When installing space heating systems, along with determining the type of radiators, boilers, circulation (forced, natural), wiring diagrams, it is important to think about which pipes to choose for heating. If you clearly and correctly approach this issue - find out the pros and cons, permissible pressure and temperature for each type of product, then a suitable thermal regime and operating efficiency of the system will be ensured for many years. The required distance between the pipes and the heating scheme itself (two-pipe or single-pipe), what elements are needed for each one and how to use them correctly are also important. For a newly constructed building, it is important to find out what the features of laying heating pipes underground are.

There are a lot of heating pipes, but you need to choose them depending on the type of heating

Rules for arranging a heating system

The type of heat source that is located in the house affects the choice of pipe that will be used for the heating system. If the house is gasified, then it is assumed that a gas boiler will be used. It is usually equipped with:

- security elements;

- built-in automation;

- pumps.

If it is not possible to install gas equipment, then an electric or solid fuel boiler is selected. When arranging and installing a room heating system, you must adhere to the following rules:

- In heating systems, different types of pipes can be combined. When choosing which type of heating to use, you should pay attention to their labeling. This information will give you an idea of how the pipes differ from each other.

- Typically, when two-pipe wiring systems with natural (forced) circulation, a metal-plastic heating pipe (16x2.0) is used.

- With a building area of, for example, 100 m2, the length of the pipeline that supplies water to the radiators from the gas boiler should be less than 25 m.

- If it is necessary to connect a large number of radiators, double-circuit wiring is used, and the pipe for organizing heating must have a large diameter.

- It is also necessary to remove the gas heating pipe outside to exhaust and remove combustion products.

- It is prohibited to install any shut-off valves between the security system and the heating boiler (for example, gas type).

- During installation, the specified distance between communications must be observed.

The choice of heating pipes depends on the type of heating boiler

In a network with forced circulation, it is better to place a filter in front of the pump. To obtain a complete and more beautiful look, it is practiced to use contours for heating pipes under the laminate.

Radiators for heating

There are no problems with the radiators. The only thing I would point out is that when you buy radiators and want to hide the heating pipes in the floor, make sure that the supply and return connectors are located at the bottom.

All connection points in radiators must be sealed during installation. This is done using ordinary flax tow. Until now, no technological tricks can replace it.

Features of networks with natural (forced) circulation

The solution to issues related to coolant circulation also determines which heating pipe is best to choose. Pipeline diagrams suggest one of two different movement options:

- with forced circulation;

- with natural circulation.

In the first option, the system is equipped with a pump that pumps water. In the second case, the coolant moves due to natural convection. In this case, no additional costs are required to create circulation and the system can function only thanks to the heat from the gas boiler.

Note! A scheme with natural circulation requires complex hydraulic calculations, maintaining the distance between heating pipes and slopes.

Forced circulation systems allow you to increase pressure, increasing the efficiency and operating efficiency of a gas boiler. Their functionality is not affected by the temperature of the water in the heating pipe, the length of communications, or significant differences in level.

A more efficient heating system is considered to be a forced one, in which a circulation pump is responsible for the movement of the coolant.

If with natural circulation you can create a pressure of no more than 1.5-2 bar, then with forced circulation - 2-4 atm.

Heating wiring diagram in the apartment

Relocating heating radiators is a complex process, not in terms of installation, but in obtaining special permission for this and approval of technical documentation. Therefore, we will consider a heating scheme when the radiators remain in their same places.

To put it simply, the entire system remains in its same place, only you can change the distribution of the pipes a little by hiding them under the floor. If you approach this issue professionally, then it is necessary to install two ball valves before and after each battery. If suddenly your radiator leaks, then with the help of these taps you can shut off the water supply to the leaking radiator, thereby the rest of the system remains fully operational.

If you chose steel pipes and the radiators themselves are made of aluminum, then be sure to make propylene inserts, as shown in the picture. This will give a chance to avoid corrosion of the two metals.

Requirements for pipes for heating systems

Undoubtedly, heating pipes play a decisive role in maintaining the integrity of systems. They ensure the delivery of hot water from the gas boiler to the battery complex. The most important requirement for a pipe is that it must be durable and it is good if this characteristic is maintained throughout its entire service life.

Heating pipes (smooth or flexible) should not be oxygen-permeable, as otherwise the systems may rust from the inside. This leads to clogging and overgrowing of pipes, which reduces the productivity of the network as a whole.

The optimal thermal regime and its maintenance depend on the tightness of the systems. The reliability of the heating pipe prevents water from leaving the circuit and damaging nearby elements and equipment. Strength characteristics, permissible temperature, and pressure are determined by the material used to manufacture the products.

The aesthetic appearance of heating pipes is very important if it is not possible to lay the system hidden

An equally significant requirement for heating from pipes is its low noise level. A properly organized system is the key to a calm and cozy atmosphere in the house. In addition, the heating pipe must have an aesthetic appearance, since it is not always possible to use a hidden gasket.

What should heating pipes be like?

Of course, not only the efficiency of the entire heating system, but also its durability will depend on the quality of the pipes, since they are operated under conditions of increased load.

The first characteristic that determines the quality of a pipe is its reliability, which is maintained over time.

In addition, regardless of which pipes you choose for heating your apartment, they must be impermeable to oxygen. This will avoid oxidation and corrosion of the pipes from the inside, and their premature wear.

