Modern air conditioners consist of several important mechanisms that provide cooling or heating. An indispensable element of this system is the refrigerant. If there is a lack of it, the equipment works with overloads, which quickly leads to breakdowns of the air conditioner. To replenish the required supply of refrigerant, it is refilled.

In the article we will look at information about refilling a room air conditioner, what freons are used, how often it is necessary to refill the air conditioning system, and the work procedure.

What do you need to know about refrigerant?

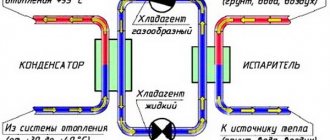

Freon is usually used as a refrigerant in modern split systems. This is a gaseous substance that, when compressed, turns into a liquid state. Passing along the internal circuit of the device, freon absorbs thermal energy. In the outdoor unit, it gives off heat to the surrounding air.

An important part of the system is the compressor, which constantly interacts with the refrigerant, compressing it to a liquid state. If there is too little freon in the circuit, the equipment will work under overload, which will almost certainly lead to its early breakdown.

The mountings of the outdoor unit are quite capable of withstanding additional load, so it is most convenient to place electronic scales and a refrigerant cylinder directly on the housing

It should be noted that the cost of a compressor can be more than half the price of a new split system. Therefore, if you discover a lack of freon in the system, you need to check the compressor and refill it as soon as possible.

If the performance of the air conditioner has dropped, it has become slower to cool the room, most likely it is time to check the amount of refrigerant in the circuit.

A freon leak may also be indicated by freezing of the outer pipe of the circuit. Very often, refrigerant leaks due to depressurization of the system. But even if there are no breakdowns, and the installation of the air conditioner is done correctly, within a year the amount of gas may decrease by 8-10%.

If the air conditioner has worked flawlessly for several years, the split unit has been serviced in accordance with the manufacturer's recommendations, and then the unit begins to cool the room insufficiently quickly, most likely it needs refueling.

But it is not always possible to simply add a small amount of refrigerant into the system. Some types of this material must be completely removed from the circuit, and then filled with new freon.

Frostbite at the ends of the copper tube and condensation on it is a clear sign that there is not enough refrigerant in the system

Most often, modern air conditioners are charged with R-410A and R-407C freon. The latter is a mixture of three different refrigerants. It is this brand that cannot be added to the remaining substances in the system. The components of the composition evaporate at different rates, so when there is a leak, the proportions change.

This does not apply to R-410A freon, a more modern version that is used in the latest models of split systems. The compositions R-407C and R-410A do not harm the environment, unlike R-22 freon. It is a legacy composition, the use of which is not recommended due to harm to the ozone layer.

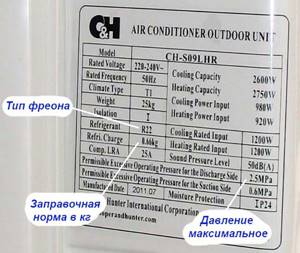

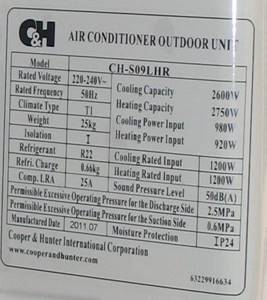

The safer freon is, the more expensive it is. But you cannot use the wrong brand of freon for the sake of saving money. Information about which refrigerant is required for a particular device is indicated in its technical passport, as well as on the nameplate attached to the body of the outdoor unit.

Questions and answers

Why is it recommended to supply freon in portions when refilling due to overheating?

Firstly, this increases the accuracy of measurements, and secondly, it avoids pouring excess refrigerant into the system and, as a result, serious consequences.

For what reason can the taps in the system freeze up after refilling the air conditioner?

The main reason is insufficient refrigerant. Accordingly, refueling needs to be repeated, or, if this does not solve the problem, look for the place where the circuit is depressurized.

Is it possible to find out how much freon is left in the circuit?

Even most service companies do not solve this problem. Accordingly, there are two ways to solve the problem with charging - abandon charging by mass in favor of another method, or completely remove the refrigerant from the circuit and carry out a full charge.

What cylinder do I need to purchase for refilling?

We must proceed from the fact that the amount of refrigerant in the cylinder should exceed the needs of the system with a margin. The latter depend on the specific model and power of the equipment, and the length of the lines. So, for a 7-8 kW split system you need a mass of freon of 700-800 g, and for each meter of pipelines - an additional 15-30 g.

Why are users warned about the danger of excess freon in the circuit?

If there is insufficient refrigerant, the system remains operational, but loses performance. When excessive, overloading of units inevitably leads to their failure. Therefore, it is better to charge the air conditioner with less freon.

