Here you will learn:

- Structure of heating systems

- What is an uninterruptible power supply?

- Types of uninterruptible power supplies

- How to choose an uninterruptible power supply

- How to make an uninterruptible power supply for a heating pump with your own hands

- Factory models

The use of heating systems with forced circulation of coolant forces us to consider providing backup power for the pumps used in them. Otherwise, cutting off the power will cause the circuit to stop. For power backup, an uninterruptible power supply is required for the heating pump. Using charged batteries, it will provide the pumping unit with alternating current at the required voltage. It is this equipment that will be discussed in our review.

Structure of heating systems

Thin metal-plastic and metal pipes used in modern heating systems do not allow for natural coolant circulation. Also affected by the absence of slopes, the presence of a large number of connecting fittings, the minimum internal volume of radiators and many other factors. To ensure that the coolant can circulate freely through the pipes and deliver heat to all corners of the house, circulation pumps are installed in the heating circuits.

Pumps used in heating are built according to a “wet” rotor design. Thanks to this, they are compact and silent. The pump units are powered from a household single-phase network with a voltage of 220 Volts. Despite the fact that rolling power outages are no longer practiced, the stability of the supply of electricity to houses and apartments remains a sore domestic issue.

In the absence of an uninterruptible power supply, each power outage leads to difficult circulation or even its cessation. The house becomes cooler, and the heating boiler, diagnosing overheating of the boiler water, turns off. If the “lights” are turned off for several hours and there is no thermal insulation, soon the air temperature will begin to drop - the conditions for staying in the rooms will not be the most comfortable. There is only one conclusion - you need an uninterruptible power supply.

Schemes for different types of systems

Initially, it is necessary to determine the insertion area of the circulation device. With its help, the process of active movement of liquid is carried out - the flow passes through the boiler and is forcibly directed to the heating radiators.

To locate a household pump, it is necessary to determine the most convenient area so that it can be easily serviced. On the supply side, it is installed after the safety block and shut-off valves of the boiler.

On the return pipeline, the pump is placed after the expansion tank in front of the heat generator.

Due to the presence of various mechanical impurities in the water, for example, sand, problems may arise in the operation of the pumping mechanism. Particles contribute to jamming of the impeller, and in the worst case, stopping the motor. Therefore, you will need to install a strainer strainer directly in front of the unit.

Separately, it is worth mentioning the issue of an open-type heating system. It is capable of operating in two modes - with forced and gravity coolant circulation.

The second option is more suitable for areas with frequent power outages. This is much more economical than purchasing an uninterruptible power supply or generator. In this case, the unit with shut-off valves must be installed on the bypass, and a tap must be inserted into the direct line.

In stores you can find ready-made units with a bypass. In place of the flow tap, there is a spring-loaded non-return valve. This solution is not recommended - the valve produces a resistance force of 0.1 Bar, which is considered a large indicator for a gravity-type circulation system.

It is better to use a reed valve instead. However, its installation is carried out strictly horizontally.

What is an uninterruptible power supply?

An uninterruptible power supply is an electronic device that provides uninterruptible power to a heating pump. To do this, it contains a battery that stores electricity from the network. When the mains power is turned off, the uninterruptible power supply (UPS) almost instantly switches to operation from the battery (or from several batteries). This device consists of several main components:

Please note that not every uninterruptible power supply is a stabilizer - this is a separate option and may not be on board.

- Battery – accumulates electricity, and during a power outage, releases it to the load;

- Voltage converter – converts direct current with a voltage of 12 Volts into alternating current with a voltage of 220 Volts;

- Filter – filters out impulse noise in uninterruptible power supply systems with pulse converters;

- Stabilizer – ensures stabilization of the output voltage within the permissible error.

Also, all UPS have charge control circuits.

UPS selection and power determination

There are two main types of uninterruptible power supply:

- Line-interactive, Line-interactive. Performs the functions of an energy storage and stabilizer. It produces a sinusoid at the output and compensates for increases and decreases in voltage. The noise level of the device is up to 40 dB. Mode switching time is about 3 – 5 Moscow time.