The tightness of the connections directly affects not only the heating mode, but also its maintenance. If the pipe is strong enough, the coolant will not be able to leak through it and will not damage the heating devices. The operating temperature loads and strength of heating pipes depend on the raw materials used for their production.

In addition, the noise level from water passing through the circuit is also an important factor. If everything is assembled correctly, the coolant circulation will not produce unnecessary sounds and will not cause discomfort. And, of course, communications should look aesthetically pleasing, because sometimes it is impossible to hide them.

How to choose the right heating pipes

When choosing a heating pipe, several important aspects must be taken into account:

- type of pipeline laying;

- average water temperature and pressure inside the systems;

- heating configuration from pipes (smooth or flexible);

- pipeline location.

The type of heating system largely determines the choice of products for its arrangement. Central heating pipes used in multi-storey buildings must be strong enough to withstand a pressure of 16 atm. Products for individual systems used in cottages or private homes operate at a pressure of no more than 2-3 atm.

Note! Pipe routing can be done externally or hidden in the walls, under the floor, inside a box made of wall panels or plasterboard.

Which heating pipe is better also depends on the possibility and ease, if necessary, of repairing batteries or other elements of the system. The network can be gravity (natural) or forced circulation, which also affects the choice of heating pipe.

An important factor when choosing pipes is the pressure in the heating system

The distance maintained between communications depends on their material and diameter.

Metal-plastic

The list is not limited to the listed types of pipes made of plastic materials. Polyvinyl chloride (PVC) can also be used for their production.

All these materials are fully endowed with one unpleasant feature - the ability to transfer oxygen from the air through existing microdamages into the cavity of the pipes. And oxygen is the strongest oxidizing agent (oxidation - from the word “oxygen”).

As a result, corrosion of metal parts of the heating system occurs. Without solving this problem, it is impossible to use such heating systems.

Various methods of reinforcing walls are aimed at strengthening them. And to solve the problem of coolant oxidation, aluminum reinforcement can be used. This material, when exposed to oxygen, creates a thin oxide film on the surface, which is resistant to most aggressive environments, excluding only mercury salts, which are extremely rare in nature.

The aluminum tape is wound in a spiral during the production process, and the edges are laser welded in a flow. An outer layer of plastic is applied over the metal jacket. In this way, a multilayer product with oxygen protection is formed.

When choosing metal-plastic pipes for heating, you need to take into account that any of their types can be used, but you need to pay attention to the characteristics of the material and the complexity of installation. Well, when choosing, an important criterion is their cost and presence on the market at the moment.

Types of heating pipes

There are three basic groups of heating pipes, which is best to use depends on the specific situation:

- metal;

- plastic;

- metal-plastic.

Metal pipes for heating are made of both copper and steel (black or stainless). Galvanized heating pipes are better suited for heating systems. They have enough pros and cons, but the main advantage is that they are less prone to corrosion under the influence of water. Because zinc oxidizes faster, it provides protection to the product. Galvanization of heating pipes is carried out using the diffusion or hot method.

The first option involves coating a steel pipe with zinc atoms. The temperature is about 400 °C. Hot galvanized pipes are produced by dipping them directly into liquid zinc. The temperature of this process is 450 °C.

It is better to organize a heating system from pipes with natural circulation using galvanized, stainless and steel products. The network is effective if the diameter of the communications is large enough (25-50 mm) and the required slopes and distances are met.

Polypropylene pipes are often used in heating systems, but in networks with high media temperatures it is better to choose reinforced polypropylene

Plastic communications are made of polypropylene and cross-linked polyethylene. Metal-plastic structures have layers of metal and polymer materials interconnected in a special way. Polypropylene pipes can even be laid underground.

What pipes are used for heating

The choice of materials is not so wide - metals (black steel and galvanized copper) and reinforced polymers - polyethylene, polypropylene. That's basically it. But recently a new product has appeared on the market - corrugated stainless steel, which is inexpensive, has high performance characteristics, and is also easy to install. True, the operating experience is still very small - it’s a new product, but all the reviews that exist are positive.

Steel pipes

If we talk only about pipes, then this is the cheapest option. But welding plays an important role in the cost of the system: the services of a good welder are not cheap (and a bad one is not needed) - few people ask for less than 15 thousand for assembling an average system. rub. So, as a result, it's not that cheap.

In addition to the low price for the material, the advantages of steel pipes include high resistance to temperature and pressure changes, low thermal expansion, as well as mechanical strength: to damage them you will need tools and remarkable strength.

High heat transfer can be attributed to both pros and cons. If steel pipes are installed inside a heated room, then such heat losses are, in principle, not dangerous - the heat remains in the room. And if the pipes go through an unheated room (basement, attic, etc.), then they require careful thermal insulation.

