taps useless, since air pockets simply will not reach these elements.

- The optimal speed value is considered to be in the range of 0.36-0.7 m/s.

Popular questions and answers to them

When installing heating systems, many people have typical questions.

Below we will answer the most popular of them:

- How to paint metal structures? To solve this problem, several types of paints are used: acrylic, alkyd enamel and water-dispersion. Each of the listed options is perfect for solving this problem.

- Should old Soviet pipes be replaced? If we are talking about black steel, then definitely. The service life of such structures is about twenty years. Accordingly, channels installed more than two decades ago need to be replaced with new ones.

- Plastic or metal products? If we are talking about creating an autonomous heating system in a private house or apartment, it is better to use polypropylene or metal-plastic channels. For central heating systems, metal must be used.

- What is the service life of iron structures? It all depends on the quality of the material. Black steel lasts up to twenty years. Galvanization can be used for thirty years. Stainless steel can last over fifty years.

Effect of characteristics on efficiency

A well-designed pipeline design has a positive effect on the performance of the heating system. The throughput of the structure depends on the cross-section of the components. The parameter shows the volume of hot liquid that will pass at a constant speed per unit of time.

Utility network performance is often influenced by factors. The efficiency of the circuit depends on 4 circumstances:

- Throughput and heat dissipation. The characteristic depends on the amount of water in the system.

- Pressure. The parameter in the heating network is associated with temperature and speed.

- Heat loss. At the joints and on the bends there will be a decrease in performance.

- Noise. The faster the fluid moves, the louder the sound.

In a heating system, with a constant flow of coolant and a decrease in diameter, the rate of water movement increases. On lines with a small cross-section, the fluid velocity will increase. Due to the low pressure in large structures, the flow rate is reduced.

Heat pipe diameterSource mastergrad.com

If the diameter of the pipes for heating a private house is too large, then the power of the pump built into the boiler will not be enough to move it. In a large system there will be a lot of coolant, so the equipment will not be able to cope with the movement of such a volume of liquid. Heating excess water will require spending more energy and time, which reduces the efficiency of the network and increases losses. As moisture passes through all rooms, it cools quickly.

The overall section is prohibited from being used in systems with natural circulation. When the speed is reduced, there is a risk of stopping and boiling the liquid in the heating boiler. With a small diameter, moisture can rupture the utility network.

What does the size of parts affect? Source ekaterinburg.kassot.com

When the speed decreases to 0.25 m/sec, air pockets often appear in the pipes. If the flow speed is more than 1.5 m/sec, then noise appears in the heating system. If the background noise standards are constantly exceeded, the inhabitants of the cottage will find it uncomfortable to live.

Installation of heating devicesSource realstroyservis24.ru

Briefly about the cost where to buy

The price of metal structures is indicated either per meter or per ton. Be sure to pay attention to this point. The cost of metal channels varies over a very wide range. The price depends on the quality of the material, production technology, wall thickness and other properties of the product.

Structures made of black steel are the cheapest. Next comes galvanization, which costs a little more. Stainless steel is the most expensive. However, as you have already learned, pipes made from it are the most reliable. Corrugated stainless steel channels are the most expensive.

The easiest way to order the products in question is from companies specializing in the sale of rolled metal products. It is advisable to deal with structural manufacturers or their official dealers. This will allow you to purchase the products you need at an affordable price.

In some cases, it makes sense to buy used pipes. The main thing is that they are in good condition. When purchasing, be sure to ask for a certificate of conformity. This will allow you to avoid purchasing inferior products.

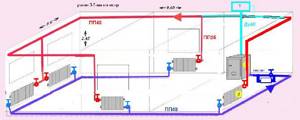

Single pipe system

A similar circuit diagram is mounted from series-connected heating devices. The liquid passes through each element of the system in turn, heating them a little at a time; because of this, it reaches the outer section with a slightly lower temperature. If the last radiator in the circuit has more sections, this will not have a negative impact on the indoor temperature.

Now there are technologies that help improve the functioning of a single-pipe heating circuit, these are the presence of:

- on batteries of special regulators;

- valves for balancing the incoming liquid;

- thermostatic or ball valves.

Such equipment is used to maintain the required temperature in the room.

Separate heating is often installed; its installation is carried out according to the following schemes:

- horizontal, with a pump, it distils the coolant using the injection method, ensuring its circulation;

- vertical - liquid flows naturally in it;

- vertical, using the injection method, with natural distillation or a combined type.

A horizontal system, so that hot water flows naturally, is constructed at a slight slope. Radiators are installed at the same level. Radiators must be equipped with air bleed valves. A pump is not installed in this line, because the coolant flows naturally.

Installation and fastening

There are two methods of installing metal structures: welding and connection using fittings. Each of them has its own characteristics. Also, when installing heating systems with your own hands, it is important to correctly wire the radiators. This operation must be performed in stages, following the technology. Do not forget about the correct fastening of metal pipes to the wall.

To create bends and turns of the contour, it is better to use the appropriate shaped parts. It is not recommended to bend metal structures by welding. During this operation, the channel performance may deteriorate.

The combination of metal and plastic products also has its own characteristics. Below we will talk about this in more detail.

Welding

Traditionally, electric welding was used to connect metal channels. This operation allows you to reliably connect two products together. The quality of its implementation must be extremely high. The performance of the entire circuit depends on how well the joint is made. If the welding was done poorly, a leak may occur in the near future.

Connections by welding can be made:

- in the corner;

- end-to-end;

- vtavr;

- overlap

Note that when installing heating ducts, butt welding is predominantly used. This method allows you to create the most reliable joint. Therefore, always connect products exclusively end-to-end.

Connection of metal and plastic pipes

Structures made of steel and polymers are joined in two ways.

Combinations of products from different materials can be:

- Rezbovym.

- Flange.

For joining small structures, a threaded connection is most often used. For this purpose, special shaped parts are used, which consist of two parts. The first is a metal thread, and the second is a plastic coupling. In this way, a transition is made from one pipe to another. The joining method is suitable for channels with a cross-sectional size of up to forty millimeters.

The flange connection is permanent. It is used for large diameter structures. This connection allows you to quickly assemble or disassemble any section of the pipeline. The joining of metal-plastic or plastic structures to steel ones is carried out using special components - flanges.

Installation of the system using gas welding

Gas welding is a method in which the ends of pipes are heated with an oxygen gas flame, the process is accompanied by filling the gap with molten metal. The mechanical parameters of gas welding compared to electric welding may differ slightly for the worse, but this technique allows you to connect pipes with thin walls (up to 3.5 mm thick), which is the main advantage of the method. The welding process uses oxygen and acetylene, the first element is designed to support the combustion of the second.

Video instructions for working with steel pipes: