What information does the meter provide?

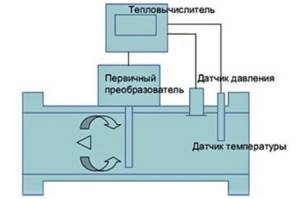

Thermal energy metering device is a complex mechanism that records signals from volumetric coolant flow and temperature sensors. The computing unit of the heat meter makes the appropriate calculations and provides results for the following parameters:

- the amount of heat energy used for a certain period (in gigacalories);

- amount of cooling energy (in gigacalories);

- thermal power (heat energy consumption per hour);

- volumetric flow rate of coolant (both in the supply pipe and in the return pipe: measured in cubic meters per hour);

- volume of coolant in each pipeline (in cubic meters);

- temperature of the coolant in the supply pipeline (in degrees Celsius);

- return coolant temperature (in degrees Celsius);

- temperature difference (in degrees Celsius);

- date Time.

Types of devices

Design features

The heating meter consists of:

- coolant flow sensor (usually hot water),

- two sensors for temperature recording,

- computing module.

These units are placed in a plastic case equipped with pipes. With their help, the meter is connected to the pipeline. Many devices are equipped with an independent battery. This removes the dependence on the presence or absence of electricity in the apartment.

The modern market offers a variety of models of heating meters. They work with different types of flow meters.

Mechanical devices

These are the simplest and cheapest devices. They are:

- screw,

- turbine (vane).

Their work is based on converting the translational movement of the coolant into the movement of the measurement element.

Mechanical meters cannot be used when . If there are particles of scale, scale or rust in the water, they clog the mechanical components. Therefore, it is recommended to install special filters first.

Another disadvantage of these devices is their intolerance to sudden fluctuations in heat consumption.

Electromagnetic type

An electromagnetic heating meter uses the factor of the occurrence of an electric current at the moment the coolant passes through a magnetic field. These devices have high metrological stability and are successfully used.

But with poor-quality installation of wires and with the appearance of impurities in the water, the inaccuracy of instrument readings increases.

Vortex devices

The operation of these devices is based on the assessment of vortices that form behind an obstacle in the path of coolant movement. They can be installed on horizontal and vertical pipelines. Their work is not interfered with by deposits inside the pipes. But they are sensitive to the following factors:

- presence of air in the system,

- welding quality,

- the content of impurities in water,

- the size of the straight parts of the pipeline around the flow meter.

Requires installation of a magnetic mesh filter.

Ultrasonic meters

The time it takes for the liquid to move from the source to the signal receiver is measured. This version of heating devices has maximum efficiency when working with clean coolant. They do not create additional hydraulic resistance.

But if air bubbles enter the coolant flow sensor or the water becomes contaminated, the device produces an error. It is also better not to install an ultrasonic heat meter on pipelines with a high scale content.

Despite these features, an ultrasonic meter is the most reliable and durable option.

It is important to know

! When buying an apartment heating meter, you need to ensure the availability of certificates and passports. After installation, the meter is sealed. Periodic verification of the device must be performed after 4 years.

General rules for reading and calculating data

For a service provider company, one indicator is important - the amount of heat energy used during the reporting period (usually per month). Payment is calculated based on this indicator. Accordingly, at the end of the reporting period it is necessary to take readings and make a calculation.

On the front panel of the heat meter there is an electronic information board on which all parameters are displayed. The first is the amount of accumulated heat energy. Necessary:

- write down readings from the screen;

- Subtract from this figure the readings taken in the previous reporting period. This will be the amount of heat energy used for the current period.

Residential heat energy meter: how to correctly take and transmit readings?

Readings from residential heat meters should be taken by analogy with water meters. The only difference is that heat meters display several indicators on the indicator and to select the one you need, you should carefully read the operating instructions and strictly follow the manufacturer’s recommendations. After receiving the necessary information, the difference in readings for the previous and reporting periods should be entered into the receipt for payment for thermal energy, multiplied by the tariff established in the region, and the resulting amount should be paid.

