Good day, dear reader! Due to its inherent shortcomings, rolled metal pipes have been used less and less in recent decades for wiring the heating systems of private houses and other buildings. Metal-plastic pipes for heating, thanks to the unique structure of the wall, are completely devoid of the weaknesses of metal products. They have anti-corrosion properties, a combination of flexibility with high strength.

Technical characteristics of MP pipes

The general technical characteristics of metal-plastic pipes, regardless of their manufacturer and geometric parameters, are:

- The permissible bending radius using the manual method is in the range from 80 to 550 mm, using a pipe bender - 50-180 mm.

- The maximum pressure level in the pipeline is 10 Bar at an ambient temperature of 95 degrees, 20 Bar at 20 degrees, the destructive pressure will be 80-94 Bar.

- The coefficient of thermal expansion is 0.026 mm/m per 1 ºC.

- Thermal conductivity coefficient is 0.45 W/mK.

Structural properties

MP pipes receive different properties depending on the barrier layer manufacturing technology used:

- Made from sheet aluminum foil. During production, an aluminum billet is welded into a metal-plastic pipe using ultrasonic welding. It is connected to layers of cross-linked polyethylene with adhesive layers. Products reinforced in this way have greater flexibility, but less strength and a small range of permissible operating temperatures.

- In the form of a rigid mesh frame welded from steel wire or strip. The metal frame is poured into the molten plastic of the inner layer, and then filled with molten plastic of the outer layer. With this manufacturing technology, there is no need to use adhesive compounds for gluing layers, which has a positive effect on the strength characteristics of products and the length of their service life.

Working temperature

Metal-plastic pipelines can be used at a constant temperature of the coolant in the heating system up to +95 ºC and for a short time at +110 ºC. Freezing of the working environment begins at -40 ºС.

Life time

Manufacturers usually indicate the service life of metal-plastic pipes for heating at an ambient temperature of +20 ºC is at least 50 years, at a temperature of +95 ºC - about 25 years.

In practice, durability is also influenced by the accuracy of compliance with established norms and rules when installing a heating system, and the conditions of its further operation.

Criteria for choosing between metal-plastic and polypropylene

Polypropylene pipes differ from metal-plastic pipes in that the former do not have an internal aluminum layer.

Comparative characteristics:

- Permissible temperature: polypropylene – 95 °C, metal-plastic – 110 °C.

- Technical characteristics: polypropylene is difficult to bend, metal-plastic is easy to bend.

- Transportation conditions for metal-plastic are more practical due to the fact that they can be compactly placed in a small place.

- The price of fittings and connecting parts for polypropylene is cheaper.

- Both products can withstand pressure up to 25-40 atmospheres, depending on the marking and purpose.

- For fastening to each other, polypropylene options involve installation with crimp couplings or press fittings; for metal-plastic, soldering couplings are also used.

The choice of pipes for water supply depends on several factors, including the type of room, as well as the terrain. Metal-plastic products are popular among buyers today. Due to the abundance of manufacturers, fasteners, couplings and pipe diameters made from such material, they are used for all sorts of purposes. The main thing is to decide on the technical characteristics.

Design Features

Metal-plastic pipes are made of composite material and have a five-layer wall structure, where the inner and outer layers are polymer, an adhesive mass is used as two connecting layers, and the barrier layer is made of aluminum foil.

Aluminum layer thickness and connection method

The thickness of aluminum foil is usually 0.15-0.6 mm. The best option for arranging heating systems are metal-plastic pipes with a reinforcing layer thickness in the range of 0.3-0.55 mm. They have sufficient flexibility and strength.

In the production of metal-plastic pipes, laser or ultrasonic welding is used to join aluminum.

The joint is performed in one of the following ways:

- Overlapping. In the finished product, a seam is formed at the weld joint, therefore, in order to maintain the evenness of the surface, manufacturers reduce the thickness of the foil, compensating for the thickening.

- Butt. The edges of the aluminum foil fit tightly to each other and are connected without any thickening. The walls of the reinforcing layer are perfectly smooth along the entire length of the pipe.

Type of plastic in the inner and outer layer

To make the outer and inner layers in high-quality metal-plastic pipes for heating, the following types of plastic are used:

. During production, special crosslinking additives are introduced into the raw materials, giving the material improved mechanical characteristics and resistance to pressure and temperature changes.

