Roof insulation with mineral wool

Varieties of mineral wool and options for installing the material on various types of roofing, pros and cons of coatings based on fiber products, rules for selecting components, installation technology.

- Features of work

- Advantages and disadvantages

- Insulation technology

- Selection of mineral wool

- Sloping roof

- Flat roof

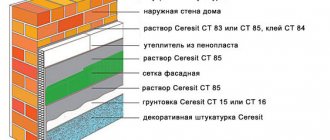

Insulating a roof with mineral wool is the creation of a shell for comprehensive protection of the house from cold, overheating, and precipitation. The composition of the thermal insulation coating includes, in addition to the main element, vapor and waterproofing materials, and a screed for protection against mechanical stress. You can learn about the rules for forming an insulating “pie” from this article.

Insulating the attic floor

Of course, the easiest way will be to install thermal insulation during the construction of the building - this will simplify the design and some of the nuances of the work. In most cases, it will not be possible to follow this advice - lack of finances or time may well interfere, so the ceiling remains without insulation. As a rule, this state of affairs persists until the first frost, and the owners have to quickly lay thermal insulation.

Before insulating the attic floor, you need to carry out a number of preparatory work, which is especially important when using bulk thermal insulation materials. There are two insulation technologies - traditional and modern.

The traditional method of floor insulation is implemented as follows:

- The first step is to treat the boards attached to the ceiling with clay or lime mortar - such treatment will ensure the structure is airtight while maintaining normal ventilation;

- When the mixture hardens, you can proceed directly to insulation work - pouring bulk materials into the space between the floor beams onto pre-treated boards.

Today, a more modern method of floor insulation is used much more often:

- First of all, a vapor barrier membrane is laid on the floor and beams with a 20-cm overlap, which will not only protect the insulating material, but will also complement its thermal insulation properties, reducing the amount of heat escaping from the building through the ceiling;

- To ensure a tight seal, the membrane in the overlap areas must be sealed using construction tape;

- The next step is laying the selected insulation (mineral wool, ecowool, expanded clay or one of the bulk materials) using the appropriate technology;

- To ensure that the floor beams do not have cold bridges, it is necessary to ensure that the insulation passes over them;

- Above the insulation, in compliance with the already known rules, another layer of vapor barrier film is laid, which is attached to the beams with counter-battens;

- All that remains is to lay a covering of boards or fairly strong plywood over the finished thermal insulation structure.

Sometimes, instead of insulating the floor from the attic side, thermal insulation is installed inside the building itself. This design is also quite effective in insulation, but requires additional finishing.

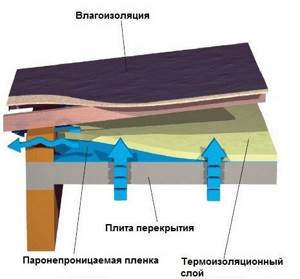

Vapor barrier materials

The most popular vapor barrier material is a special film that protects wood and insulation from the effects of steam, which turns into condensation as a result of temperature changes. The negative impact of moisture on the elements of the roofing structure need not be mentioned once again - suffice it to say that it significantly reduces the service life of the roof and the effectiveness of the thermal insulation material.

The vapor barrier membrane is attached to the roof or ceiling before thermal insulation materials are laid. In rooms where heating is installed, a vapor barrier should be installed only under the finishing layer. To protect structures that are constantly exposed to temperature contrast, a vapor barrier layer must be placed on both sides. The exception is concrete floors, which do not require such protection.

To create a vapor barrier layer, a film with different characteristics can be used. The simplest option is a film made of non-woven material, but a much more effective option is a foil membrane. The latter option, as its name implies, has a thin layer of foil on one side, which prevents heat from escaping beyond the structure. The roof vapor barrier installed from the inside of the house is connected with special tape, ensuring a tight connection.

Installation of mineral wool between the rafters from the inside of the roof

Before you insulate the roof of a house from the inside with your own hands, you need to understand the options for installing thermal insulation. When laying thermal insulation material from the inside of a roof structure, the simplest option would be to install it in the space between the rafters. True, this method is only relevant if the thickness of the insulating layer does not exceed the width of the rafters, otherwise you will have to do combined thermal insulation of the roof.

