- Types of installation: where to install

- How to choose the size and shape of a chimney

- Preparatory stage

Before you begin installation, familiarize yourself with how to properly install a chimney pipe in a bathhouse with your own hands. The process largely depends on how competently you can choose a design, based on the parameters of the stove and the volume of the steam room.

In addition, it is necessary to consciously approach the choice of material, set of elements and installation method. And also in this article we will talk about the main design features of chimney systems, and the problems that can arise if installed incorrectly.

Design features of a chimney for a steam room

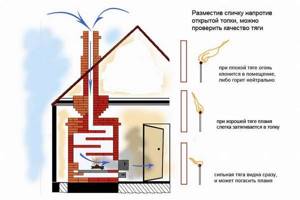

- The chimney is a vertical structure mounted inside the bathhouse or on the facade of the building. Its main task is to remove fuel combustion products at a speed sufficient to maintain natural draft in the furnace.

- A well-designed design ensures quick heating of the bath, maintaining the necessary microclimate in the steam room and economical fuel consumption.

- The most common problems with smoke exhaust ducts: Extremely strong draft, which will lead to rapid burning of fuel without adequate heating of the steam room. Traction too weak. An inadequate amount of oxygen enters the firebox, as a result of which the combustion process is interrupted, and then the thermal conductivity of the stove decreases.

- Proper installation of the chimney is a guarantee of your own safety and the longest possible service life.

What materials are resistant to high temperatures?

When the stove is heating up, the temperature reaches a critical level, so the wood can ignite from direct contact with a hot pipe, which will lead to dire consequences.

To avoid fire, you need to create an insulating layer from any non-combustible material. Perfect for this:

- Mineral wool. Fiber insulation made from inorganic threads. Confidently tolerates temperatures up to 300 degrees Celsius. Choose brand PZh-175 or PPZh-200 to ensure maximum thermal insulation properties. Such mineral wool products are manufactured in accordance with GOST 9573-96 Mineral wool slabs of increased rigidity and in accordance with GOST 22950-95, as well as in accordance with GOST 21880-94 - pierced mats.

- Minerite. Thermal insulation material consisting of cellulose and limestone on a cement base is a dense slab that can effectively withstand temperatures up to 150o C. The maximum heating temperature that mineralite can withstand reaches 400 degrees.

- Basalt cardboard. Dense environmentally friendly material with a thickness of 5 mm, which reliably protects and withstands temperatures up to 900o C.

- Asbestos cardboard. It also allows you to create excellent fire protection. Has a thickness of up to 10 mm. Does not lose its properties for many years. The only drawback is the production of toxic fumes when heated, which is a critical factor for use in a bathhouse.

If you want to carry out the initial cladding of the ends of the floor and have already accurately taken all the measurements and made indentations, then you can also use low-flammable materials, including:

- Magnesium glass sheet - the standard option is not suitable for protecting wood, so choose premium products.

- Fireproof plasterboard - differs in characteristics from standard plasterboard in that it has enhanced adhesion of layers and reinforcement on the inside. Therefore, fire-resistant drywall has protection against critical temperatures and does not ignite even if it is thrown into the fire for 15 minutes.

If you want to create an additional layer of thermal insulation for the chimney, then give preference to basalt wool. It does not deform and does not lose quality even at a temperature of 1000 degrees Celsius.

To protect the box when the pipe passes through the ceiling, basalt cardboard should be laid. To save money, but not lose quality, you can fill the walk-through box with clay. A metal sheet with sides containing clay (uniform distribution with a thickness of up to 2.5 cm) will help protect the ceiling from elevated temperatures in the area where the box is attached.

Choosing material for a chimney in a bathhouse

The market offers a wide range of raw materials for the production of smoke exhaust structures; let’s briefly name each of them.

Asbestos cement pipe

It is low cost and easy to install, however, due to its porous structure it can accumulate condensate.

Black metal

It conducts heat very well and heats up quickly, but lacks corrosion resistance. It has a large mass, which complicates the installation process and also requires the construction of a foundation.

Brick chimney

The model is quite expensive and difficult to install, although its appearance is very pleasant. If you do not line the inside, the structure becomes clogged with soot, susceptible to condensation, dampness, and subsequently cracking and allowing carbon monoxide to leak.

Ceramic chimneys

Due to its strength, ceramics can withstand high temperatures, are durable and can be used with any type of boiler. However, the installation of such a chimney is very expensive, and the design itself is poorly maintainable. Therefore, installation should only be carried out by a qualified technician, and the owners will have to treat this ventilation system with care.

Stainless steel

Most bath complexes - home or commercial - use this option. This is due to excellent resistance to atmospheric agents; soot virtually does not accumulate, and the installation will last for many years. The appearance fits well with any bathhouse exterior; the shiny surface is pleasing to the eye. In addition, this design is quite easy to maintain.

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

Glass

A glass smoke duct is a good choice, since this material has minimal inertness and is resistant to moisture and corrosion. The constant increase in the cost of installing such a structure is due to the complexity of the process and the high cost of fire-resistant glass in general. Therefore, such chimneys are the most expensive systems these days, although the cost is fully justified by the advantages of this option.

Pipe passage through a chimney without a factory passage unit

It is possible to remove the chimney without a passage device. In this case, the edges of the hole in the ceiling are also sealed with a fire-resistant heat insulator, and metal strips are placed on top of it. A protective plate made of non-flammable material is put on the sandwich coming from the oven, in which a hole of a suitable diameter is cut, and holes are drilled along the edges for fasteners. Traditionally this is a sheet of metal. Next, the sandwich is passed into a hole in the ceiling and fixed there using some non-flammable guides. For example, you can use drywall profiles or something similar. The main thing is to securely fasten the pipe and observe the basic rule of fire safety: there must be a distance of at least 36 cm from the edge of the pipe to the flammable material.

