Justifications for isolation

The bathhouse is traditionally built from a log house. Today it is being replaced by other materials, but the internal lining is wooden lining. The ignition temperature of wood is considered to be +450 degrees Celsius.

Stone stoves are less commonly assembled today due to the high cost of the event. However, the outside of a brick chimney heats up to a safe level. Modern units for heating steam rooms and heating water are compact and function well. Here, as a rule, a metal smoke exhaust duct is installed. It can heat up to +600 degrees Celsius, which exceeds the permissible value. This is the main argument that determines the need for thermal insulation for chimney pipes.

Stone sauna stove Source stroyfora.ru

Another reason is the thermal conductivity of the metal. It heats up and cools down quickly. All sources of heat leakage in the steam room must be eliminated. A metal chimney also applies to them. Additionally, the risk of condensation formation inside the channel is reduced to a minimum. It is worth noting that the appearance of moisture inside the chimney leads to the formation of a sulfuric acid solution, which can destroy virtually any base in a short time.

Necessary activities

The construction of a bathhouse must be carried out taking into account the rules. There are standards that are prescribed in GOST 52953 of 2008. These include:

- pipe height – at least 5 meters;

- the length of the chimney between the stove and the ceiling is 0.5 m and 1.5 m for brick or metal, respectively;

- fireproof distance from the pipe to combustible structures is over 25 cm;

- A spark arrester must be installed above flammable roofing material.

The main tasks that are important to solve are protecting the chimney from overheating and moisture. That is, waterproofing of channels and fire prevention measures are carried out. The best option is complex insulation. It will apply both to the chimney and to the surrounding and adjacent architectural elements of the building.

See also: Catalog of companies that specialize in the design and construction of baths of any complexity

How to build a ceiling in a bathhouse, sequence of work

Of all the mentioned methods of arranging a ceiling for a bathhouse, we will dwell in more detail on a false ceiling, since this is the option chosen by the overwhelming number of homemade ones.

The work includes the following construction stages׃

Installation of load-bearing beams

The beams are installed along the shortest span of the “box” of the structure with an interval of 0.5–1 m. Their height and width depend on two parameters: loads (permanent + temporary) and the distance between the supporting walls. For selection, special calculation tables by I. Stoyanov are used.

For example:

Span width – 4.5 meters

Load – 250 kg per linear meter

Result: beams with a cross section of 10×20 cm are required

After installing all the beams, a hole for the chimney is formed in the resulting “ladder” - perpendicular jumpers are inserted in the selected place, cutting them into the beams (at 1/2 thickness) and additionally securing them with nails.

Laying vapor barrier

The vapor barrier of the bathhouse ceiling is attached directly to the beams using a stapler, while it is necessary to leave an overlap of 15-20 cm on the side walls. For these purposes, use ordinary film or special multilayer membranes, reinforced with foil and a reinforcing “mesh” (it is recommended to strengthen the thermal insulation above the steam room) . The joining seams are covered with an overlap (15-20 cm) and glued with special tape.

Fitting interior ceiling boards

The boards are attached to the beams with nails (2 pieces for each support), the length of which is twice their thickness. The starting crossbar is adjusted to fit the wall, completely cutting off the mounting groove on one side, and then the sequential laying of the wooden paneling begins, using a mallet to help place the tenon in the mounting hole of the adjacent element.

Installation of heat insulator

The selected insulation for the bathhouse ceiling is laid directly on top of the vapor barrier film. Please note that cotton insulators cannot be stored outside without film, as they quickly absorb moisture. We adjust the mineral or glass wool mats so that they fit tightly in the “sockets”, without side gaps. It is better to make a pattern with a margin and slightly compress the material rather than letting it “walk”.

Laying waterproofing

The waterproofing material is laid in the same way as a vapor barrier, making sure to include overlaps on the side walls. There must be at least a minimum ventilation gap between the cotton insulation and the film.

Arrangement of attic covering

For the floor of the attic, edged boards are used, laying them similarly to the ceiling covering inside the bathhouse.

Materials used for insulation

Today, owners of baths and saunas rarely turn to old-fashioned methods of chimney insulation. Clay, asbestos, and other available non-combustible materials with low thermal conductivity were used here. The modern market offers durable products that are easy to install and aesthetically pleasing. Let's take a closer look at how you can insulate a chimney.