Insulating the roof with mineral wool from the inside in this case will look like this:

- The first step is to take a building level and measure the lower level of the rafters, which should be uniform along the entire perimeter of the frame. If there are deviations from the level, it is necessary to align all the rafters so that they run along the same line.

- A waterproofing film must be laid in advance on top of the rafters, which protects the insulation from moisture. If this film was not used when installing the roof, then it will no longer be possible to lay it, so the thermal insulation will be without proper protection.

- Mineral wool is cut into suitable pieces. When installing insulation between the rafter legs, the material is fixed due to the bursting force, so the cut elements should be 2-3 cm wider than the distance between the rafters. When laying the material in two layers, you need to ensure that the joints of one layer do not coincide with the joints of the other.

- The next step is adjusting the vapor barrier. Cut membrane strips are installed above the insulation to protect it from moisture and air. The vapor barrier membrane is installed parallel to the roof slope and fixed with a construction stapler.

- The last stage is covering the insulation, for which plasterboard, plywood or edged boards are usually used. In the future, the cladding will act as a support for the decorative finishing of the attic walls.

When installing insulation on a roof with a slope angle of less than 25 degrees, the following situation may arise: the insulating boards will simply fall out due to a lack of pushing force. To prevent this from happening, the insulation must be additionally reinforced with slats or strong fishing line stretched between the rafters. On slopes with a large slope this problem usually does not arise.

Selection of material for insulation

Today, the choice of thermal insulation materials is so large, and their characteristics are so different, that making the right choice for a particular case can be very difficult.

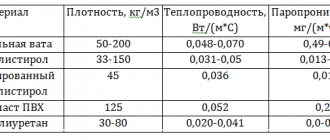

Most often, developers prefer the following materials as insulation:

- glass wool;

- mineral wool;

- basalt (stone) slabs (there are ready-made sandwich panels with basalt insulation);

- foam plastic (expanded polystyrene);

- polyurethane foam (liquid sprayed insulation).

Recently, Izover, a fiberglass material characterized by a high level of heat and sound insulation, has become especially popular when insulating pitched roofs. Due to the content of air in the structure of this material, its low thermal conductivity is ensured, not exceeding 0.044 W/mK. In addition, this material has incredible durability (at least fifty years), excellent vapor permeability and high fire resistance (flammability class - G1).

When considering other types of roof insulation, you should pay attention to expanded clay. It is also characterized by excellent heat and sound insulation, environmental friendliness and fire safety

Since clay is used for its manufacture, it does not lose its properties under the influence of temperature, does not deform and does not emit any substances harmful to humans, which is possible when using synthetic heat-insulating materials.

Pros and cons of the material

Roof insulation with mineral wool has the following positive properties:

- high heat-protective characteristics;

- strength and durability;

- resistance to biological influences (mold, fungus, rodents);

- resistance to fire and high temperatures, which is especially important when ensuring the fire safety of a wooden house;

- when insulated from the inside, the slabs hold quite well without additional fastening (during operation, the bottom sheathing becomes an additional holding element);

- Do-it-yourself thermal protection with mineral wool ensures free movement of air through the material, this has a beneficial effect on the microclimate of the premises of the house.

It must be remembered that protecting the pitched roof of a house with mineral wool has its own characteristics and disadvantages:

- DIY installation requires special clothing, gloves and a mask, since fiber particles getting on the skin and lungs cause itching and irritation;

- a sufficiently high degree of water absorption of mineral wool requires the mandatory presence of vapor barrier and waterproofing;

- When insulating a house with mineral wool, it is important to remember that it weighs more than, for example, polystyrene foam or penoplex.