Steel pipes for heating are the most budget option, but not the best

Disadvantages: heavy weight, difficult installation, low resistance to external influences. They are afraid of freezing - due to low plasticity, frozen water simply breaks the pipes. A rough internal surface negatively affects the performance of the system: it leads to increased resistance to water flow, as well as to the accumulation/deposition of sediments and oxides on the walls. They say the system is “silting up” or “overgrown.” Sometimes the gap remains a few millimeters, but it takes more than one year for such a quantity of sediment to accumulate. It is worth saying that the durability of use in heating systems is affected not only by the quality of the metal and the pipes themselves, but also by the composition of the coolant. In closed systems there is not much oxygen, and it quickly binds and reacts, so the pipes are not destroyed from the inside much. To protect against external destructive influences, painting is required. Moreover, it has to be renewed regularly: the paint loses color due to temperatures, sometimes peels off, and you have to clean everything off and paint it again. Hidden laying is possible, but is done very rarely: after all, ferrous metal is not intended for walling: it is too susceptible to destruction and oxidation.

Galvanized pipes

Quite expensive material. But it is resistant to corrosion and easily tolerates changes in temperature and pressure. The pipes are thick-walled: even if you dance on it, all you can do is damage the fasteners in the wall. It will also be possible to achieve a “drop” from the nearest threaded connection (this can be corrected simply by replacing the winding). It’s just that it’s very inconvenient to assemble – using threaded connections. And each thread must be cut by hand, and each pipe weighs quite a lot and this procedure takes a lot of time and effort. Here are the disadvantages: heavy weight and difficulty in assembly, expensive material.

Galvanized pipes are assembled with threaded connections

And if it is still possible to use it for external wiring, then for a hidden location in the walls this option also does not work, but because of the threaded connections, which are better not to be hidden in the wall or floor.

Galvanization is resistant to external influences, but it is painted for aesthetic reasons: the new one looks great, but after a while it becomes completely unpresentable. The difficulties are the same: the paint changes color and peels off, it has to be replaced.

Copper pipes

Let's start with the positives. Beautiful and corrosion-resistant material. The walls of the pipe inside are nasty, so there are no or almost no deposits. High ductility and elasticity of the material, which makes it possible to bend in the right places using a pipe bender. The same plasticity allows you to tolerate freezing/defrosting. The high strength characteristics of the material make it possible to make thin-walled products, so that the weight of the pipes is light. All these properties allow the use of copper pipes for both external and hidden installation.

Copper pipes for heating - expensive, but not ideal

Assembly is easy: using soldering and fittings. Where branching/connection is required, bronze or brass fittings are installed; there are copper fittings for soldering. The plasticity of copper makes it possible to directly solder two sections of pipe of the same diameter, slightly widening one end (by chamfering). The soldering process itself is simple, so you can easily assemble a copper pipeline yourself. Copper itself tolerates high temperatures easily, but it is recommended to use the pipeline up to 110 ° C - this limitation is imposed due to the soldering points: at high temperatures, tin can leak and depressurization will occur.

Now about the cons. Copper is an expensive material. And this is a very significant drawback. However, corrosion resistance is also relative. In the presence of a potential difference (and copper is an excellent conductor of current, and in the city there are a lot of stray and induced currents, so there will be a potential difference on any sufficiently long section of the pipe), in a certain environment, and in the presence of oxygen, it oxidizes and is destroyed quite actively. As a result, fistulas may appear after a few months. This process is called electrochemical corrosion. You can get rid of it by selecting a neutral environment (in terms of acidity), adopting grounding and dielectric inserts in the system.

There is one more nuance: copper does not tolerate the proximity of other metals: chemical corrosion begins. Thus, it is impossible to use copper pipes and aluminum radiators in one system, and elements made of other metals can be connected to copper through brass or bronze fittings.

Another drawback is the same plasticity: a few blows on the pipe and it’s not a pipe, but a flat piece of iron. The same softness and plasticity leads to rapid abrasion in the presence of abrasive particles in the environment, and there are enough of them in centralized heating. In general, this is also not the best option.

Read more about copper pipes for heating here.

Stainless steel for heating

Stainless steel in the form of ordinary/familiar heating pipes is not applicable: welds are destroyed quickly. Unless you cut a thread and assemble it like galvanizing, but it requires a lot of effort. This assembly cannot be called easy. But all the advantages are obvious. But they do this, still very rarely.

Corrugated stainless steel pipes are an excellent choice for heating

However, it is possible to make heating from stainless steel: several years ago we introduced corrugated stainless steel pipes. They combine the excellent performance characteristics of stainless steel and the flexibility of the corrugation, plus easy assembly on crimp fittings (not under a press, but regular crimping using a screw-on ring). The material turned out to be almost perfect: the only drawbacks are not the best characteristics for the passage of water flow, and high thermal conductivity, which is excellent for heated floors, but not very good for conventional systems. And so the price is low, and lightness (the wall thickness is only 0.3 mm, but it “holds” pressure up to 50 Bar) and a wide temperature range (it is not afraid of defrosting). In any case, no real shortcomings were identified on the forums. All reviews from those operating systems with similar pipes are only positive. Having studied this material in more detail, you may come to the conclusion that corrugated stainless pipes are the best for heating in an apartment or house. Read more about corrugated stainless steel pipes and reviews about them in this article.

Metal-plastic pipes

Quite a popular material that combines the properties of aluminum and plastic. It is lightweight, durable and chemically neutral. It has a fairly decent appearance, is assembled using fittings of three different methods of fixation, does not conduct currents, and has an internal smooth surface. Flexible to a certain extent (can be bent by hand or with a pipe bender), and has slight thermal expansion. MP is suitable for both installation in the floor/wall and for open installation. Only the collapsible fittings cannot be closed: they need to be tightened periodically, as they begin to “drip”, but those that are pressed can be monolithic.