Brick

Red refractory bricks are used for insulation work. It is characterized by heat resistance, long-term heat retention, and moisture resistance. The method is relevant in the case of a stone stove.

Red fire brick Source serpuhovo.pechnik-online.ru

The thickness of the walls of the masonry insulation should be about 40 cm. Only fire-resistant mortar is used, seams do not exceed 5 mm. Additionally, the structure is plastered with a solution that is resistant to operating conditions. It will additionally protect the insulating material from moisture.

Mineral wool

Fibers from mineral rocks are resistant to open fire, preventing its spread. Insulation for chimney pipes has low thermal conductivity. For a small structure, low weight is also important. There is no need to strengthen the foundation or adjacent structures.

Craftsmen give preference to basalt slabs or fiberglass sheets. The advantages of the material look like this:

- environmental friendliness;

- no toxic emissions or odor when heated;

- durability (over 50 years);

- inertness to biological activity and corrosion.

The disadvantage of mineral wool is that it absorbs moisture well and retains it in conditions of poor ventilation.

This increases the thermal conductivity of the canvas and its density. To prevent such phenomena, it is necessary to create a barrier to water. This may be a separate casing or a finished product with a foil shell.

The need for thermal insulation

The feasibility of insulation is due to several reasons.

- The thermal insulation of the chimney prevents its rapid cooling. Accordingly, the heat in the house is maintained for a longer period of time;

- thermal insulation prevents heating of the home structure;

- Perhaps the most compelling reason is the accumulation of condensate in an uninsulated chimney pipe, the impact of which destroys the chimney structure. This problem applies not only to stove heating systems, but also to modern gas boilers.

During operation of the stove or fireplace, oxygen vapor accumulates in the chimney. As the ambient temperature decreases, its amount increases. It should be understood that condensation is by no means simple dampness, but in fact a very aggressive substance, which is a mixture of moisture and acids.

Condensation can lead to serious damage to both the heating system and individual structural elements of the house, reducing the effectiveness of facade insulation to zero. But, of course, due to condensation, the materials used to create the chimney are destroyed first.

- if the work on insulating the chimney pipe with your own hands is carried out at a high professional level, you will have to clean the toxic gas exhaust system less often, because less soot will be deposited on its walls;

Good to know! It is allowed to insulate not the entire pipe.

In some cases, it is possible to partially insulate the pipe, paying attention only to problem areas

As for thermal insulation of an iron chimney pipe with your own hands, here you need to listen to the recommendations of professionals.

- it is mandatory to insulate the outer part;

- It is also advisable to insulate the area between the roof and the attic floor. Although the attic is warmer than outside, in a cold winter the process of moisture condensation can begin there;

- It is worthwhile to insulate the pipe in the house itself, unless taking into account fire safety requirements. In addition, the risk of getting burned is minimized.

Mounting soft insulation

Before wrapping a metal chimney pipe in a bathhouse, it is recommended to treat the surface of the channel with a heat-resistant sealant. It must withstand heating up to +1000 degrees Celsius. This will prevent the insulating sheet from slipping.

Pieces of mineral wool with a thickness of 5 mm or more are fixed to the chimney by stitching. Galvanized binding wire is used as a fixer. Another option is a metal plumbing clamp.

Chimney wrapping with mineral wool Source yandex.net

A casing is installed on top of the winding. It is necessary to prevent the formation of voids inside in order to maintain the energy efficiency of the structure. Another solution is to fix the reinforcing mesh and apply a cement-lime plaster mixture.

Foil materials are fixed with wire or metallized tape. They are wound over the insulation. The box can be installed to create a more attractive appearance.

Chimney installation

Installing a chimney is not as simple a task as it might seem at first glance. There are many nuances that should be taken into account. If the chimney is installed insufficiently well, this can lead to damage to property, as well as creating discomfort for the people inside and harming their health.

Stages of work:

- The preparatory stage, where a work project is selected, materials are purchased, and the form of construction is determined. There are straight chimneys, as well as designs with various bends.

- Now you can begin assembling the chimney. Pipe connections, elbows and tees must be secured with clamps.