Instructions for insulating a pitched roof

The entire installation process can be divided into several stages of work:

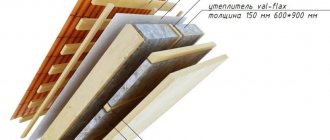

Padding on the rafter legs on the inside of the sheathing boards in increments of 20 to 30 cm - they are needed for attaching the insulation. Mineral wool is laid on the outside of the rafter legs. If insulation is installed for cold regions, it is better to increase the number of layers to two or three. The main working condition is to tightly press the joints of the slabs to the rafters

It is important to ensure that there are no through holes in the mineral wool layer. If after installation you still notice holes, they need to be eliminated using polyurethane foam. When the installation of mineral wool is completed, it is necessary to install a waterproofing membrane

To do this, they simply nail it onto the rafter legs, leaving a slight sag. Installation "in tension" is not advisable. The waterproofing membrane must be positioned correctly. The fact is that such material has a front and a back side. The first is designed to prevent the passage of moisture, but the lower one, on the contrary, allows moisture and vapor to pass upward. The waterproofing material is laid in strips, leaving a slight overlap. It is also necessary to create a gap of 5 cm between the membrane and the mineral wool.

When the waterproofing material is attached in place, we move on to the additional ventilation device. To do this, blocks of wood with a cross-section of 25x50 or 50x50 cm are stuffed onto the rafter legs. They can be used as trimmings of beams. The length can vary from one to two meters. When the bars are in place, it is necessary to fill the sheathing, placing the boards across the rafters. This will create a gap that will facilitate the evaporation of condensation and moisture that will collect on the waterproofing membrane. The roofing material is laid on the sheathing. Do not forget about treating wood with antiseptic solutions. This will help increase the service life of the roofing pie structure. Creating a vapor barrier is an important step in roof insulation. It will prevent water vapor from entering the mineral wool. The vapor barrier film is stretched over the inside of the rafter system. To be able to finish the room, it is necessary to lay sheathing boards on top of the vapor barrier material. For this, slats are used, onto which the internal lining in the form of lining, plasterboard, plywood, etc. will later be attached.

Calculation of insulation thickness and rafter height

When choosing the height of a board or beam for rafter legs, you must be guided not only by strength calculations, but also take into account the thickness of the insulation. For central Russia, the thickness of the mineral wool layer for a residential building is in the range of 100-150 mm; for the northern regions, the thickness should be increased.

For example, the required height of the rafter leg is 150 mm, and the thickness of the insulation is 180 mm. In this case, you will need to increase the height of the rafters so that it allows you to completely lay mineral wool between the wooden structures and provide a ventilated layer 5 cm thick. If necessary, you can use boards of small cross-section, laid along the rafters. Such boards are called counter-lattice and allow you to competently perform thermal protection of the roof of a house with your own hands from the inside.

You can perform a full thickness calculation without special skills. To do this, you will need to install the Teremok PC application or use the online version.

The program is a fairly simple calculator that can calculate the required insulation thickness or check the already accepted one.

Features of roof insulation from the inside with mineral wool, and the cost of work

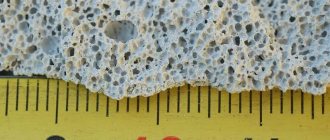

Mineral wool is the collective name for three types of insulation that have one common property – a fibrous structure.

Basalt or stone wool is made from rock. It lasts for a very long time, so it is used for capital construction. The most expensive type of mineral wool.

Glass wool made from the same components as regular glass. Cheaper than basalt, but its service life is much shorter. It is used in places where it can be quickly and cheaply replaced.

Slag wool, for the production of which waste from blast furnaces is used. The price and properties are similar to glass wool.

These materials are available in a variety of forms. These can be slabs, rolls, mats, and cylinders.

Insulating a roof with glass wool from the inside is the most effective and affordable way to retain heat in the attic.

In order to insulate the roof from the inside, especially when it comes to a structure made of wooden structures, materials that meet serious requirements should be used. They should be:

- Non-flammable (fire safety class G3 and higher).

- Durable.

- Eco-friendly.

- Rot resistant.

- Possessing not only insulation, but also soundproofing properties.

- Not affected by temperature changes.

- Resistant to damage from insects and rodents.

