A windproof membrane (wind-waterproofing membrane) is a material that consists of many layers that performs the following functions:

- waterproofing;

- creation of a windproof coating (high-quality wind protection);

- formation of vapor diffusion.

This material provides protection from wind, climatic precipitation, and ultraviolet rays (direct sunlight). Windproof membranes have recently appeared on the construction market.

Its popularity began to grow due to the construction of frame houses. In this article we will look at the main types of windproof membranes, their properties and areas of application. We will also discuss step-by-step instructions for installing this material.

Purpose of using a windproof membrane

The windproof membrane neutralizes various wind currents:

- The membrane is capable of retaining lightweight insulation.

- The product separates the two zones. The first zone is cold outside and warm inside.

- Thanks to this material, the fibers of the heat insulator are protected. They are protected from blowing out.

- This construction product is a barrier that prevents the influence of climatic precipitation.

- Heat loss becomes significantly less. Thanks to this, you can save your money on heating the room.

Wind protection for roofing

In modern low-rise construction, great attention is paid to the thermal characteristics of the building. High-quality protection of the house from cold in the winter and off-season, and from heat in the summer heat allows owners to reduce heating and air conditioning costs

This factor is becoming increasingly relevant and pressing as energy prices are constantly rising.

During construction, it is rational to provide not only for laying a heat-insulating layer when installing a pitched roof, but also for its wind protection. The fact is that most insulation materials, even the densest ones, have a porous structure, so air circulates freely in the body of the insulating layer, reducing its thermal efficiency. The presence of a wind barrier prevents cold air from penetrating into the insulation, increasing the thermal insulation of the roof structure and the house as a whole.

Areas of use of windproof membrane

Let's look at each area separately:

- This material is used for thermal insulation of the roof, attic and attic floors. The windproof membrane provides protection to the thermal insulator during installation of the roof covering(s). Thanks to this, condensation does not penetrate into the “pie” during operation.

- Windproof film is used for the walls and facades of the house. Here the main role is played by the function: vapor diffusion, as well as hydrophobicity. The windproofing agent allows you to create ventilation, thanks to which the surface can “breathe”.

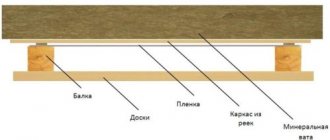

- It is used for floors and floors along joists. In this case, films that are capable of transmitting only steam and not water are suitable.

- Waterproof and windproof film is used for frame partitions. This material helps prevent mineral wool particles from “spraying”. It also provides protection against condensation accumulation. The effectiveness of air tightness of partitions increases.

The second mistake - the vapor barrier was laid on both sides of the insulation and the wooden floor

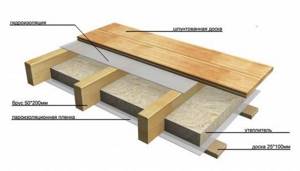

How to properly vapor barrier a wooden floor in a wooden and frame house? This issue worries many developers, and is a bottleneck in many designs. Let's say right away that we are talking about the overlap between two residential and constantly heated floors.

We are insulating the floor of the second floor in a wooden house. I'm already confused about where to install the vapor barrier! On some sites they write that the first layer is laid between the finished ceiling of the first floor and the subfloor of the second. On others, that on the subfloor and insulation immediately on it. It turns out there will be a vapor barrier on both sides?

I also saw on the Internet many schemes for installing vapor barriers in the ceiling of the first and second floors. Moreover, some manufacturers recommend laying a vapor-proof film on the bottom and top of the insulation. Tell me how to properly make a vapor barrier for the ceiling if the first and second floors are heated?

To answer these questions, we think logically.

- In frame walls and ceilings, vapor barriers are installed where there is a temperature difference. Those. the room, where there is a plus, is thermally insulated from the street, where it is cold.

- In the interfloor ceiling, between two heated floors, there is no sharp temperature difference. Therefore, water vapor trapped in the insulation will not condense.

- Hence: mineral wool insulation, laid in a wooden floor between the first and second heated floors, is rather needed not for insulating the structure, but for soundproofing the floor.

- That is, in fact, you can do without films, but the living space must be protected from the possible release of thermal insulation particles into the air.

- But, do not forget that in the house, where the residents live, there are constant sources of moisture and water vapor - the kitchen, bathroom and toilet.

- Water vapor, due to the pressure difference, will tend to get from a warm room to a cold zone - through the walls to the street, or from bottom to top, into a cold attic through the ceilings. Or in the under-roof space, if we are talking about an insulated attic.

So, we have insulation laid between wooden beams in the ceiling of the first and second floors and water vapor, from which these structures need to be protected. Water vapor, if it gets into the ceiling, must be able to escape from it. Therefore, the overlap pie must provide this opportunity. Because Now we are talking about covering the first and second floors, we offer this “pie”:

- Finishing and rough finishing of the first floor ceiling.