. It has a unique molecular structure that allows this material to achieve high impact resistance, resistance to cracking during bending, and heat resistance over a wide range of operating temperatures (from -50 ºC to +95 ºC).

Products that use varieties of low-density polyethylene PEHD, PE-RS, PE and HDPE for the same purposes can be operated at temperatures not exceeding +75 ºС. When the parameters are exceeded, the plasticity and fluidity of plastics increases, which can lead to loss of integrity of metal-plastic heating pipes. In addition, products made from low-density polyethylene wear out quickly when exposed to ultraviolet rays, so they need to be insulated.

Bonding layer

Plastic and metal are combined with special compounds, the properties of which make it possible to combine layers of different materials into a single structure. The proportions of components in the composition of each company may vary, but the requirements for glue for safety for human health are strictly observed.

Adhesive layers not only act as a binding material, but are also responsible for the elasticity of metal-plastic heating pipes. When the glue loses its elasticity, the product delaminates and leaks occur. Therefore, when choosing such pipe products for heating, it is necessary to check the cut for the absence of delamination. The presence of delamination is a prerequisite that the heating system wiring assembled from such pipes will quickly fail.

Plumbing solution

There are no restrictions in terms of choosing metal-plastic pipes for water supply. But if you need to supply warm water, you should give preference to the linear version made of cross-linked polyethylene. Pipe marking is of particular importance. The type of material, operating pressure, product lot number and the name of the manufacturing plant should be displayed here. Before purchasing material, you need to find out what pressure indicators may exist for the water supply in the apartment.

In such a situation, water is used, which will also be used for drinking, so the material must be absolutely safe. This will be confirmed by certificates of compliance with hygienic standards.

The presence of foreign inclusions in the structure, as well as dents and scratches, is unacceptable.

Materials used to make pipes

Modern heating systems are assembled using pipes made of different materials:

- Carbon steel.

- Copper.

- Stainless steel.

- Metal plastic.

- Polypropylene.

The last two materials are relatively new. Here are their features.

Metal-plastic

Metal-plastic is a construction material consisting of a steel strip coated on both sides with a polymer film.

It has properties inherent in both plastics and metals. Metal-plastic is plastic, suitable for processing on mechanisms that produce pipe products.

Polypropylene

Polypropylene is a chemical compound developed specifically for the manufacture of plumbing products. It is light, elastic, durable, absolutely not subject to corrosion, frost-resistant, and inert towards chemically active substances.

Types of chimneys

The modern range of smoke exhaust pipes is pleasing to the eye. This includes expensive smoke structures made of ceramics (usually used for baths), and steel and thermoplastic products. However, stainless steel pipes are considered the most reliable today - they can withstand heating up to +600°C. Due to the perfect fit, the entire structure made of this material is sealed, so there is almost no soot and condensation formed here.

But ceramic products, on the contrary, are used quite rarely, since they have a considerable weight, which can only be supported by a massive stationary stove used to heat a residential building.

When building a summer house, a country house or carrying out renovations in an apartment, special attention must be paid to the arrangement of communication structures: water supply, gas pipeline, sewerage. For each type of communications, a certain type of pipe is suitable, differing in characteristics and service life

General requirements for the operation of pipeline systems

During operation of pipe products made of metal-plastic, the following requirements must be observed:

- Heat sources with a heating temperature higher than +150 ºC should not be placed in close proximity to metal-plastic heating pipes.

- In case of fire, use sand to extinguish.

- Periodically inspect the joints of parts and, if necessary, tighten detachable connections.

- Do not use metal-plastic pipes for external communications; system wiring in unheated rooms must be protected from heat loss.

Types of drainpipes and ways to combat their icing

The peculiarity of using metal-plastic products for laying water pipes is the ability to adapt to the angles and unevenness of the base of the walls.

However, if such a product is used for external water supply, it is worth remembering the ability of the liquid to freeze at low temperatures.

To prevent icing, you need to consider the following points:

- laying in the ground is carried out below the freezing level - approximately 1.2-2 meters;

- water pipes passing through beams, concrete barriers or foundations will freeze. Additional insulation is required.

