Sequence of work during insulation

When working with isolon, you must adhere to the basic rules of installation and operation, which will allow the insulation to last longer, performing its duties efficiently.

Insulation of ceiling and floor with Izolon

This material has a small thickness, therefore, in order to obtain a high-quality thermal insulation cake, it is often combined with other insulation materials, for example, mineral wool.

The ceiling insulation method consists of the following steps:

- Mineral wool is laid between the ceiling joists.

- Isolon is attached stretched along the joists.

- They stuff the counter-lattice.

- Apply the finishing touches.

Isolon can serve as a sound insulator, for which it is placed directly under the finish. In this case, the material is attached end-to-end to the working surface using a construction stapler.

Note! If possible, it is better to leave a gap between the isolon and the finish necessary for the evaporation of moisture.

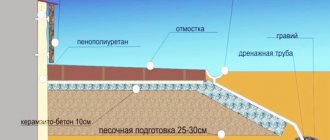

When insulating the floor with isolon from the inside, the work order looks like this:

- Dismantling the old coating. If insulation is carried out in an old house, then first of all it is necessary to dismantle the existing floor covering.

- Preparing the base. At this stage, the underlying structures are restored: the cracks are sealed, a new screed is poured.

- Installation of floor waterproofing. The base is coated with a primer. After it has dried, the surface is covered with plastic film or a waterproofing membrane. Coating waterproofing can also be used.

- Laying a thermal insulation layer. Sheet or roll insulation is adjusted in size so that it covers the entire surface. The joints are sealed with foil tape - there should be no gaps at the bottom, as they significantly worsen the thermal insulation properties.

- Waterproofing material is laid on top of the isolon and a fine finish is provided.

Note! If necessary, double-layer insulation is installed.

Wall insulation with Izolon

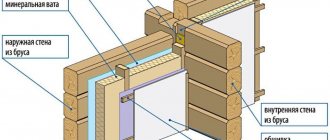

As a rule, such work is carried out using additional insulation - mineral wool.

- Wooden blocks for the future counter-lattice are attached to the wall.

- Mineral wool is laid between the bars.

- Foil-coated isolon is nailed on top of the bars. Its shiny side should be directed towards the room.

- The rolls are laid end to end. Existing cracks are covered with aluminum tape.

- The counter-lattice is nailed.

- The trim is attached.

Additional Information! A gap of at least 15 mm should be left between the finishing material and the foil.

How to glue isolon to concrete

how to glue isolon to concrete

During the construction of industrial facilities and residential buildings, modern building materials are used to meet the most important construction requirements for heat and sound insulation. Such material, for example, is isolon or polyethylene foam. The use of isolon allows you to reduce construction time and heating costs due to the excellent thermal insulation properties of this material.

Isolon has the following characteristics: 1. Low density (light weight) and at the same time good thermal insulation properties. A 10 mm layer of isolon can replace a 15 mm layer of mineral wool, 45 mm of wood or 150 mm of brickwork.

This reduces the weight of structures and helps save usable space. 2. Freons and other substances hazardous to humans are not used in the production of isolon. Izolon is non-toxic, does not affect the skin, and does not emit harmful substances when used. Has a hygiene certificate, 3.

Isolon is a chemically inert material and is not affected by organic solvents. It is possible to combine isolon with other building materials (concrete, gypsum, cement, lime, wood). It practically does not absorb water and steam, therefore it is resistant to rotting, mold and aging, 4.

Excellent shock-absorbing properties due to flexibility and uniform cellular structure. Isolon is used as a backing for carpet, laminate, linoleum or parquet. Izolon sheets are used to separate adjacent walls if the adjacent walls are subject to movement or vibration, 5. The operating temperature range is from -60`C to +75`C, and if there are no mechanical loads, the operating temperature increases to +100`C. With the exception of special isolons with fire-extinguishing additives, isolon is a flammable material. But at temperatures less than +140`С no harmful substances are released from isolon, 6.

Izolon is produced in different thicknesses and densities (with different foaming coefficients) and is supplied in the form of rolls, sheets, tape or blocks. This significantly increases the possibilities of using isolon in construction. Depending on the production method, isolon is divided into cross-linked (when molecules are cross-linked, a network molecular model is formed) and non-cross-linked (there are no chemical bonds between the polymer molecules).

Cross-linked isolon, compared to non-cross-linked, has improved characteristics: 1. Heat resistance increases (the operating temperature range increases by 20°C), 2. The service life of the material increases due to increased resistance to ultraviolet radiation and organic solvents: oil, gasoline, diesel fuel, Izolon can be used 1.

For sound, steam, heat, waterproofing of walls, foundations, floors and roofs for country houses, cottages, garages, 2. As a sealant under slate, ribbed metal roofs or tiles, 3. Isolon tapes with an adhesive layer seal the joints of windows and doors, connections between the frame and glass, protect from dust, moisture and noise, 4. Izolon strips can be used to insulate cold and hot heating pipes, as well as ventilation pipes, 5. Izolon with a polymer metallized film is used as a heat-reflecting screen to protect against heat loss through the areas behind the radiators of the walls. When using a combined material, a double effect is obtained.

Due to the metallized film, up to 90% of the heat emitted by radiators or other heating devices is reflected back into the room. The big advantage of isolon is its ease of use and installation. It is easy to cut and can be glued to the surface with adhesives (pre-glued surfaces should be cleaned of dust and degreased).

To attach to a smooth surface, use screws, slats, and furniture staplers. To connect the joints, use a hair dryer. Isolon is attached to curved surfaces with double-sided mounting tape.

Thus, when using this modern material, it is possible to significantly reduce construction time and heating costs.