You can make a passage through the ceiling with your own hands

Important! When installing and securing the chimney, keep in mind that the pipe changes its size due to thermal expansion. It must be secured so that it can move relative to the roof. Then from below (from the ceiling) the pipe is hemmed with non-flammable material

From the attic or second floor side, the voids formed in the groove are filled with a heat insulator. The requirements for it are still the same: tolerance to high temperatures. Expanded clay may be the most budget-friendly. Actually, this completes the exit of the chimney pipe through the ceiling

Then the pipe is lined with non-flammable material from below (from the ceiling). From the attic or second floor side, the voids formed in the groove are filled with a heat insulator. The requirements for it are still the same: tolerance to high temperatures. Expanded clay may be the most budget-friendly. Actually, this completes the exit of the chimney pipe through the ceiling.

You can make a passage through the ceiling with your own hands

What pipes are used

You need to know that the likelihood of using the sauna without a threat to your health depends on how the chimney of the sauna stove is installed.

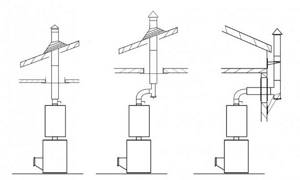

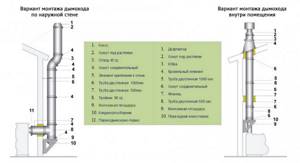

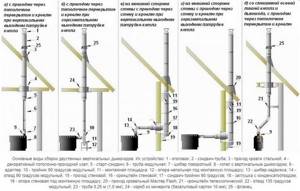

The chimney installation scheme comes in two configurations: internal and external. Depending on this, the chimney elements are selected.

Types of installation: where to install

Installation can take place on brackets through the wall or straight through the roof.

In the first case, the entire system is carried into the wall, and then rises, adjacent to the bathhouse, but without passing through it. This looks more aesthetically pleasing, and has the following advantages:

- the free space of the steam room is not used;

- there is no risk of getting burned on steel or stone;

- less chance of fire;

- it’s easier - you don’t need to make a hole through the entire attic;

- cases of smoke are easier to detect, as well as to track the general condition.

But at the same time:

- heat loss increases, since steam actually immediately enters the outside;

- the installation itself is more difficult due to the need to comply with the dimensions of the connection between the hole in the wall and the parts of the product;

- The heating of the pipe is greater due to the fact that the gases escape in the horizontal direction. With this arrangement, the resistance of the flue gases when moving through the channel increases;

- In terms of the number of elements, this option is 10% more expensive than the usual one.

When installing smoke exhaust systems in a straight line through the roof, the chimney is located straight, without bends, it departs from the boiler and goes upward, where it crosses the ceiling and exits on the back side of the roof. Advantages of such a connection:

- Stable draft due to the location of the chimney closer to the roof ridge.

- The condensate container is kept warm, so its cleaning pocket is dry and clean. This extends the service life.

- Cold bridges do not form in the walls, and thermal insulation is not compromised.

- The stability of the smoke exhaust duct is higher due to the fastenings to the roof. The fasteners themselves can be chosen cheaper than for the option on the facade.

- The aesthetics of the structure are not spoiled by side smoke outlets.

- Only a small part of the structure is located outside, which deteriorates over time from snow and rain. You can inspect and clean most of it without leaving the building.

- You can use non-insulated parts of the chimney that are located inside the bathhouse.

- This option is easier and 10% cheaper to install than when outputting through a wall.

- Flue gases go up, there is no obstacle to their exit. Heating is less than with a horizontal connection, since the resistance to smoke flow is minimal.

However, there are also weaknesses:

- The probability of “missing” the occurrence of a fire is higher, since smoke occurs in the ceilings that are located in the attic and on the roof, and they are simply not visible until the fire appears.

- Heat loss through the roof. Tightness is restored when waterproofing is installed before coating.

- Reduction of usable area, since according to safety requirements there should be nothing around the stove pipe for a bath.

- Increased costs for changing the roof and ceiling of the steam room, in particular, after finishing the final finishing.

- If the integrity of the smoke exhaust structure is damaged, the bathhouse begins to smoke.

- Condensation leaks and accumulated soot spoil the appearance of the roof.

- Burns from heated parts are possible in emergency situations.

When deciding on the installation method, the following nuances must be taken into account:

- dimensions of the building - if it is very small, then it is logical to make an external structure;

- the steam room is built from scratch or in an old room - in the first case, you can immediately think about the issue of insulation;

- Do you need to heat adjacent rooms?

External placement

An external smoke channel device is more expensive and difficult to install. This is due to increased requirements for compliance with the dimensions of the connection between the hole in the wall and parts of the product. For external installation, it is necessary to use double-walled chimneys to avoid the formation of condensation and fire. It is external structures that are the least flammable, since the smoke is instantly directed outside, rather than circulating through a pipe located in the building. The advantage of such a system is the absence of the need to make a hole in the ceiling and roof and saving of internal space. This reduces the risk of carbon monoxide poisoning.

Internal placement

The main advantage of the internal location of the chimney is the easy provision of draft in the chimney structure, which is achieved by the vertical direction of the exhaust gases. In this design, the main part will be located in the interior of the building, which allows the bath room to heat up much faster. However, from a fire safety point of view, this design is more dangerous, since it is much more difficult to notice smoke in the ceiling or in the attic.