- pipes smaller than 50 mm in diameter cannot be used;

- if the pipeline operates irregularly (at a dacha), the water is drained during the absence of residents;

- In severe frosts, it is also recommended to drain the water overnight.

Freezing of metal-plastic pipes does not cause their deformation if during installation work the labeling rules for the product used were followed. There are separate classifications of pipes for water supply inside and outside buildings.

Is it possible to use metal-plastic pipes for heating?

It is possible, since MP heating pipes can withstand higher temperatures compared to conventional polymer products, they are much more convenient to install and look more aesthetically pleasing. The presence of a metal layer in the material provides them with high oxygen impermeability, which reduces the risk of corrosion of other metal parts in the heating system.

Preparatory work and accessories

The set of tools for installing a water supply system is minimal:

- Calibrator - to give the pipe an even shape and edge;

- Drill, hammer drill;

- Scissors designed for cutting metal;

- Adjustable wrench, pliers;

- A spring for bending without damage, or a pipe bender. This device must be purchased, since bending the pipes manually may cause the pipe to burst. Aluminum is very brittle;

- Valves;

- Roulette.

For convenience and clarity, it is better to depict a diagram of the passage of pipes. We draw a floor plan for the bathroom, toilet and kitchen. We make duplicate wiring for the faucets - for hot and cold water, while the toilet and washing machine are content with cold water. The diameter of the water pipe is 16 or 20 mm.

Fittings for metal-plastic pipes

Advantages and disadvantages

Metal-plastic pipes have the following advantages:

- Absolute corrosion resistance.

- Immunity to aggressive chemicals.

- High throughput. MP pipes for heating have smooth walls on the inside, which offer little resistance to the flow of the internal environment.

- Low electrical conductivity.

- Wear resistance of internal surfaces.

- High ring rigidity.

- Low thermal conductivity coefficient.

- Resistant to silting and water stone formation.

- Low specific weight, facilitating transportation and installation of pipe products.

- Higher strength than plastic counterparts under tensile, lateral and impact loads.

- Bacteriological resistance. Metal-plastic successfully resists the formation and development of mold, as well as fungal deposits dangerous to health inside communications.

- Easy to install Heating systems made from such products are easily assembled using fittings without the use of welding equipment.

- Good flexibility, allowing to reduce the number of connecting parts.

- More affordable price compared to the cost of pipes made of cast iron or copper.

- Aesthetic appearance - no need for painting.

The disadvantages include:

- There is a danger of leaks at the joints of parts that occur during temperature changes due to different linear expansion coefficients of plastic and metal interlayers. To avoid such situations, heating pipes are laid with a small allowance, and compensation loops are installed at bending points.

- Low frost resistance. External lines of heating systems must be thermally insulated, since frozen water can rupture MP pipes.

- Instability to ultraviolet radiation, therefore metal-plastic products cannot be laid in places where there is a danger of direct sunlight on their surface.

- High cost of connecting parts (compared to polypropylene pipelines).

- Risk of fatigue damage after several bends.

Production of modern pipes

Metal-plastic pipes consist of a two-layer molecularly cross-linked polypropylene called PE-X. A thin aluminum substrate is laid between it. All three layers are connected using a specially developed adhesive composition. Each manufacturer strives to use its own individual adhesive composition.

Aluminum gives the pipes strength, and thanks to propylene, you can bend such plumbing equipment at an angle without much effort. Aluminum tape of minimal thickness is made of two semicircular fragments. They are connected end-to-end or overlapped with each other. For reliable adhesion, welding is used using ultrasound. After this procedure, layers of polypropylene with an adhesive composition are applied on the outside and inside.

After reliable coupling, the pipes must be marked and coiled for ease of transportation. It is in this form that they arrive in stores.

Which heating pipes are better - metal-plastic or polypropylene?

On construction forums there is often a debate about which pipes are better for heating - polypropylene or metal-plastic.

When comparing the complexity of installation work, the cost of components, resistance to the influence of external and internal conditions on the durability of the system, you can choose a more suitable material for organizing heating:

- Installation methods. The joining of parts made of polypropylene is carried out mainly by soldering, but to form a contour from metal-plastic products, fittings are needed. There are never leaks in soldered joints, but connections using fittings are less reliable and can leak due to differences. Therefore, it is not advisable to hide metal-plastic in the wall.

