Options for thermal insulation materials

Materials suitable for floor insulation must have sufficiently low thermal conductivity. Most of these materials can also insulate the room from noise.

The most popular options are:

- Mineral wool is an inexpensive material that is effective both as insulation and sound insulation. Cotton wool is very easy to install, fireproof, and resistant to biological contamination. However, it absorbs water very easily, which is why good waterproofing is required. In addition, this material can release glass particles into the air, which can cause allergies.

- Expanded polystyrene and other types of foam are polymer materials that are resistant to moisture and fire. They do not deform, do not allow heat to pass through, and absorb noise.

- Bulk materials – expanded clay or wood shavings. They have excellent thermal insulation properties and can form a leveling layer when constructing a dry screed.

All these materials are good in their own way; the choice is based on operating conditions. Whichever material is more convenient is the one worth using, there is not much difference between them.

TOP 3 manufacturers of electric heated floors

| Photo | Name | Rating | Price | |

| #1 | Devi | ⭐ 97 / 100 | More details | |

| #2 |

| Caleo | ⭐ 96 / 100 | More details |

| #3 |

| Unimat | ⭐ 94 / 100 | More details |

Unimat

The products of the Korean company have proven themselves well in the Russian market. Infrared carbon rods that heat the surface are not afraid of high humidity. Unimat is an infrared heating mat that uses flexible rods made of a composite material based on carbon, silver and graphite.

Unimat

pros

- the heating system is quite economical;

- low cost;

- suitable for tiled floors;

- “living” heat that does not dry out the air;

- The warranty period is 20 years.

Minuses

- it will not work as the main heating in severe frosts.

heated floor unimat

Caleo

Caleo film infrared heated floor is designed for quick installation of a “warm floor” heating system using the “dry installation” method, without screed and dust. Ideal for cosmetic repairs under laminate, carpet, linoleum and parquet boards.

Caleo

pros

- good heat dissipation;

- The kit includes everything necessary for installation: high-quality clamps, wires, insulation; possibility of self-installation;

- Installation and assembly instructions are included.

Minuses

- increased film fragility.

warm floor caleo

Devi

Devi electric heated floors are manufactured in Denmark. The products are distinguished by their affordable price, high quality and versatility. All components of this brand are suitable for any type of heated floors produced by this manufacturer.

Devi

pros

- a large assortment;

- acceptable price;

- simple installation;

- does not dry out the air;

- manufacturer's warranty;

- service life more than 20 years.

Minuses

- high energy consumption.

heated floor devi

Wood floor insulation

When insulating floors in an apartment on the ground floor of a wooden house, thermal insulation material is usually placed in the spaces between the joists on which the decorative coating lies.

Insulation of wooden floors in an apartment occurs as follows:

- The old covering material is dismantled.

- A vapor barrier is laid - usually a simple polyethylene film. The film strips are laid overlapping and secured with tape. The film must be applied to the walls so that the edges eventually protrude above the surface of the finished floor. They can be trimmed later.

- Insulation is being installed. If bulk material is used, it is poured between the joists, using them as beacons for leveling the insulation using the rule. Other types of thermal insulation are rolled out close to the joists, avoiding even the slightest cracks.

- If absorbent cotton wool is used, it is additionally covered with another layer of film to protect it from moisture on all sides.

- Leveling slabs of plywood or gypsum fiber sheet are attached to the joists on top of the insulation. You can skip this step and immediately lay the floorboard.

- Any type of decorative covering can be installed.

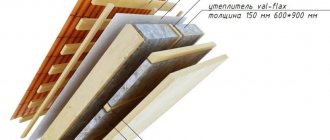

Types and structure of sheets

Plates of this thermal insulation material are produced in a standard width of 0.6 m and lengths of 1.2 m and 2.4 m. The thickness of the slab varies from 0.02 to 0.1 m, so depending on the needs and the possibility of increasing the height of the floor pie, you can choose the appropriate one insulation.

When producing slabs, manufacturers maintain precise dimensions of the sheets, which makes it easy to install the material. When determining how to insulate a floor with penoplex, you need to familiarize yourself with the technical and operational characteristics of various brands of material.

Technical characteristics of the property

| Characteristics | Penoplex 31 | Penoplex 31C | Penoplex 35 | Penoplex 45 | Penoplex 45C |

| Density (kg/m3) | 28-30,5 | 25-30,5 | 28-37 | 35-40 | 38,1-45 |

| Compressive Strength(MPa) | 0,20 | 0,20 | 0,21 | 0,41 | 0,5 |

| Flexural strength (MPa) | 0,25 | 0,25 | 0,4 | 0,4 | 0,4-0,7 |

| Water absorption per day (%) | 0,4 | 0,4 | 0,4 | 0,4 | 0,2 |

| Fire resistance category | G4 | G1 | G1 | G4 | G4 |

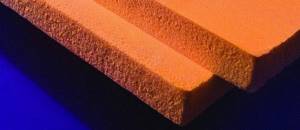

Expanded polystyrene for flooring is a modern, technologically advanced building material that combines the properties of foam and plastic. Thanks to its specific cellular structure, penoplex retains heat perfectly and does not actually absorb moisture.

It is distinguished from similar sheet heat insulators by its high density and fracture strength. The rigid structure of the slab allows you to create frameless floor insulation with polystyrene foam.

Screed

One of the most common methods of thermal insulation is laying insulation under a cement screed with your own hands. The insulation of the screed is carried out in this way:

- The old coating is removed down to the base. The old screed is also removed.