Many home craftsmen are interested in how to charge the air conditioner at home with their own hands. Almost anyone can master the technology, but they will require specific tools and skills to work with them. To avoid gross mistakes and failure of climate control equipment, it is better to use the services of specialized service companies, especially since you will not be able to save much on self-refueling - about 2-3 thousand rubles.

How to prepare the device?

You can't just take a bottle of refrigerant, attach it to a pipe and let some of the substance into the system. The fact is that you first need to prepare the device for this operation. If freon flows out unnaturally quickly, the housing is most likely depressurized.

Leakage may occur at the junction of the copper tube with the outdoor unit due to improper installation and damage to the flared edge

You need to find out the cause, eliminate it, and only then let a new portion of gas into the system. The tightness of the circuit is also checked when it is necessary to replenish the refrigerant lost during operation. Very often, a leak occurs after inept installation.

For example, some inexperienced craftsmen carelessly cut off the flared edge of a copper tube and forget about the need to restore the flaring. As a result, a leak occurs at the junction of the tube and the outdoor unit. Copper is a fairly soft material.

Before starting work, you need to clean the air conditioner unit from accumulated dust so that the fan can operate without additional loads and the most correct data can be obtained.

You can damage the rolling without even cutting the tube, just screw the fasteners unevenly. Therefore, before refueling the split system, you need to unscrew this connection and check the condition of the edge of the tube. If it is damaged, it should be cut, flared and screwed into place. In this case, you should act carefully; the nut should go easily, without effort.

Additional information about possible air conditioner breakdowns and how to fix them is presented in this article.

Immediately before refueling, the system is drained. Nitrogen or freon is introduced into the circuit to displace foreign substances from it. At high pressure, the device is carefully inspected in search of a gap from which gas flows. Sometimes it is advisable to use an ultraviolet lamp.

Final tips

Most likely, refueling the split system yourself will not bring much financial gain, only moral satisfaction and experience that will be useful in the future. To avoid making mistakes, listen to the following recommendations:

- Pay close attention to leak detection and vacuuming. It is better to spend time redoing the rolled connections of copper pipes than to lose freon again.

- Take your time and remember to close the valves in the correct sequence.

- Purge of air from the hoses is strictly necessary - moisture and oxygen should not be allowed to enter the circuit.

- Before disconnecting the hoses from the air conditioner, close the cylinder valve and release the remainder from the pipes through the pressure gauge station.

For a refrigeration technician, the filling procedure will take no more than an hour; you should allocate twice as much time to complete the work. Watch the instructions for downloading R22 freon presented in the last video.

Methods for controlling the amount of freon

When figuring out how to charge a split system with freon yourself, you should remember that the amount of refrigerant should be sufficient, but not excessive. If there is too much gas in the circuit, the operation of the device will be seriously impaired, since the refrigerant simply will not have time to evaporate. This can seriously damage the compressor.

This situation is worse for the device than if the system is missing a few grams of refrigerant. Therefore, during refueling, it is necessary to organize control of the amount of freon entering the system.

They do this in the following ways:

- by measuring the change in mass of the refrigerant cylinder;

- taking into account the pressure in the system, which must reach a certain level;

- assessing the condition of the circuit through the sight glass;

- taking into account the temperature change at the indoor unit fan.

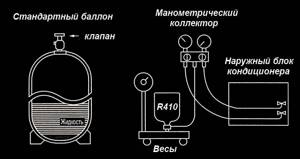

The easiest way to control the amount of freon is to record changes in the weight of the cylinder. To do this, before refilling, place the container with the refrigerant on the scale, reset the result and observe the change in indicators when the cylinder tap is open.

As soon as its weight decreases by the required amount, refueling is stopped immediately. Of course, this method is only used to completely charge the circuit. If you just need to top up the system, you first need to find out the weight of the refrigerant that is already inside, but this is difficult to do at home.

There are professional scales designed for these purposes, but many masters make do with inexpensive household models.

The device must meet the following requirements:

- load capacity – at least 20 kg;

- scale gradation – from 100 g;

- Availability of container weighing option.

It is most convenient to use electronic scales, which make it easier to track changes in the weight of the refrigerant container.

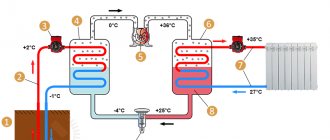

Another available option is to bring the pressure inside the circuit to the desired level. To perform this type of filling, you will need a pressure manifold. Using this device, the pressure inside the system is assessed.

The refrigerant is supplied to the circuit in small portions, constantly checking the pressure information with the standard indicator until a match is achieved.