- Flexibility. Metal-plastic pipes easily bend in any direction, which is impossible to do with rigid polypropylene products. With a complex configuration of the heating system and installation of its elements in hard-to-reach places, it is much more difficult to form a polypropylene turn.

- Coolant temperature. The favorable temperature regime for the operation of polypropylene products is up to 75 ºC, while metal-plastic can function at +95 ºC and can withstand +95 ºC for a short time.

- Cost of components. Polypropylene is approximately 2 times cheaper than metal-plastic, the difference in price is especially noticeable for connecting parts.

Polypropylene

.

Low heat loss compared to metal-plastic. The disadvantage of using pipes for heating is that polypropylene is a porous structure. The material from which the pipe is made gradually allows oxygen to pass through. The pipe seems to breathe, saturating the liquid with oxygen. As a result, closed heating systems need to be topped up. However, since it is periodically necessary to change the coolant in the heating system, this minus turns into a plus. This is a plus for the water supply - because such water in the pipes will always be saturated with oxygen, which prevents the effect of souring and unpleasant odors. Compared to other types of pipes, polypropylene pipes have a fairly significant thermal elongation. What is detrimental to the rigid fixation of the pipe. When assembling water supply or heating from polypropylene, it is necessary to provide for the fact of pipe movement. For example, expansion compensators are always installed at distances of more than 10 meters. They look like rings that dampen the flow of the pipe and prevent it from breaking. One of the facts of polypropylene pipes

is its softness when heated.

Thus, all polypropylene pipes are limited to a maximum temperature of 90-95 degrees Celsius. Also, when heated to 70 degrees Celsius, the pipe will sag in large areas, so it is recommended to fasten it every 50cm. Note that an aluminum-reinforced pipe is free from the sagging effect, but retains the same elongation properties as a conventional non-reinforced pipe. A pipe reinforced with glass fiber also has longitudinal elongation, but much less than without reinforcement. It doesn't sag as much anymore. It is the best option between a pipe without reinforcement and a pipe with aluminum reinforcement. Why is that? The fact is that an aluminum-reinforced pipe cannot be found everywhere, and it is bad to place it in hot water without reinforcement, since the elongation of such a pipe will be approximately 10 cm by 1 meter at a temperature of 75-80 degrees Celsius. Fittings for polypropylene

come in different modifications. For example, a “five-piece” is used for a two-pipe installation. For such a gasket there are special double fastening clips. Couplings and tees with transition to metal connections. Collar for connecting polypropylene water supply to metal flange connections. Clamps for water meters. In a word, the variety is great, due to the widespread use of polypropylene for water supply and heating.

Unlike metal

-

polypropylene

becomes brittle at low temperatures and is also susceptible to rupture. Due to the elasticity of the walls, frozen liquid does not deform the pipe, which reduces the likelihood of pipe rupture, unlike the same metal pipe.

Selecting a heating scheme

The choice of a heating scheme where MP pipes are used is based on factors such as:

- Type of heating device and its location.

- Electrical connection.

- Number of floors, building dimensions and layout features.

- Water supply entry point.

- Coolant circulation method (natural or forced circulation type).

From the point of view of pipe routing, heating schemes are classified into:

- Single-pipe - effective for small building areas.

- Two-pipe - two pipes are connected to each radiator (supply and return risers). The heated coolant, under the action of the pump, moves from the boiler to the battery, where it gradually cools. The cooled liquid returns to the boiler through a separate riser (return), no longer coming into contact with the heated coolant.

- With bottom or internal wiring.

- Collector. They are expensive in terms of the amount of material, but they allow you to regulate the heating temperature of each element individually.

- With floor-to-floor wiring and others.

How to determine the required pipe size

In apartments, risers are usually made with a diameter of 25 mm, and intra-apartment wiring is 20 mm. In private houses - the supply from the main line is 25 mm (occasionally 32 mm), the wiring is 20 mm.

It all depends on the number of water points, the number of residents and the number of floors. If you have a house with an area of more than 300 m² and more than four bathrooms, you should contact plumbing designers. Diameters are external.