- Vapor barrier.

- Insulation.

- Vapor-permeable diffusion membrane.

- Rough and fine finishing of the second floor floor.

With this scheme, water vapor will freely escape from the ceiling, and the structure will “breathe”.

Important! In an insulated wooden interfloor ceiling, do not install a vapor barrier on both sides

Types of windproof membrane

The cheapest options for this material are polyethylene film and glassine. Glassine has significant disadvantages. Firstly, this product has a short service life. Secondly, glassine has a low level of biostability. Therefore, glassine is most often used to create a temporary coating.

Polyethylene film is also not intended for long-term use, since this product blocks not only wind flows, but also steam. Therefore, the heat insulator, accumulating condensate, will collapse after some period.

Windproof membranes, which consist of many layers, are most effective. The outer layers make the material strong and stable, thanks to them the wind and waterproof film does not tear. The inner layers perform the function of vapor diffusion. Due to the fact that the multilayer windproof membrane has a specially designed impregnation, this material can be used as a roof for some period or as facade cladding.

Types of windproof membrane:

- The first type is moisture and windproof. A distinctive feature is that they have a high level of vapor permeability and a low level of water resistance.

- The second type is superdiffusion. Their vapor permeability starts from 1000 g/m2. They are also able to withstand more than 1000 millimeters of water column.

Let's look at each type separately.

Moisture-windproof membranes

This protective type consists of two layers. The outer layer is smooth, which protects against splashes and powder. The inner layer is porous. The moisture-windproof film not only removes moisture, but also makes the coating resistant to air pressure.

Superdiffusion membranes

This type is most effective for areas where there is a huge amount of precipitation. Due to the fact that the product consists of three layers, unique vapor permeability is formed, while at the same time providing a heat insulator against precipitation (rain or snow) if insufficient sealing is carried out. Although this type is more expensive than polyethylene film, nevertheless, thanks to its long service life, you will be able to recoup your money spent.

Films Onditus

Might be interesting

Waterproofing

Foundation waterproofing: optimal choice of technology

Waterproofing

Clean water is the key to health, waterproofing concrete…

Waterproofing

Instructions for waterproofing a swimming pool

Waterproofing

Selection of materials, methods of waterproofing work...

Additionally, let's consider Onditus films. The main advantage of these films is that they retain their qualities even if the temperature drops to -40 degrees Celsius. Also, the films can withstand temperatures of +80 degrees Celsius. There is a high level of resistance to climatic precipitation.

There are four variations in total:

- The first variation is A100. This variation is of high quality because it can withstand a breaking load of 125 N. Vapor permeability is 3500 g/m2. The water resistance value starts from 215 millimeters of water column.

- The second variation is A120. This material has a special coating that has a high level of resistance to ultraviolet rays. Variation A120 can replace façade cladding for three months. This is possible due to the fact that A120 has a water resistance of 250 millimeters of water column. Breaking load – more than 140 N.

- The last two variations are A100 Smart and A120 Smart. These two films are an improved version of the first two variations. They already have mounting tapes applied at the joints.

Recommendations and tips

Quite often, when choosing a material to protect against moisture and wind for a roof and future installation, most developers have a logical question about which side to lay the windproof film on the surface of the insulation. If you take into account the recommendations that the manufacturer specifies in the instructions for use, you can figure out exactly how to install wind protection. If there are no instructions, then we advise you to adhere to the general rules that are ideal for such building material:

- If you have chosen the simplest wind protective membrane for your roof, which is made in one layer, then it is not at all important which side the material will be adjacent to the insulation - this is due to the fact that such types of material have vapor permeability on both sides.

- Waterproof and windproof films can also be made in several layers, and we recommend laying this material in such a way that the water-repellent side is located on the outside, and usually this surface is perfectly smooth, and often the manufacturer paints it in a different shade or uses special marking symbols for recognition .

- If a superdiffusion membrane has been chosen for the roof, you should take into account the fact that such materials are distinguished by the presence of a multilayer structure, which helps to increase resistance to moisture and vapor permeability - we recommend laying this type of building material with the marked side out.

During the process of house construction, special attention should be paid to the roofing layer, which protects and in the future significantly improves the microclimate in the entire room. Due to the wide range and price range, it is possible to buy inexpensive, but at the same time high-quality materials from manufacturers in Russia or give preference to popular imported brands. The choice will entirely depend on the budget.

Please note that an additional hint to help you understand exactly how to correctly lay roof wind protection is that during the production process the material is rolled up in such a way that it can be conveniently laid in the future by simply unwinding it.

Advantages of using a windproof membrane

Let's look at the main advantages of this product:

- The product is an absolutely environmentally friendly material. The film does not cause any harm to human health or the environment.