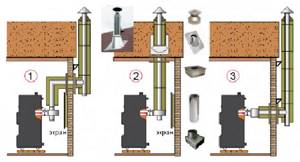

Design of external and internal chimneys

The design of the chimney is selected depending on the characteristics of the selected stove. The pipe package includes several components, each with its own functional features. For a bathhouse with a brick stove, you can use brick, metal, ceramics, and for a metal stove - a ceramic or metal chimney. You can use brick, but laying the pipe yourself will be difficult. You will have to hire a bricklayer - a stove maker.

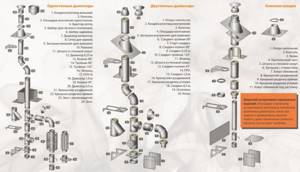

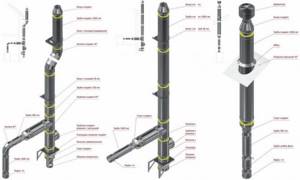

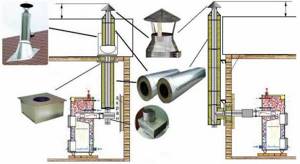

The main components of the chimney (design lists start from top to bottom):

- Head (probe) - prevents sparks from hitting the roof and neighboring buildings, as well as from flooding during rain.

- Master flush.

- Chimney made of double sandwich or brick.

- PPU (Ceiling assembly where it goes through).

- Chimney made of double sandwich or brick.

- Single iron pipe.

When choosing a brick structure, you need to be prepared for complex cleaning and maintenance. A massive foundation is needed for the stove, since a brick chimney weighs a lot, and the entire load will fall on the stove.

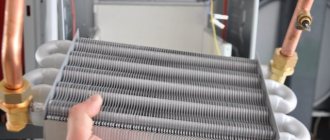

A simpler assembly that does not require special knowledge is a ready-made structure made from sandwich pipes. It consists of a double structure between which asbestos is laid. More heat-saving and lighter. They are made up of individual elements: elbow, deflectors, tees, rain protection, adapters and gate. Fastened using brackets that are mounted with clamps.

Is it possible to install a sandwich chimney in a bathhouse with your own hands?

The use of this design allows you to prevent and protect the room from possible fires. Thanks to the insulation, the heating temperature of the pipe usually does not rise.

There is a certain sequence that accompanies proper self-assembly. Strict compliance with the rules and recommendations of the manufacturer, guaranteeing the uninterrupted operation of the chimney system.

Why is chimney insulation necessary?

The main task of thermal insulation of a chimney pipe is to create thermal conditions under which condensation will not form in the pipe cavity. As is known, due to a significant temperature difference between the interior of the operated chimney and the cold outside air, condensate forms in significant quantities on the walls inside the pipe. Insulating the chimney allows you to move the so-called dew point outside the chimney, thereby eliminating the very cause of moisture condensation.

The condensate formed in the chimney contains water and a solution of sulfuric acid, which is obtained as a result of complex processes that occur during fuel combustion. The result of exposure of the pipe to such an “explosive” mixture is its active destruction from the inside.

This applies to the maximum extent to single-layer pipes made of metal. Sandwich, brick and asbestos-cement pipes are somewhat less susceptible to harmful effects.

Condensation stains caused by lack of pipe insulation

What should you pay attention to when installing a chimney in a bathhouse?

Below are guidelines on what to focus on first.

How to choose the size and shape of a chimney

The small cross-sectional size will prevent the removal of fuel products in the required quantity. The volumetric section, on the contrary, contributes to the movement of smoke too quickly, which will not allow the bathhouse room to be properly heated. This, in turn, will increase fuel costs. You should take this point seriously, since the result will depend on it.

Deciding on the form is easy if you take into account the basic principle of its operation. Chimneys tend to heat up unevenly, as a result of which smoke comes out to the roof surface along the central axis. It follows that the correct shape is a circle. Cylindrical structures heat the room much faster and do not require unnecessary financial costs.

A chimney with a rectangular cross-section provokes turbulence that interferes with the necessary draft. A rectangular configuration is permissible only when we are talking about heating devices that do not require powerful traction.

Pipe diameter

The scale is determined by the degree of power draft of the sauna stove and is located in the intermediate range from 115 to 270 (mm). However, in order to accurately determine the diameter, you need to familiarize yourself with some of the requirements specified by the manufacturer in the instructions. If you do not have a diagram for installing a chimney for a bathhouse with your own hands, then it will be enough to know the ratio of the cross-sectional diameters of different shapes. It looks like this:

- cylindrical – 1 to 10;

- rectangular - 1 to 1.5.

For brick chimneys, the minimum cross-sectional diameter should be 140x140 mm.

The successful operation of a chimney system primarily depends on how accurately the pipe size is determined.

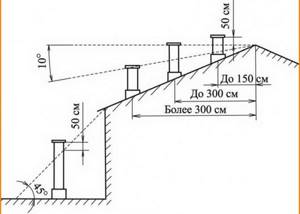

Flue height

According to the standard, its height should be at least 5 meters. The calculation of the height of the chimney is carried out in accordance with the basic technical characteristics of the materials.

The channel should be located at least half a meter above the roof ridge and not below its level. In this case, it is worth taking into account the thickness of the roofing covering and the angle of inclination of the roof slope. The height is selected without taking into account the chimney “umbrella”.

Homemade ceiling cuts

It is possible to install a chimney through the ceiling in a bathhouse without using factory components. You will need:

- Find or cut a sheet of stainless steel that will cover the hole of the required size.

- In its middle, cut out a circle, one or two millimeters larger than the diameter of the pipe that will pass through the ceiling. If it is a sandwich, then slightly larger than the outer diameter of the sandwich.

- Cut a hole of the required size in the ceiling.

- The edges of the cutout along the perimeter are sealed with a layer of basalt wool.