Tips for choosing

The best models of metal-plastic pipes for assembling heating systems will be products that have:

- The connection of the aluminum barrier layer is made by butt welding.

- The foil layer has a thickness ranging from 0.3 to 0.6 mm.

- The inner and outer layers are made of PEX or PE-RT polyethylene; other types of plastic reduce the durability of the products.

- There is no delamination at the pipe cut.

Diameter

Pipes with an outer diameter of 26 mm, an inner diameter of 20 mm and a wall thickness of 3 mm (26x20x3) are suitable for arranging heating systems in private houses working with low-pressure flows, as well as heated floors.

In individual heating systems and utility networks for industrial use with an increased level of medium pressure, it is necessary to install pipes with a higher throughput - 40x32x3.9 mm.

How not to buy a fake

Unfortunately, not only high-quality but also counterfeit products are sold on the building materials market. In order not to buy a fake, you need to first select a well-known manufacturer and study information about the features of the products they produce, namely:

- The color of the outer and inner layer of polymer material.

- Texture (smooth or rough).

- Range of diameters.

- Product brand.

- Type of marking.

You should only make a purchase in a specialized store, where you can view the certificate and inspect the product for compliance with the specified criteria. Often, just by the external signs and clarity of the markings, you can identify a fake.

You should pay attention to the cut of the pipe. Most large companies weld the barrier layer end-to-end; an overlap joint is a characteristic feature of low-quality products. The thickness of the layers should be the same along the entire length of the metal-plastic heating pipe, and the inner surface should be even and smooth.

Area of use

Metal-plastic pipes are used in various areas of industrial and civil construction. They are reliable, which is why they are used when installing water supply systems in private households and apartments. They are also suitable for:

- heating systems;

- arrangement of wells and wells;

- organizing watering of plants.

Pipes can be used when laying sewer systems and for supplying compressed air. Installation of these products does not require welding, so their installation is carried out in areas where welding work is prohibited. These materials are not suitable for rooms where powerful heating systems are located.

Main manufacturers

The largest European manufacturing companies producing metal-plastic pipes for heating and components for them are:

- Italian. Valtec pipes (PEX/AL/PEX) use granulated high-pressure polyethylene with a cross-linking degree of 65% for the manufacture of internal and external layers, which gives them strength and ductility in an optimal ratio.

- Belgian. For the manufacture of the inner and outer layers, cross-linked polyethylene PE-Xc is used, the reinforcing layer is made of aluminum foil with a thickness of 0.4 mm and is connected in a butt manner. Two connecting layers - special glue. The operating temperature of metal-plastic products is 95 ºC; short-term operation is allowed at 110 degrees.

- Oventor (Germany) is a manufacturer with extensive experience, producing about 400 types of products for the installation of engineering communications for any purpose.

Not inferior in quality to Russian products. Their Classic metal-plastic heating pipes are in great demand among consumers, as they are produced in compliance with technical and hygienic standards, have high strength and reliability, bend well and are easy to install.

Marking of metal-plastic pipes

The marking of metal-plastic pipes from different manufacturers may differ in the sequence of marking code values. Often it has the following sequence:

- Name of the pipe manufacturing company.

- Certificate of conformity according to which the pipe was manufactured.

- Design characteristics.

- Diametrical characteristics, wall thickness. Designations are given in millimeters.

- Nominal pressure value. The indicated value is the water pressure in a metal-plastic pipe at an ambient temperature of 20°C.

- Designation of a medium that is suitable for transportation.

- Date with batch number.

Design characteristics include pipe material and stitching method. The material is designated as follows: PP-R – polypropylene; PE-R – polyethylene, PE-X – cross-linked polyethylene. The method of cross-linking is indicated in the marking by the following letters: a – pyroxide method; b – using silane; c – using a flow of electrons; d – azo compound of molecules.

Important! When laying pipes, markings must be left visible to the user so that they know which pipes have been used.

The marking is applied after a certain, very short interval, so that the information is preserved even on small sections of pipes.

Selection of fittings

The heating system can have different configurations and includes many components: boiler, radiators, shut-off and control valves, etc. All of them are combined into a single structure using pipes of different diameters.