Metal-plastic pipes are a good option for heating

There are some restrictions on the use of metal-plastic pipes in terms of temperature: they can tolerate up to +110°C and cannot tolerate defrosting. But for most systems this is a completely acceptable mode. Among the significant disadvantages: the high cost of the system due to expensive fittings, as well as the narrowed clearance of the pipes, again due to the fittings: they have such a design. This material, if not the best, is quite suitable for both private houses and apartments. It is not suitable for dachas - freezing is not allowed, and is not the best choice for systems with natural circulation - due to the reduction in pipe clearance by fittings.

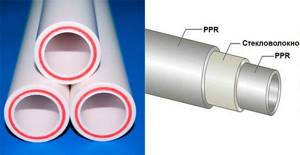

Polypropylene pipes

Pure polymer pipes can be used in heating, but only in systems where the temperature does not exceed 70°C. This solution is far from the best: polypropylene has a very high expansion coefficient and when heated, the pipes will sag.

Polypropylene pipes for heating use reinforced

But for PPR-reinforced pipes, the thermal expansion is several times less. These are the ones recommended for use in heating systems. True, the temperature regime is approximately the same: operating temperatures up to 70-80°C (depending on the type of polymer). There is a special PPS polymer that feels great at 95°C. Reinforced polypropylene pipes are lightweight, reliable, durable, resistant to corrosion, and have low thermal conductivity, so they almost do not need additional thermal insulation. Their inner surface is smooth, so they offer very little resistance to the flow of water, and deposits do not form on their walls. PPR pipes are not afraid of defrosting and feel great both in the wall and in the floor. When laid open, they do not spoil the appearance of the room. The disadvantages are the need to have welded equipment for connecting pipes and fittings and temperature restrictions. But you can learn to use such a device in a few tens of minutes, so self-assembly of polypropylene is possible. Another disadvantage is the large number of fakes that have completely different quality and characteristics. Read more about polypropylene pipes and fittings here.

This is what part of the polypropylene heating system looks like

As you can see, there is no ideal solution. There is something better than others that suits your conditions. This is what we need to find.

Black steel heating pipes: disadvantages

Iron pipes for heating began to be used almost immediately after it entered the market. It has great mechanical strength and the ability to withstand significant pressure and temperature.

According to the manufacturing method, there are seamless (seamless) and suture. The second type is obtained by bending and welding sheet metal.

Note! Which heating pipe is best to choose depends on the situation, but seamless products are more durable and reliable.

A steel pipe for heating is not without its drawbacks, including susceptibility to corrosion, heavy weight, an insufficiently smooth internal surface, and the need for welding during installation. The outer surface can be protected with a layer of paint and must be renewed periodically.

It is impossible to protect the inner surface in this way, so it is subject to corrosion, especially if there is no water in the system or it is drained from the pipe. The wall thickness, and, accordingly, the outer diameter of steel pipes is greater than that of communications made of other materials with a similar internal cross-section.

Disadvantages of black steel heating pipes

Black steel pipes have long been used for heating installations, since such products are quite durable and resistant to high pressures and temperatures.

There are two types of black steel pipes - seam and seamless or seamless. Products with seams are obtained by bending and welding sheet iron.

Although both types of products can be used for various purposes, the strength indicators of seamless pipes are higher.

However, black metal pipes have a number of imperfections. They are prone to oxidation and corrosion, so the inside begins to overgrow over time, especially if the pipeline is empty in the summer. The inner surface of the pipes is not too smooth, and installation is carried out only by welding.

The outer layer of protective paint must be periodically restored. But it is impossible to apply such protection from the inside at all. Compared to other products with a similar internal diameter, steel pipes have thicker walls, which makes them quite heavy (about

Advantages of steel pipe

To avoid corrosion, it is better to use stainless steel pipes for heating; however, their cost is higher.

Steel pipes have been used in heating systems for a very long time and are most often found in apartment buildings

The main advantages of black steel products include:

- ability to withstand heavy mechanical loads and shocks;

- high temperature, significant pressure and water hammer have no effect;

- no need for compensation devices;

- excellent rigidity.

Even if the water temperature is at its maximum, the pipes have low linear expansion. Such characteristics make it possible to determine steel products as the best for heating systems with natural or combined circulation.

They are good to use where it is difficult to regulate the water temperature and compliance with the slopes of heating heat pipes is mandatory. An example of such systems could be complexes that operate from a solid fuel boiler or a furnace with a heat exchange part.

They should use a heating pipe that is only capable of withstanding the boiling of the coolant in an emergency.

Steel heating

Metal products were among the first to be invented. Today they are mass produced, due to the development of the construction industry. Pipes for water supply, hot water supply and heating are made according to the requirements of GOST 3262-80 from steel strip.

The most commonly used material is St. 3 kp, ps, sp. The choice is due to the requirement of good weldability, since when installing water pipelines it is preferable to use this connection method en masse.

The above standard regulates the production of products in the following sizes. The numbers in brackets indicate the outer diameter of each pipe size, while the first of them indicates the nominal diameter, which practically corresponds to the cross-sectional area.

