Instantaneous water heaters running on natural gas are very efficient household appliances that can supply heated water for household needs indefinitely. And although their operating principle has not changed since their invention, the design has undergone many improvements. It would not hurt for users to study the structure of a modern geyser in order to successfully operate it, and sometimes even repair it on their own.

Construction of modern geysers

At the moment, two types of household water heaters can be purchased in the retail chain:

- The most common option is geysers with an open combustion chamber (atmospheric). In them, air for gas combustion comes from the room naturally, passing through the opening at the bottom of the apparatus and the viewing window.

- With a closed combustion chamber (otherwise - turbocharged or supercharged). Here, air is forced into the combustion zone by means of a fan.

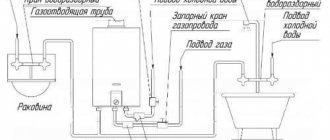

A water heater in the kitchen of an apartment (photo on the left) and in the boiler room of a private house.

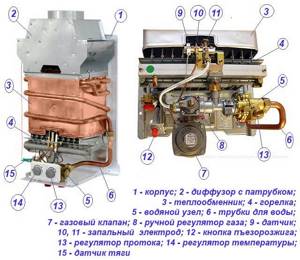

First, let’s look at the design of simpler atmospheric speakers, consisting of the following basic elements:

- metal case;

- gas burner with igniter;

- finned heat exchanger with casing and copper coil;

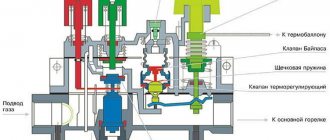

- automatic gas valve with combustion intensity regulator;

- mechanical water unit with safety valve;

- ignition system;

- diffuser with a pipe at the end for connecting the chimney;

- tubes for water and gas coming out from the bottom and ending with connecting fittings.

Ignition systems in columns are used in several types: piezoelectric and electric from batteries, a hydrogenerator or the house electrical network.

A draft sensor is installed in the water heater diffuser, where combustion products are collected, connected by wires to a gas valve. A flame presence (ionization) sensor is placed directly in the combustion zone, also connected to this valve. Below is a diagram showing in detail the structure of an atmospheric gas water heater:

Nowadays, instead of a burning wick, ignition electrodes are increasingly used, igniting the gas with an electric discharge

Now let’s talk about how the turbocharged version of a hot water heater with a closed combustion chamber works. It is similar in design to the atmospheric one, but has the following differences:

- Instead of a conventional manually controlled burner, a stepped or modulating burner is installed, changing the intensity of the flame in automatic mode.

- The combustion air is supplied by a fan, whose performance is regulated by a controller (electronic unit).

- The ignition system is fully automatic, operating from the mains or a hydrogenerator.

- The column device provides for maintaining water heating at a set level (for example, up to 60 °C). This is monitored by a separate temperature sensor connected to the controller.

The diagram of a turbocharged gas water heater is shown in the figure:

In such devices, all functions are fully automated, and the desired water temperature is set on the LCD display

How does a water heater work?

The task of water heaters of this type is to react by turning on the burner to the opening of a hot water tap anywhere in the house and ensure its heating to the desired temperature. To describe in detail the principle of operation of a gas column, we list the sequence of processes occurring in atmospheric models:

- At the first stage, the user lights the igniter located in the viewing window and directed towards the main burner.

- After opening the tap in the hot water system, a flow of water appears and the pressure increases. The design of the water unit (in common parlance - frog) provides that the membrane is activated and moves the rod connected to the gas valve.

- From the influence of the membrane of the water unit, the valve opens the fuel supply to the main burner, which is immediately ignited from the igniter or directly from the spark electrode. The user can adjust the flame power manually using a tap located on the front panel.

- The water entering the heat exchanger of the geyser begins to heat up in the coil made around the copper casing. This principle of operation avoids the formation of condensation on the tubes due to the temperature difference between the cold water and the burner flame.

- Heated water is supplied to consumers. After closing the tap, the “frog” membrane pulls back the rod, the valve shuts off the gas supply and the burner device goes out and the heating stops.