Currently, modern heat metering devices are equipped with a built-in interface that allows you to read data automatically. For example, the domestically produced Kombik-T meter has a built-in radio antenna, which allows you to take readings from the device even without entering the apartment. It should be noted that a water meter (water meter) with a pulse output can be connected to such a device, which will allow you to take readings of water consumption (hot and cold) also without visual contact. Installing such metering devices will be a good solution for people who often go on business trips or trips and cannot personally meet the controller who comes to take readings.

Please note that an individual heat meter can only be installed in apartments that have horizontal piping and separate coolant inlets. In houses with heating systems with vertical wiring, individual meters are not installed.

From the information provided in this article, we can conclude that the procedure for taking and transmitting heat meter readings should be treated with a sufficient degree of responsibility.

Source

Keeping a log book

The remaining parameters shown by the heat meter are auxiliary. However, with their help you can monitor the stability of both the meter itself and the heating system in the apartment. Therefore, it is advisable to keep a log of readings. A table is created in which all the parameters produced by the device are recorded. To take readings, you need to press the corresponding button on the front panel. The best option is to keep records every day, but it is also possible after a certain period of time.

How to take heating meter readings?

An individual heat meter is a fairly simple piece of equipment, but any new device seems very confusing at first. Sending heat meter display readings also often causes some difficulties. To prevent such situations, it is first recommended to carefully read the device passport. It is better to do this several times, because the answers to most questions are given there.

Despite the large number of indicators, most of them are not important for the supplier company. The main figure for her is the amount of energy consumed over a certain period of time - per month. All indicators are displayed on the information board, but only the first of them is needed for transmission. This is the amount of heat energy. This parameter is written off from the display, then the readings for the last month are subtracted from it. The result of the subtraction will be the desired one - the amount of thermal energy used.

Another option is the help of specialists: taking readings by a representative of the heating service (management company). In this case, the owners only need to provide access to the heat meter located in the apartment.

Sending metrics

However, collecting data and sending it depends on the design features of heat meters. The operation of sending data is done in this way:

- They rewrite it, take it away, and send the result. Readings from the liquid crystal display help you find the menu, the sections of which can be switched with a button.

- The ORTO transmitter, which is equipped with devices manufactured in Europe, makes it possible to display detailed information on a PC monitor and then print it out.

- The radio module included in some models is designed for wireless data transmission. Its radius is several hundred meters. After the receiver hits it, this device records the readings and then delivers them to the heat supply organization.

- Another “smart” type is the M-Bus module. It comes with separate meters, which are then combined into a single system so that heat supply organizations can collect data. A group of devices is connected by a twisted pair cable, then the network is connected to a hub, whose responsibility is to periodically poll them. Based on the results obtained, a report is created, delivered to the organization, or displayed on a PC display.

If we talk about the most convenient method, it is transferring data to the organization via the Internet. This method guarantees time savings, makes it possible to check debts, control payments, and also track heat consumption at different time intervals.

To transfer readings, you need to find the address of the supplier organization, then register on the website, being able to log into your personal account. It has a form for entering readings, so the last stage usually does not cause any difficulties.

Logging

This type of control will allow device owners to verify the stability of operation, not only of the heat meter itself, but also of the heating system as a whole. For this purpose, all readings are recorded in the log - the amount of thermal energy used, as well as other (auxiliary) parameters that are not required by the heat supply organization, but will become informative for the owners.

Records can be kept daily. For this purpose, a table is first drawn: on paper or using a computer program. If you do not want to write off parameters every day, then the interval can be increased, but the first option for assessing the operation of the device is still optimal.

Data reading methods

If you have a device with visual reading installed, you can only take readings directly from the information display. The consumer can record the data himself and then transfer it to the management company or service provider organization. In addition, employees of the management company or heating service can take readings. The consumer is obliged to provide them with access to the heat meter located in the apartment.

Remote data reading is also possible. To do this, the device must be equipped with one of the following modules:

- with pulse output. It is equipped with a sealed contact, the closure of which leads to the formation of an electrical pulse. This impulse is recorded by a reading device, which transmits information to an automated control center;

- with radio output. Information is transmitted over a radio channel independent of cellular communications;

- with digital output. The RS-485 interface is used. Data is transmitted over a wired communication line.

Remote readings are relevant if access to the heat meter is difficult or if a building-wide metering system is organized in an apartment building. Equipping devices with these modules allows not only to read information remotely, but also to store it in a non-volatile archive for further viewing, output to paper, and inclusion in reporting documentation.