- With nominal bore 6 (10.2) – 8 (13.5) – 10 (17.0) – 15 (21.3) – 20 (26.8) – 25 (33.5) – 32 (42.3) ) – 40 (48) millimeters. These dimensions are used when installing internal heating distribution networks.

- With a nominal bore of 50 (60.0) – 65 (75.5) – 80 (88.5) millimeters. These are the dimensions for intra-house wiring of apartment buildings or supply branches of individual buildings.

- With a nominal diameter of 90 (101.3) – 100 (114.0) – 125 (140) – 150 (165) millimeters. Such products should be used in intra-block and yard distribution of heating mains.

For heating installation, it is better to use steel pipes with a protective coating. It is applied to the outer and inner surfaces by hot-dip galvanizing or electrolytic method, which significantly increases their service life. After welding galvanized parts, the seams must be treated with a special paint consisting of 95% zinc powder, the rest is binders.

The limiting parameter when bending pipes is the internal radius, the minimum size of which must be at least 2.5 times the diameter of the product.

The positive properties of steel water pipes, allowing their use for heating, include the following characteristics:

- High plasticity and workability of the material, allowing the formation of a pipeline at the site of its installation.

- Availability.

- High temperature coolant, which can be transmitted through a metal pipeline.

- Possibility to set increased pressure in heating networks.

However, there are also disadvantages in their use:

- The need to orient the workpiece when bending so that the longitudinal weld is located inside the bend.

- The inner surface creates difficulties for the flow of coolant.

- The need for regular maintenance of the heating system to tighten threaded connections, eliminate leaks and paint the outer surface.

- Inevitable clogging of the internal lumen with iron oxidation products.

- Limited service life compared to plastic heating systems.

In recent decades, such products for heating systems are increasingly being replaced by plastic ones .

Use of copper pipes for heating

When deciding which pipes to choose for heating, you can choose copper products. It should be remembered that they oxidize in the presence of eddy currents and interaction with aluminum. Eddy currents appear when a heating pipe is laid in a wall near electrical wiring.

Copper pipes can be used not only for connecting batteries, but also in underfloor heating systems

Copper pipes perform their functions perfectly even if the temperature of the flowing water is unstable (from negative to +500 °C).

Note! Due to the presence of smooth and corrosion-resistant internal walls, the material exhibits good wear resistance (it lasts up to 100 years).

A copper pipe for heating has high throughput and thermal conductivity, it is resistant to rupture, can withstand high pressure and is impermeable to oxygen. In addition, the material has a bactericidal effect. A system made of copper products should be installed in one of the following ways:

- low temperature;

- high temperature.

It is better to give preference to the first method, which involves the use of flux. Copper pipes for heated floors are ideal for laying laminate flooring. Their cost is slightly higher than that of analogues made from other materials.

Stainless steel

Of course, stainless steel products have an order of magnitude higher performance characteristics compared to black steel products. They are not subject to internal and external corrosion, and also require virtually no additional care and maintenance.

At the same time, stainless steel has a much lower thermal conductivity, and in a private home this causes the consumption of more fuel, which can be considered a disadvantage. The second reason for the low popularity of stainless steel pipes for heating is their higher cost, sometimes an order of magnitude higher than analogs made from other materials.

For stainless steel during installation, you need to use special press fittings, the cost of which is also prohibitively high.

Does your house or apartment need a heating system whose service life is many times longer than the normal life cycle of a residential building? That's it!

Features of metal-plastic products

Structurally, the pipes are plastic layers with metal foil between them. Polymer layers can be made from cross-linked polyethylene or other types of plastic. This structure makes it possible to achieve very smooth internal and external surfaces.

One of the advantages of metal-plastic pipes is the ability to use them for installing heated floors

When choosing heating pipes, you should take into account what the temperature of the coolant should be and whether the selected pipes can withstand such heating. Metal-plastic communications are resistant to high temperatures - up to 95C. This explains their popularity. The absence of thermal linear expansion allows installation into the wall or floor under the laminate without expansion joints. Also, metal-plastic pipes for heating are applicable in systems with natural (forced) circulation of coolant.

Today there are 3 types of heating under laminate:

- infrared;

- electric;

- water.

It is important to know that laminate is a cold coating. To make it comfortable to walk on, you need heated floor equipment. The laminate is laid on a special substrate that provides softening, sound insulation and moisture protection.

Characteristics of metal-plastic pipes

The structure of metal-plastic pipes consists of two layers of polymer, between which a metal foil is laid. It can be cross-linked polyethylene, polypropylene and other polymers. This design allows you to achieve perfect smoothness on the outside and inside.

When choosing this type of pipe, you need to make sure that the coolant temperature in the system does not exceed 95 ℃ - these are the values that metal-plastic pipes are designed for. Such a high threshold determines their popularity.

Products of this type do not have linear thermal expansion, therefore they are acceptable for laying water-heated floors under laminate or in walls without compensation devices. They are also used for structures with forced or spontaneous circulation of liquid.

Using polypropylene heat pipe

When deciding which pipe to use for heating, do not forget about polypropylene communications. Reinforced (aluminum or fiberglass) products are more suitable for constructing such systems. Thanks to this, they hardly stretch if the temperature rises significantly. This property is important when placing heating pipes in the wall. There are enough pros (and cons) of such placement.

