Repairing a balcony is a simple process that, it would seem, does not require large investments. However, after you begin to evaluate the entire amount of work, you realize that not everything is so simple, because when finishing a balcony it is important to do everything so that the repair lasts a long time. In addition, it is worth paying great attention to the covering material, especially for the floor. Laminate balcony floors are considered to be of the highest quality, allowing you to create not only comfort, but also a stylish atmosphere.

Laminate, its classes, application

Laminate - consists of several layers that differ in their material and function:

- The stabilizing (bottom) layer is responsible for the laminate’s lack of tendency to deform. It also increases the hardness of the board and its water resistance. And in winter on a cold balcony and the question is whether it is possible to put a refrigerator on the balcony. All about balconies and loggias: on the balcony you can store things and shelves and drawers with your own hands. The layer material is kraft cardboard impregnated with polymer resins.

- The load-bearing (base) layer absorbs all weight and mechanical loads. This is a very compact fiberboard with locking grooves machined around the perimeter.

- The decorative layer makes the floor board attractive, imitating natural materials. Refrigerator on the balcony: can it be installed? Consists of paper impregnated with melamine resin.

- The protective (top) layer is responsible for the wear resistance of the entire laminated material. You shouldn’t put laminate on a cold floor; it’s better to put foam blocks on a moisture-resistant one. Almost everything depends on its strength and thickness.

Groups of material, called classes, are designated by the numbers “2” (domestic) and “3” (commercial). Is it possible to lay laminate flooring in what to lay them on the balcony? Can you lay laminate flooring on. Currently, only commercial laminates with high wear resistance are made. The 2nd number indicates the durability of the supporting layer. The abrasion resistance of the protection layer is indicated by “AC” signs with numbers from 3 to 6.

Installation of sheathing

Wooden beams are used to install the sheathing. It is advisable to combine the installation of the sheathing with insulation of the balcony.

- Eliminate cracks and seal joints with polyurethane foam; after the foam has dried, cut off the excess.

- Apply an antiseptic solution to the base of the balcony slab and place a layer of foil insulation.

- Lay out the wooden beams on the floor level in increments of 50-60 cm and attach them using anchors.

- Place insulation (penoplex or mineral wool) cut to size in the spaces between the joists.

- On top, under the base for the laminate, you need to place sheets of plywood or fiberboard on the sheathing and fix them to the sheathing with self-tapping screws.

- Next we move on to installing the sheathing on the walls. Attach vertical bars of the required size to the parapet at intervals of 40 cm from each other and secure horizontal bars to them. If horizontal laying is planned, then you need to make a vertical sheathing.

- Place insulation between the joists.

- If you plan to install the laminate on the ceiling, then the lathing on the ceiling is done using the same method.

Scope of application of the classes of produced laminate:

- 31(AC3) – residential premises with light loads;

- 32(AC4) – housing and work premises with medium loads;

- 33(AC5) – water-resistant material for loaded floors of offices and public institutions;

- 34(AC6) – amazing wear resistance and moisture resistance allow this laminate to be used in airports, gyms, train stations, and car showrooms.

The optimal material for a balcony is class 33. You can also lay 34, but its cost is very high.

What is attractive about laminate?

- Aesthetics is the main advantage of the material. Stylishness, traditional severity, solidity, chic, expensive simplicity - these are just some of the appropriate epithets to address the appearance of laminate floors. Thanks to this quality, most future buyers choose this particular material for the final floor covering, wall finishing, furniture facades and other surfaces.

- The ease of working with the material allows any home craftsman to perform high-quality floor installation without the help of others upon first acquaintance with laminate. It is enough to stick to easy technology and take into account certain aspects.

- The affordable cost of the product allows you to select a material of the required class, corresponding to the features declared by the manufacturer.

- The highest (depending on the class) resistance of the material to mechanical loads.

- Not bad resistance to ultraviolet radiation. Laminate boards do not fade under short-term exposure to direct sunlight.

- The material is hygienic, resistant to fungus and damage from other microorganisms.

- The good thermal conductivity of the material allows it to be used for laying on top of a heated floor.

- Temperature changes do not affect the properties and characteristics of the laminate.

- A large assortment of laminates of various classes, price ranges, with excellent imitation of various surfaces of expensive natural materials, and a large selection of color shades is available on building materials trading platforms.

- The fire safety indicators of the material comply with the standards.

- The surface of the laminated board can be easily cleaned from dirt with mild detergents, without damaging the top protective coating.

- The method of fastening the laminate allows you to easily replace its individual element after unexpected damage.

- Impressive service life for heavily loaded flooring – up to 10 years.

Selection and preparation of material

Before going to a hardware store, owners should decide on the functional load that the room will perform. Most premises of this type are divided into:

- Unglazed loggias where owners hang laundry and store unnecessary items.

- Closed balconies that you cannot stay in for a long time in winter due to lack of insulation.

- Insulated balconies that can easily act as an additional living room.

Depending on the type, the requirements for the laminate itself change, which is undoubtedly worth considering when purchasing building materials.

Without glazing

For open loggias that are constantly exposed to various weather conditions, conventional laminate is completely unsuitable. High humidity and temperature changes outside quickly damage it. Vinyl laminate comes to the rescue because it is not susceptible to condensation and seasonal temperature fluctuations.

Cold glazing

Cold glazing prevents precipitation from entering the room, but humidity is still quite high, especially in autumn and winter. Temperature changes also do not disappear anywhere - during the day the thermometer can fluctuate by 5-10 o. Therefore, if the glazed balcony is not equipped with additional heating elements, experts recommend using vinyl or any other moisture-resistant material as finishing.

