When water is supplied to the consumer from a centralized pipeline with low pressure, the owners have to deal with the difficulties that arise on their own. Often, problems associated with low pressure are solved by purchasing a special pump from a retail chain that increases the pressure in the water supply.

Selecting the required booster pump from a number of models of domestic and foreign production requires certain knowledge of its design and preliminary calculations. Many users, in order to save money, install an electric booster pump with their own hands - although the work is not particularly difficult, it requires certain skills and compliance with installation technology.

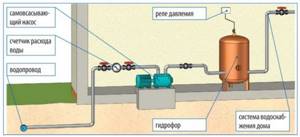

Rice. 1 Pump increasing the pressure in the water supply system in operation

When to buy a pump to increase water pressure

If the indicators of the actual water supply in the centralized water supply do not meet the standard (cases of too high pressure, which reaches ten bar, are not considered), which causes inconvenience to the residents of the apartment, it is worth considering purchasing a special pump that increases the water pressure.

The standard pressure that should be provided by any domestic water supplier to the population is 4 bar. According to the current technical documentation, namely SNiP No. 2.04.02-84, the minimum permissible pressure must be at least 0.3 atmospheres, and the maximum - no more than 6 atmospheres (one atmosphere is equal to the pressure of a water column having a height of 10 meters). If the pressure does not correspond to this indicator established at the official level, normal showering, washing dishes and the operation of some household (including kitchen) appliances will be limited, and may even be impossible.

This is due to the fact that when the load on the water network increases, which mainly occurs in the evening, on weekdays, as well as on weekends and holidays, the already too low pressure decreases even more and the water flow simply cannot reach your tap in your apartment (house). Conventional pressure gauges can measure pressure.

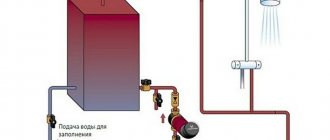

Water supply diagram Source travelerscoffee.ru

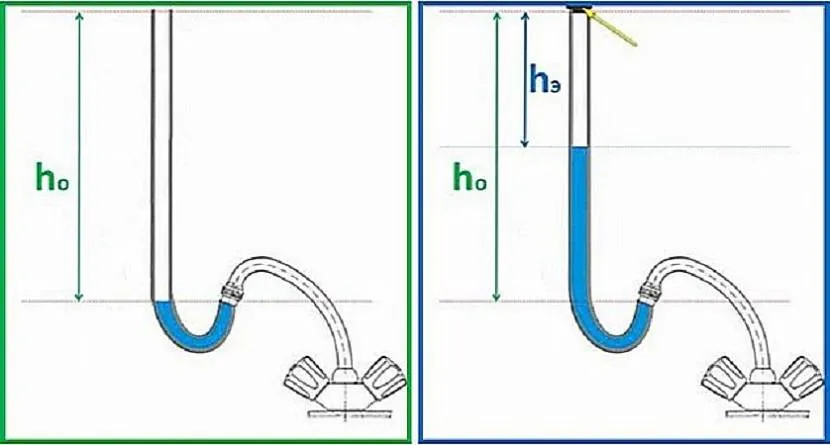

To make a pressure gauge, instead of purchasing it and complex installation, you can use knowledge of simple physical laws. It’s easy to implement a one-time water pressure measurement on your own. To do this, prepare a transparent tube in which the water level will be visible. Its length should be about twenty centimeters. Connect this pipe to the water tap in your apartment, making sure that the connection is tight. This can be achieved by using a fitting that screws onto the faucet and is designed to cut the flow of water.

When the tube is tightly screwed to the faucet, position it vertically. Open the cold water valve and wait until the liquid level reaches the faucet level. Measure the length of the part of the tube that does not contain water. This indicator is noted as h 0.

Close the top of the tube tightly with a stopper and turn on the water in the tap to full. When the level has stabilized by compressing the air in the tube, again measure the length of the part of the experimental tube that does not contain water. This indicator is called h e, that is, the experimental height of the air column.

Experiment with measuring water pressure Source remont-book.com

Having found out all the necessary indicators using the above method, we will take the initial pressure in the tube equal to ordinary atmospheric pressure and call it P o. It turns out that P o = 1.0332 atm (atmospheres). Now all that remains is to substitute all the obtained values into the formula:

P in = P o × (ho / h e)

As a result, you will find out what the water pressure in your tap is (P in). Carry out such measurements on different drains (bathroom, toilet, kitchen). If the readings are different, some pipes are too clogged. In the case where the indicator is practically the same and at the same time it does not correspond to the standard nominal value and is the same in several apartments located on the same floor, it is worth increasing the pressure by installing a special pump.

However, the previously mentioned water pressure standards do not apply if we are talking about an apartment located on the twelfth floor and above. In this case, the required pressure parameter must be greater by 0.4 atm for each floor. Thus, the calculated (normal for apartment residents) water pressure, for example, on the 16th floor should be at least 1 atm + 0.4 atm*16 = 1 atm + 6.4 atm = 7.4 atm.

Remember! A conventional water pressure booster pump cannot be installed where water completely disappears from the tap due to very low pressure.

Water supply to a tall building Source pravdaurfo.ru

How to choose a pump to increase pressure in a water supply system

Electric booster pumps, due to their limited use, are not represented on the domestic market of pumping equipment in a very wide range; these are mainly Russian, European (Germany, Belgium, Italy) and Chinese brands. When choosing a model, several factors are taken into account, the main ones being cost, manufacturer, volume and pressure characteristics, and energy consumption.

Rice. 5 Structural design and materials of manufacture of Grundfos UPA 15-90

What parameters do the pumps differ in?

Like any electric pumps for water supply, booster units are selected according to several basic parameters:

Pressure The maximum or nominal liquid lift height is the main criterion when purchasing any electric pump; it is measured in meters of water column. For most centrifugal electric pumps with a wet rotor, this figure is 9 m, vortex pumps have higher pressure parameters up to 15 m, the highest pressure is produced by powerful dry rotor modifications, household varieties of which are capable of raising the water pressure in the water supply system to 20 m.

Performance. The second main characteristic of any electric water pump is the volume of pumped liquid; the higher it is, the greater the productivity of the device. Since any pump for water supply is selected according to its volume-pressure characteristics, where the digital supply scale is located on the horizontal axis, and the pressure scale on the vertical axis, both of these indicators are closely interrelated, that is, a decrease in one of them leads to an increase in the second and vice versa.

Usually the maximum volume indicator is indicated in the passport data. In centrifugal wet-rotor modifications, the maximum volume reaches 4 m3/h, in vortex modifications the pumping volume is 1.5 m3/h, in powerful dry-rotor devices the figure reaches 10 m3/h.

Minimum feed. When booster pumps operate in automatic mode, they react to the flow using a special reed relay; if it is too small, the relay does not operate and, accordingly, the device does not turn on. Therefore, the passport data often indicates the inlet pressure required to ensure the start of the electric pump; its standard value is 0.2 or 0.3 atm.

Rice. 6 Pressures at the inlet of plumbing fixtures and electrical equipment

Control. A typical pressure-increasing electric pump has a button on the body to switch its operating modes to the following positions:

- On—power is supplied to the motor winding.

- Automatic mode - sets the device to turn on when the flow switch is activated, with the minimum pressure in the system being 0.2 or 0.3 atm.

- Forced mode - if water flows through the pipes at low speed, and it is below the flow switch response threshold, this mode allows you to turn on the electric pump manually and increase the pressure in the water supply for comfortable use of water, and then turn off the device after water intake.

Temperature of the working fluid. Typically, booster electric pumps are designed for cold water, although the design and material of some products allows them to pump hot liquid with a temperature of up to 110 °C at ambient temperatures of no more than 40 °C.

Protection. Models with a wet rotor are cooled by liquid passing through their rotating units - in its absence, the winding of the electric motor instantly burns out. Therefore, household appliances must have protection against idling (overheating of the winding).

Power. It is a secondary indicator related to the main technical parameters of the device; its maximum and nominal value is indicated in the passport. The power parameter of most household wet-rotor units rarely exceeds 200 W.

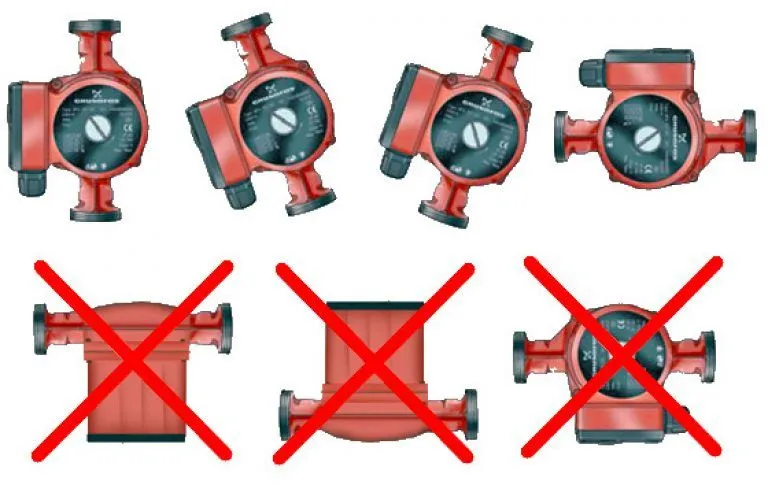

Installation method. Different models differ from each other in the way they are installed into the water line - for many devices the body must be located in a strictly horizontal position. Electric pumps also differ in the design and size of the suction and discharge pipes - many of them have American-type connecting fittings with a standard outer diameter of 3/4 or 1 inch.