Reinforced pipes have higher strength and a lower expansion coefficient than products without a reinforcing layer

Note! An unreinforced pipe can elongate so much when heated that the fasteners that hold it in place break.

When determining which heating pipes are better - reinforced with fiberglass or aluminum, it should be noted that both of them are suitable if the coolant temperature is up to +95 ° C.

It is better to use polypropylene pipes for heating when installing a network in a private home, where it is possible to regulate the heating of the coolant. If the water temperature rises, the operating pressure decreases.

The answer to the question of which heating pipes can be laid underground will also be polypropylene products. They are connected to each other with fittings.

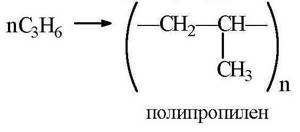

Polypropylene pipes

One of the most common materials of this family is polypropylene. Polypropylene is produced from propylene gas by polymerizing its molecules. This occurs at elevated pressure and temperature.

As a result of the reaction, a fairly strong substance is obtained, suitable for the production of various products.

Polypropylene is thermoplastic, this is its main feature. Under the simultaneous influence of temperature and pressure, the material floats and loses its shape, which makes it impossible to use it in its pure form.

There are several types of polypropylene. In relation to heating systems, it is necessary to use PPRC type products made from random copolymer of propylene. This material copes more successfully with the factors mentioned above. When choosing polypropylene pipes for heating, let’s pay attention to reinforced samples of these products. At the moment there are 3 types of them:

- Reinforced with aluminum sheet. For this purpose, strip aluminum with a thickness of 0.1 - 0.5 millimeters is used. It is wound onto a base and laser welded. There are options for installing aluminum strips with glue. But in any case, the result is a reliable, durable product that can withstand the effects of negative factors well. In addition, the aluminum jacket protects against the penetration of oxygen, which promotes active corrosion of metal elements of the heating system - locking mechanisms, the inner surface of the boiler and others.

- Glass fiber reinforcement is produced during extrusion by the combined supply of the base material and the reinforcing additive. The fiberglass layer is located in the middle of the wall thickness. Mixing glass fibers with long chains of polymerized molecules gives the material greater stability when curing.

- Reinforcement is also made from a pre-prepared mixture of fiberglass and polypropylene, which produces a homogeneous composition, strengthened according to the principle given above.

Reinforced polypropylene systems stably withstand temperatures of +95 degrees Celsius at pressures of up to 10 atmospheres. In this case, a painless short-term increase in temperature up to +110 degrees is possible. When choosing polypropylene pipes for heating, you undoubtedly need to choose reinforced products. They are marked: PPR3-80 or PPR3-100.

Considering the possibility of using polypropylene pipes for water supply and heating systems, appropriate fittings and installation methods have been developed that allow the formation of networks of any degree of complexity.

XLPE pipes for heating

Transparent heating pipes made of simple polyethylene cannot be used. A product made of cross-linked polyethylene is suitable as thermal communication. Cross-linking technology makes it possible to obtain additional bonds between molecules in the polymer structure.

As a result, the material has a high density and can withstand significant pressure and coolant temperatures up to +90 °C. It can be used to make heated floors under laminate and used for laying underground. When heated, a polyethylene heating pipe can be deformed to give it the required shape, which is retained after cooling.

The lightness of the structure does not create excessive load on the load-bearing elements. When choosing the required product, it is important to consider at what pressure the heating pipe will mainly be operated.

XLPE pipes are used in complex high-pressure heating systems

The lifespan declared by the manufacturers, communications made of cross-linked polyethylene are operational in the following modes:

- 7 bar at 90 °C;

- 11 bar at 70 °C.

Polyethylene pipes for heating are connected to each other using press fittings using a special tool.

To get a consultation:

For the manufacture of heating pipes, 6 materials are used:

- steel;

- stainless steel;

- copper;

- polypropylene;

- cross-linked polyethylene;

- metal-plastic.

They all have pros and cons. Let's consider each material separately.

Steel

Previously, this was the only option for heating systems. Now steel is becoming a thing of the past, but is still not completely forgotten.

Advantages of steel pipes:

- They have high strength: they are not afraid of pressure surges or mechanical stress.

- They do not expand during heating, so there is no need to install compensators in the system.

- 100% gas tight.

- Low cost.

- High thermal conductivity - the pipes heat up themselves and transfer heat to the room.

Due to the fact that steel is susceptible to corrosion, pipes do not last long - about 10 years. They do not bend and require a welding machine to connect, which complicates installation. In addition, they have high electrical conductivity, so it is not advisable to connect them to an electric boiler.

Stainless steel pipes

Corrugated pipes are made from stainless steel. This is a good option for organizing heating in a private home. Such pipes are used in heated floors, for hot and cold water supply. Their main advantage is their ability to bend, which greatly simplifies installation.

Advantages of stainless steel pipes:

- Not subject to corrosion, scale formation, and not afraid of water hammer.

- Can be installed with a small number of connections.

- They have a low coefficient of thermal expansion.

Such pipes are more expensive than conventional steel pipes, but their convenience and durability more than pay for it.

Copper pipes

Copper is a rather controversial material. He is both persistent and fragile at the same time.

Copper pipes have many advantages:

- Provides quick heating of rooms.