- On-line, or double conversion . This device is capable of ensuring the supply of the highest quality electricity from the network. The essence of its work is that the energy is first converted into direct current, supplied to charge the batteries, and it immediately turns into alternating current of the required magnitude. In addition, the transition time from mode to mode tends to 0. It is more often used for sensitive electronics, for servers and computers. It is also worth choosing this type of UPS if, in addition to the pump, a boiler with its demanding electronics will be connected to it.

The double conversion system is an energy-consuming process, so devices of the second type heat up more, make noise and lose efficiency (70%, versus 90 - 95% for an interactive one).

Number of phases. Uninterruptible power supplies can be single or three-phase. The latter are most often used for industrial equipment. For the heating system of a private house, single-phase models are chosen.

The power of the UPS is selected based on the total power of all nodes connected to it. It should be taken into account that during startup, the load increases several times. In the documentation for the circulation pump, this indicator is stated as “Starting current”. When selecting the power of a UPS, this value must be taken as a basis, otherwise the uninterruptible power supply may fail from the very first start. The exception is pumps with a soft start function.

Example. Circulation pump power – 250 W. The current multiplicity at start-up is 4. This means that the starting power = 250 x 4 = 1000 W. Accordingly, a UPS must be purchased with a power of 1 kW and above.

Operating voltage range . This indicator is calculated based on voltage drops in a particular network. If, for example, these fluctuations reach ± 9%, then an uninterruptible power supply with a range of 220 ± 10% is purchased. If you do not calculate this indicator, the uninterruptible power supply will switch the pump to autonomous operation (from the battery) every time the voltage in the network jumps. And such a mode with frequent transitions will quickly disable it.

Some models can be equipped with:

- Cold start function. Makes it possible to turn on the uninterruptible power supply when the electricity has already been turned off.

- Equipment status indicators.

- Alarm about critical charge level.

- Microprocessor control.

- Self-diagnosis during switching on.

- LCD display.

There are floor-standing models, similar to a computer system unit (the most common), and wall-mounted ones.

When choosing the power of single-phase equipment, it makes sense to choose a device with a power reserve. This will ensure longer operating time and also make it possible to connect other devices to the UPS in the future.

Types of uninterruptible power supplies

When choosing an uninterruptible power supply for a heating circulation pump, you should pay special attention to its technical characteristics. First, let's define the types of this equipment:

- Linear uninterruptible power supplies (backup) are extremely simple. There is no stabilization of the input voltage; when powered from the mains, it fluctuates over a wide range. When the power supply is turned off, the equipment is powered by a built-in or plug-in battery;

- Line-interactive uninterruptible power supply units – models with voltage stabilization function. They are built on the basis of autotransformers;

- UPS for a double conversion heating circulation pump is the most complex uninterruptible power supply. The first converter outputs a constant voltage, from which the batteries are charged. The second converter outputs alternating current with a voltage of 220 Volts.

Uninterruptible power supplies with double conversion are complex, but the most stable. They do not use direct power supply to consumers from the mains - the current undergoes double conversion.

The optimal purchase for powering a circulation pump would be an uninterruptible power supply with double voltage conversion (inverter for a heating pump).

UPS classification

There are certain differences in different UPS depending on the required data and layout features. They are divided into three key varieties:

- backup uninterruptible power supplies;

- linear-interactive;

- Double invert UPS.

Reserve

In normal mode, the boiler is powered from the mains. In the event of a catastrophic shutdown, the automation itself switches to battery power. But there is one indispensable condition - convert direct voltage into alternating voltage and increase it to 220 volts.

In devices of this level, the voltage is not balanced, but a passive network filter can be used to the maximum against voltage fluctuations.

Pros:

- They have decent efficiency;

- Minimal heat generation and noise;

- Relatively inexpensive.

Minuses:

- Reconnection takes a long time;

- It is quite possible to obtain a distorted voltage at the output;

- Amplitude and frequency cannot be adjusted.