Rice. 7 Pumping station connection diagram

Rules for selecting power, pressure and supply volume

When choosing the characteristics of an electric pump for increasing pressure, the following considerations are used:

Selection of pressure. Building codes and regulations (SNiP 2.04.02-84) stipulate that the minimum pressure at the highest water consumption on the surface of the earth at the entrance to the building cannot fall below 1 atm., with an increase in the height of the structure, 0.4 atm is added to each floor. (for example, the pressure at the entrance to a 3-story building should not fall below 1.8 atm. or 18 m).

For normal operation of household appliances, a pressure of no higher than 0.6 atm is required; if at the outlet of the water supply system into the building the pressure is 0.2 atm, then when purchasing a standard unit with a maximum pressure characteristics of 9 m, the electric pump will add 0.9 atm to the pressure. (excluding losses). In total we get an indicator of 1.1 atm. - this is enough for the correct functioning of any sanitary and electrical equipment, or a small group of 2 - 3 devices when turned on at the same time.

It is clear that if there is a low pressure at the entrance of a private house, and its height is 2 - 3 floors, then to obtain the required pressure parameters it will be necessary to install a more powerful booster unit or two devices connected in series.

Another option for solving a situation with a large difference in incoming and outgoing pressures is a centrifugal external electric pump or pumping station for increasing pressure, which, due to the high noise level when placed in a house, is best installed in the basement or ground floor.

The optimal, but high-cost way to maintain stable and high pressure is to use high-tech surface centrifugal electric pumps, both stand-alone and as part of stations, with automatic frequency control of the shaft speed (Grundfos CMBE, CME units based on CM pumps). During operation, such units analyze the pressure and, if it deviates from the specified value, which is set on the control panel, they automatically change the speed of the centrifugal wheel to achieve the specified parameters.

Rice. 8 Price list for frequency-controlled pump CM Grundfos and stations CME, CMBE based on it

Feed volume. The pressure and supply volume are related; most household appliances are capable of maintaining a pumping volume of 2.4 m3/h, so the consumer does not have too much choice.

Power. Power is not the main indicator that people pay attention to when choosing an electric pump; to reduce energy costs, it is better to choose a device that has the lowest energy consumption with the same volumetric pressure indicators as its analogues.

It should be taken into account that domestic and Chinese-made devices often indicate inflated parameters. In addition, the winding of electric motors in budget models is made of aluminum with a copper coating (mix) - this reduces efficiency and accordingly increases electricity consumption.

Ultimate pressure. In accordance with construction standards SNiP 2.04.02-84, the maximum pressure in water supply networks should not exceed 6 bar; when pressure testing, limit values of 10 bar are acceptable.

Therefore, the housings of many electric booster pumps are designed to operate with a similar maximum hydraulic load of 6 bar.

Types of water pressure boosting pumps

A pump that increases water pressure in a water supply system can have a different design and unique design features that allow each property owner (private house or apartment) to choose the most suitable device. Among the many types of pumps for normalizing low water pressure in a residential area or building, the following types are distinguished:

- Self-priming (helpful for all living areas of an apartment or private house);

- Circulating (eliminates the problem only in a small section of the water supply):

- for cold water (made of plastic, they work with water having a temperature of up to forty degrees Celsius);

- for hot water (made from good steel or other metal alloys that are harmless to humans and good heat-resistant rubber).

See also: Catalog of companies that specialize in water supply and sewerage.

Depending on the type of control of the water pump, there are manually or automatically controlled pumps. Usually the hand pump is turned on only for a while. Automatic pumps can operate continuously. They have special sensors that regulate and change the operation of devices depending on changing external data.

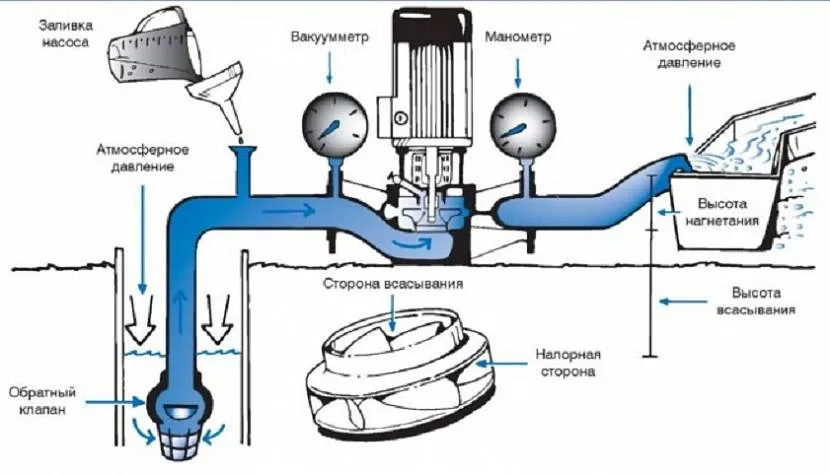

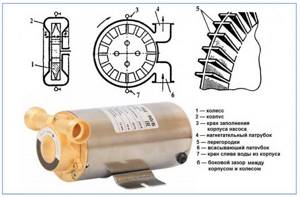

You can also purchase a vortex device to increase water pressure. It has a pressure and suction pipe located on the side of the device. As is clear from the name of these elements, along one of them water is sucked into the device, and through the other, on the contrary, it is pushed out of it.