Types of heat meters

Massive and expensive devices are installed in apartment buildings where heating is centralized. Due to the large volume of coolant, the diameter of their pipes can be 32-300 mm. The purchase and installation is carried out at the expense of the residents; a representative of the utility services, or a person unanimously elected at a general building meeting, is responsible for monitoring the readings of the devices.

Individual devices are smaller in size and their price is also lower. Their compactness is explained by their lower throughput - maximum 3 m3/h. Installation depends only on the characteristics of the heating system. In houses with a horizontal arrangement, it is enough to install one device. If the apartment has vertical risers, then a heat meter will have to be installed on each of them. In new residential complexes, devices are often installed during construction.

Any device has identical components, so the principle of operation of the heat meter is the same. However, there is a difference: this is a feature of measuring coolant flow. Devices are:

- mechanical;

- electromagnetic;

- ultrasonic;

- vortex.

None of the types is without some disadvantages, but each device also has its advantages.

Mechanical (tachometer)

These are the simplest rotor-type devices: screw, vane, turbine. Mechanical heat meters are similar in operating principle to water meters, the only difference being the presence of temperature sensors that are located at the inlet and outlet. The advantages of the mechanical variety include:

- quite low price;

- possibility of vertical installation;

- simplicity due to the lack of electrical elements;

- Autonomous operation, as the device is powered by batteries.

The first disadvantage is the need for a mesh filter, without which it quickly becomes clogged and therefore the mechanism of the device becomes unusable. For this reason, such devices are only allowed as an individual meter. Lack of protection against water hammer, inability to save information for a day, lack of remote data reading are other weaknesses of mechanical models.

Electromagnetic

In this case, the principle of measuring indicators is based on electromagnetic induction. This heat meter is a hydrodynamic generator. Due to the influence of a magnetic field, an electric current is excited in the liquid. The device determines the amount of heat by the field strength and the potential difference across the electrodes. Advantages of electromagnetic devices:

- the most compact sizes;

- greater accuracy of indicators;

- power supply variability - the ability to operate on batteries or mains;

- installation in any position, if the coolant is always available at the installation site.

The disadvantage of these devices is their high sensitivity. It requires high-quality installation and constant maintenance. Without regular cleaning, an increase in error is inevitable. The electromagnetic device is capable of responding to electronic devices located nearby. Another disadvantage is the high price.

Ultrasonic

These devices use ultrasound. The heat meter measures the travel time of an ultrasonic wave from the transmitter, which is installed on one side of the pipe, to the receiver, located on the other, opposite side. There is absolutely no impact on hydraulic pressure. Other advantages of ultrasonic equipment:

- high accuracy of indicators, almost “eternal” service life;

- maximum information content, the ability to read data remotely;

- models that have the function of adjusting water through 2 channels, it allows you to change the speed of the coolant and the degree of heating of the heat exchangers.

The disadvantages of ultrasonic devices are an increase in error due to the poor quality of the coolant, high price, operation only from the network, which requires the purchase of a UPS. These disadvantages do not prevent these heat meters from remaining very popular. The reason is their maximum reliability.

Vortex

The operating principle of the heat meter is based on vortex formation, which appears when water encounters any obstacle. The mechanism uses:

- a magnet located outside the pipe;

- a prism located vertically in it;

- an electrode that is fixed further along the flow of the liquid.

When water flows around a prism obstacle, it forms vortices. Using the frequency of their formation, the device displays information about the volume of liquid passing through the pipe. Advantages of vortex devices:

- transmission of fault signals via radio communication;

- complete absence of influence of water quality (pipes) on the devices;

- Possibility of installation in vertical or horizontal position

- absence of error in the readings of devices installed in old houses;

- minimal energy consumption: one battery in the device can last for several years.

Vortex equipment has disadvantages. Its operation can be affected by water hammer, air in the system, or large particles of debris trapped in the coolant.

What affects the accuracy of readings

Understanding how to take readings from the heat meter in an apartment is not enough. It is important to know what affects the accuracy of the readings and carefully monitor the parameters. This will help to eliminate failures in a timely manner and, accordingly, avoid overspending.