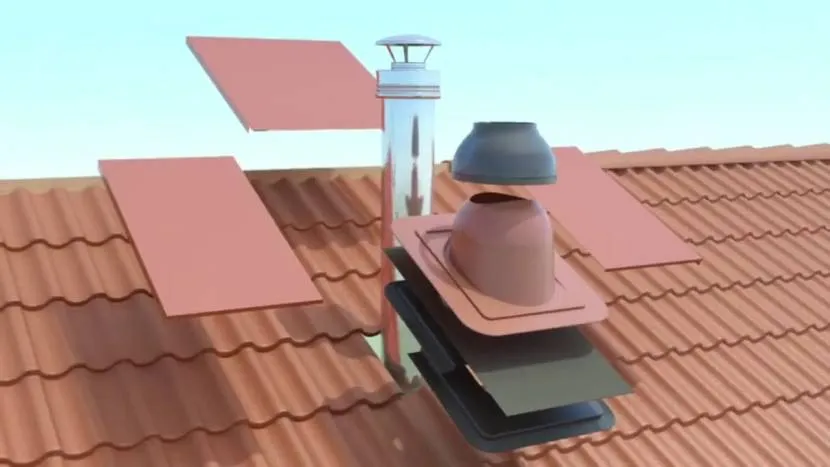

- Carrying a chimney through the roof using a special tool. To begin with, the level of the roof slope is determined, and based on the data obtained, a suitable location is selected. A hole is cut in it for the workpiece. Everything is insulated from above with a roof section, and from the inside - with a tire sheet.

Pipe waterproofing

Protection against precipitation is carried out in two ways. The tip is closed with a special cap. The area on the roof is decorated with a waterproofing apron. If a ready-made version of mineral wool with a casing is used as insulation for the chimney, then a factory passage can be installed. It is also suitable for working with sandwich pipes. In other cases, craftsmen limit themselves to thin-sheet galvanized steel.

Installing an apron on the roof of a bathhouse Source ytimg.com

The optimal solution here is a special box. There is a galvanized sheet around the perimeter. Between the pipe and the body there remains a void 256-30 cm wide, which is tightly filled with granular or cotton insulation.

Making boxes

Many people are afraid to make a metal box for the chimney pipe themselves. But it doesn't contain much complexity.

When making a box you need the following tools:

- Metal scissors.

- Galvanized sheet.

- Self-tapping screws.

- Compass.

- Drill.

Further sequence of actions:

- The hole is being prepared. Its edges need to be secured with support beams. They will create support for the box.

- A couple of parts are cut from a galvanized sheet. Along their edges, at a distance of five centimeters, a 90-degree bend is made. These U-shaped parts are fastened with self-tapping screws to prepared holes in the ceiling covering.

- Two more U-shaped blanks are prepared in the same way, and they are overlapped onto the existing sheets. The result is a solid frame for the exit made in the ceiling covering.

- The next part of the action is the bottom for the box. An element is cut out from the same galvanized sheet, the dimensions corresponding to the opening made. In its center, draw a circle with a compass for the entrance of the smoke exhaust billet.

- From the central part of the bottom of the box, 4 fasteners are placed (each of them has a two-centimeter width). Next, they are cut out and bent at an angle of 90 degrees. As a result, a base is formed with a hole and 4 strips for fastening.

- The bottom is attached to the walls. A chimney is inserted through the exit and secured with a clamp. The empty space is filled with an insulating layer.

Using the suggested instructions, making a box is not difficult. If you follow everything exactly, the work will not be difficult even for an inexperienced layman.

Briefly about the main thing

The chimney must be protected from moisture and overheating.

The solution is thermal insulation and waterproofing materials.

Mineral wool, foiled polyethylene foam, and expanded clay are used as insulation.

Additionally, a casing can be installed, plastering done, and brickwork done.

An innovative option is a sandwich pipe, which does not require additional waterproofing.

Ratings 0

Positive factors of an insulated chimney

Before answering the question - how to insulate a pipe, it is necessary to highlight the advantages of an insulated chimney. An insulated gas outlet protects the heating system from the influence of the external environment and combustion products. Of course, thermal insulation cannot completely protect the structure from destruction, but it will extend its service life. This occurs due to the following factors:

- Pipe insulation allows you to maintain a thermal balance in the middle of the structure, eliminating the possibility of aggressive acids and condensate falling onto the walls. Combustion products completely evaporate along with the smoke stream.

- Chimney insulation minimizes the possibility of temperature differences between the cooled smoke duct and the hot steam.

- Energy-saving properties are increased, contributing to fuel economy.

- The strength of the steam exhaust structure increases due to the reinforcing frame.

Properly selected chimney insulation increases the frost-resistant properties of the system, ensures long-term preservation of appearance and increases service life, which is very important.