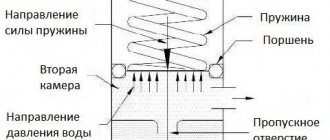

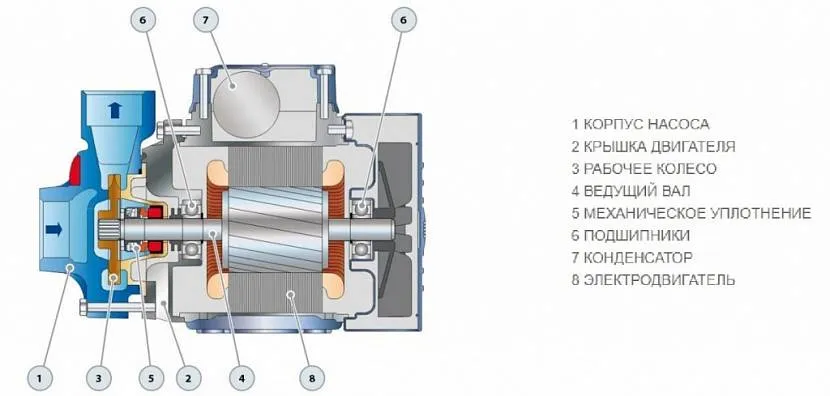

Vortex pump booster device in section Source remont-system.ru

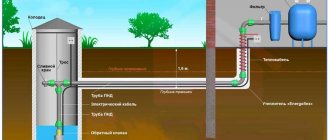

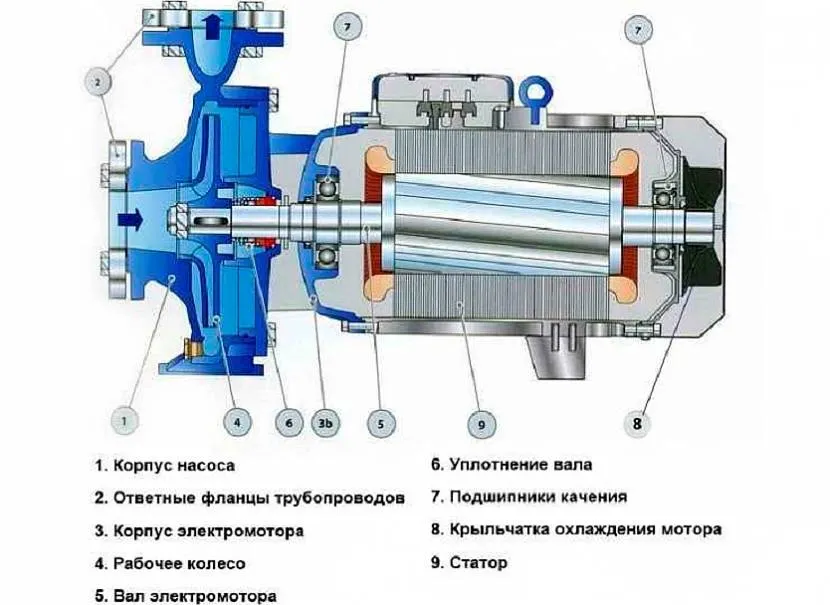

Self-priming pumping stations

A self-priming pump is the only type of pump that can be placed even where the water level is unattainable, since this type of device allows using a surface pump and a hydraulic accumulator to raise the water in the pipes higher. Stopping the pump operation along with further regulation of water in the water supply becomes possible after closing the system and pumping water into the accumulator.

The performance of the mechanism is regulated by the operation of check valves of the air membrane and a pressure switch. When properly installed and properly configured, such devices operate automatically and can raise water to a level of up to twelve meters.

Self-priming pump Source sabtiya.com

Water pump for heating: installation

The correct installation of the water pump determines how well it will perform its functions, as well as the efficiency of the heating communication in general. There are several basic recommendations that should be followed when carrying out installation work.

How to properly install a heating circulation pump? Installation of such equipment on the heating circuit is carried out only after shutting off the water in it. It is very important to remember that the rotor axis of the device must be horizontal. Installation of this element in a vertical plane is strictly prohibited. It is also recommended to install a filter in front of the circulation device, which is necessary to catch solid foreign elements of the working environment.

It is optimal to install the circulation pump in a heated floor system on the supply pipe

If you plan to install a circulation pump in a heated floor heating system, then it is necessary to place it at the correct point in the circuit. The most suitable option is installation on the supply pipe. This is due to the fact that the risk of air locks in it is minimized.

You should also not forget about sealing the connections, which is done using a special FUM tape. After installation of the equipment, it is necessary to check its functionality. To do this, a test run is performed, however, before this, care must be taken to remove air from the system.