Before charging the system with refrigerant, it is necessary to find out why the leak occurred and then correct any problems found. Re-inspection is carried out after completion of work

A collector is quite expensive equipment that does not make sense to buy only to use once every few years. It will be useful not only at the stage of pumping freon, but also when draining and vacuuming the system. You can borrow such a device from a familiar master or rent it at a specialized point.

The sight glass method is available to professionals. It consists of observing the state of the refrigerant flow, monitoring the moment when air bubbles disappear from it. At home, the first two methods are often used.

Measuring temperature is a simple, but not very reliable method. When the fan circuit is full, the temperature should usually be about eight degrees, although there are models for which this figure is five; a deviation of a couple of degrees is allowed. The refrigerant is introduced in small portions, taking measurements periodically.

Charging technology based on refrigerant weight

The essence of the method is to completely replace freon - the old gas must be released into the atmosphere, and fresh freon must be filled in instead. For beginners, this is the most acceptable option - only an experienced technician is able to determine the remaining refrigerant in the system and accurately refill the missing amount. We will describe other download methods below.

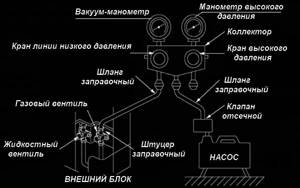

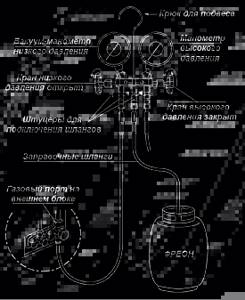

Connecting the manifold to the ports of the external module

Advice. Before refueling, correct the problem that caused the loss of old gas. Ideally, a split system should undergo a pressure test with nitrogen pumped under the maximum pressure specified in the product data sheet (usually 25-30 Bar).

We present instructions on how to charge an air conditioner with freon using a scale:

- Drain the old refrigerant into the atmosphere in any convenient way - through an unscrewed tube or spool of the service port. Release the gas slowly so as not to lose oil. While emptying, use the hexagon to open both taps hidden under the protective nuts.

- Close the taps and connect the left hose of the pressure gauge station (blue) to the spool. Make sure the manifold valves are also closed.

Connection diagram for vacuum - Connect the yellow middle hose to the vacuum pump fitting and start the unit. Open the left low pressure valve (on the left in the diagram) and watch the vacuum gauge - the arrow should fall below zero and show a value of minus 1 bar. Also open the service port valves.

- Evacuate the freon circuit for 20 minutes. After stopping the pump, wait half an hour while watching the pressure gauge. If the needle moves back to zero, look for a leak.

- Switch the hose from the pump to the cylinder, close the left valve of the manifold. Open the tank valve a few turns and purge the hose with freon. The operation is simple: open the right valve of the station (high pressure) for 1 second.

The filling vessel is connected with the same hose as the vacuum pump - Place the cylinder on the scale properly and reset the display to zero. Open the left manifold valve again and monitor the decrease in gas mass. When the display shows the required amount of refrigerant, close the tap.

- Close both valves on the service ports, disconnect the pipe from the spool and check the split system for operation.

Standard R410 refrigerant container must be inverted

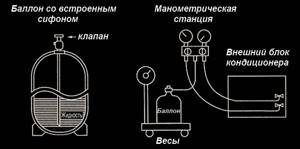

Important point. Freon R410a is poured only in a liquid state, so the cylinder is placed on the scale upside down. During refueling, the flow of substance can be easily seen in the manifold inspection window. If the tank is equipped with a siphon or R22 refrigerant is pumped in, there is no need to turn the tank over.

During operation, it is important not to confuse the sequence of operations and not accidentally open the filled circuit. The minimum evacuation time is 20 minutes; during this period, the pump will remove not only air from the system, but also moisture that can harm the compressor. How to refill an air conditioner with R410a freon, watch the video:

How often to refill your home cooler

Freon is pumped into a split system in three cases:

- during installation or reinstallation to a new location;

- after repairs that involve disconnecting freon lines;

- as a result of refrigerant leakage from the circuit.

For reference. Mobile and window air conditioners, designed as a monoblock, practically do not require additional freon filling. Short tubes installed at the factory are located inside the housing and are inaccessible to “cranky-handed” installers. Another thing is the car cooler, which is subject to vibration and loses coolant much more often.

Coolers - monoblocks lose gaseous freon much less often than splits with external communications

In fact, after installing a new air conditioner, there is no need to fill in freon - the manufacturer pumps the gas into the outdoor unit. Competent craftsmen do the same thing - when repairing or dismantling a split, the refrigerant is pumped into the heat exchanger of the external module. The first two cases involve the loss of substance due to unsuccessful actions.