Fittings are used as connecting elements. There are several types of them for metal-plastic:

- Detachable.

- Compression.

- Crimping.

- Press fittings.

Detachable

Detachable are the connecting pipeline parts that, if necessary, can be repeatedly disassembled and reassembled.

These include collet and threaded fittings:

- Tees.

- Crosses.

- Corners.

- Adapters, etc.

To ensure the tightness of connections with threaded type fittings, flax strands or FUM tape are used; in collet parts, this function is performed by a sealing ring - collet. It is installed as follows: a nut is put on the calibrated mounting end of the metal-plastic heating pipe, then a collet, after which the housing is pushed all the way. Next, an o-ring is threaded onto the outlet pipe of the housing, which is pressed with a nut. It is tightened first with your hands and then with a wrench.

If the nut is not tightened enough, then leaks are possible at the connection point, but even with excessive force, the nut can be overtightened and damaged. In addition, such a fitting cannot be embedded in a wall, since during prolonged use the nut may become loose and will have to be tightened.

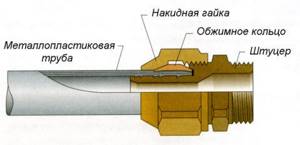

Compression

This type of connecting elements consists of:

- Union nut.

- Fitting.

- Cut ferrule ring.

During installation, the nut and cut ring are removed from the fitting and placed on the end of the pipe. Then lubricate the fitting with silicone grease and insert it into the metal-plastic pipe. The connection is tightened using a nut by hand and a wrench.

Press fittings

Press fittings form permanent connections. They are installed using special tools:

- Hydraulic press machines with microprocessor control.

- Manual press pliers.

This method of joining parts is highly durable and reliable, so it can be used for laying heating lines in concrete structures.

Components for press connection pipelines are of the following types:

- Tees are transitional and with fastening.

- Couplings.

- Squares.

Crimping

The design of the fitting that forms a rigid crimp connection includes the following elements:

- Union.

- Crimp coupling.

- Dielectric gasket.

The coupling can be made of brass or steel; it is pressed around the pipe using press pliers, eliminating leaks. The dielectric gasket prevents charge from accumulating due to the potential difference between the plastic of the top layer of the metal-plastic pipe and the brass.

Installation and connection technology

Fastening metal-plastic pipes during the installation process is carried out using several methods. They connect the pipes with their own hands using fittings. If soldering is involved, then you cannot do without skills and specialized equipment. Sequence of actions:

- The shaped part is selected - fittings, couplings, adapters, corners. More often the diameter does not exceed 25-40 cm.

- The area at the entrance to the pipe is cleaned.

- The shaped parts and the pipe are heated by slightly turning both sides.

- The connection is made on a special machine with an overlap or butt.

- Two heated pipes are inserted into one fitting.

Features of movable and fixed supports for pipelines

If the water supply is being installed in a domestic environment, fasteners with holders (double or single) are used.

They are attached to a solid base and fix the pipes in a stationary position. The use of such supports eliminates the possibility of the pipeline shifting in any position - vertically or horizontally.

Sliding support for pipelines is used when laying communications above ground (external method). The function of the device is to ensure free movement of the pipeline horizontally and vertically. An auxiliary function is considered to be protection of the pipeline from abrasion.

DIY installation features

Do-it-yourself heating system installation begins with installing the boiler. If it is gas, then it must be installed by qualified workers of the relevant services.

The next stage will be the installation of radiators, heated towel rails and other elements of the heating system. Metal-plastic or cast-iron radiators are hung on the walls using special brackets. Under them, holes are drilled in the walls into which anchor bolts are screwed.

After this, you can proceed directly to laying the pipes.

Necessary tools and components

To assemble a heating system circuit with your own hands, you need to prepare in advance a set of tools consisting of:

- Pipe bender - to create an even cut line without burrs, scuffs or damage to the protective coating.

- Calibrator and chamfer - tools to ensure cutting of the desired shape and flaring of the pipe without deformation of the seals.

- Open-end or adjustable wrenches. For tightening threaded, compression and push-in fittings.

- Crimping pliers. For making connections with press fittings.

- Electric tool.

It is also necessary, according to the project, to prepare a sufficient number of fittings, fasteners (clamps and clips), shut-off and control valves.