Upon completion of installation, it is necessary to check the functionality of the equipment

Knowing how to properly install a heating pump, you can save a lot, since such work is not cheap to have professionals do. But if you do not have confidence in your own abilities, then it is better to use the services of a master.

Video description

Review of one of the self-priming pumps in the video:

Circulation pumps

The circulation type of pumps, which increase water pressure, is the most common, standard device for improving water pressure. Such devices are small. They are inserted (cut) into a certain part of the plumbing system and, using the operation of a motor equipped with an impeller, increase the pressure of hot or cold water in the system. The simplest pump circulation device has the ability to increase pressure by at least two to three atmospheres.

Circulation pump Source rusklimat.ru

"Wet" and "dry" pumping devices

To ensure that the device does not fail due to overheating, the pump designs provide a special cooling mechanism. Depending on this, the pump that increases water pressure can have a “wet” or “dry” rotor. “Wet” pumps cool their parts by running cold water directly through the pump. Thanks to a competent design, such devices can operate almost silently.

“Dry” pumps for increasing water pressure in a private house or apartment are cooled by air rather than water from the system. This is helped by blades attached to the shaft of the water pumping mechanism. The positive side of using such pumps is their high performance, and the negative side is the fairly high noise level generated during their operation.

Dry pump Source optolov.ru

Which brand of pump to increase water pressure is better to choose?

Both small local companies and global manufacturers of machinery are involved in the production and development of household pumps to increase water pressure. A good reputation of a company indicates good technical service, quality parts, and a long warranty. The rating includes products from the following companies:

- Jemix is the largest Taiwanese corporation, dating back to 1958, when the company began to study and produce the first electric pumps for the home. Now the main direction of the manufacturer’s development is optimizing its equipment for various purposes.

- Grundfos is a Danish company whose activities are aimed at creating pumping equipment. It has proven itself well in the markets of Europe and Asia.

- Aquario - in development has a wide range of devices for providing central and local water supply. The company's products include spare parts, pumps for wells and fountains. Aquario representatives select the necessary equipment individually and help with solving technical connection problems.

- Wilo is a company specializing in the development of industrial and household appliances for water supply. The company's head office and part of the production are located in Germany; large purchases of spare parts are made in China.

- Gilex is a Russian brand that owns part of the production of household and industrial equipment in China, India and Korea. The company specializes in sediment collection and supply of spare parts to Russia.

- Dab - produces and develops reliable pumping equipment, devices for heating, air conditioning, dehumidification, wastewater and sewage disposal.

- Termica is a South Korean company with an official representative in Russia and is very popular on the world market. Develops and produces various equipment for swimming pools, heating, industrial and private water supply.

The best economical boilers

Differences in operation and design of devices

To choose the right pump, you should understand the nuances of the operation of each type of such device.

The peculiarities of the operation of the suction pump (mainly installed for private residential buildings) is the ability to increase pressure due to the rarefaction of air during rotation of the pump impeller and calculate the suction value from the distance to the place of water intake using a simple formula. This formula looks like this:

H = L / 8 + h,

where L is the distance to the water supply point,

H is the maximum required value for raising water in the water system used,

h is the difference in terrain heights between the water level and the place where the pump is planned to be installed.

The entire operation of the vortex pressure booster pump occurs thanks to the built-in electric motor. A distinctive feature of this type of pump is the minimum distance between the blades of the so-called vortex wheel and the walls of the working chamber (casing). Because of this, for long-term operation of such a device, the maximum requirements for water purity are imposed: if the liquid that gets inside the device is not clean, it will quickly fail.

Suction pump Source syko.ru

A booster pump for water supply should be selected based on such fundamental indicators as:

- power;

- pressure (performance);

- minimum feed;

- pressure (maximum);

- ease of control and comfort of use;

- permissible operating temperature conditions;

- availability of protection;

- installation method.

To select a pump based on power, it is advisable to estimate the number of drainage points in the house. This includes sinks in kitchens and dining rooms, sinks, water supplied to showers, bathrooms, toilets, urinals, and bidets. Also, to assess the power of the pump, you must immediately analyze the pressure characteristics of the above taps and water supply points.

These indicators are marked on the packaging of sanitary products. When making such an assessment, it is important to know that on the boxes of domestic or Chinese taps these indicators are often overestimated. For a small apartment or home with low water consumption and a minimum number of drainage points (taps), you can consider choosing a low-power pump to save money.

Pump selection Source syko.ru

As for the minimum or maximum flow, this value indicates the volume of water with increased pressure that a particular pumping apparatus is capable of delivering per unit of time in normal operation. Everything is simple here: count the number of water supply points and multiply by 2.4 cubic meters per hour (an approximate indicator of the volume of water pumped by standard plumbing and household appliances). After this, all that remains is to choose a water pump that is capable of pumping at least the calculated volume.