- Withstands short-term heating up to 500°C.

- They can work with very hot coolant (up to 115°C).

- They are not afraid of subzero temperatures; they cannot depressurize due to the fact that the material can stretch a little.

Copper pipes are expensive. In addition, they are produced by foreign manufacturers. There are also other disadvantages:

- Copper is not compatible with aluminum adapters (gases are formed due to the reaction of the two metals). Therefore, brass fittings and adapters must be used for pipes.

- Copper is scratch-resistant, so filters are necessary.

- The material conducts current: grounding is required.

- Pipes are susceptible to mechanical stress and must be protected from shock.

- Complex installation that must be carried out by a specialist.

Due to the high cost and capriciousness of the material, you should think carefully about installing copper pipes. If you want just such a system, choose a reliable manufacturer and professional installer.

Polypropylene pipes

When organizing heating of a private home, polypropylene pipes are used most often. They are inexpensive, weigh little and are easy to install.

Benefits also include:

- Durability - can last more than half a century.

- Resistance to plaque accumulation, corrosion, low temperatures.

- High tightness.

Such pipes can operate in a system where the coolant temperature does not rise above 90-95 degrees. They expand easily, which requires the use of expansion joints. The material cannot boast of high rigidity, which is why the tubes sag. To avoid this, choose reinforced options.

XLPE pipes

This option has great advantages and, apart from the price, has no disadvantages.

XLPE pipes:

- Durable (last 50+ years), not afraid of chemical exposure.

- They do not crack, and after freezing and thawing they return to their original characteristics.

- Elastic and low weight.

- They have high sound insulation.

- Can be used for hidden installation.

Metal-plastic pipes for heating

This option is optimal in terms of reliability and cost.

Metal-plastic pipes:

- Absolutely smooth, so they do not accumulate deposits.

- They have perfect tightness.

- They bend well, so they are suitable for houses with complex geometry.

- Can be used for hidden installation.

- They serve for about 50 years.

The disadvantages include:

- Fear of frost - pipes need to be insulated to prevent them from bursting.

- For hidden installation it is necessary to use only a crimp connection and not a threaded one.

So which pipe should you choose for heating a private home? There are three good solutions here: pipes made of polypropylene, metal-plastic or stainless steel. In addition to the material, you need to decide on the desired diameter.

The principle of heating with air from a gas boiler

One of the relatively new home heating systems is air heating, which is heated from a gas boiler. In this case, contact occurs through a special heating element. There is no high temperature and pressure in the heating pipes.

The operating principle is as follows: using gas equipment, the metal is heated, which transfers heat to the air; Then, thanks to the fan, it enters the pipes, which need to drive the heated air into the room. In this scheme, it is better to use metal thin-walled or flexible corrugated foil products.

Note! The air heating system must be calculated and installed during the construction phase of the building.

Placing a heating pipe in the wall is often used, however, it is important to note its bulkiness and loud noise during use.

A separate issue is related to the circulation of warm air. Highlight:

- closed circulation;

- forward flow;

- recirculation with the possibility of replenishing air from outside (from the street).

The principle of the air heating system does not imply the presence of high pressure in the network, so pipes can be selected without special strength characteristics

The last option is best suited, which, by installing additional filters (electronic, mechanical or chemical), allows you to fill the room with purified air. The advantages of such a system are the organization of heating from pipes without batteries, efficiency of more than 90%, efficiency and aesthetic appeal.

Classification

To avoid problems during the assembly and operation of the pipeline, you need to choose the right material from which the individual elements are made. Types of heating pipes:

- made of metal - different types are used;

- made of plastic (polypropylene);

- made of metal-plastic (a combination of two materials).

Metal

Types of metal heating pipes:

- steel;

- copper;

- made of stainless steel.

Advantages of steel:

- Resistant to water hammer and high temperatures.

- Durability, wear resistance.

- High thermal conductivity.

- Thermal expansion is low.

Flaws:

- Low resistance to rust formation.

- Heavy weight.

- Conductivity of stray currents.

- Difficulty in installing individual elements.

Benefits of copper:

- Durability.

- High thermal conductivity.

- Resistant to rust formation.

Copper parts have no serious disadvantages. However, the technical characteristics of this material are determined by its high price.

Advantages of stainless steel:

- Rust resistant, durable.

- High thermal conductivity.

- Resistant to pressure surges and temperature changes.

- Low thermal expansion.

The disadvantage of stainless steel parts is their high price.

Plastic

Advantages of plastic:

- Durability - 50 years.

- Resistant to rust.

- Low price.

- System tightness.

Disadvantages of plastic:

- For installation you need to buy additional equipment.

- High temperatures destroy the material.

- Low thermal conductivity.

Metal-plastic

Advantages of metal-plastic:

- Service life - 50 years.

- Stray currents are not transmitted through metal-plastic.

- High tightness.

- Resistant to rust.

- Durability is higher than that of plastic.

- You can bend parts to create complex shapes.

Flaws:

- Weak resistance to UV rays.

- Destruction of material from exposure to high temperatures.

- High price.

Procedure if a pipe bursts

In the event of a heat pipe failure, measures must be taken immediately. To ensure that problems are resolved correctly, a repair team or an on-duty plumber is called. If the normalized distance is maintained during installation, then independent access is provided to the areas.