Linear interactive

Here a simple stabilizer is included in the circuit. It is used to equalize voltage. In essence, this is an ordinary autotransformer with an electronic switch. If we include such a stabilizer in the UPS circuit, we will obtain output voltage parameters absolutely no different from the nominal one. Also, such devices are supplemented with a voltage converter, as well as a mandatory surge protector.

Pros:

- They have high efficiency;

- Minimum noise level;

- Stable voltage.

Minuses:

- Reconnection takes a long time;

- Insufficient accuracy;

- Trapezoidal stress shape;

- Frequency offset may occur.

Double invert UPS

The uninterruptible power supply for a heating pump with dual conversion is fundamentally different from previous schemes. Thanks to this technology, there are a number of advantages that other backup systems do not have.

Here the mains voltage is already rectified at the input and divided into two streams:

- Part goes to the capacitor bank;

- The part is converted from direct to alternating current.

Dual purpose capacitors:

- At high voltage, excess is stored.

- If the voltage drops, it releases the stored energy.

The entire process is automated through the use of a microcontroller with a quartz oscillator. This makes it possible to equalize both voltage and frequency with high accuracy.

Such UPSs are capable of operating not only to supply electricity in autonomous mode, but also serve as a means of improving the quality of electricity, on which the operation of the most critical energy supply systems depends.

A UPS for a heating pump with double inversion has its undoubted advantages over other similar systems.

Pros:

- Operate over a wide range of mains voltages;

- Very reliable correctness of stabilization;

- Instant switching to offline mode;

- Correct proportionality of frequency;

- No output interference;

- Maximum level of protection;

- Perfect voltage configuration.

Minuses:

- A bit expensive compared to other UPSs;

- Not the greatest efficiency;

- Running fans create extraneous noise.

Ideally, all uninterruptible power supplies should operate while maintaining a sinusoidal output signal. Only devices made using the double conversion program produce a clear sine wave.

Other UPSs may produce a signal that is completely different from a pure sine wave. The electric motor of the pump will work with such a sinusoid, but not for long. Eventually this will lead to poor results and a complete engine replacement will be required.

The advantage of UPSs over such additional power sources as mini-power plants or generators is precisely that they are able to switch to backup mode almost instantly in 3–11 milliseconds during emergency power outages.

And in UPS systems with double conversion, there are no switching delays at all, which has a beneficial effect on the operation of the automation system and does not stop the operation of the pump supplying water to the heating system.

On a note! Circulation pumps of boiler equipment are very demanding regarding the form of operating voltage. A UPS with a pure sine wave is preferable.

If you are choosing a UPS for a heating circulation pump, it is recommended that you carefully study the product data sheet. As a rule, the distortion factor of the current in a sinusoid is indicated there. It should not go beyond 8%.

With such a UPS, the operation of the pump will be almost silent, in addition, the service life of the pump motor itself can be significantly extended.

How to choose an uninterruptible power supply

You can buy an uninterruptible power supply at any store that sells plumbing and heating equipment. There is an impressive variety of models here – it’s easy to get confused. Let's see how to choose the right uninterruptible power supply.

Selection by type

The main advantage of inverter uninterruptible power supplies is that they provide a so-called continuous sine wave - when switching from the network to the battery, the output current is not interrupted.

Of all the above UPSs, the models with double conversion (inverter) stand out with the best characteristics. Their advantages are good stabilization, the correct shape of the output voltage (sinusoid, and not its stepwise approximation or other shapes). They are also characterized by the absence of high-frequency interference at the output. Thanks to this, inverter uninterruptible power supplies can be used to power boilers with sensitive electronics on board. But they also have a minus - they are noisy, since coolers are installed inside.

Linear uninterruptible power supplies have the lowest cost. When feeding heating system pumps, they do not stabilize the mains voltage. Due to the use of the simplest converters, the shape of the output current is far from ideal - because of this, the circulation pump may fail, and you will be left without heating. But these UPSs have the highest efficiency.