- Place strips of metal on top of the heat insulator.

- You begin to assemble the chimney. Place the first single-walled piece of the stove tube, put a stainless steel square with a cut-out hole on it, and install the sandwich.

One of the options for fixing a pipe in a cut hole - Place the pipe strictly vertically. From the attic side, use metal strips to secure it in the desired position. The planks serve only as guides. The chimney itself does not need to be fixed: it should move freely when changing dimensions (occurs when heating and cooling).

- On the side of the room, place a layer of heat insulation between the ceiling and the plate, and screw the plate onto self-tapping screws. It is better to drill holes in advance: four along the edges, and at least one or two on each side.

- Next, insulate the resulting passage.

As you can see, ceiling cutting is easy to do with your own hands. This is the simplest, but quite reliable option. Another option is presented in the video. The work is more complex, but if you have the appropriate skills, this option of passing a pipe through the ceiling can also be done with your own hands.

General installation recommendations

It is necessary to study in as much detail as possible the information on how to properly make a chimney pipe in a bathhouse and all the details related to its installation, because reliability, service life, performance and, above all, your safety will depend on its quality. Any seemingly insignificant mistake can provoke irreversible consequences.

First you need to familiarize yourself with the main instructions of specialists and instructions (if available).

Preparatory stage

The areas where the smoke channel passes through the ceilings must first be protected. The step-by-step guide for this stage of installing a chimney in a bathhouse with your own hands is as follows:

- Preparing the passage pipe. It is required to fill its exterior with basalt wool.

- Next, you need to insulate the inside of the unit - decide on the installation point on the ceiling and prepare a hole of the desired shape.

- In the area where it meets the ceiling, spread another thermal insulation layer and then proceed to the cutting device.

- Be sure to leave a small gap between the passage unit and the smoke channel.

Roof work

Start this stage by dismantling the roof:

- It is necessary to determine the dimensions from both the internal and external areas of the roof, taking into account the roof slope (slope).

- Cut a hole inside the roof. To do this, cover the opening areas with metal sheets on both edges, the thickness of which should be 0.5 (mm). You need to make 4 holes measuring 450 by 450 (mm), using the square section method. The scale depends largely on the adapter.

- A roof flashing or master flash is used to pass the chimney through the roof. Their main task is to seal the passage and protect against moisture.

Please note: the master flush must be placed under the top edge of the roof to avoid leakage. Also, seal the joint with the pipe and secure everything with roofing screws.

Passage through the wall

We invite you to familiarize yourself in more detail with two installation schemes with detailed descriptions.

In the case of installing a chimney for a bathhouse with your own hands with a side outlet, the process is carried out as follows:

1 installation option

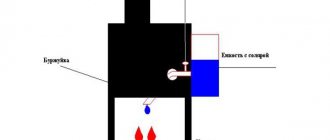

Passage through the wall, outside the bathhouse. When choosing a chimney for a wood-burning stove in a bathhouse, you need to choose a stainless steel pipe 0.8 mm thick. We install an adapter on the furnace pipe (if you have a metal one) (this is the starting element when assembling condensate), then a single-wall pipe of at least 0.5 m or a pipe heat exchanger (if you plan to have hot water in the washing room). We install a damper on the heat exchanger. We will talk about the need for a gate in a separate article.

Next, we place a 90° elbow on the gate, place a start-sandwich on it to transition from a single-wall pipe to a double-wall, and then a 1.0 m sandwich pipe. If your wall is not wide, then you can put a 0.5 m pipe.

An important point: to pass through walls and ceilings, it is necessary to use a sandwich.

The section of the wall (as well as the ceiling) is the most fire hazardous in the bathhouse, so it is necessary to take the equipment of this unit seriously. We propose installing a PPU (ceiling-passage unit) inside the steam room; the opening is closed from the outside with a screen (stainless steel sheet). If your wall is wide, then you will need a second PPU for installation outside. Ferrum's assortment includes polyurethane foam of various configurations. We will go into more detail in a separate article on this element.

It is necessary to loosely lay kaolin wool or sheets of technical mineral wool into the passage unit in a layer of 5-7 cm in order to remove “excess” heat. There is no need to add more cotton wool, as this may cause the sandwich to overheat. Next, we attach a sandwich tee to the pipe outside the bathhouse. We install a condensate drain at the bottom of the tee. On top of the tee we attach 1.0 m sandwich pipes in the amount of 3 pieces or more, depending on the height of the bath.

Given the weight of double-walled chimneys, you will need to install a mounting platform and a console from below to strengthen the kit. For stability from above to the wall of the bathhouse, we attach the chimney with a wall clamp. The final element of the main pipe will be the head.

The next stage of work will be connecting a 75 liter water tank to the heat exchanger, but we will talk about this separately.

Special instructions:

- After you have checked that all the chimney elements are in place and fit together well, we recommend sealing the joints with silicone sealant at 150° before installation.

- During installation, all modules are attached inside the previous element with the narrow end (along the condensate).

- Do not forget that all joints of the sandwich pipe, elbow, tee and adapter must be secured with clamps. All these elements are available in a wide range in the Ferrum line, the price list for which can be found on the website.

- The lengths of the chimney elements must be selected so that the connection does not end up inside the ceilings.

- If there is a tee in the chimney, then it must be placed on the mounting platform with fastening. The distance between sites must be at least 5.0 m from each other.

- To pass through the floors, it is necessary to use a ceiling-passage assembly.

Installation option 2

Internal location of the chimney. In terms of the set of elements, this option is almost no different from the first. It is imperative to use a sandwich pipe to pass through the ceiling.

An additional element when installing inside a bathhouse is the roof trim.