The indicator “ease of control and comfort of use” is the presence of several operating modes, as well as a low noise level. For complete comfort of use, a pressure-boosting device must have manual control and automatic operation. The machine is turned on using a signal supplied from the flow switch.

Also, in some cases, it is necessary to purchase a pumping device that has a forced operating mode, which is suitable for one-time use. Once water is no longer needed for domestic or other needs, such a pump, operating in forced mode, is simply turned off.

Water pump with automatic mode Source optica-center.ru

The water pump in a private house must be suitable for your home (your apartment) in terms of installation method. If the instructions for the device indicate that the location must be strictly horizontal or vertical, this rule must be observed. In the case when pipes are just being laid (for example, they are being replaced), and it is not yet known in what position the pumping equipment will be installed, it is better to choose a pump that is universal in the installation method. Another extremely important point when purchasing a pumping device for a water pipe is to check the diameter of the pipes (connecting parts) provided in the selected product.

When is a booster pump needed?

The water pressure at the inlet of the internal water supply in a private house with individual water supply is determined by the settings of the main element of automation - a pressure switch, the highest standard response threshold of which, when manually configured, does not exceed 5 bar. Therefore, it makes no sense to install a booster pump in a private house with an autonomous water intake - if the supply volume is insufficient, it is cheaper and easier to install a high-capacity storage accumulator. A similar picture is observed in apartment buildings - there the water pressure is fixed and maintained at the required level by utility services. But sometimes in apartments and private houses the following situations arise when it is necessary to install booster electric pumps in the water supply:

a). With autonomous water supply, water is taken from boreholes or well sources, using submersible wells, borehole electric pumps or surface installations. Each water supply unit has certain technical characteristics, the main of which are pressure (indicated in meters) and pumping volume (passports usually indicate the value in cubic meters per hour).

Pressure is the determining criterion for the distance to the point of water consumption and the immersion depth of the unit; usually 1 m is equated to the same 1 m of a vertical column and 10 m horizontally. If the well is located at great depth or the distance to the house is large, the pressure created by a low-power electric pump (errors in calculations when choosing, decreased performance during operation, impossibility of replacing a worn-out unit with a new one) is not always enough to transport an acceptable volume of water per unit of time for the required distance. In this situation, a booster electric pump can be installed in the external pipeline.

Rice. 4 Vortex electric pump and its operating principle

b). But more often, booster pumps for cold water supply are installed inside the house for water supply to electrical and sanitary equipment in cases where the liquid pressure at the water intake points from the centralized main is too low or the private house has a high number of storeys with a branched and extended water supply line. In a home microclimate, their service life is significantly longer than outdoors; moreover, the devices require installation built into the pipeline, which is technically impossible to achieve on an external underground pipeline or in a narrow distribution (inspection) well.

The best pumping units to increase water pressure

Grundfos

The Grundfos UPA_15-90(N) is rightfully considered the most convenient, high-quality and reliable, simply the best wet rotor pump. Made in Denmark, Grundfos has a durable cast iron stainless steel body and can operate with different pressures. There are several operating modes available in the control, which can be selected by the consumer at will. Grundfos can raise water to a level of eight meters. In this case, the minimum inlet pressure will be 0.2 bar, and the electricity consumption will be high - only 0.12 kilowatts.

Grundfos pump Source valves-msk.ru

The noise level is an important point for a pump installed inside a small apartment. For Grudfos it is no more than 35 decibels. The pump is lightweight, easy to install, durable (can operate for at least ten years, according to the established official service life).

The best pumping stations to increase water pressure

A pumping station is a special design, a set of devices that ensure water circulation under the required pressure. The station includes a pump, a hydraulic accumulator, a pressure gauge and a check valve. The advantage of this design is its particularly reliable assembly and convenience, since there is no need to select each part separately.

Gilex Jumbo 50/28 Ch-18

The pumping station for domestic use has a high throughput capacity of 4 m3/h and a head of 50 m. The station has an asynchronous electric motor, a pump, and turns on automatically if the pressure in the pipe system decreases to 1.5 bar. The pump is equipped with reliable protection against motor overheating.

The station parts are made of stainless steel, and the body itself is made of cast iron, which is why the device has a lot of weight with small dimensions. There are several sealed control buttons on the body. The pump is easy to disassemble and clean if necessary.

Advantages

- Good power;

- Compact dimensions;

- There are many spare parts available for sale;

- Cast iron body.

Flaws

- Low power;

- There is no check valve.

The device is only suitable for increasing pressure or for lifting water from a shallow well (up to 5 m). The expansion tank is small, so at low water flows the pump automatically turns off.

Dab E.sybox Mini 3

The pumping station is housed in a green plastic case; there is a screen on the front to control the operation of the device and demonstrate the current parameters. The unit operates silently, its parts are protected from dust and dirt, and is well suited for use in country houses. The device ensures the operation of all necessary household appliances.