For example, a too small difference in temperature conditions in the supply and return pipelines may indicate that the extraction of heat energy is disrupted (not enough heat is supplied to the room) or that an excessive amount of coolant is supplied. Accordingly, if the heating system is not working correctly (the hydraulics are broken or there are other problems), you need to contact specialists to identify and fix the problem.

The difference in coolant flow rate in the supply and circulation pipes indicates the presence of a coolant leak or a malfunction of the heat meter. In this case, it is necessary to check the heating system for leaks. If this is not detected, diagnostics of the metering device is necessary.

If the date and time of the device’s built-in calendar fail, the computing mechanism is most likely faulty. A malfunction of the heat meter is also indicated by error data, display of any parameters in a negative format (for example, –12° C) or a complete absence of an image on the display.

Methods for logging errors

The following factors influence the accuracy of heat meter readings during calculations:

- temperature sensor readings;

- flow sensor data when calculating the coolant volume;

- accuracy of processing of received signals.

As a rule, all modern metering devices are equipped with a self-test program that regularly checks the equipment and registers an error if damage is detected. The most common causes of problems:

- lack of food;

- malfunction of the computer or temperature mode;

- memory damage.

According to paragraph 89 of Resolution No. 1034, if violations occur, the consumer is obliged to report this to the service organization within 24 hours. After this, a report is drawn up and submitted to the heat supply company.

The amount of thermal energy consumed during equipment malfunction is determined by calculation.

It is legally established that the performance of the heat meter should be checked at least once a year, namely:

- serviceability of each measurement channel;

- presence of seals and verification period;

- permissible measurement range;

- characteristics of heat meter settings.

How to check the operation of a heat meter

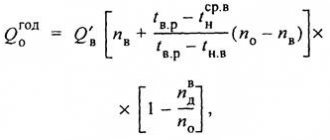

One of the main characteristics of a heat meter is its ability to automatically calculate the amount of thermal energy used. You can check this “mathematics” using a regular calculator. To do this, you need the following data for the reporting period:

- coolant flow in the supply pipe;

- temperature of the coolant in the supply pipe;

- return coolant temperature.

We calculate the temperature difference in the pipelines and multiply the resulting figure by the coolant flow. We get the amount of heat used. This result must match the parameter indicated on the heat meter screen.

Before the start of the heating season, it is also recommended to check the meter:

- activate the work by clicking on the appropriate button;

- record readings;

- turn on the heating radiators;

- After about an hour, check for changes in readings;

- If the data has not changed, error information has appeared, or the image is missing, contact the management company or heating supply organization.

Installation issues

Installation of a heat meter

Recently, during the construction of apartment buildings, horizontal ones have been installed. It is enough to install one meter in such an apartment.

The room model of the meter is installed on a straight pipe through which the coolant is supplied to the apartment. Sometimes the device is placed on the return pipeline.

When installing a heat meter by a specialized organization, its employees perform the following actions:

- production of the project,

- coordination of the project with the organization responsible for heat supply,

- registration of the installed metering station,

- commissioning to representatives of the supervisory company.

About technical limitations

Almost all old houses have a vertical heating pipe distribution system. That is, there are several risers installed in the apartment. It is not profitable to equip each of them with a separate meter. For these cases, distributors are suitable that measure coolant flow based on the difference between two temperatures:

- indoor air,

- on the radiator ().

How to choose a company to install the device

In order not to make a mistake in choosing the organization that installs the measuring device, you should pay attention to important aspects:

- free visit of an engineer to inspect communications and select equipment for a metering unit,

- performance of the entire range of installation work by qualified specialists using special equipment,

- the company has permits (certificates, licenses, SRO approvals),

- availability of information about the company in the Unified State Register of Legal Entities,

- warranty obligations for the work performed,

- preferential services for certain categories of citizens,

- providing payment in installments,

- possibility of service.

Heat meter verification

To avoid malfunctions in the operation of the heat energy meter, it is necessary to regularly check it. Data on the initial verification and the verification interval are indicated in the device passport. Initial verification is carried out by the manufacturer before release for sale. The inter-verification period is counted from the date of its implementation, and not from the moment of installation of the device. Subsequent verifications are carried out by specialized accredited organizations. Their implementation is confirmed by a certificate issued to the consumer.