The following signs indicate an insufficient amount of freon in the climate control system:

- cooling efficiency decreases - the fan of the indoor unit drives warm air;

- the compressor operates continuously at full load;

- the inverter air conditioner goes into error and often turns off (the display shows a fault code);

- the service port located on the external unit, where the liquid line enters, is covered with ice;

- under the influence of freon pressure, oil appeared on the leaky connection;

- freezing of the evaporator of the indoor module.

Note. The service ports of the split system are located under a cover on the side wall of the outdoor unit. 2 lines are connected to them, where freon circulates in liquid and gaseous states. The diameter of the liquid tube is smaller than that of the gas tube.

A full set of consequences - the gas service port is covered in oil, the liquid port is covered with frost, in the photo on the right - a frozen evaporator of the indoor unit

On videos and websites of companies involved in the installation of refrigeration machines, there is a recommendation: household air conditioners need to be refilled almost annually. In fact, a properly installed split can easily serve without refueling for 3-5 years, since a large volume of refrigerant cannot leak out through reliable connections.

If the above symptoms are observed frequently, you need to disassemble the joints and check the quality of the rolling. Factory defects inside units are rare even for the “Chinese”.

Hence the advice: do refueling when it is really necessary. But the air conditioner needs to be cleaned annually.

Service maintenance of wall-mounted split system 30 BTU (8.8-10.4 kW.)

- Elimination of minor faults that do not require disassembling the equipment

- Cleaning the outdoor unit condenser

- Cleaning the evaporator of the indoor unit

- Filter cleaning, disinfection

- Cleaning and disinfecting the drainage system

- Checking the condition of the compressor under load (presence of extraneous noise, vibration, temperature.)

- Monitoring the operation of the outdoor unit fan electric motor, cleaning and balancing the impeller if necessary

- Monitoring the condition of electrical circuits, checking connections, stripping and tightening if necessary

- Check the tightness of the refrigeration circuit, refill if necessary. (The cost of work includes refilling with refrigerant up to 300 g.)

- Checking the functionality of the remote control.

- Control measurements of temperature at the outlet of the indoor unit

- Testing the operation of the system as a whole, in all modes

- Show all list

Causes of freon leaks

The split system includes a pair of blocks connected by a freon route made of copper tubes. To connect them, nuts and flared joints are used; sometimes they serve as a point of freon leakage if the seal is insufficient during the installation process. Fistulas and cracks may occur in the air conditioner itself as a result of vibration during the operation of the fan and compressor, which can cause the tubes inside the device to fray. They also serve as a source of leaks. Leaks sometimes appear in places where internal parts are soldered. In some situations, the technician cannot immediately determine the location of the leak, so he uses nitrogen pressure testing to identify the problem.

Equipment and materials for work

To refuel your home split system yourself, buy, or better yet, rent a small set of equipment:

- two-stage vacuum pump equipped with a check valve;

- manometric manifold with inspection window and a set of hoses;

- electronic floor scales;

- open-end wrenches and hex keys measuring 5-8 mm (possibly found in the household).

Note. Pump models equipped with a check valve do not “throw” their own oil into the freon lines during operation.

Next, you need to choose the right freon for the air conditioner, based on the nameplate on the external unit or the operating instructions for the cooler. The plate indicates the brand of refrigerant and the filling rate, expressed in kilograms (or grams).

When choosing the type of refrigerant, use simple recommendations:

- Buy the freon indicated on the tag; other brands will not work. The most common two-component gas is R410a, less common is R22 or R134a (in cars). Freon R12 is considered obsolete and therefore discontinued.

- When renting a gauge manifold, be sure to provide the brand of refrigerant you are using. The device and hoses that worked with R22 freon cannot be used to fill R410a gas, since different oils are added to them - mineral and synthetic based, respectively.

- To connect the pressure gauge station to the service ports of a split system operating with R410a refrigerant, a special adapter is used.

- Calculate the weight of the refrigerant with a reserve. Blowing the hoses will take approximately 50 grams plus 30 grams for each extra meter of lines if their length exceeds 3 m.

- For most air conditioners installed in apartments, 1 kg of freon is sufficient, taking into account the reserve. You can rent it along with the cylinder or buy it in a separate container.

Some types of cylinders have a built-in siphon, shown in the diagram. Such tanks do not need to be turned over to fill the refrigerant in a liquid state. Check with your dealer or landlord about the type of cylinder.

Clarification. Cylinders charged with R410a gas are painted pink, and R22 freon - green.

There is a specialized electronic device that detects minor defects in pipes and connections - freon leak detector . If cooling efficiency has decreased, but no obvious leaks are found in the air conditioner, the meter will help you find a fistula the size of a human hair. If necessary, the device can be rented, but buying is expensive and pointless.

Tips and tricks

When refilling the air conditioner yourself, you need to follow the recommendations. This applies not only to the selection of freon, but also to the entire process .