Mineral wool meets these requirements best of all. To insulate the roof from the inside, mineral wool is used in the form of a roll or mattress. The last option is the most convenient to install.

Prices for mineral wool allow almost every owner of a cottage, bathhouse or garden house to use it for roof insulation.

The only disadvantage of this material is its ability to absorb water, losing up to 40% of its thermal insulation properties. However, insulating the roof from the inside with mineral wool, carried out in strict accordance with technology, helps prevent liquid from entering the insulation.

Well, the quality of roof insulation can be seen using a thermal imager, which can instantly show the places through which heat loss occurs.

What set of tools and consumables will be needed to insulate the roof from the inside?

When carrying out roof insulation yourself, you should prepare everything necessary for the work:

- Minvatu.

- Wooden blocks with a cross section of 40 mm.

- Vapor barrier (for example, any waterproofing film).

- Drill.

- Glue.

- Antiseptic solution for wood.

- Nails or screws.

- Hammer.

- Mineral wool dust respirator.

What is Fastboot Mode on Android

The Android mobile operating system is distinguished by its functionality, reliability and deep management capabilities. Because user actions can sometimes cause more harm to the system than malware, access to system functions is limited to developers.

At the same time, experienced users often open root rights to make changes in their own way, but do not forget that interfering in the Android environment without certain knowledge and skills is dangerous for the system. In addition to root access, Fastboot Mode, which exists separately from the operating system, offers ample opportunities.

The shell, comparable to the BIOS on computers, is part of the software for Androids; this software component is used to debug the smartphone, flash it and make other adjustments.

Despite the high level of reliability, malfunctions also occur on Android devices, for example, sometimes users can observe a spontaneously activated fast boot mode, for which the phenomenon of “self-starting” is not typical, so it may well signal a problem, although often the situation is one-time. Rebooting the device in this case is ineffective, but there is no need to panic, even if you absolutely do not understand what to do with all this. Correct actions and following the instructions for exiting the mode will help solve the problem in a matter of minutes.

Working with Fastboot Mode in Android.

What is Fastboot Mode

In Russian, the name of this software tool sounds like “fast boot mode” and in the case of use on laptops, its task is to speed up the startup of the operating system, bypassing the BIOS and debugging software. The Fastboot component is not tied to a specific OS, but is more often found on Android, and here its functionality is different. In many ways there are similarities with the more popular Recovery.

Speaking about Fastboot Mode, we will look at what it is on Android, since users most often encounter this mode on smartphones and tablets. The Fastboot Mode tool is a system-independent software component used by developers to configure applications and reinstall the OS. In addition, the capabilities of Fastboot can be used by service specialists and experienced users. Fastboot Mode in Android devices is implemented at the hardware level.

The program code is written in the memory chip, in a place protected from writing and reading, which means it cannot be damaged.

The tool provides access to system elements of smartphones and tablets to control them from a computer. In order for a PC or laptop to recognize a device immersed in this mode, it is necessary to install drivers for communication between devices that correspond to the smartphone model. Considering what Fastboot Mode is on Android, here is a list of the main features available when activating the component:

- System backup and recovery;

- Reinstalling the operating system;

- Changing hidden system settings;

- Troubleshooting OS problems;

- Obtaining root rights;

- Installation of components;

- Application recovery;

- Software testing, etc.

Fastboot Mode starts before the firmware, it is autonomous, which means that the mode can be used even if it is impossible to boot the system or if it does not work correctly due to serious failures.

In what cases is fastboot mode activated?

Fastboot can be launched in various ways, through the standard menu or by simultaneously pressing the power and volume buttons, but spontaneous startup is often a bad sign. The following factors can trigger Fastboot Mode to boot on its own:

- System failure;

- Accidental activation of the mode by the user;

- Unsuccessful attempt to reflash the device using Recovery Mode;

- Connection via USB to a computer with the “Quick Start” option activated;

- Obtaining root rights using third-party software;

- Removal of system executable files by the user due to illiterate use of root rights;

- The influence of malware that can damage or delete system elements, which is not excluded if you have advanced user rights.