Connection methods

It is better to connect the parts of the heating system in one of the following ways:

- Compression fittings - when the gasket is open.

- Press fittings or crimp couplings - for hidden installation.

How to bend a pipe

In places where the metal-plastic pipeline changes its direction, fittings can be installed, but such a technique will increase the cost of the structure.

It is more economical to simply bend the pipe in one direction or another with your hands or use an external or internal mandrel in the form of a spring, a hair dryer, or a pipe bender for these purposes. In this case, the bending radius should not be less than a value equal to 7 diameters of the connected product. If this parameter is less, you need to install an angle fitting.

How to connect metal-plastic pipes with metal ones

To connect to metal pipes or to the outlet pipes of a water heating device, a special coupling with one threaded type connecting pipe is used. This fitting is initially screwed onto the mounting end of a metal part equipped with an external thread.

The joint is sealed with tow and paint.

The other side of the coupling, where the metal-plastic pipe is connected, may have a sliding washer or a press fitting.

About installation errors

Let's think about why a metal-plastic pipe for water supply leaks. The reason lies solely and exclusively in gross installation errors.

How to

A compression fitting for metal-plastic is a herringbone fitting with one or two rubber O-rings seated in grooves. It is these rubber rings that must ensure the sealing of the connection. The shape of the fitting is intended only to ensure reliable fixation of the pipe crimped with a split ring.

Compression fitting device

Rubber O-rings provide sealing

Here are step-by-step instructions for installing the connection yourself:

| Image | Description of the work stage |

Roller pipe cutter for metal-plastic | Cut the pipe to size using a pipe cutter. A specialized tool for metal-plastic makes the cut perfectly even and strictly perpendicular to the longitudinal axis of the pipe. |

Fitting calibration | Calibrate the end of the pipe using a hand calibrator. Small diameter pipes are usually supplied in coils, and after unwinding they retain an oval cross-section. The calibration makes it perfectly round. |

Manual calibrator with chamfering knives | Remove the internal chamfer at the end of the pipe. The chamfer will allow it to fit onto the fitting without moving the O-ring on its fitting. Calibrators for metal-plastic materials are often equipped with chamfering knives. |

Silicone Release Grease | Apply a little neutral lubricant (silicone, liquid soap, etc.) to the fitting nipple. Do not use petroleum-based fuels and lubricants as a lubricant: the O-rings may crack over time. |

Assembling the fitting connection | Using a forward movement, slide the pipe with the union nut and split ring onto the fitting fitting and tighten the nut with moderate force. In this case, the fitting body must be held with a second key, which will prevent it from turning. |

How they do it

Now let’s remember how newcomers to the field of installing these pipes assemble heating and water supply from metal-plastic.

- For cutting, a hacksaw is usually used. The cut is only very approximately perpendicular to the axis of the pipe;

- No one removes the chamfer at the end. Moreover, even burrs from cutting are not always removed from the inner surface of the pipe;

- Calibration? No, we haven't heard. There is definitely no calibrator in the arsenal of a novice master. The oval pipe is pulled onto the fitting with force and tightened until it stops with a nut with a split ring.

The result fully corresponds to the efforts expended:

- An oval pipe with an oblique cut and an uncleaned chamfer pulled over the fitting pulls the O-rings out of the grooves and moves them towards the fitting body. In this case, the sealing rings often break (the edge of the pipe, as we remember, is uneven and has burrs);

- When tightening the union nut, the split ring compresses the pipe onto the fitting, ensuring sealing of the connection due to deformation of its inner shell;

- When heated to 70-80 degrees or more, softened polyethylene is squeezed out of the gap between the fitting and the core;

Polyethylene melts at +120 degrees, but it begins to soften already at 80 °C

- With subsequent cooling and the accompanying compression of all parts involved in the connection, the fitting leaks.

Sometimes, after two or three tightenings of the union nut, the connection can be sealed by crimping the fitting with a soft aluminum core. In this case, the polyethylene is completely squeezed out from under the core, leaving it defenseless against electrochemical corrosion. More often than not, small irregularities on the surface of the core and fitting interfere with sealing, and the connection continues to leak.

Irregularities and scratches on the fitting may interfere with sealing