- The reference is made exclusively to the brand of freon specified in the instructions. As a rule, this is R410a. Sometimes there are R 22 or R 134a. If you come across R 12, then you shouldn’t take it, since this brand is outdated.

- Depending on the brand of freon, a pressure gauge manifold is selected. Its hoses are configured to work only with a specific type of gas. This is due to the fact that the refrigerant contains mineral and synthetic oils.

- The amount of freon is taken with a reserve. It is necessary for blowing hoses and filling lines over 3 m. The standard weight is 1 kg.

- During work, you need to spend time searching for freon leaks. If found, take action to eliminate them.

- Operate the valves in the specified sequence.

- Do not ignore the hose purging step. Do not allow oxygen or moisture to enter the system.

- Be sure to tighten the cylinder valve before disconnecting the hoses.

We recommend that you read: Floor standing air conditioner without duct

What should be the volume of refrigerant

Refilling a home air conditioner is impossible unless you become familiar with the device.

The design includes:

- Closed loop. Serves to accommodate freon, which constantly circulates.

- Compressor. Used to increase the temperature of the gas.

- Capacitor. In it, hot freon under high pressure gives off heat, turning into a liquid state.

- Evaporator. Used to evaporate liquid after spraying in an expansion valve.

For the unit to function properly, the compressor must be repaired in a timely manner if it fails. It is necessary to regularly check the tightness of the connecting sections and refill household air conditioners. Before refueling the unit yourself, you need to find out how much freon is in the air conditioner.

The unit consists of two blocks. One is mounted indoors, the second is installed outdoors. The compartments are connected to each other by a cold main, through which an electrical cable and a drainage system pass. Freon circulates along the route. Copper tubes with a small diameter are used to make the cold line.

The amount of refrigerant depends on the length of the refrigeration line and the power consumption of the device. There is no single meaning for structures. At manufacturing plants, the air conditioner is charged taking into account the length of the refrigeration line. As a rule, the length of copper pipelines is never less than 3 m. At the factory, 0.15 kg of refrigerant is charged for each meter of route. The compressor power indicator is added to this weight.

How much refrigerant is in the installation and how much it needs to be refilled can be found on the metal plate - nameplate. The nameplate is located inside the unit body. Refueling of air conditioners with freon is carried out at a set of specified indicators. You can calculate the amount of gaseous substance using a pressure gauge.

Company advantages

Professional maintenance of equipment requires competence and experience from employees. Mos Eco-Clean craftsmen are trained to work in industrial enterprises, catering organizations, in private and apartment buildings.

Prevention protects the air conditioning system from breakdowns and extends its service life. At the service center you can order scheduled maintenance on a regular basis and refilling of air conditioners in Moscow and the region. This way, during the summer, there will be no interruptions in the operation of household appliances. We offer our customers a number of advantages:

- quality guarantee and official contract for work;

- free travel to your home, office, private sector or enterprise;

- choosing a time convenient for the client;

- urgent call to a technician within one hour (within city limits);

- carrying out preventive maintenance on climate control equipment (monitoring the condition of components, refilling the air conditioner with freon, antibacterial treatment);

- discount program for regular customers.

If there is a refrigerant leak, the air conditioner stops cooling, or water is leaking from it, the main reason may be improper installation or damage to the route. A company employee will diagnose and fix the problem. Our manager will calculate the cost of refilling the air conditioner personally, taking into account the customer’s wishes and the address of the facility.

Mos Eco-Clean restores the performance of air conditioners of any brand. Repair of split systems and refilling of household air conditioners is carried out at the customer’s home or in a workshop, if stationary equipment is needed. Orders are accepted throughout the city and region. We guarantee quick repairs at a reasonable price. Refilling an air conditioner at home takes no more than 6 hours if the necessary parts and consumables are available. The work guarantee is 12 months.

Causes of leakage

There are several reasons for freon leaks.

These include:

- Installation errors. Copper tubes used for refrigerant circulation are flared during installation of the structure.

- During transportation. During transportation, the amount of freon may decrease slightly. The same thing happens during dismantling and re-installation.

- The appearance of gaps between connecting elements.

It is not difficult for the user to determine independently that a failure has occurred in the unit.

The signs are:

- Poor cooling or heating of air;

- Involuntary shutdown of the compressor sensor, which serves for protection;

- Formation of oil on parts and a burning smell when the device is turned on;

- Dark thermal insulation on the compressor;

- Burnt insulating coating near the capillary tube;

- Ice formation on the pipes of the unit located outside.

A timely detected leak will help avoid device failure and financial costs.

As a result of long-term leakage, the following problems arise:

- Compressor overheating. Due to insufficient freon, the compressor will constantly overheat and eventually break down.