Selection by power

Here you need to look at the technical data sheet for the pump and clarify its power consumption. We multiply the resulting value by 3 and obtain the maximum power of the uninterruptible power supply. The need for multiplication is explained by the fact that the heating pump is a reactive load. And at the moment of start, it consumes power 2-3 times higher than the rated one. This is precisely why we have provided a substantial reserve.

Battery capacity

Small uninterruptible power supplies can last only a few hours on batteries. On-board batteries most often have a small capacity. If power outages in your area are frequent and long-lasting, we recommend choosing a UPS with a battery capacity of a hundred amperes - depending on the power of the pump used, it can work for almost a day or even more.

To ensure long-term heating operation from a backup power source, choose uninterruptible power supplies with external plug-in batteries. The optimal type of battery is gel, maintenance-free.

Input and output voltage error

An important parameter for an uninterruptible power supply. The smaller the output error, the better - ideally no more than 5%. The greatest discrepancies are observed at the input, therefore, for correct operation of the heating, you should choose an uninterruptible power supply that can operate in a wide range of supply voltage - from 150 to 250 Volts.

Pump installation diagram

To perform its functions, household circulation equipment, regardless of the manufacturer, must be correctly installed on a pipe or shut-off and control valves.

Fastening is done using union nuts. This fixation option will allow you to remove it if necessary, for example, for inspection or repair.

Correct installation of all elements of the heating system ensures uniform heating of the entire line.

When installing the circulation pump, the following rules must be observed:

- It is allowed to install the device on any section of the pipe. The pipeline can be located horizontally, vertically or inclined. However, the rotor axis must be in a horizontal position. Therefore, installation “head down” or, conversely, up is impossible.

- It is worth paying close attention to the location of the plastic box where the power supply contacts are located - they will be on top of the body. Otherwise, they may be flooded with water in an emergency. To do this, you will need to unscrew the fastening screws on the casing and turn it in the required direction.

- Observe the direction of flow. It is indicated by an arrow on the device body.

With all its weight, the pump presses on the body of the ball valves located nearby. This should be taken into account when choosing fittings. High-quality parts are equipped with a powerful body, which during operation will not become cracked from daily stress.

How to make an uninterruptible power supply for a heating pump with your own hands

Many people who are inclined to save money are accustomed to doing everything themselves. This is commendable, as it indicates the presence of brains and direct hands. To make a UPS for a heating circulation pump with your own hands, you will need additional knowledge in the field of electrical engineering - you need to assemble a converter (also known as a charge controller). If you don’t have the appropriate knowledge, then it’s better not to take it on.

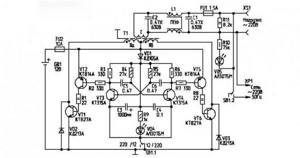

As an introductory example, we present a circuit diagram of an uninterruptible power supply for a heating pump using domestic radio components.

Installation of additional equipment

Regardless of the type of heating circuit used, where one boiler serves as the heat producer, it will be sufficient to install a single pumping device.

If the design of the system is more complex, it is possible to use additional devices that provide forced circulation of liquid.

This becomes necessary in the following cases:

- when heating a house, more than one boiler unit is involved;

- if there is a buffer capacity in the piping scheme;

- the heating system diverges into several branches, for example, servicing an indirect boiler, several floors, etc.;

- when using a hydraulic separator;

- when the pipeline length is more than 80 meters;

- when organizing water movement in floor heating circuits.

To perform the correct piping of several boilers operating on different fuels, there is a need to install backup pumps.

For a circuit with a heat accumulator, the installation of an additional circulation pump is also required. In this case, the main line consists of two circuits - heating and boiler.

A more complex heating scheme is implemented in large houses with 2-3 floors. Due to the branching of the system into several lines, 2 or more pumps are used to pump the coolant.

They are responsible for supplying coolant to each floor to various heating devices.

If you plan to install heated floors in the house, then it is advisable to install two circulation pumps.

In the complex, the pumping and mixing unit is responsible for preparing the coolant, i.e. maintaining the temperature at 30-40 °C.