Making and installing a protective (pass-through) box with your own hands

- Make 4 metal sheets on a scale of 50 by 50 (cm) with holes cut out (in the middle) in accordance with the size of the pipe.

- Using a welding machine, connect the existing sheets to each other or fasten them with self-tapping screws.

- The resulting metal box is insulated using basalt wool, and a foil coating is made on top of the previous layer.

- A pipe is inserted into the box. The box is installed in the ceiling passages and secured with screws.

- Then attach a steel sheet with a pre-cut hole for the chimney to the roof surface.

Assembling the chimney structure

When the stove is not located clearly under the ceiling opening, an elbow (bend) is used. But you shouldn’t overuse it, as soot and fumes can accumulate inside.

A head is attached on top, which you can build yourself in a simple way. But it is still recommended to purchase a ready-made version.

The outer pipe is designed as follows:

- First, the knee is attached to the wall, and only then the main device.

- A ready-made protective box filled with expanded clay is attached to the wall, from which the main part rises outward.

- Then, from the outside of the room, a tee is attached to it. Each of the parts is connected in turn.

Fastening: how to properly install a chimney pipe in a bathhouse

Upon completion of the chimney assembly, attach the tee to the mounting platform and tightly compress all existing joints with clamps. A cone is placed on the last pipe (sandwich), an umbrella or deflector is placed on the cone to prevent precipitation from entering and wind blocking the smoke channel.

The pipe is more than 1.5 meters higher than the roof and is secured with a tension clamp.

Installation of a chimney

A window measuring at least 50x50 cm is cut into the ceiling or wall covering. A passage unit with a hole equal to the diameter of the pipe, plus 3-5 mm, is mounted into this hole for free installation, which must be secured with special metal fasteners in pre-made holes, after which, fastened with a wall. Then the pipe is inserted into the protective box. From the attic side, fill the metal box with expanded clay. As a decorative element after installation, you can use a stainless steel protective screen, which increases fire safety.

Completion of installation work

Next, when you have completed the installation process, be sure to remove the additional coating from the pipes and apply a fire-resistant sealant instead.

How to bring a pipe through the roof

To organize a hermetically sealed connection between the roof and the chimney, an internal apron is created at this point. To create it, use the lower abutment strips. The strips are applied to the walls of the chimney, where its upper part is marked. A groove is made along this line using a grinder. Then the dust is carefully removed from the formed border. This is done so that small particles of sand and cement do not fall on the surface of the waterproofing or roof. In some cases, fine grains of sand will turn into an abrasive over time, which can seriously damage the roofing material.

The lower apron begins to be installed from the bottom wall, while only one part of the apron is inserted into the groove. Similarly, this element is attached around the entire perimeter of the chimney. Individual elements must be overlapped with an overlap of 15 cm. The joints are sealed.

For chimneys with a round cross-section, you can purchase special passage elements in hardware stores, consisting of a steel sheet and an apron cap. Their use allows you to significantly speed up the work on equipping the passage of the chimney pipe through the roof. The purchased or manufactured apron should be securely fixed to the roof. At the same time, it is not rigidly fixed to the chimney, since expansion of the material or shrinkage of the rafter system can cause damage to the chimney by the apron (be sure to read: “Roof penetration - device”).

The passage of a chimney pipe through the roof, detailed video instructions:

At the junction of the pipe and the apron, a skirt is installed - a steel clamp, which is secured using a heat-resistant gasket. This approach can significantly improve the waterproofing of the roof in a given location. Upon completion of the installation of the apron, it is necessary to apply sealant to all junctions between the element and the chimney. This helps to obtain a reliable connection that does not leak.

Mistakes when installing a chimney in a bathhouse

- Assembly based on smoke, not condensation. The most common and common mistake that very quickly damages the pipe.

- Placement of wooden floors close to the pipes in the ceiling and walls. Savings on polyurethane foam.

- The use of materials that are strictly contraindicated for use as a smoke exhaust, since some of them can cause a fire.

- Insufficient chimney height.

- Grouping several chimney structures into one.

- Arbitrary calculation of the scale and diameter of materials.

Installing a chimney is a very serious process that requires the necessary skills, attentiveness, patience, and a responsible approach to studying information about various installation methods. If you strictly follow the manufacturers' instructions or the tips given in this article, you will definitely not make mistakes in the process.

Remember that chimney repairs often cost many times more than just installation services. It is for this reason that it is better to follow all the rules and recommendations at the bathhouse design stage.

Sandwich pipes - a modern solution for chimney thermal insulation

Recently, various manufacturers have begun to produce new safe sandwich pipes for baths and saunas. With such a design, there is no longer any need to worry about how to protect the pipe in the bathhouse (more details: “Advantages of a pipe for a sandwich bathhouse when building a chimney”). The design of such pipes involves quick and convenient assembly of sections inserted into each other. Moreover, it is optimal to use such pipes with an iron stove.

The sandwich pipe is a multilayer structure, inside of which there is a stainless steel frame, then insulation made of mineral or basalt wool is laid, and a galvanized casing is placed on top. Thanks to this structure, soot does not accumulate inside the chimney, the outer layer of metal does not experience overheating, and the entire structure looks beautiful and laconic.

Options and features of exterior finishing

The chimney trim on the roof plays a decorative role. To avoid maximum smoke removal and prevent the formation of condensation, the outer part of the pipe must be insulated, and insulating materials require mandatory external protection. The finishing of the chimney pipe should be in harmony with the design of the roof, and it will make the smoke exhaust structure a full-fledged decorative element.

There are a lot of finishing options, the most current ones can be named:

Plaster. This is a simple solution that allows you to protect the pipe from the cold and provide it with a pleasant appearance. At the request of the house owner, mineral chips are added to the plaster mortar, which allows the finished cladding to be given a beautiful relief structure.