- Breakage of blocks and units. The parts are connected to the compressor.

- Loss of oil. When a leak occurs, oil spills out, which damages the condenser.

- Moisture penetration. Moisture can enter the system through the gap.

Attention! If you do not notice the leak in time, you will have to replace the compressor or the entire unit. Therefore, it is necessary to monitor the operation of the equipment and carry out technical work in a timely manner.

How can you top up your split system?

There are two ways to refuel the installation at home.

These include:

- By pressure level. To determine the amount of gas that has evaporated, you need to know the optimal pressure (indicated in the instructions). It is then compared with the pressure in the air conditioner. To determine this, you need a collector. This method is used when there is a refrigerant leak due to prolonged use.

- By weight. The method is used when replacing freon completely. First, the refrigerant is removed from the system. Then, based on the weight determined on the electronic scale, the air conditioner is charged.

Reference! It is known that climate-class appliances during operation lose 8% of refrigerant in one year. For this reason, it is necessary to refuel every two years.

You can fill the unit using a measuring glass, but it is used extremely rarely.

Types of freons for refilling

Charging the system with the correct refrigerant will ensure its long and trouble-free operation. The quality and service life of the equipment largely depend on the qualifications of the technician and the quality of the freon used.

Types of freons used in air conditioners:

- R-22 is the most popular type of refrigerant used in inexpensive equipment; if there is a leak, its components evaporate evenly, which allows for successful refilling;

- R-32 – difluoromethane, a new development used in mixtures to increase the activity of freon, is considered the most effective and safest from an environmental point of view;

- R-134a – tetrafluoroethane, one of the first refrigerants created without the use of chlorine, most often used for automobile air conditioners or in mixtures;

- R-125 is used both independently and as part of mixtures, and is often used to extinguish fires;

- R-410A - a modern development that does not affect the ozone layer, consists of a mixture of R-32 and R-125 freons, allows you to save energy;

- R-407C is a mixture of three freons: R-32, R-125 and R-134a, most often used in industrial air conditioning systems.

Frequency of refilling air conditioners

Split systems

We are often asked the question, how often do you need to recharge your air conditioner?

It is impossible to accurately determine the refilling time, since it depends on the quality of installation, as well as the quality of the air conditioner itself.

It is better to focus on signs indicating a freon deficiency.

But in any case, it is better to check the presence of freon in the system at least once every two years.

It is convenient to do this in conjunction with cleaning the air conditioner, that is, to carry out maintenance

Mobile and window air conditioners

These types of air conditioners are assembled in a single housing and all connections are located inside and are made at the factory using the soldering method.

Such air conditioners require refilling very rarely. But their peculiarity is that they cannot be refueled—the entire system must be completely refilled.

You will need to refill the air conditioner after certain types of repairs:

- compressor replacement

- replacing a four-way valve

- replacing the filling port

- after damage to the heat exchangers - condenser or evaporator

- after damage to freon tubes

Cost savings compared to calling a specialist

Knowing the need for materials and equipment, it is easy to calculate how profitable it is to refill the air conditioner yourself. We take the rental price from the Internet resources of companies offering this service in the Moscow region:

- vacuum pump + manifold with hoses – 700 rub. per day (12.5 USD);

- a complete set, including a gas cylinder, a pressure gauge station and a pump - from 1000 rubles/day (18 USD);

- the most expensive type of freon is R410a - 650 rubles. for 0.6 kg (12 USD).

Note. Prices are taken as of March 1, 2021. The equivalent in conventional units is indicated in brackets, since the cost of services changes over time.

Let's take into account a more expensive option - renting equipment plus buying freon: 700 + 650 = 1350 rubles. (24.5 USD). The minimum cost for refilling split systems, declared by various companies, is 2,000 rubles. (35 USD). The benefit from carrying out refueling work yourself is not too great - 650 rubles. or 10.5 USD e.

Consider a number of conflicting factors:

- To rent equipment and accessories, you need to spend personal time.

- Prices listed on the Internet may be lowered to attract customers or simply become outdated.

- Often, a company charges additional costs for a visit or issues an invoice for each job separately - vacuuming, diagnostics and refueling.

- There is a possibility that “cheap” craftsmen will perform the work poorly and after a year the freon will disappear again.

- The cost of renting electronic scales is not taken into account. It is allowed to use tabletop kitchen scales designed to measure weight up to 20 kg with a display accuracy of up to 1 gram.

Hence the conclusion: correctly done independent freon injection is preferable to contacting a company that provides services at a reduced price. The work of experienced specialists is expensive.

Step-by-step instructions for refilling the air conditioner with your own hands (+2 videos)

How to properly refill the air conditioner with your own hands:

- Open the window and inspect the outdoor unit. You need to find a casing on the side under which 2 hoses go.