This is how most inexpensive atmospheric gas water heaters work with a constantly burning igniter that does not need to be connected to the electrical network.

If, for various reasons, the burner flame breaks off and it goes out, the thermocouple will operate and the valve will stop the gas supply. The same thing will happen if the draft in the chimney disappears based on a signal from the corresponding sensor. More details about the operation of the unit are described in the video:

This operating principle is inherited from instantaneous water heaters of the old design. More modern models lack a wick that never goes out, causing the heat exchanger casing on the front side to collapse over time. For example, the design of the Neva gas water heater, originally from St. Petersburg, provides for electric ignition from batteries at the moment a water flow appears.

Scheme of operation of a water heating apparatus not equipped with a wick

The operation of forced-air water heaters is based on automatically maintaining the water temperature set by the user. Ignition is carried out from the electrical network or from a hydrogenerator built into the water supply system and generates electricity when a flow occurs. Then the heating is controlled by a controller based on the readings of the temperature sensor. It changes the fan performance and combustion intensity depending on the outlet water temperature.

Causes

Loud operation of the equipment is caused by the following possible reasons:

- There is a shortage of water in the heating system, the presence of airiness - you should definitely check the pressure gauge readings, and also bleed the air from each battery.

- The formation of scale in the coolant, which breaks off with temperature changes and contributes to overheating of the antifreeze.

If the boiler becomes noisy, do not ignore it, but immediately call a specialist to find and fix the problem.

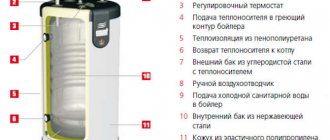

What should you consider when choosing a water heater?

A household gas water heater is not a boiler for heating and it is difficult for the average user to choose it based on power. It is much clearer when it comes to the amount of water heated. This value is indicated in the technical data sheet of the product of any manufacturer and is expressed in liters per minute when heated to 25 °C.

For clarity, we present a table with data on water heaters of the Russian brand Neva, showing the dependence of performance on the thermal power of the unit:

Reference. Dispensers for DHW needs are inferior in efficiency to gas heating boilers by 3 to 5 percent. If the efficiency of an atmospheric heater is about 88%, then the efficiency of the same water heater is 84%. But it is impossible to feel this difference in practice.

When choosing a device for heating water, you first need to determine its performance. Next, we suggest following simple recommendations:

- If your budget is limited, and electricity is often cut off in your area of residence, then a simple non-volatile atmospheric model is just what you need. The ignition system is from a piezoelectric element or battery-powered; they last quite a long time (2-3 months with intensive use).

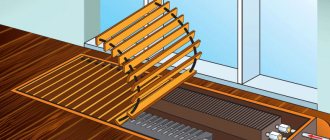

- In most apartments it is impossible to install atmospheric speakers due to the lack of chimney ducts, and the removal of combustion products into ventilation shafts is prohibited. No problem, buy a turbocharged water heater with a coaxial chimney that goes outside directly through the wall. Just determine the location of the pipe exit and coordinate it with your neighbors. Read more about connecting chimneys to gas water heaters in this article.

- In our conditions, when the water supply networks are worn out, it is better not to install devices with ignition from a hydrogenerator. The latter can quickly fail due to poor water quality and water hammer in pipelines. To protect the generator, you will need a water reducer, and this is an additional expense.

- Try to select modern modifications of devices where the igniter does not burn around the clock. It slowly but surely consumes gas, destroys the front wall of the heat exchanger and smokes onto the front panel.

The choice of a suitable manufacturer is up to you, but there are still brands whose products are time-tested and have proven themselves well in their work:

- Junkers (Junkers), aka Bosch;

- Beretta (Beretta);

- Electrolux (Electrolux);

- Neva;

- Vector.

Self-repair of equipment

The purchase of any heating boiler is accompanied by the issuance of instructions and technical documentation, which cannot be avoided in the case of equipment repair. The instructions, as a rule, always contain a list of the most common problems and methods for eliminating them.

Modern technology is equipped with special sensors and elements that monitor correct operation. That is why, in the vast majority of cases, protective systems are triggered on time, thereby preventing a lot of problems.

Experts say that repairing a gas boiler with your own hands is justified only in cases described in the documents accompanying the equipment, that is, if the defect is clearly identified and does not require complex manipulations.

All other types of breakdowns require a theoretical basis, practical skills, and often the use of high-tech specialized equipment.

Important: breakdowns of gas boilers should not be treated negligently; this may endanger the life of the user due to carbon monoxide emissions or fire!

Troubleshooting Methods

- If you detect a burning or gas smell, you should immediately open the doors and windows. Most likely, the combustion sensor that responded to the signal from the emergency thermostat has failed. It is necessary to turn off the boiler, allow it to cool completely, then check the quality of the draft and try to start the unit. If nothing works out, there’s no point in taking the risk; it’s better to call the gas workers right away.

- If the problem is a contaminated heat exchanger, then the problem will make itself felt by overheating of the boiler. In this case, the heat exchanger is cleaned and the operation of the equipment is tested again. If the heating of the boiler remains at the same level, then the automation is probably not functioning correctly.

- A clogged column manifests itself by extinguishing the flame. You can clean it yourself, according to the instructions.

Common faults

Like any gas-using equipment, the hot water column must be serviced and repaired by a specialist in this field. But there are a number of simple faults that the owner of a private house or apartment can fix on his own. The most common problems with instantaneous water heaters are:

- The igniter does not ignite.

- The wick burns, but after opening the tap the main burner does not turn on or ignites, but immediately goes out.

- There is insufficient water heating.

- Water begins to drip from the bottom of the case.

There can be many reasons for the occurrence of the listed symptoms, but we will indicate the most obvious ones, which the user can eliminate with his own hands.

The draft in the chimney should be checked regularly, as shown on the left. On the right is cleaning the heat exchanger from scale when the column does not heat the water.

It often happens that the igniter does not ignite due to a trivial reason - the batteries are discharged.

The cause of burner extinguishing may be:

- lack of draft in the chimney channel;

- faulty traction sensor or poor contact in its wiring;

- leaky membrane of the water unit;

- Inlet filter clogged (if equipped).

Low temperature of the leaving water, which happens after several years of operation, is usually associated with the appearance of scale in the heat exchanger and it will have to be washed. But drops of water from under the housing indicate a leak in some connection, safety valve or heat exchanger itself. The reason is the device overheating when the water is turned off.

Malfunction with overheating is inherent in atmospheric geysers. The mechanism is as follows: when the water is suddenly shut off and the burner is turned off, the heat exchanger remains hot, boiling occurs in it and steam is formed. If the situation is constantly repeated, the steam will eventually break out, breaking the weakest seal. Hence the recommendation: in such devices you must first turn off the gas and then turn off the water.

The boiler also does not turn on, but that is not the problem

This may be due to a clogged filter under the boiler. You need to find it and close both filter taps, unscrew the nut and pull out the mesh from there, which you need to rinse with water and put back. When cleaning the filter, as when performing any other actions, be sure to turn off the boiler.

Coarse filter

The reason may also be the pump, which does not supply heat for two reasons:

- due to air accumulation;

- The rotor is jammed.

To determine the cause of a pump malfunction in a gas boiler, you first need to check the operation of the rotor. To do this, you need to unscrew the nut on the pump, from which a little water should flow out, then insert a screwdriver inside; if you hear a characteristic sound, then everything is in order with the rotor. If not, then you should turn it with a screwdriver by the slots or do it with a special key.

Pump in a gas boiler

If air accumulates in the pump, it is necessary to open the air vent and release the air. The air vent consists of a rotating or rising cap; when released, the sound of escaping air should be heard.

- The pressure gauge needle is close to the red zone.

When the cold system has pressure near the red zone, it is necessary to turn on the boiler and heat it up. If, with slight heating, the pressure rises strongly from 0.7 to 1.5 bar, this will mean that air must be added to the expansion tank due to its loss. To do this, you need to reset the system pressure to zero (open the tap and drain some water) and use a regular car pump or compressor to pump it up to 1.3 bar, then bring the system pressure to 1.5 bar.