Decorative brick. This is another common solution that is widely used in finishing brick buildings. This finishing of the fireplace chimney allows you to maintain the temperature in the chimney; it lasts for a very long time and does not collapse even from very strong heat. Artificial or natural stone

A stone chimney looks very solid and stylish; it attracts attention to the roof and performs its functions perfectly. This is an almost eternal facing material that will make the smoke removal system more reliable.

Finishing the chimney with corrugated sheeting. An interesting option is one in which the smoke exhaust duct is designed in the same way as the roof itself. Finishing a chimney with a metal profile is a fairly strong and durable option; such lining is installed on a metal frame and reliably covers the insulating material.

These are just some of the external cladding options that will help make the chimney beautiful and very noticeable. An ordinary pipe can be turned into a real home decoration.

Finishing the chimney with a metal profile on the outside

Finishing a chimney on the roof with corrugated sheeting is one of the simplest options; even a novice home craftsman can handle such work. A galvanized sheet equipped with an anti-corrosion coating will be a strong and durable solution: it does not burn, does not collapse under the influence of high temperature or strong vibrations, and installation of such cladding does not take much time. However, this is a cold material, so the chimney will have to be insulated.

Finishing the chimney with a metal profile is carried out after the construction of the metal frame. Metal sheets are installed overlapping on it to ensure the strongest possible connection. To ensure that the sheets are positioned evenly, a building level is used when attaching them.

The metal profile is attached with self-tapping screws; this work is more convenient to carry out using a screwdriver. Between the metal sheet and the smoke exhaust pipe there is a layer of non-combustible insulation.

Finishing the chimney inside the building

A fireplace or stove is usually installed in a living room or study, so it becomes necessary to conduct smoke exhaust ducts through the second floor and the attic or attic room. The decoration of the chimney inside the house can be very diverse in appearance, but in any case it is installed on a common basis. The interior finishing of the chimney is carried out as follows:

- To line the chimney, a metal profile frame is built around it, which is sheathed with special plasterboard sheets. They must be fire-resistant, this will ensure the fire safety of the house. Such sheets are designated by the special abbreviation GKLO.

- The frame is insulated: a layer of mineral wool or other non-combustible insulating materials is laid around the chimney.

- Smooth plasterboard sheets are finished with any selected materials: it can be ordinary wallpaper, ceramic tiles, plaster and much more. This decoration of the fireplace chimney allows it to be harmoniously integrated into the space of the room, and the choice of material depends on the style of interior design.

The interior decoration of chimney ducts can have a wide variety of colors, so it can be chosen to suit every taste. However, in any case, it is recommended to choose non-combustible materials so as not to increase the risk of fire

This is especially important in a wooden house: walls located near the chimney, and especially all bending areas, must be treated with fire retardants

External and internal finishing of the chimney will allow you to turn it into a full-fledged decorative element: the choice of materials depends on the design features of the building and the financial capabilities of the owner. Self-installation of the cladding will allow you to save a lot, but it must be carried out in strict compliance with all technological requirements.

You need to enable JavaScript or update your player!

Features of the chimney

Removal of gases through the channel will occur effectively only if the pipe is constructed according to standard dimensions and made of the correct material. These pipe characteristics are selected depending on the type of fuel; the material for the chimney is:

- refractory ceramic bricks;

- asbestos pipes;

- stainless steel;

- sandwich pipes with an inner layer of insulation.

Brick channels are made in the case of a stationary chimney that ensures the removal of gases when heating with wood and coal

To determine the diameter and internal size, the boiler power and the dimensions of the firebox are taken into account. If the calculation is incorrect, reverse draft results or the useful effect of the furnace is significantly reduced.

For gas boilers, it is effective to use pipes with two walls, between which insulation is laid. The problem with a chimney for a gas fuel boiler is internal condensation, so insulation will help avoid significant temperature differences.

It is allowed to install one chimney for two operating heating units, if the internal size of the chimney, raised to the required height above the roof ridge, allows combustion products to be easily removed from both stoves. The cutting section pipe is about 0.8 m high.

Dependence of draft on pipe height

The importance of the chimney in the heating system cannot be overestimated. Attempts to save on an extra meter of pipe will lead to cold walls during the heating season and excessive waste of fuel

The danger of carbon monoxide is that it is invisible and undetectable, but can be fatal.

A narrow chimney of great height relative to the ridge will accelerate the smoke masses, thus reducing heat transfer. To maintain the desired temperature in the room, you will have to add fuel in excess of the norm. A wide channel of small height will allow smoke and gases to rotate arbitrarily in the pipe, their movement will slow down, and most likely a reverse flow of gases will result. Most often this happens in autumn or spring, when the temperature difference between outside and inside decreases and smoke, without overcoming resistance, is drawn into the room through the firebox.

Chimney location and height

To correctly select the height of the chimney relative to the roof ridge, you need to take into account the location of nearby structures. For an outdoor home, the draft indicators will be good, since there is constant blowing and pick-up of smoke masses. If we talk about a small building surrounded by high-rise buildings, then the length of the pipe should be increased. The height of the chimney depends on several factors:

- slope of the roof plane;

- location of the channel on the roof plan relative to the ridge;

- the location of surrounding buildings and trees;

- estimated thickness of snow cover in a specific area.

When installing a chimney, you should determine:

- elevation of the pipe relative to the roof ridge;

- the total length of the smoke channel from the stove;

- type and dimensions of the head;

- the height of the chimney relative to ventilation and windows of neighboring buildings.