- We unscrew the screws holding the casing, under which the 2 tubes go, and remove it. One tube supplies refrigerant in a gaseous state to the outdoor unit. The second tube removes liquid refrigerant from the outdoor unit.

- We drain the old refrigerant into the atmosphere - through the spool of the service port or through an unscrewed tube. Be sure to drain the freon slowly so as not to drain the oil as well. For replacement at home by an inexperienced person, this is the most acceptable option: you are unlikely to be able to correctly calculate the remainder for refueling.

- We connect the left (blue) hose of the pressure gauge station to the spool.

- Check that the manifold valves are closed.

- We connect the middle (yellow) hose of the pressure gauge station to the fitting of the vacuum pump.

- Open the low pressure valve and monitor the readings: you want the pressure gauge to show -1 Bar.

- Open the service port valves.

- We vacuum the circuit for 20 minutes. When the pressure drops to -1 Bar, wait another 20-30 minutes: won’t the needle rise back to 0? If it does, it means there is a leak somewhere in the circuit. It must be found and fixed, otherwise the charged refrigerant will leak again.

- If no leaks are found, 30 minutes after evacuation, disconnect the yellow hose of the station from the pump and connect it to a cylinder with freon.

- Close the left manifold tap.

- We put the freon cylinder on the scale and remember how much it weighs now.

- Open the valve on the cylinder.

- We open for 1 second and then close the right valve at the pressure gauge station - to blow out the rods (so that there is no air left in the hose that will enter the circuit).

- Open the left (blue) tap at the station. After this, freon will begin to flow from the cylinder into the air conditioner circuit. The weight of the cylinder will begin to decrease. We monitor until it drops to the required level (that is, until the circuit is filled with as much gas as needed for your model), and turn off the blue tap.

- We turn off both taps on the unit, disconnect the station and check how the air conditioner works.

Refilling the climate system in the car

Nowadays, most modern cars are equipped with air conditioning, which allows you to create comfortable climatic conditions in the cabin regardless of the time of year. However, sometimes the driver notices that his air conditioner is not performing its functions. As a rule, this happens due to depressurization of the air conditioning system. As soon as the tightness is restored, the car air conditioner will need to be refilled. Doing this yourself is not difficult, but you will have to buy a special kit for manually pumping freon.

Refueling a car air conditioner is carried out in the following order:

- using the attached instructions, assemble a kit for pumping freon;

- thoroughly clean the surface around the low-pressure hole from dust and dirt, remove the protective cover;

- connect the hose from the purchased kit to the low pressure hole;

- the car is put on the handbrake;

- The gear shift lever is moved to the neutral position;

- turn off the valve on the refrigerant cylinder;

- sit in the cabin, start the engine and intensively press the gas pedal, giving the freon the opportunity to be evenly distributed throughout all the pipes of the system

- the refueling process is stopped as soon as the cabin becomes noticeably cooler;

- tighten the valve of the freon cylinder, disconnect the hose and close the low pressure hole with a lid.

The car air conditioner is ready for use. The process of filling it is shown in more detail in the video:

So, refilling the air conditioning system with freon is quite within the capabilities of a skilled home craftsman, but this will require additional professional equipment, which is not practical to buy for one time. In addition, there is a possibility of damaging the system, which will not only invalidate all efforts, but also force you to purchase a new air conditioner. Therefore, it is worth considering inviting specially trained professionals to carry out this procedure.

Methods for refilling an air conditioner with freon

There are several basic methods for charging refrigeration systems with freon, applicable to home air conditioners (splits), multi-splits, mobile and multi-zone systems.

Refilling the air conditioner with your own hands will require the following kit:

- pressure gauge;

- Vacuum pump;

- freon cylinder;

- construction scales;

- locksmith tools - Swedish key, hexagons, screwdriver.

Instead of a pressure gauge and a vacuum pump, you can purchase a pressure gauge station.

Refueling by scale

If you need to fill a completely empty air conditioner with 22 or 410 gas, the process proceeds as follows.

Vacuuming. Screw the pressure gauge onto the shredders and open the tap. Turn on the vacuum pump and wait 10 minutes. Close the tap on the pressure gauge and turn off the pump.

Connecting a freon cylinder. The container with gas is turned upside down and placed on a scale, the readings of which are first reset to zero. Open the tap on the pressure gauge and pour in the required amount of refrigerant according to the scale.

The norm for each air conditioner and the type of gas poured into the compressor are indicated in the technical documentation and on the nameplate.

Close the tap and disconnect the pressure gauge, after which the caps on the ports are screwed on. Turn on the air conditioner and check its functionality.

This method is considered the most correct, but it is complicated by the need to have expensive scales for weighing freon.