- The film has a high level of fire resistance. Fire resistance is created by specially designed additives contained in the product. These additives prevent combustion.

- This material is easy to use. Installation can be carried out in any season, and the material does not need to be individually protected.

- Technical properties. This includes unique resistance to ultraviolet rays, moisture resistance, elasticity, resistance to various mechanical damage and sudden temperature changes.

- Huge service life. The product does not lose its high technical characteristics even after several dozen years.

- The membrane can be attached to various parts of the house.

Wind protection functions

Wind protection for a frame house is a mandatory element that is used in this type of house construction. Such a layer can protect the entire house from blowing. It is worth noting that if this layer is neglected, then during strong winds the walls will let in cold from the outside and give off their heat from the inside. And this will lead to high costs for heating the room.

The wind protection layer has the following functions:

- ensuring the most acceptable level of microclimate in the house;

- preventing walls from freezing in winter;

- protecting your home from moisture;

- protection from strong winds;

- ensuring steam escape.

Which windproof membrane to choose?

Before choosing this or that material, you need to pay attention to the following nuances:

- The first point is toxicity. The windproof, vapor-permeable membrane must be an environmentally friendly product and not emit toxic substances.

- The second point is technical properties. In this case, it is necessary to pay attention to the value of strength, UV resistance, and permissible temperature range.

- The third point is the service life of the material.

Also, many people pay attention to the cost of the product. Superdiffusion membranes are the most expensive, but they have the best characteristics. There are no differences in terms of installation; all films are mounted the same way.

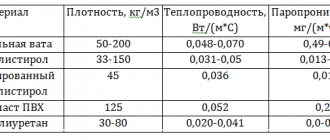

Types of wind and moisture protection

There are many types of wind and moisture protection. They differ from each other in their properties and technical characteristics.

Accordingly, they are divided into two segments: membranes and films.

- Films are usually single-layer, polypropylene. When installing this material, an air gap of 4-5 cm thickness is required for the thickness of the counter-batten. For weathering of water vapor and under-roof condensation. This material is not intended for use as a main or temporary covering.

- Single-layer, two- or three-layer membranes During installation, no additional lathing is required since they are laid directly on the insulation, which avoids the cost of additional lathing between the insulation and the membrane. Some membranes can serve as a temporary coating for up to six months.

Installation of a windproof membrane

Before you begin installing this product, you must carefully read its instructions, which are located on the roll. You also need to observe the following nuances:

- Moisture and windproof films that do not have a print can be installed with absolutely any side facing the heat insulator.

- If you are installing superdiffusion membranes, then during this procedure the side on which the logo is depicted must be mounted outward.

- On thermally insulated roofs, a double ventilation hole must be made. The gap should be between the heat insulator and the film, as well as between the film and the roof covering. The size of the ventilation hole is five centimeters.

- During vertical installation, the material adheres tightly to the heat insulator. In this case, the ventilation gap is made between the membrane and the outer skin. The size of this ventilation gap is three centimeters.

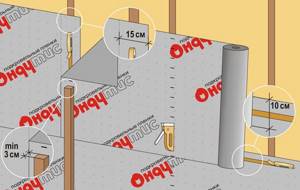

Let's look at the general instructions for installing a windproof membrane:

- First you need to prepare the necessary construction tools and materials. In order to secure the protective film, you will need a specially designed construction stapler. In order to fix the batten covering (lathing), you will need a screwdriver, as well as suitable fasteners. If the membrane does not have an adhesive layer, then you need to additionally purchase mounting tape to seal the joints.

- Next, you need to unroll the roll and cut it into sheets of the required length. In order to apply markings, you can use an ordinary pencil.

- The direction of laying the strips is from bottom to top.

- There should be an overlap of approximately 15 centimeters. Perform sealing using mounting tape. There must be an additional strip of membrane at the ridges, valleys and corners.

- Avoid the formation of small holes. All intersections must undergo a sealing procedure. Therefore, it is necessary to make a cut in the membrane with the letter H, which should taper towards the bottom. Next, it is necessary to secure the upper and lower flaps to the lath covering (lathing). The side flaps must be moved upward and secured to the protruding part.

What is its structure

The basis for wind protection of the frame structure is a special membrane. This windproof porous film for the walls of a frame house is made in such a way as to accumulate water that comes from inside the premises and remove it, preventing moisture from penetrating from the outside.

Based on this function of the film, it is used to cover the walls so that the moisture that comes from the interior of the house condenses on the rough side. While the smooth side of the material should be turned towards the street, in order, on the contrary, to prevent the penetration of vapors into the building. Everything that condenses on the inside of the sheets is removed to the outside through special pores.