The maximum power is 800 W, the pressure is 20 m, which is the average for pumping stations. Users note that if the equipment breaks down, it is difficult to assemble and disassemble it yourself and suitable spare parts are rare.

Advantages

- Almost silent operation;

- Power;

- High-quality assembly;

- There is a screen and control menu in Russian;

- Can be hung on the wall.

Flaws

- Overcharge;

- The case is made of low-quality plastic.

As the power increases, the noise increases, so it is better to install the station in technical rooms. There are interruptions in updating the operating system, and sometimes the electronic control freezes.

Termica Comfortline TL PI 15

The unit is made in South Korea, the body of which is made of cast iron, and the parts are made of high quality stainless steel. The station has an asynchronous motor, a modern flow sensor, which records all pressure fluctuations and accurately turns on the pump when necessary. The model has compact dimensions and light weight, is mounted in a vertical position, so it can be installed in hard-to-reach places.

The pump for increasing pressure in a private house has average technical parameters - flow 1.5 m3, head 8 m. It works with water of almost any temperature, so it goes well with water heaters or geysers. The minimum pressure for operation is 0.2 bar.

Advantages

- Compactness;

- Light weight;

- Easy to disassemble;

- Low price.

Flaws

- Not suitable for process water;

- It is very noisy when working.

The equipment is convenient to use for the garden and easy to transport. The pump quickly becomes clogged if you try to pump water from a pond or lake. Suitable for supplying water to a washing machine or dishwasher.

Briefly about the main thing

Pumps that increase water pressure in a water supply system have different designs and corresponding applications. When choosing, you should be guided by both the requests of the owners of the residential premises, the parameters of the pumping unit, and the indicators of the actual water pressure in the pipes. Not the least important role is played by the budget allocated for the purchase and the persistence of the problem with insufficient water pressure.

| A little more attention! Write in the comments - how often do you have to deal with poor water pressure and where does this happen? |

Ratings 0

Read later

What is a circulation pump for?

Open heating systems, in which the coolant circulates in a circle, operate according to the following scheme: cooled water enters the boiler, and after heating due to thermal expansion, it rises up through the heating pipes, heating the radiators. Then, along a closed circuit, it goes down and through a horizontal pipeline with a slight slope again reaches the heating elements of the boiler.

The main disadvantage of natural circulation is the small size of the circuit, the length of which does not exceed 30 meters, therefore forced circulation is used in most household heating systems.

To move water through pipes into the main, an electric pump is installed, which pushes the coolant with the blades of its impeller. The temperature in heating radiators is adjusted by changing the temperature of the water in the heating boiler; the second method is by regulating the speed of water flow through the pipes.

Many types of circular heaters have 2 or 3 (less often 4) speeds, which make it possible to increase the heating properties of radiators by increasing the speed of coolant movement.

Fig.2 Heating system with forced circulation of coolant

Manufacturers and prices

When choosing manufacturers of a circulation pump, the approach is the same as when selecting any type of equipment. If possible, it is better to take equipment from European manufacturers who have been on the market for a long time. The most reliable circulation pumps in this sector are Willo, Grundfos, and DAB. There are other good brands, but you need to read reviews for them.

| Name | Performance | Pressure | Number of speeds | Connection dimensions | Maximum working pressure | Power | Housing material | Price |

| Grundfos UPS 25-80 | 130 l/min | 8 m | 3 | G 1 1/2″ | 10 bar | 170 W | Cast iron | 15476 RUR |

| Caliber NTs-15/6 | 40 l/min | 6 m | 3 | external thread G1 | 6 atm | 90 W | Cast iron | 2350 rub. |

| BELAMOS BRS25/4G | 48 l/min | 4.5 m | 3 | external thread G1 | 10 atm | 72 W | Cast iron | 2809 RUR |

| Gilex Compass 25/80 280 | 133.3 l/min | 8.5 m | 3 | external thread G1 | 6 atm | 220 W | Cast iron | 6300 rub. |

| Elitech NP 1216/9E | 23 l/min | 9 m | 1 | external thread G 3/4 | 10 atm | 105 W | Cast iron | 4800 rub. |

| Marina-Speroni SCR 25/40-180 S | 50 l/min | 4 m | 1 | external thread G1 | 10 atm | 60 W | Cast iron | 5223 RUR |

| Grundfos UPA 15-90 | 25 l/min | 8 m | 1 | external thread G 3/4 | 6 atm | 120 W | Cast iron | 6950 rub. |

| Wilo Star-RS 15/2-130 | 41.6 l/min | 2.6 m | 3 | internal thread G1 | 45 W | Cast iron | 5386 RUR |

Please note that all specifications are based on water movement. If the coolant in the system is a non-freezing liquid, adjustments must be made. You will have to contact the manufacturer for relevant data for this type of coolant. It was not possible to find similar characteristics in other sources.

Installation recommendations for all types of systems

There are recommendations for installing all types of pumps:

- Installation of the system, which includes a circulation pump, is carried out with the connection of a backup power supply with a operating reserve of 4-6 hours.