In some cases, the installation of pumping units is not required at all. Many models of wall-mounted electric and gas generators already have built-in circulation devices.

Factory models

You can buy an uninterruptible power supply suitable for its characteristics in heating and plumbing stores. They are also sold in online stores. Final prices vary depending on the manufacturer, type of equipment and technical specifications. We will look at the most popular models and give their estimated cost.

Energy PN-1000 with 75 A battery

We have a simple uninterruptible power supply with a good battery capacity of 75 A/h. With a pump power of 100 W, the battery life will be about 8 hours. The peak power is 1000 W, which is enough for any reactive load. At the output, the device produces a pure sine wave. And it refers to line-interactive UPSs, characterized by high efficiency and an affordable price.

The cost of the model on the domestic market is about 260,000 rubles. Modifications with different battery capacities are also available for sale:

- At 100 A/h – up to 11 hours when operating with a load of 100 W;

- At 55 A/h – up to 6 hours when operating with a load of 100 W;

- At 200 A/h - up to 23 hours when operating with a load of 100 W.

If power outages in your area are frequent and long-lasting, we recommend paying attention to the latest modification - its cost is 36-37 thousand rubles.

SVC DI-600-F-LCD

A compact uninterruptible power supply that can work with boilers and pumps, ensuring continuous circulation of coolant in the heating system. It belongs to the category of linear-interactive and produces a pure sine wave at the output without any distortion. The equipment does not require user intervention in its operation and provides an output voltage error of no more than 10% - this is the norm for pumps, but for boilers it could be less.

The speed of switching to operation from the battery does not exceed 20 ms. There is no built-in battery here; an external battery with a capacity of up to 200 A/h is connected to the uninterruptible power supply - this will ensure up to 24 hours of autonomous operation of the heating system. The peak load for this model should not exceed 360 W. The estimated cost of the model is 6.5-7 thousand rubles.

Tieber T-1000

If you need an uninterruptible power supply with a maximum capacity, from which the pump can operate for up to two days, you should look at this model.

It works with two batteries with a capacity of up to 200 A/h each. The manufacturer recommends using maintenance-free gel batteries, as they do not emit harmful gases into the atmosphere - this is important for residential premises. The maximum load power is 800 W. An uninterruptible power supply can power fairly powerful pumps and heating boilers, as well as units of water heated floors. The output voltage form is a pure sine wave, as required by pumping equipment motors. The device is designed for floor installation; batteries are placed next to it. The maximum charging current is 12 A/h.

Solid fuel pump and boiler

The pump is connected to the system with a solid fuel unit on the return line. In this case, the pumping device is connected to the boiler circuit with a bypass and a three-way mixing valve. In addition, the latter can be equipped with a servo drive and an overhead temperature sensor.

Due to the fact that the maximum performance of heating equipment is used to its fullest extent only during the cold period, it is possible to install a heat accumulator (TA). It is able to absorb excess heat and then, on demand, release it to the heating circuit.

This battery is made in the form of a tank and is lined with thermal insulation material. On one side of the device there are two pipes intended for connecting it, and two on the other - for connecting to the radiator line.

As the liquid passes through the boiler, which operates at maximum, the coolant in the heat accumulator warms up over time to 90-110 degrees. In a large circuit, the insertion of another circulation device is required.

Depending on the degree of cooling of the liquid in the heating system, the required amount of heat from the storage device will enter through the valve.

Scheme and principles of operation of heat pumps

Structurally, the device is a complex of main and auxiliary elements:

- Impeller or impeller. Parts with blades that capture liquid and direct it to the heating system devices.

- Electrical engine. The element is needed to put the equipment into operation.

- Pumping chamber. The compartment is equipped with coolant supply and pressure pipes, which are connected to the system pipelines.

- Frame. Serves to protect the device from damage due to mechanical impact; it can be made of cast iron or heat-resistant plastic.

- Terminals. A box with terminals is needed to connect the unit to the electrical network, to receive power for all elements and control parts.