Safety regulations

When installing a chimney in a bathhouse through the ceiling, you must follow the recommendations of Sanitary Norms and Rules 41 – 01 – 2003. According to clause 6.6.22, it is necessary to ensure a distance of 130 mm in the case of a brick pipe passing through the ceiling for a chimney, which provides protection for wood. But given that in most cases metal pipes are used in baths, you need to focus on the following standards:

- It is necessary to maintain a distance of more than 380 mm to flammable objects protected by insulation;

- The minimum distance to flammable objects without insulation must be more than 500 mm.

In this case, these distances must be ensured before the pipeline comes into contact with the tree.

Ideally, these distances would not be covered with anything at all, but this option will contribute to increased heat loss, which is economically unprofitable. Therefore, this volume is covered with non-combustible materials.

The maximum length of the pipe passing through the ceiling in the bathhouse should not be more than 1000 mm. The chimney cannot be fixed to the roof in a rigid manner, because when the temperature changes, the pipe may change slightly in size, which can lead to deformation of the ceiling.

The bathhouse often uses pipes of a special design, called “sandwich”. They are two pipes of different diameters, one of which is located inside the other. The space between them is filled with a layer of insulation. Not many people know that the outer part of such a structure has almost the same temperature as the inside of the chimney.

Often, in order to quickly heat the bathhouse, owners allow the stove to overheat. If the temperatures of the external part of the pipe exceed the permissible values of 400 ºС, then this threatens the failure of the external part of the sandwich, which will lead to a fire hazard. Therefore, under no circumstances should the distance between the pipe and surrounding objects be reduced.

SNiP 2.04.05-91 (clause 3.83) gives the following recommendations.

The distance to combustible structures when using brick or concrete pipes must be at least 13 cm. For ceramic pipes not equipped with insulation, the corresponding distance will be more than 25 cm, for pipes with insulation - 13 cm.

It is advisable to set these parameters at the bathhouse design stage, since the step when installing floor beams is usually not large. If it is 60 cm, then it will be possible to use only insulated pipes.

The diameter of the outlet part of the pipe is often 11.5 - 12 cm. If a sandwich uses 10 cm thick insulation, then we get a diameter of the outer part of 31.5 - 32 cm. We add the distance recommended for insulated structures of 13 cm on each side, we get a width of 57, 5 cm. That is, this design fits perfectly into the existing distance between the beams of 60 cm.

Now let's see what distance between the beams should be when using an uninsulated chimney. If the internal diameter is 11.5 mm, then we add to it the distance required by safety rules on all sides of 25 cm, we get 61.5 cm. The result obtained does not fit into the existing distance between the beams. Moreover, the diameter of the pipe can be even larger, and then the discrepancy between the size of the chimney and the pitch of the beams becomes even more noticeable.

Traction force

Insufficient draft force may be due to improper design, non-tight connection of parts, small diameter of the chimney, large accumulation of soot and ash inside the duct or in the boiler, as well as poor thermal insulation of the outer sections of the structure.

To avoid having to think about how to increase draft in the chimney, you need to:

- When installing the structure, monitor the quality of the connections of the parts,

- install a grate (grid-irons), which will ensure that the ash itself pours out of the combustion chamber,

- insulate the outer part of the pipe with basalt mineral wool on an asbestos sheet,

- When firing the stove, ensure that the ash door is sufficiently open to ensure adequate air exchange in the heater.

Fire protection

So, what insulating material is best to use for thermal protection when constructing a chimney passage through the ceiling with your own hands?

- Mineral wool. Retains its properties up to 300 ºC. Rigid mineral wool PZh - 175 can withstand higher temperatures (up to 1000 ºC). The disadvantage is the release of formaldehyde, which can be harmful to health. Also not resistant to water;

- Expanded clay. Tolerates wetness well. The disadvantage is the need to construct additional containers to accommodate it;

- Basalt cardboard. Environmentally friendly. A sheet 5 mm thick can withstand temperatures up to 900 ºС;

- Asbestos. It copes well with fire protection, but at the same time emits harmful substances. Therefore, if it is used for a chimney, it is necessary to isolate the room from it using metal sheets;

- Minerite. Able to withstand heating up to 600 ºС, without being destroyed by water and being an absolutely environmentally friendly material.

Excellent fire protection. Some experts still use sand or clay for thermal insulation, but this method is gradually becoming a thing of the past.

You can reduce the likelihood of a fire using several other methods.

- Construction of a water jacket on the chimney. This will require a remote tank. It will also be necessary to supply cold water. But the hot water generated can be used in the shower or for heating. But the temperatures above the water jacket will drop significantly, which will reduce the likelihood of the pipe burning out;

- You can place a water tank above the stove, which will also protect the chimney from excessive heating. But with this method, you will have to constantly ensure that the water in the tank does not boil and pour cold water in time;

- Place stones on the pipe. You will need support to redistribute their mass.

Using all these methods, it is possible to reduce the temperature in the installed passage, which will significantly increase fire safety.

To increase fire safety in the bathhouse, you can use materials such as glass-magnesium sheets and fire-resistant plasterboard sheets. They are used to cover the ceilings themselves and the openings in them through which the chimney passes. Only Premium class sheets marked “NG” are suitable for fire protection. If such marking is absent, then such products cannot be used for fire protection.

How to insulate a chimney

On the modern construction market there are many sandwich pipes that are already thermally insulated and do not need to be further insulated. If you decide to use a regular metal pipe without insulation, then I bring to your attention the following insulation materials:

- Mineral wool . Often used, but not the best option for open insulation. There is an opinion that when heated min. cotton wool releases resins and formaldehyde into the air, which is not very beneficial for humans. In addition, for min. condensation may form on the cotton wool, then it will reduce its insulating properties several times. Use is questionable.