The material from which such a membrane is made is special polymer fibers. A distinctive feature of such polymers is their high wear resistance and strength. Thanks to the moisture removal provided by the already mentioned porosity of the material, the film never gets wet and does not allow the wood to rot.

In the wall construction, a windproof membrane is placed between the insulation and the second sheathing. The latter is necessary to organize a ventilation gap.

What are ventilation gaps

The already mentioned ventilation gap is a mandatory element that a wind barrier for an ordinary frame house must contain. To make it, vertical posts are used that are attached to the membrane and allow it not to fit too tightly to the exterior finish.

The reason for creating a ventilation gap is quite simple - it prevents moisture from condensing on the surface of the windproof membrane. Despite the fact that water penetrates into the wall in fairly small quantities, this does not prevent it from accumulating there over time.

Its accumulation on the surface of the film leads to the fact that it begins to damage the thermal insulation. The energy efficiency of the house decreases, and subsequently the wooden material of the walls is damaged, which becomes vulnerable to fungus and mold.

The principle of operation of the ventilation gap is that moisture condenses on the surface of the membrane, it ensures free air circulation. That, in turn, helps the water evaporate faster.

The creation of such structural elements is especially recommended if the house is planned to be finished with siding. The reason is that the vapor permeability of siding is minimal, so it is not able to pass excess moisture through its pores. Everything that condenses on the membrane with this finish remains there. And if you do not provide additional channels for removing moisture, you can get a lot of problems.

There are various options for arranging ventilation gaps. But the basic technology is generally the same - inside the walls, after thermal insulation and a windproof membrane are installed, additional vertical beams-racks are installed. Their function is to be the basis for fastening subsequent external wall decoration. The width of the timber used in this case is usually 5-10 cm.

Bottom line

There is a FAQ. For example, which side should windproof membranes be attached to? If mineral wool is used as insulation, the product must be attached from the outside. In most cases it's the other way around.

How to attach this product? It is necessary to tighten and fix it using a construction stapler. But this is only for a while. You also need to screw the slats on top. If you are working with curtain facades, the fastening procedure is more complicated.

For what period of time can the film be left open? Although manufacturers claim that the film can remain open for quite a long time, nevertheless, after just six months the film will lose its technical qualities.

Therefore, it is advised to cover the material with cladding almost immediately after installation. This must be done because frequent rains can cause the product to begin to leak moisture. Therefore, after installing each element of the house, cover the film with cladding.

The windproof membrane is suitable for walls, facades, roofs, and partitions. These simple tips will help you install a windproof membrane.

What is its structure

The basis for wind protection of the frame structure is a special membrane. This windproof porous film for the walls of a frame house is made in such a way as to accumulate water that comes from inside the premises and remove it, preventing moisture from penetrating from the outside.

Based on this function of the film, it is used to cover the walls so that the moisture that comes from the interior of the house condenses on the rough side. While the smooth side of the material should be turned towards the street, in order, on the contrary, to prevent the penetration of vapors into the building. Everything that condenses on the inside of the sheets is removed to the outside through special pores.

The material from which such a membrane is made is special polymer fibers. A distinctive feature of such polymers is their high wear resistance and strength. Thanks to the moisture removal provided by the already mentioned porosity of the material, the film never gets wet and does not allow the wood to rot.

In the wall construction, a windproof membrane is placed between the insulation and the second sheathing. The latter is necessary to organize a ventilation gap.

What are ventilation gaps

The already mentioned ventilation gap is a mandatory element that a wind barrier for an ordinary frame house must contain. To make it, vertical posts are used that are attached to the membrane and allow it not to fit too tightly to the exterior finish.

The reason for creating a ventilation gap is quite simple - it prevents moisture from condensing on the surface of the windproof membrane. Despite the fact that water penetrates into the wall in fairly small quantities, this does not prevent it from accumulating there over time.

Its accumulation on the surface of the film leads to the fact that it begins to damage the thermal insulation. The energy efficiency of the house decreases, and subsequently the wooden material of the walls is damaged, which becomes vulnerable to fungus and mold.

The principle of operation of the ventilation gap is that moisture condenses on the surface of the membrane, it ensures free air circulation. That, in turn, helps the water evaporate faster.

The creation of such structural elements is especially recommended if the house is planned to be finished with siding. The reason is that the vapor permeability of siding is minimal, so it is not able to pass excess moisture through its pores. Everything that condenses on the membrane with this finish remains there. And if you do not provide additional channels for removing moisture, you can get a lot of problems.

There are various options for arranging ventilation gaps. But the basic technology is generally the same - inside the walls, after thermal insulation and a windproof membrane are installed, additional vertical beams-racks are installed. Their function is to be the basis for fastening subsequent external wall decoration. The width of the timber used in this case is usually 5-10 cm.