- Floor slabs are repaired if necessary, and joints are sealed. Then the surface is thoroughly cleaned of debris and remnants of the old screed, and vacuumed with a construction vacuum cleaner.

- Waterproofing is being carried out. A thick film is laid over the base. The edges of the material need to be placed on the walls. The edges, overlapping each other by 10 cm, are secured with adhesive tape.

- The selected insulation is laid on top of the waterproofing layer. Sheets of expanded polystyrene and unwound rolls of glass wool should lie close to each other.

- The insulation is covered with an additional layer of film.

- A reinforcing mesh is placed on the insulation. It is needed in order to increase the strength of the screed.

- The cement-sand mixture is poured. The thickness of the screed must be at least 50 mm at its highest point, otherwise during operation it may become covered with cracks and begin to crumble.

- The surface of the dried screed is covered with two layers of primer for final leveling, strengthening and clogging of pores in the concrete.

- The finishing coating is laid on the finished screed.

Dry insulation on joists

The process is similar to insulating floors in an apartment on the first floor of a wooden house, with the only difference being that in this option the logs will have to be installed on a reinforced concrete base with your own hands.

Insulation along the joists is carried out as follows:

- The concrete base is cleaned of old coating, screed and debris.

- The floor is waterproofed. To do this, you can use bitumen or polymer mixtures, applied with a brush or roller, like paint. A less effective, but cheaper and faster way is to lay plastic film.

- Wooden logs are installed a meter apart from each other, no more, so that the floors do not sag. These logs can also be used as beacons for filling expanded clay. It is important to ensure that the upper edges of the joists are in the same plane.

- The selected heat-insulating material is laid. The insulation should be installed close to the joists, avoiding any gaps.

- The floor covering is formed from plywood, gypsum fiber sheets or fiberboard. The thickness of this layer should be about one and a half centimeters. To do this, the material can be laid in two layers, so that the slabs lie crosswise and the joints do not coincide. The sheets are fastened with glue and self-tapping screws.

- Any type of finishing coating can be installed.

Thermal insulation methods

At the moment, there are only 2 methods for insulating concrete floors in any residential buildings; the choice of a suitable material largely depends on them:

- the so-called dry method - insulation on joists;

- “wet” method - laying insulation under a cement-sand screed.

Note. There is a practice of thermal insulation of rooms on the first floor from below, from the basement. This is convenient and cheap, but not very effective, since it must be combined with insulation of the foundation and basement of the building. When there is none, the cold will penetrate from the street through the edge zones of the concrete foundation.

The method of insulation on joists is quite accessible and, with the proper approach, can be easily done with your own hands. It involves the use of both roll and slab insulation for a concrete floor and is designed for subsequent laying of a finishing coating of linoleum or laminate over a flooring made of boards or OSB (chipboard). The list of insulation materials used is very wide:

- mineral or ecowool in rolls and slabs: has high fire resistance, but easily absorbs moisture and at the same time ceases to be an insulator;

- foamed polymers in slabs (foam plastic, extruded polystyrene foam, penoplex), on the contrary, are not afraid of water, but are susceptible to combustion and have better thermal insulation characteristics than cotton wool;

- foamed foil polyethylene (penofol, isolon): the material repels moisture well and has zero vapor permeability, but is flammable. Works great together with other insulation materials;

- sprayed polyurethane foam: the best insulation of all, but also the most expensive, resists moisture, flame (for a certain period of time) and has the highest thermal insulation rates;

For reference. There is also cork insulation on sale, but it is usually not chosen for insulating concrete floors; it is intended for heat and sound insulation of walls.

The essence of the second method of insulation is to monolith the heat-insulating layer under a cement-sand screed, and lay almost any floor covering on top of it. This means that floors insulated in this way are not only made for laminate or linoleum, but are also suitable for laying tiles. This is true in the kitchen or bathroom, where there is high humidity, where the screed will last much longer.

When installing electric or water heated floors, this insulation method is also the most effective. Of course, you can lay heating circuit pipes between the joists, but this will not achieve a large heat transfer area. And the screed monolith becomes like a solid heating device, heating the room with its entire surface. Therefore, warm floors are usually made of the same type (under screed) throughout the entire house, and not just in the bathroom or kitchen.

It is logical to assume that for the second method of insulating concrete floors it is impossible to use soft or rolled materials. Foamed polymers or basalt wool in slabs are suitable here, and the density of the latter should be at least 115 kg/m3 and thickness 100 mm. Expanded polystyrene can be taken thinner - 50 mm, polystyrene - 80 mm with a density of 35 kg/m3.

Spray insulation

Another way to ensure thermal insulation on the ground floor is professional insulation with a thin layer of polyurethane foam. It forms a seamless polymer surface about 7 cm thick on the floor.

The polymer is applied using special equipment that delivers the material in the form of an aerosol under high pressure. In just a few seconds the substance hardens and turns into durable foam. In terms of its effectiveness, such insulation is superior to all other methods.

In addition, polyurethane foam does not need waterproofing. The service life of the material is estimated at tens of years.

Alternatives

If the heat loss in the apartment is insignificant, you can not lay an additional layer of insulation, but simply use a finishing coating with a fairly low thermal conductivity index. For example, carpet insulates the floor of the first floor quite well. Carpets with long pile have even better insulating properties.

Another option is to use linoleum on a thick base of jute or felt. In the same way, you can insulate the floor by laying parquet with your own hands. You just need to use a backing made of warm material - cork, polyethylene foam or polystyrene foam.