Rules for installing slopes on wooden windows yourself and finishing methods

Insulated balcony

An insulated balcony means a room that is equipped with:

- insulated walls;

- double glazing;

- additional heating systems;

Most often, an insulated balcony is equipped with a heated floor system, since the installation of radiators is considered an illegal redevelopment of the premises. In this case, before purchasing a laminate, read the “scope of application” paragraph on the packaging. If there is no marking on it that allows you to lay the material on a heated floor, look for products from another manufacturer.

Disadvantages of “artificial parquet”

There are no ideal building materials suitable for use in various conditions and maintaining properties over a wide range of loads. Laminate flooring also has its disadvantages:

- When facing any vertical surfaces, the significant weight of the material creates certain difficulties. This problem does not exist for working with horizontal planes.

- Cellulose, which is part of the laminate, under certain operating conditions of the coating is capable of reacting to short-term increased or constant humidity.

- The susceptibility of the material to temperature changes (especially in combination with high humidity) is expressed in a short-term change in its linear dimensions. The gaps around the perimeter of the laid laminate are designed to smooth out the possible consequences of this property.

- Laminate has poor performance in terms of thermal and sound insulation (the acoustic effect of this coating is quite strong).

- Its installation is carried out on an ideal surface - completely dried, smooth, without cracks, differences and debris. Proper foundation preparation may require additional money and time.

The listed disadvantages are not critical, allowing us to definitely reject the material as a floor covering. But it is necessary to take them into account when choosing.

Balcony underlay

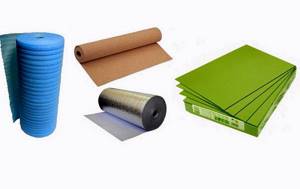

All about the refrigerator on the balcony. All about the refrigerator on the balcony. Is it possible to buy a refrigerator or freezer? Is it possible to use a refrigerator on the balcony: features of operation in winter and summer. It is responsible for eliminating minor unevenness in the floor, protecting the board from moisture, muffling steps and excess noise. Let us briefly describe the types of substrate:

- Izolon - has excellent moisture and heat insulation properties, the most economical material. Is it possible to cover floors on a cold glazed balcony? The main disadvantage is fragility due to the ability to be compressed under constant loads, after which the properties of the material are lost and its destruction occurs.

- Cork is a shock-absorbing natural material made from oak bark for significant loads. Is it possible to cover floors in cold weather? The coating is expensive and attracts moisture. We will not recommend it for a balcony.

- Foiled polystyrene foam is ideal for “warm” floors, has the best price-quality ratio, and hides defects of an uneven floor base well.

Laying laminate

After purchasing the selected laminate and underlay, prepare the surface of the balcony floor for laying the covering. It must be even (differences no more than 2 mm), dry and clean. Installation of the laminated board is carried out after laying polyethylene film and backing on the screed or slab.

The film is needed for waterproofing the floor

Begin laying from the wall in stripes parallel to it. What can the floor on the balcony be made of? And it can hardly be a cold balcony. When answering the question whether it is possible to install an air conditioner on a balcony, it is worth focusing on the various options for the location of climate control equipment on open and closed balconies. Other methods are also possible - diagonally or across the balcony. To adjust the size of the coating, the lamellas are easily cut with a hacksaw for metal. To securely fit the boards and secure them in the locks, they are tapped through a wooden block. There is a desire to cut off the fire escape on the balcony and weld the hatch. Could there be a check? The finished coating must have mandatory gaps (from 10 mm) from the walls and parapet to compensate for the linear expansion of the material under the influence of temperature and humidity. Is it possible to install an air conditioner on a loggia? To do this, use plastic wedges or pieces of the same laminate. In the future, baseboards and thresholds will hide the gaps and protect the laminate from moisture and dirt.

Leave a gap from the wall

Installation steps

Covering the loggia with laminate is carried out in two main stages.

Installation of sheathing

The preparatory stage, the quality of which determines the reliability of the entire structure.

- Check the evenness of the walls with a lath. Why run it along the wall in a vertical direction? If depressions are found, mark them with a pencil. Knock down the bulges using a chisel or scrape them off.

- Plaster the wall (alternatively, level it with moisture-resistant plasterboard). The latter must be secured in several places with self-tapping screws to prevent the subsequent cladding from collapsing.

- Install a stop at the bottom for the first row of laminate panels.

- Find the horizontal line using a plumb line.

- Select the location of the vertical support structure based on the size of the panels. If the laminate is large, then the lathing profile should run along the edges and middle of the panel. On average, the profile installation step is 40 cm.

- Drill holes with a drill in the appropriate places. Insert screws.

- Start installing the metal sheathing from the outermost elements. Stretch a rope between them as a guide for the intermediate profiles.

- Attach wooden slats to the metal sheathing.

- Lay insulation between the sheathing elements.

Installation

Consider the option of laying laminate horizontally on the wall.

- Secure the first board with 2 clamps as follows: insert them into the grooves of the panels and screw them with self-tapping screws or nail them loosely with small nails to avoid peeling or swelling of the laminate in the winter.

- The subsequent cladding is carried out clockwise, turning the panels one relative to the other and thereby closing the “locks”.

- Treat the joints with sealant to increase the service life of the finish and prevent moisture from entering there.

- Attach aluminum corners to the edges of the laminate boards and cover them with sealant.

Thus, a laminate coating can be used for cladding a loggia if all the requirements for this type of room are met during installation.

You can install it yourself if you follow the given technological sequence. And then a balcony covered with laminate will delight you with its exquisite design for many years.