How to glue isolon to concrete

How to glue Izolon to concrete How to glue Izolon to concrete During the construction of industrial facilities and residential buildings to ensure the most important construction requirements for heat and sound insulation

Installation features

Instructions from specialists apply to any surface for insulation. When laying insulation, the following rules should be observed:

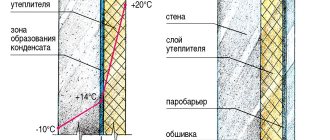

- Internal insulation involves fastening Izolon between the finishing and the wall - the thermal efficiency of the structure increases.

- The highest percentage of heat retention is provided by material with double-sided foil.

- Two layers are laid on the concrete. The first is on the covering, the second is on the joists.

- It is better to insulate a loggia or balcony with single-layer foil Isolon according to the “construction pie” principle.

- In the apartment, you can place the material behind the radiators - this eliminates the need to dismantle the walls.

- The foil layer should not come into contact with the wiring.

- To prevent the formation of condensation, an air gap is required between the insulation and the rest of the structure.

The material is laid only joint to joint and must be glued with aluminum adhesive tape.

Thanks to closed cells of rolled insulation, 70% more heat is retained in the room. When performing thermal insulation, additional load on the structure is eliminated - a thin layer of material is highly energy efficient. It can be laid on any surface - walls, ceiling, floor or laid out on the balcony.

Types of foil penofol

There are 3 types of penofol with foil on sale. Each is marked with Latin letters, which indicate the packaging.

Folgoizolon for external and internal work

Produced in different thicknesses. Suitable for complex insulation of buildings inside. Glass wool is used together with this insulation. They also produce foil insulation with perforation. It is installed in log houses to allow the wood to “breathe.” TYPE B – foil is located on both sides. This is maximum protection against heat loss. Penofol type “B” is used for thermal insulation of the attic, supporting structure, basement, and floor. As well as insulation of the pipeline and heating system.

TYPE C - on one side there is foil, on the other there is a thin layer of glue protected by film. Self-adhesive penofol is easy to install without spending a lot of time. For installation, cut into pieces of the required length and glue to the prepared surface.

TYPE R – a complete comparison to type “A”, but with a pattern on the foil. Used as decor for indoor walls. And also with multi-layer insulation, creating an air gap.

TYPE ALP – high degree of reflection. This insulation is used in agriculture, for example, to insulate incubators or buildings for calves.

Type NET is analogous to type “B”. Produced in narrow rolls or coils. Used for pipeline insulation.

2000 Type C – reduced performance. The adhesive layer is of poor quality and has poor adhesion.

Which is better, foil penofol or basalt insulation?

The building materials market is full of types of insulation. They have their own characteristics, positive and negative sides.

General thermal insulation parameters:

- Weight. The insulation should not weigh much, because when installing it on the structure there should be no weight.

- Thickness. The thinner the material, the more space remains in the room.

- Low thermal conductivity.

- Moisture permeability. The material should absorb moisture as little as possible.

- Noise insulation. Does not allow sounds from the street to pass through.

- Environmentally friendly material. Should not emit harmful substances.

- Easy to install.

When comparing basalt insulation and foil penofol, you need to compare their characteristics.

Basalt wool

Made from rock of volcanic origin. It does not burn, has good sound insulation properties, and does not lose its qualities over time. It is completely safe for health.

Penofol - application

Made from polyethylene foam with a porous structure.

A layer of foil is glued on top as a heat reflector. This thermal insulation material is several times thinner than basalt wool. In addition, it reflects heat and practically does not absorb it. Which insulation to choose depends on the budget for insulation, as well as personal preferences.

Advantages and disadvantages of the method

Insulation with foil has a number of features and a minimum of negative aspects. Advantages:

- Foil reflects heat. Thus, the heat remains in the house, on the other hand, it does not allow heat to enter the house in the summer.

- Increased wear resistance.

- Partially applicable as a waterproofing material.

- Easy installation, light weight, simple dismantling.

- The insulation does not allow cold wind to pass through. Maximum insulates from external influences. Resistant to deformation due to sudden temperature changes.

- Keeps out noise from the street.

- Does not rot or mold.

- This material is thinner than others, but is 20-30% more effective.

- The insulation does not emit substances harmful to health and prevents the smallest irritants and allergens from getting inside.

- There is no rigidity, so the top cannot be covered with plaster or wallpaper.

- Special adhesives are required for fixation.

- Sometimes insulation with foil is not enough to insulate a room.

Despite the disadvantages, foil material is widely used for various purposes.

Manufacturers: list of verified brands

Penofol can be glued to concrete using different compounds; there are several manufacturers on the market offering proven substances.

The best options for compositions for gluing penofol to concrete:

- Weicon Easy-Mix PE-PP 45 is a two-component adhesive that provides high quality fixation. The base is methyl acrylate.

- Moment is a two-component sealant, prepared from two substances according to the instructions, and must be used within the specified time.

- Tilit - suitable for joining seams, but can also be used for gluing sheets.

- Titanium is an easy-to-use, lightweight composition that exhibits high adhesion to concrete, one-component, and adheres well to foil-coated foam.

- Ceresit (CT83) is a universal composition for all types of surfaces.

- Atlas Stopter K-20 kley – exhibits high technical characteristics and provides a high-quality connection.

- Allfix is a universal composition, suitable for all types of bases, provides a high level of adhesion.

- The facade is a one-component composition, frost-resistant and waterproof, suitable for outdoor work.

- Luxe-88 is a three-component adhesive, antibacterial and absolutely safe, provides instant adhesion.

- T-Avangard-K - not only glues, but also provides additional waterproofing.