- For 1;-2-circuit systems, the installation of a bypass is mandatory, since in the event of a power outage it will ensure the natural movement of energy flow in the system.

For reference! A bypass is a bypass, a small section of pipe with shut-off or adjustable valves, sometimes with a check valve. It is built to bypass the circulation pump and, when it stops, ensures free flow movement.

- The operation of the pump can only be checked when the system is full. The main indicator of correct installation is the uniform distribution of heat between all radiators.

- Pumps with a wet rotor type are installed in a vertical position.

Manufacturers usually illustrate how to install the pump correctly Source as-elit.ru

- Installation of a coarse filter is required, and installation of a fine filter is desirable.

- The pump must be located in a place accessible for maintenance.

- After all the calculations, add 20% of the rated power, so you will ensure gentle operation of the equipment in the optimal mode of 85-90%, excluding operation at the limit of possibility.

Selection of a circulation pump for a heating system - calculation based on pump parameters

When determining the parameters of circulation pumps for heating systems, their following main indicators are taken into account:

- Pressure When a heat-conducting liquid moves along the line, it overcomes the hydraulic resistance of pipes, heating radiators, and plumbing fixtures. The pressure created by the pump allows the coolant to move through the pipes, overcoming this resistance; the parameter is measured in meters of water column and shows to what vertical height the working fluid can be raised.

- Feed volume. This indicator indicates the amount of coolant that is supplied to heating radiators per unit of time; the parameter is directly related to the speed of rotation of the impeller.

All other characteristics of pumping equipment (power, motor shaft speed) are derived from the basic parameters. The power and frequency are selected according to the best indicators from the model range of units from different manufacturers after calculating the required pressure and supply volume.

If you do not seek help from specialists, then the parameters of electric pumps are calculated manually, using tables, using online calculators that are available on the websites of some well-known manufacturers, or using computer programs - the latter method is the most accurate.

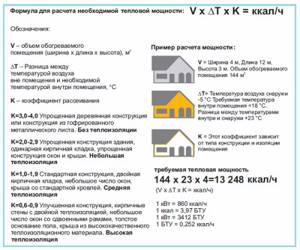

It is not too difficult to calculate the main technical parameters yourself manually using formulas; the result can be compared with the data indicated in the table, which is provided by some manufacturers. The table (Fig. 11) indicates the power of the heating boiler and the volume of the heated room; a suitable pump model is selected based on these data. The tabulated results are not very accurate - they do not take into account the hydraulic resistance corresponding to losses in the forward and return lines, but they can be used to check the results obtained manually or using online calculators.

Rice. 10 Calculation of the heating power of the house

Why do you need to do the calculation?

The answer to this question is obvious; for the optimal selection of pumping equipment, a preliminary calculation of the circulation pump for the heating system is necessary; the more accurate the calculations, the more optimal the choice will be. A properly selected heating pump will operate within the operating area that provides the highest efficiency - this will save energy resources.

Also, many circular machines have several speeds for adjusting the rotation speed - if the calculations are correct, choose a model with the optimal speed so that switching to other speeds allows you to comfortably use heating or save energy resources without worsening living conditions.

Calculation of pump performance

The supply volume of the electric pump is calculated using several formulas, one of which is:

Q = P/(1.163 x (Tf – Tr)) or Q = 0.86R/(TF–TR) (m3/h)

Where:

- Q is the volume of pumped coolant in cubic meters per hour;

- P – thermal consumption of heated premises (thermal power) in W;

- (Tf - Tr) - the temperature difference in the pipes leaving the boiler and supplying water back (for long pipelines with water heated floors, the difference is about 20 C; if short circuits with a small number of heating radiators are used, the value is taken about 10 C; if only a small area underfloor heating is heated, the temperature difference is taken equal to 5 C.);

- 1.163 – coefficient of specific heat capacity of water in W.*h./kg.*K. (for antifreeze, the indicator has a different meaning, determined from reference literature).

Another formula that allows you to select a circulation pump for a heating system is as follows:

Q = 3.6 x P/(C x (Tf - Tr)), (m.cub./h.)

where: C is the heat capacity (for water it is 4.2 kJ/kg*C), the remaining symbols are similar to those given in the previous formula.

When calculating the thermal power of a room that is being heated, we are guided by SNiP 2.04.07-86 for heating networks; in them, for one- or two-story buildings at an external temperature of -20 to -30º C, a heat consumption indicator of 173 - 177 Watts per square meter is accepted, for For larger buildings with three or four floors, this parameter is 97 - 101 W/sq.m.

It is clear that the total thermal power of energy consumed by the entire house, which is necessary for calculations, consists of summing up the areas of all rooms in which heating radiators are installed.

The above formulas are used in the initial calculations of the heating main - on their basis, depending on the heat consumption of the premises, a heating boiler is selected. If it is installed, instead of the required thermal power, the boiler parameters are used in the formula, example (boiler power 50 kW.):