If you want to fill the air conditioner 410 with freon yourself, then first completely bleed off its remains into a pressure gauge station for collection, and then pour in the gas according to the scales. This is due to the fact that this type of freon consists of a mixture of various gases with varying degrees of volatility. If one of the components leaks in a larger volume, the composition changes, and, consequently, the necessary properties of the refrigerant are lost.

If you need to fill the air conditioner with R22 freon, then they resort to the following method: filling the air conditioner by pressure.

Filling by pressure

First you need to connect the pressure gauge to the gas port of the air conditioner operating for cooling. The operating pressure of the device should be 3-3.5 atm. If it is below these marks, then refueling is required. To do this, connect a cylinder with freon and begin to fill it into the system in small portions by opening the taps on the pressure gauge for 5-10 seconds.

To avoid burning your hands with gas, it is more convenient to use quick-release connections.

This method is convenient specifically when you need to refill the air conditioner yourself with a small portion of R22 refrigerant. In all other cases, the simplest and optimal method is refueling with scales, that is, by weight.

Refueling for overheating and hypothermia

A fairly accurate method is to refill the air conditioner based on overheating or overcooling. The whole point is to focus on the temperature difference.

In the case of supercooling, we mean the ratio of the temperature indicators of liquid and condensation at the same pressure. The condensation temperature can be determined as follows: its pressure is measured with a manometer, and then the data is correlated with the scale values of the manometric manifold depending on the refrigerant. To determine overheating, the temperature values of the gas in the normal state and when it boils under conditions of the same pressure are compared.

A refrigerant leak and the need to refill it are indicated by overheating above normal and subcooling below normal.

These methods are not suitable for refueling home air conditioners, that is, wall-mounted split systems. But they are very convenient for semi-industrial installations, since their external unit has the required fittings. In addition to the tools, you will need an infrared thermometer.

A non-professional is unlikely to be able to refill the air conditioner with his own hands using these two methods, as they require a sufficient knowledge base in the field of air conditioning systems. Although the ease and accessibility of previous methods for the common man is also a controversial issue.

Refueling the air conditioner using current

Many craftsmen do not use this method, but its use is quite justified in cases where it is not possible to use scales to weigh freon. So how to charge the air conditioner yourself using current?

To determine the operating current of the compressor, you will need special current clamps, which are applied to the phase of the power wire of the operating external unit. If the values obtained are lower than those indicated in the manual or on the nameplate, and the pipe is frozen, then refill with freon until the indicators level out.

All other stages completely coincide with the stages of filling the air conditioner with freon using scales, which can be viewed in the video at the end of the article.

This method is also applicable in the case of eliminating the consequences of leaks in semi-industrial equipment.

If the length of the freon route of the air conditioner exceeds the length of the line without refueling specified by the manufacturer, but does not exceed the maximum permissible value, then you need to refuel the device at the rate of 30g (up to 3.5 kW) of gas per meter.

When is freon refilling required?

According to statistics, even the highest quality air conditioner loses up to 8% of the pumped refrigerant during the season. This means that at least once every 2 years the home climate system needs to be refilled with freon.

A clear sign of the need for such maintenance is an increase in the time it takes to set the specified climatic parameters. However, it is quite difficult to clearly judge that it is time to refill the air conditioner.

Loss of cooling capacity can be caused by more than just a refrigerant leak. It is no less affected by contamination of the evaporator and condenser, radiators, and problems with the operation of the fans of the external unit of the split system.

With a high degree of certainty, we can judge the need for refrigerant charging only if the system undergoes maintenance at the correct intervals, and after cleaning the components, the cold performance has not reached the optimal level.

Periodic refueling is required during operation

The frequency of equipment cleaning largely depends on the location of the unit:

- Split systems on floors 1-4 need to be cleaned before the start of each season.

- When installing blocks at a height of 5 - 8, cleaning can be done once every 2 years;

- Blocks on the 9th floor and above need to be cleaned no more than once every 3 years.

Expert opinion

Starostin Konstantin Adreevich

Air conditioner installation and maintenance specialist

If the air conditioner is used in winter, cleaning will be required much more often - at least once a month, and in some cases - once a week.

Most equipment owners have no idea how to charge their home air conditioner themselves. In reality, this process is not so complicated, but it will require certain knowledge about the design of equipment, the availability of specific devices and tools, and skills in their use.

At the same time, some errors (for example, an excessive amount of refrigerant in the system) can lead to completely the opposite result - instead of restoring operating parameters, the air conditioning unit will completely fail. To avoid such an unpleasant outcome, entrust the work of refueling to the service center specialists.

Another compelling argument in favor of such a decision is the very insignificant savings when doing the work yourself (in the best case, it will be 2-3 thousand rubles).