- Expanded clay. A good option for thermal insulation, it has low weight and low heat capacity. Cools quickly and does not emit harmful impurities. Expanded clay of medium and fine fractions is used, poured into the groove, between the screen and the pipe. The best option.

Example of filling with expanded clay

- Sand. Poor thermal insulation option. Heats up quickly and takes a very long time to cool down. In addition, he constantly wakes up through the cracks in the bathhouse. I don't recommend it.

- Clay . I've heard a lot of recommendations from experienced bathhouse attendants, but I haven't tried it myself yet. They say it doesn’t leave a burning residue on the pipe, and the pipe itself doesn’t burn out. A good option.

Now you can start choosing stones for heating the bathhouse.

How to make a chimney: choosing insulation

Fireproof plate

We believe that special attention should be paid to the choice of insulation. We repeat: most will put expanded clay or mineral wool inside the box, and cover it on the outside with mineralite (its analogue is Flamma sheets) or basalt cardboard. This is a valid solution. It is doubtful to use asbestos instead of mineralite.

asbestos cardboard (asbestos cardboard)

ADVICE! Do not make an internal backfill of sand, because it transfers heat perfectly, and when the chimney heats up to 400 degrees, even this is a guaranteed fire. Because wood lights up at 330 degrees, but if you heat it for a long time, it will light up at 150-170 degrees. Sand will do a very bad job.

However, in our time, other refractories have appeared - the same calcium silicate, known commercially as superisol or Silca slabs. But it is a slab material.

The chimney in the ceiling of the bathhouse in the area of the polyurethane foam can be lined with other materials, such as cotton wool or felt. If we talk about stone derivatives, these are basaltine and Basfiber, which are technologically more advanced modifications of mineral wool.

But now you can buy not only them, but also ceramic fibers, in particular, Supersilica, which is a silica fiber from which either cotton wool or mats are made. It has no binding substances at all, which in mineral wool burn out over time, causing it to crumble. The manufacturer's website directly states that this fiber is suitable for insulating the ceiling passage in a bathhouse.

Below is a video that shows a funny stress test of everything that can be stuffed into a PU foam assembly:

There is also mullite-silica wool, but this is a real refractory that can withstand temperatures twice as high as the maximum for a chimney.

Construction of a gable roof for a bathhouse

Construction of the rafter system

The roof structure is based on a rafter system, which is a complex of wooden elements:

- Mauerlat - a base that creates support for the entire structure on the walls of the building;

- Rafter trusses are elements in the form of isosceles triangles, the legs of which are the rafter legs. It is the shape of the triangle, as the most stable figure, that allows the gable roof to withstand large external loads;

- Lathing is a sparse or continuous system that allows roofing material to be attached to the rafters.

All wooden elements of the rafter structure are made from dried wood with a moisture content of no more than 20% without knots and cracks. Before installation, the wood is treated with special means to prevent the formation of mold, mildew and pest damage to the wood.

There are two ways to build a truss structure:

- Hanging. Suitable for small buildings. The rafters in this system have only two points of support: the mauerlat and the ridge beam. This type allows you to avoid supports in the center, which allows you to make maximum use of the attic area.

- Layered. Used in large buildings. The rafters have additional support points in the center of the house in the form of load-bearing walls.

When calculating and choosing material for the rafter system, the total load on it is taken into account, which depends on the weight of the structure, snow load, etc. As a rule, rafters are made of wooden beams with a section of 50 * 100 mm.

Let's look at how to properly make a rafter system for a gable roof:

- The Mauerlat is laid on walls insulated with a layer of roofing felt and secured to them with anchor bolts, studs or twisting. In a bathhouse made of timber, the role of the Mauerlat is performed by the upper crowns, fastened with staples;

- The trusses are fastened at the top with a metal plate. First of all, the outer trusses are mounted, and then, according to the level specified by them, the rest are set at a gap of approximately 60 cm. The rafter legs can be attached to the mauerlat by notching or metal elements.

Roof lathing and insulation

An important point in the construction of a roof structure is its vapor and waterproofing. The protective material is spread over the rafters with an overlap of up to 10-15 cm at the joints of the material and fixed with nails or staples

It is important to create ventilation gaps between the waterproofing and the roof. For this purpose, a counter-lattice is created under the lathing system.

Next, the sheathing is filled, the pitch of which depends on the selected roofing material. For soft roofs, a continuous sheathing is made of moisture-resistant plywood; for other materials, the pitch of the system can be increased to 40-50 cm, depending on the slope of the slopes.

If you want to create a warm roof for the bathhouse, insulation is used, which is laid on the attic side between the rafters and covered with a layer of vapor barrier material.

Installation of roofing material and pipe outlet

One of the final types of work is the installation of roofing material on the bathhouse roof. Regardless of the chosen roof, the work order will be as follows:

- Laying the first row of roofing along the eaves, maintaining the level and firmly fastening the first row of material;

- Installation of the next rows of roofing from the eaves up to the ridge. Each next row is laid with an overlap of 10-15 cm with the previous one to avoid roof leaks;

- Lastly, the roof ridge is installed, the options for which vary depending on the chosen roofing material.

An important point when building a roof on a bathhouse is the question: how to make a chimney? It is most advisable to route the pipe in the bathhouse through the roof 30-50 cm from the ridge with an elevation of 50 to 100 cm above the roof. The passage of a pipe through a roofing pie, the materials of which easily and quickly catch fire, must be associated with mandatory insulation of the pipe. To do this, a special hole is made in the constructed roof, the walls of which do not allow the pipe to come into contact with the flammable elements of the roof.

The final work is the installation of a drainage system, covering the roof overhangs and cladding the roof gables.