There is not always time to wait for help if heating pipes have burst. What to do in this case is determined by the possible threat of flooding of the premises and the danger to humans. In such a situation, it is better to independently take any actions that limit the area of water spread. It is important to remember that the coolant temperature is quite high.

If a pipe bursts, you can place any suitable container under the stream to collect the liquid so as not to damage the laminate or other floor covering. Although laminate flooring can deteriorate even with slight exposure to hot water. It is also important to try to shut off the riser using valves. They are usually installed both in the basement and in the apartment. The control valves of the heating system are often located on the supply line.

If the batteries break down or if a hot water pipe bursts, it is better to use thick rubber gloves when performing manipulations to eliminate or reduce the level of damage.

When a heating pipe breaks, it is worth remembering that the temperature of the flowing water is very high

Insulating mats

Whether you decide to replace radiators or not, you still need to think about how to cut off the flow of heat that goes out. For this, there are special aluminum insulating mats that are installed on the wall behind the heating radiator. If we take a block Khrushchev building, then with installed mats, the heat transfer from the battery increases by 20 percent.

The insulating mat is easy to install. It is necessary to cut holes in the insulation for the hooks on which the radiators hang. Apply silicone or mounting adhesive to the wall itself. Next, we take the insulating screens, put them on hooks and press them against the wall, gradually smoothing them out. You should not use insulating mats made of mineral wool. The glass contained in the product may harm your health. Thermal insulation mats must be made of natural or organic fibers.

How to insulate the front door?

If you want to give an aesthetic appearance to old radiators, then special radiator screens are needed. Many people make them themselves, many buy them. Remember that not every screen will be good, as thermal conductivity should also be taken into account when installing them.

How to ensure sealing of a breakout site

If a heating pipe ruptures and the arrival of emergency services is delayed, then the water leakage point must be temporarily sealed. To do this, you will need any piece of rubber (for example, from an old camera) and a screw clamp.

Regardless of which pipe is used for heating, in case of a break, you can do the following:

- Wrap the damaged area with several layers of rubber tape, and then secure the patch with clamps.

- If there are no clamps, thick wire or cord can be used.

- The final step in sealing the heat pipe or batteries is to wrap several layers of high-density fabric and apply adhesive tape (such as tape).

Since water pressure actively affects the place where the pipe has burst, such actions will help stop the coolant spill for a while. When choosing pipes for heating, it is important to note that both stainless and galvanized products are very durable, but unsealed threaded connections can leak.

You can solve the problem of leakage from a heating pipe before replacing the damaged section using a clamp

Pros and cons of metal-plastic

Let us make a reservation that metal-plastic pipes for heating should be compared with polypropylene pipes under equal conditions. Therefore, detachable joints on collapsible fittings are not considered - they are expensive and unreliable, although convenient for craftsmen without experience. Good tightness will be ensured only by the joint with the press fitting.

The condition also applies to the method of reinforcing the pipe; for comparison, let’s take metal-plastic and PPR reinforced with aluminum. Now about the advantages of metal plastic:

- Having special pliers, it is quite simple to install heating from metal-plastic parts.

- The pipe is bent and supplied in coils, and therefore is cut into sections of the required length, without any unnecessary joints.

- Thermal elongation of the material is insignificant and does not require a scrupulous approach when securing long sections.

- Can be installed in any weather.

- Laying in any hidden way is allowed, including under the screed along with the joints.

What is better in systems made of metal-plastic is the technology for connecting the elements. The end of the cut section is calibrated, pulled onto the fitting and crimped with pliers, and that’s all. A minimum of space is needed, since there is no need to insert a healthy soldering iron between the parts to be joined; the pliers are applied after joining. With the help of a spring, the metal-plastic bends well under a safe radius, which greatly simplifies the installation.

Separately, it is worth mentioning about heated floors, where it is customary to lay metal-plastic or cross-linked polyethylene, but not PPR. These materials do not need compensation and feel good inside the monolith, providing effective heating of the entire surface. It is worth imagining polypropylene in their place with its thick walls, extension and 90° joints, and it immediately becomes clear which pipes are best used in heated floors.

Press connection pliers are not a cheap tool; for 1-2 installations it is better to rent them

Reference. Cheap, low-quality metal-plastic is often found on sale; in practice, it often delaminates at bends. Fixing a leak under a screed is not easy; you can’t do it without opening it. Those who like to save on materials should think about using cheap metal-plastic pipes for heated floors.

Now about the disadvantages of metal-plastic, of which there are actually two:

- high cost of all elements;

- The range of pipes is limited to a maximum diameter of 63 mm (DN50).

Proponents of heating made from polypropylene constantly pay attention to another disadvantage of metal-plastic - a reduction in the flow area at connections where brass fittings are installed. They say that this leads to an increase in the hydraulic resistance of the network and the rapid “overgrowing” of passages when working in a central heating system, where the coolant can be dirty. The statement is true regarding collapsible fittings; in them, there is actually a narrowing of the diameter relative to the passage in metal-plastic.

High-quality fittings for press joining metal-plastic pipes also have a narrowing, but it is not so large as to significantly affect the hydraulics of the system. It is better to use them for heating, especially when laying hidden lines. Our expert Vladimir Sukhorukov shares the same opinion, whose video we recommend watching: