Features of soft roof covering TechnoNIKOL

Confirmation of the high quality of TechnoNIKOL roofing is the ISO 9001 certificate, which guarantees the reliability of the manufacturer of this brand. Bitumen is used to make soft roofing.

The following types of TechnoNIKOL products are available for sale:

- rolled materials;

- polymer membrane;

- flexible tiles.

The structure of TechnoNIKOL roof coverings is characterized by a high degree of resistance to mechanical stress and weather conditions.

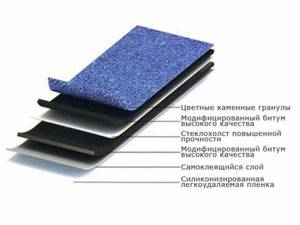

In the production of flexible tiles, fiberglass is used as a base, which is impregnated on both sides with modified bitumen. On the outside, the products are protected from coarse-grained basalt chips. This coating paints the tile sheets in a variety of shades and colors.

On the reverse side of the product there is a bitumen-polymer coating - it is protected by a layer of film. It is removed before installing TechnoNIKOL.

The polymer membrane is produced in three versions:

- based on plastic polyolefins;

- using synthetic rubber;

- with the addition of plasticizers.

The most in demand is a membrane produced on the basis of PVC with plasticizers, which give the roofing elasticity and resistance to the influence of negative temperatures. To increase tensile strength, the base is reinforced with a polyester mesh.

Purpose of TechnoNIKOL roll insulation for foundations

The manufacturer in question is one of the leaders in the Russian market in the production of roll-type moisture protection (4 mm), which is mounted both externally and internally. Let's take a closer look at film 1 for finishing the base of the house:

- High-quality surface protection from water (TechnoNIKOL aquamast bitumen mastic).

- Cut-off insulation that does not allow small moisture vapors to pass through (TechnoNIKOL 600, providing reliable protection of structures).

- Bipole EPP 3 allows the surface of the structure to breathe and does not allow moisture to pass through, which is why fungus does not appear.

As a rule, the foundation is constantly exposed to groundwater, which is why it can quickly collapse. To avoid such a problem, roll insulation is used, which reliably protects the structure.

Among most manufacturers, this particular brand stands out, since its products have an optimal price-quality ratio, thanks to which even corporate developers are often the company’s clients.

How to properly install TechnoNIKOL

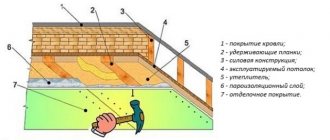

TechnoNIKOL soft roll roofing is laid on flat roofs of buildings for industrial and administrative purposes. The welded products are produced on a synthetic basis; they have a five-layer structure.

During the production process, a reinforced base such as fiberglass is coated with a bitumen coating on both sides. The material is protected on top with a mineral coating with colored granules, and on the back side the self-adhesive layer is covered with plastic film.

The advantage of this roofing product is its absolute waterproofing, resistance to sub-zero temperatures and sound insulation qualities.

Another positive point: TechnoNIKOL’s soft roof installation technology does not require the use of complex equipment. Since the welded material can easily take the shape of roofs of various configurations, including domed ones, it is often used by designers to realize their original ideas.

A large assortment of soft roofing coverings, especially flexible tiles, which are made in a variety of colors, allows you to diversify the appearance of private households.

Insulation with membrane

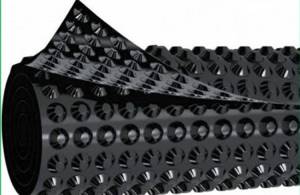

When ground moisture lies high or there is a lot of it, protection is used in the form of a drainage system. When assembling drainage, membrane waterproofing is used, which is created on the basis of high-density polymers.

PVC membrane

During the work process, the foundation is partially excavated, dried, covered with a primer and waterproofing, and then a membrane is installed. The purpose of the membrane sheet is to collect excess water and redirect the liquid to the drainage pipes.

The canvas is laid so that the rounded spikes remain outside. The material is resistant to cold down to -50 degrees, durable, however, does not at all interfere with the movement of air flows. Under the shelter, neither concrete nor earth will rot - ventilation proceeds almost as usual.

Sequence of installation of roll roofing

When installing coatings made from TechnoNIKOL materials, one of two methods is used:

- mechanical;

- using fusion.

The first of them is used when arranging a pitched roof. To fix the canvases, special mastic and galvanized fasteners are used. In the second case, fusing is performed using a gas torch.

This TechnoNIKOL installation technology is used for work on flat roofs:

- You should start laying the sheets from the lowest point of the roof.

- First, a roll of material is rolled out and adjusted to the contours of the surface, ensuring that the coating extends onto the protruding areas of the roof.

- You need to know how to properly lay a soft roof so as not to spoil the material. To prevent the canvas from moving during the adjustment process and when straightening, one edge must be fixed with a heavy object. Roofers recommend placing the roll upside down a few days before starting work so that the material takes on a round shape.

- When fusing the roof, they use the “pull” method. This technique allows you to monitor how warm the bitumen layer is. As a result, the roofer can see whether the torch still needs to be used. Movements should be done smoothly and evenly. In places where TechnoNIKOL soft roofing is laid overlapping, additional heating must be performed.

- The burner must be held so that both the bitumen layer of the coating material and the base are heated at the same time. When heating is done incorrectly, a bitumen bead will appear in front of the rolled roll.

- During work, you need to monitor the uniform melting of the bitumen layer to prevent the appearance of cold and overheated zones.

- The moment the pattern floats is a signal to the builder that he should roll out the material further. When the bitumen is melted, it begins to protrude along the edges of the canvas. The result is seams about 25 millimeters wide (about

Waterproofing a wooden floor with mastics

A less acceptable option for waterproofing wooden floors. What stages does it consist of?

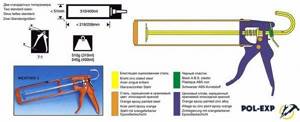

Surface preparation

In addition to cleaning and repair work, you need to take measures to prevent moisture from getting into the cracks between wooden floor coverings. To do this, it is recommended to use plastic polymer sealants. They are sold in tubes; to fill the cracks you need to use special guns. Step 1. Thoroughly clean the cracks from dust and dry the floor. Dust and moisture are the main enemies of any sealants and waterproofing materials; they significantly reduce the adhesion of surfaces. You can clean the cracks with any available objects of suitable size. After removing dirt, each crack should be thoroughly vacuumed.

Important! The cracks should be filled with sealant throughout their entire depth. If necessary, you can go through one place several times.

What parts does a sealant gun consist of and how to work with it? A typical manual sealant gun is assembled from the following elements:

- frame;

- stock;

- trigger;

- pen.

How does a nail gun work?

Gun body and trigger A cartridge or tube with sealant is inserted into the body; the trigger on the handle, when pressed, sets the rod in motion. There is a large washer on the rod, the diameter of the piston in the tube; it rests against the piston and gives it forward motion. As a result, the pressure in the tube increases and the mass is squeezed out of the spout. All models have a special mechanism for instant pressure release. It is needed to ensure that the sealant does not spontaneously squeeze out of the tube during a technological break.

Use a sharp knife to cut off the tip of the tube

The tip is screwed on, the cap is removed. The tube is closed hermetically, which increases the shelf life of the material; before starting work, the tip should be cut off with a knife. The tip has a thread for screwing in the spout. Cut off the spout following the above recommendations and screw it onto the tube. To prevent the sealant from drying out, cover the tip of the spout with a special cap. The tool is fully prepared for use.

The tip is cut at an angle of 45 degrees. Now move the gun piston to the rearmost position. To do this, you need to press the limiting mechanism and pull the rod until it stops against the body. Insert the tube with sealant into the body and move the rod forward with the handle until it reaches the piston of the tube. The gun is ready.

The tube is inserted into the gun body

Using wood floor sealant

Properly installed layers of heat, moisture and vapor insulation will help ensure good performance.

Preparing the roof for work

The welded type of roofing is laid on reinforced concrete, or on mineral wool slabs without pouring a leveling screed, or on an asphalt concrete coating, or on a dry base of cement-bonded particle blocks or asbestos-cement sheets.

The preparatory stage involves a number of measures to eliminate protruding elements on the roof. Vertically located pipes, ventilation ducts, parapets are first plastered with cement mortar, applying it to the height where TechnoNIKOL soft roofing materials will be reached.

Soft roofing technology

Lay the covering on a flat base. The area of gradually increasing irregularities present on the surface should not exceed a size of 2 by 4 meters. Installation is carried out on a dry base, and a moisture meter is used to check the humidity level.

When such a device is not available, then a piece of plastic film is placed on the surface. If after 4 hours there is no moisture on it, then you can begin arranging the roofing.

Before installation, the base is thoroughly cleaned, after which it is primed with a bitumen primer - you can either purchase it or make it yourself from bitumen and gasoline in a 1:3 ratio.

To ensure the longevity of the soft covering on the roof of your own household, the manufacturer’s instructions will help, which describe in detail how to properly glue TechnoNIKOL and arrange a weld-on type of roofing. It must be strictly followed and then an excellent result will be ensured.

Characteristics of TechnoNIKOL roofing materials

Soft materials for TechnoNIKOL roofing are made from bitumen.

Such products are:

- flexible tiles;

- polymer membrane;

- roll coverings.

The structure of these materials is resistant to weather and mechanical factors.

The soft tiles are based on fiberglass, impregnated on both sides with modified bitumen.

The outer side of the product has a protective layer in the form of coarse basalt topping. It is the coating that gives the roofing carpet made of soft tiles different colors.

The inner side of the product is covered with a bitumen-polymer mixture, in turn it is protected by a film layer, which is removed before installation.

There are three types of polymer membrane: with the addition of plasticizers, made on the basis of plastic polyolefins or synthetic rubber.

A PVC-based membrane with plasticizers is considered the most common.

Plasticizers make the roofing covering elastic and give it resistance to exposure to negative temperatures. Tensile strength is increased by reinforcing the base with polyester mesh.

Roll roofing is used for arranging flat roofs of civil and industrial buildings.

The deposited materials are made on a synthetic basis, their structure is five-layer.

It consists of several layers of bitumen coating, which is applied to a reinforced base, for example, fiberglass, and two protective layers: the outer one is mineral coating, the inner one is polyethylene film.

The advantages of soft roofing sold by the manufacturer TechnoNIKOL include 100% waterproofing of the material, a high level of frost resistance and sound insulation.

In addition, installation of any type of TechnoNIKOL soft roof does not require the use of special equipment.

Since the welded material can easily take the shape of any roof (from pitched to dome-shaped structures), designers are always ready to use it in their ideas.

Technonikol's wide range of soft roofs allows you to diversify the roofs of country houses, especially when it comes to flexible tiles, which are produced in a wide range of colors and can take on different shapes during production.

Types of insulating materials

Modern roll waterproofing is divided into classes according to different criteria:

- according to the method of attachment to the base;

- according to the base material used.

Based on the method of fastening, insulating materials are divided into welded, adhesive or mechanically fixed.

Welded waterproofing

The welded insulating material is a rot-resistant base with a layer of binder coating applied to it. The lower part of the roof insulation is a layer of polyethylene, which when heated by the burners melts and is firmly fixed to the surface.

The basis of the fused insulation can be fiberglass/fiberglass, polyester. These materials replaced the cardboard traditionally used in previous years.

The astringent component of roll waterproofing is bitumen or bitumen-polymer mastics, often with the addition of APP (atactic polypropylene), called artificial plastic or artificial rubber SBS (styrene-butadiene-styrene).

Fused roll waterproofing is the most commonly used roofing material. Its popularity is due to its high performance characteristics, easy installation and affordable price. Fused roofing can be installed at any time of the year and on any base. In addition, the fused insulation laid in accordance with the technology is a single whole; there are practically no cracks or joints in it, which enhances its waterproofing properties.

Mechanically fastened roll waterproofing

Unlike built-up waterproofing, in mechanically fixed roll roofing material the bottom layer is not a polyethylene film, but fine-grained sand. The prototype of roll waterproofing with mechanical fastening to the surface is the well-known roofing material.

Modern waterproofing is produced in rolls; the canvas is attached to the base using self-tapping screws or overhead strips. The disadvantage of using this option for fastening insulation is the laboriousness of installation and reduced effectiveness in protecting the roof/foundation from moisture penetration.

Adhesive (adhesive) waterproofing

Adhesive waterproofing, similar to built-up waterproofing, has a base made of PVC or fiberglass with an applied bitumen-polymer component and mineral topping. To install the adhesive waterproofing, mastics or glue based on epoxy resin are used. Reliable protection against moisture is achieved by installing 2-5 layers of insulating material.

Pasted waterproofing can be mounted on any base; their installation does not require special knowledge or additional tools. The main condition for flawless waterproofing using adhesive materials is a flat base surface, without protrusions or irregularities. In addition, adhesive waterproofing requires drying conditions, so installation is carried out in warm, rainy weather.

Features of the TechnoNIKOL roof arrangement

Installation of TechnoNIKOL roofing roll covering can be carried out mechanically and by fusing.

The first fastening option is used for roofs with slopes: the panels are fixed using special roofing mastic and galvanized fasteners.

When fusing a soft roof, the bitumen melts under the influence of a gas burner.

This installation technology is used for flat roofs. Laying the panels begins from the lowest point of the roof.

First, the roll is rolled out and straightened, adjusted to the location, and the material is ensured to reach the protruding parts of the roof.

To ensure that the canvas does not move when straightening and at the time of adjustment, one of its edges is fixed with something heavy.

Experienced roofers know that a built-up roll roofing will lay down exactly when the rolled material is left standing upright a few days before the start of work. Thus, the canvas takes on a round shape.

Roll roofing is fused using the “self-facing” method - this approach allows you to control the degree of heating of the bitumen layer.

By rolling out the roll towards itself, the roofer sees at what point it is necessary to continue working with the burner.

The movements of the gas burner must be smooth and uniform; it is very important to carry out additional heating in those places where the material is overlapped.

The gas burner must be held so that the base and the bitumen layer of the roofing sheet are simultaneously heated.

If heating is performed correctly, a bitumen bead will appear in front of the roll being rolled out.

In the process of fusing TechnoNIKOL soft roofing, it is important to control that the melting of the bitumen layer occurs evenly, which will eliminate the appearance of cold and overheated zones.

The installation of surfaced materials is simplified by the presence of a pattern on their inner side, which helps control the degree of bitumen melting.

When the pattern floats, this will serve as a signal to the roofer that it is time for him to roll out the roll further.

If the bitumen is melted correctly, it will begin to appear along the edges of the canvas, after which smooth seams approximately 25 mm wide should remain.

If, when installing a roll-floated roofing, it is necessary to fuse the sheet on top of the mineral coating, then simply heating the surface and laying the material will not be enough; this method threatens the roof with leakage.

It would be more correct to first thoroughly melt the surface with the topping, then use a spatula to drown it in a layer of hot bitumen. After this procedure, you can proceed to the standard method of fusing the fabric.

TechnoNIKOL for garage roof: varieties and characteristics

How to cover a garage - TechnoNIKOL ! Such a soft roof refers to flexible finishing coatings made on the basis of bitumen. The material is based on fiberglass or polyester , impregnated and coated on the top and bottom sides with a special type of bitumen.

The top side has an additional basalt topping , which makes the material resistant to mechanical, atmospheric and temperature influences. The underside of the material is equipped with a self-adhesive bitumen layer with a protective film.

Technonikol roofing materials is their varied colors. The surface covered with this type of soft roof is not only durable, but also aesthetically attractive.

TechnoNIKOL garage roofs come in the following types:

- soft tiles;

- welded roll coating.

Advantages and disadvantages

TechnoNIKOL soft roofing has many advantages and disadvantages compared to other garage roofing materials:

- Resistant to both high and low temperatures. It will perfectly withstand heat of plus 50 , and frost of minus 50-60 degrees .

- One hundred percent waterproofing even in conditions of heavy rains and active snow melting.

- Anti-corrosion . The material does not rot, does not rust or oxidize at any level of air humidity.

- Resistant to wind and mechanical stress. Even the strongest hurricanes are not afraid of this roof. It cannot be torn off by a strong gust of wind, nor can it be damaged by hail or branches falling to the surface.

- Ease of installation . You can cover a garage with such materials yourself, without the use of special equipment.

- Attractive price. A variety of materials in different price categories will allow each consumer to find an option that suits them.

TechnoNIKOL soft roofing is the need for a continuous base for its installation. This requires additional costs for installing a pitched roof and laying a layer of plywood on it.

Installation terms and conditions

Features of installing a soft roof depend on the selected type of material. There are two main installation methods: fastening and fusing . The first is used on sloping roofs and requires the use of fasteners with nails, screws, and staples. Built-up roofing is designed for flat roofs . Rolled materials are rolled out over the surface and secured by heating with a gas burner.

, the roof base must be carefully prepared before installation . The surface is leveled, cleaned and thoroughly dried.

The air temperature for work should be no lower than plus 6-7 degrees and no higher than 25-26 degrees. The best time to work is from spring to early summer and early autumn.

Preparing the base

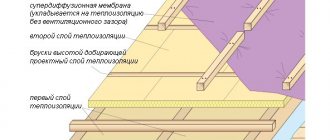

The longevity of a roof using TechnoNIKOL depends on the correct installation of the roofing pie and the organization of ventilation of the space under the roof. A roofing pie is a multi-layer structure that protects the interior space from precipitation and retains internal heat.

The design of the pie depends on material :

- Wooden cold roof. The roofing pie consists of layers:

- roofing;

- lining;

- base (plywood flooring). Experts recommend using moisture-resistant chipboard or OSB. The thickness of the plywood is ten to eleven millimeters. A gap of 3-5 mm is left between the plates in case of possible expansion due to changes in temperature and humidity;

- sheathing. The sheathing material must be impregnated with an antiseptic;

- rafter layer.

- Warm wooden roof. Its design requires the installation of additional insulating layers:

- roofing material;

- lining;

- diffuse membrane;

- insulation;

- vapor barrier;

- plywood base;

- sheathing;

- rafter leg;

- sheathing for insulation;

- lining of the internal roof space.

- Concrete roof. Roofing TechnoNIKOL on a flat concrete roof involves the installation of the following layers:

- roofing material;

- slope - expanded clay fill or concrete screed;

- thermal insulation;

- vapor barrier membrane.

TECHNONICOL self-adhesive floor waterproofing - an ideal solution for a frame house

Currently, frame housing construction is rapidly developing in Russia. Such houses have many advantages: speed of construction, the possibility of using energy-efficient construction technologies, and low cost. However, one of the conditions for the longevity of wooden houses is proper protection from the harmful effects of moisture. In this case, we are talking about rooms that are characterized by high humidity: bathrooms, toilets and kitchens. Waterproofing floors using screeds in frame houses is not always possible, because this significantly increases the load-bearing load on the wooden floor.

In cases where the structure of a wooden floor is not designed to withstand the additional load from a cement-sand screed, but it is necessary to waterproof the floor, to help builders, TECHNONICOL Corporation has released a new rolled waterproofing product that will serve as a solution in such a situation. We are talking about TECHNONICOL floor waterproofing. This is a baseless bitumen-polymer material intended for waterproofing interfloor ceilings.

The material can be installed either under a protective screed or without it. Laying tiles directly on TECHNONICOL floor waterproofing (without installing a protective screed) is ideal for installing waterproofing in frame houses. Using this material, the work can be done independently, without the use of complex technical equipment and the involvement of specialists. And if additional labor is involved, you can easily control the work, since laying the material is simple and clear.

The material is self-adhesive; to install it you will need a simple set of tools - a knife, a rolling roller, a brush and a roller (for priming the base and waterproofing). In addition to the TECHNONICOL Floor Waterproofing itself, you will also need a water-based TECHNONICOL bitumen-emulsion primer or a deep penetration latex primer.

Preparation of the base for installation of TECHNONICOL floor waterproofing

When preparing the base for installation of roll self-adhesive waterproofing, it is important to know that the base must be as non-shrinking as possible. Taking into account the fact that the load-bearing load of a wooden floor may not be designed to weight the structure with a screed, the installation of TECHNONICOL Floor Waterproofing can be carried out without its installation. In this case, the top rough covering of the floor, which will be the basis for gluing the waterproofing, must be made of low-shrinkage material, for example, DSP boards. They are resistant to changes in temperature and humidity conditions and retain the shape of the structure.

The base for installation must be level, since the finishing tile covering is immediately installed on top of the waterproofing. For the same reason, it is very important that by the time the waterproofing is installed, all engineering communications have already been installed either outside or in the body of the house structures in compliance with fire safety standards.

Material calculation

TECHNONICOL floor waterproofing is available in rolls 75 cm wide and 10 meters long. For a standard bathroom with an area of about 4 sq.m. one roll will be enough. When calculating material consumption, it is necessary to take into account the fact that waterproofing must be installed on vertical surfaces to a height of 20 cm. Based on this, the waterproofing calculation coefficient is equal to 1.75 to the floor area of the room.

Preparing the base

In addition to the fact that the installation base must be level, it must be free of debris and, ideally, dust-free. If it is possible to use a construction vacuum cleaner, then it is better to use it.

In addition, the base for installation must be treated with a primer to improve adhesion, i.e. gluing waterproofing to the surface. For this purpose, you can use either a water-based TECHNONICOL bitumen emulsion primer or a deep penetration latex primer. It is important to take into account that not only the horizontal base is treated with the primer, but also 20 cm of adjacent vertical surfaces.

The most convenient way to apply the primer is with a paint roller with a long handle or a brush.

Preparation of material

Initially, it is necessary to measure the base and cut the material into strips of the length required for installation, taking into account longitudinal overlaps 10 cm wide and transverse overlaps 15 cm wide.

Additionally, we prepare the elements that we will place on the vertical surface. To do this, we cut elements 30 cm wide, of which 10 cm will be mounted with overlap on a horizontal base, and 20 cm will be mounted on the wall. On prepared strips of material, it is necessary to carefully trim the protective film along the bend line of the canvas from horizontal to vertical surface along the entire length of the material. We also cut the film on these elements to form transverse overlaps, the width of which is 15 cm.

Places of longitudinal and transverse overlaps of all prepared material elements must be treated with a primer (TECHNONICOL water-based bitumen-emulsion primer or deep penetration latex primer). The width of application of the primer composition corresponds to the width of the overlaps (longitudinal - 10 cm, transverse - 15 cm)

Before installation, all prepared material must lie on a horizontal surface for at least 30-60 minutes.

Installation of TECHNONICOL floor waterproofing under tiles (without a protective screed): Installation on a horizontal surface.

You can begin laying the material only when the primer composition has completely dried both on the base and on the material sheets prepared for installation. For ease of installation, prepared waterproofing strips can be rolled into rolls immediately before starting work. Installation begins from the far corner of the room. Laying is done by carefully removing the protective film and gradually gluing the material to the base. The already glued waterproofing needs to be additionally rolled with a roller, this will help to avoid possible bubbles or waves.

During installation, you should ensure that in places of transverse and longitudinal overlaps, the lower sheet of material must be treated with a primer at the stage of preparing the material for installation.

The discrepancy between the end overlaps of adjacent rolls must be at least 50 cm.

Installation on a vertical surface.

In order for the installed waterproofing to work, it is necessary to install it not only on a horizontal surface, but also to place the waterproofing material on the vertical surface of adjacent areas to a height of 20 cm. Carefully removing the protective film, first lay the material on a vertical plane, smooth it, press it and roll it with a rolling roller. We make sure that the material adheres evenly to the surface.

Next, remove the protective film from the second part of the element and glue it to a horizontal surface on the installed waterproofing.

To strengthen internal and external corners, use triangular patterns made of self-adhesive waterproofing. We pre-treat the corners with a water-based bitumen primer or latex primer, wait for complete drying, and then lay the waterproofing patterns on the corners and carefully roll them to the base.

You can immediately install tiles on top of the installed TECHNONICOL Floor Waterproofing. To do this, the surface of the material must be treated with a soil composition of the “ConcreteContact” type. This will strengthen the adhesion of the tile adhesive to the installed waterproofing.

Installation of tiles must begin after the applied “Betonkontakt” has completely dried.

TECHNONICOL floor waterproofing is a modern self-adhesive waterproofing roll material that is the optimal solution for protecting the floors in frame houses and timber houses from the destructive effects of moisture. Thanks to the ability to abandon the screed and lay the tiles directly on the material, you can not only avoid additional loads on the wooden floor structures, but also save resources.

Installation technology

How to cover a garage with Technonikol ? Installation of a soft roof is simple, but requires compliance with certain rules and a strict sequence of actions, depending on the type used.

For the vapor barrier layer, it is advisable to use a special TechnoNIKOL . They consist of three layers that will help maintain a balance of temperature and humidity inside the garage.

In addition, the strength of the material allows it to be laid on any, even untreated surface. For pitched roofs , a membrane should be used; for flat roofs , perforated and non-perforated film should be used.

Range of waterproofing products from Technonikol

During construction, many important and small details are taken into account. Protecting the foundation from the action of water in the ground is one of the most serious issues. Ignoring it often leads to negative consequences:

- the foundation is destroyed faster than expected, both outside and inside;

- the basement or underground garage is constantly flooded;

- The operating time of the entire building is reduced.

The use of TechnoNIKOL foundation waterproofing can avoid damage and extend the life of the house. The company produces materials that differ in the methods of their application to the base. The following technologies are used:

- pasting;

- smearing

The products are produced in the form of rolls and mastics. Installed waterproofing membranes are also used. They are used in conjunction with other types of products. Not only the cost of the product, but also its quality and practical effectiveness depend on the components included.

You should pay attention to the markings when choosing. It should be borne in mind that the polyester fiber base is inherent in cheap, budget products

Installation of TECHNONICOL flat roof waterproofing

Do you want to know how to make reliable waterproofing of the flat roof of a domestic building, gazebo or garage with your own hands without the involvement of expensive specialists and without the use of expensive equipment?

With the new roll material “Flat Roof Waterproofing” this has become possible.

In this article we will tell you how, using “TECHNONICOL Flat Roof Waterproofing”, a bitumen primer (or bitumen-polymer primer) and a simple set of tools (rollers, roofing knives, spatulas and brushes) you can independently waterproof a garage flat roof