Features of mineral wool

is very popular as insulation. This material is easy to work with and has a number of advantages, including:

- low thermal conductivity;

- combustion resistance;

- environmental friendliness;

- resistance to aggressive environments;

- high level of heat saving;

- good noise absorption;

- hydrophobicity. This property manifests itself as resistance to wetting; You cannot rely only on the hydrophobic qualities of mineral wool. It is imperative to take measures to protect the under-roof space from moisture. When wet, any insulation will reduce its effectiveness by a couple of times.

- high resistance to deformation;

- ease of installation;

- length of service life.

Unlike foam plastic, careless transportation of the material will not lead to damage. And thanks to the softness of mineral wool, it is easy to install.

Despite similar insulation procedures, mineral wool differs from ecowool, which appeared on the construction market not so long ago, which is an insulator characterized by friability and light weight. Ecowool contains cellulose, antiseptics and boric acid.

Safety precautions

When independently insulating the roof of a house from the inside with mineral wool, the following precautions must be observed:

- the room should be well ventilated;

- cutting tools are used as sharp as possible to reduce the crumbling of mineral fibers;

- workers must have gloves and a mask that will prevent particles of material from entering the skin and lungs;

- After completing the work, it is strongly recommended to immediately change clothes, wash your hands thoroughly, and then wash your face with cold water.

When fiber particles come into contact with the skin, redness and itching appear. To avoid unpleasant sensations, it is enough to follow safety precautions.

The use of mineral wool in construction is very wide. This material is most often used for roofs, since it fits best between the rafters and has many other positive characteristics.

In order for mineral wool to last a long time and not cause problems during operation, it is enough to follow the installation technology and purchase high-quality material. There are several well-known manufacturers on the market, such as Rockwool, Isover, Ursa, Paroc. These materials are used in many types of construction and have proven themselves.

Insulation of the roofs of private houses is done from the inside and can be done with your own hands,

if the owner is determined to pay close attention to such an important operation to ensure heat conservation in the house.

The most common material for home insulation is considered to be mineral wool .

Mineral wool has many advantages and it is rightfully recognized by many builders.

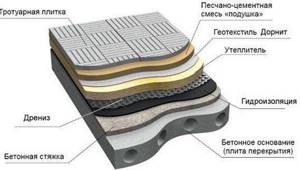

Insulation of a flat roof

Quite often, flat roofs of houses are used to equip terraces, winter gardens, sports or children's playgrounds. Therefore, such a design must be as reliable as possible and capable of withstanding significant loads, and the thickness of the roof insulation must also be quite significant (also read: “House roof diagram - features”).

Insulation of such a roof is carried out as follows:

- First, a cement screed is installed on the reinforced concrete floor slab, forming a slope. Then a layer of waterproofing is laid;

- after this, a layer of extruded polystyrene foam with a density of at least 35 kg per square meter is laid;

- then, to create filtration, everything is covered with fiberglass, covered with a layer of gravel or pebbles, and finally paving slabs or paving stones are laid.

Foam can also be used to insulate the roof or foam concrete applied to the vapor barrier layer and covered with a foam fiber concrete screed. After this, a welded or membrane coating made of polyvinyl chloride is installed.

In cases where flat roofs are used as an attic, and a soft roof with insulation is planned, a vapor barrier layer and insulation are laid in the attic, and a waterproofing layer is laid under the roofing material. It is also possible to insulate the attic floor with expanded clay. If the use of a flat roof is not expected, then it can be insulated both from the outside and from the inside (for more details: “Insulation of a flat roof and its features”).

Types of insulation

Of course, it is necessary to insulate the slopes only when installing a warm roof. The thermal insulation layer is laid in the space between the rafters at the stage of roof installation when there is no finishing coating yet - this approach is quite convenient and does not require significant effort.

Roof insulation can be performed with the following types of mineral wool:

- Glass wool . This heat-insulating material contains glass fiber with a thickness of no more than 15 microns. Glass wool can be produced in rolls, slabs or mats. The characteristics of this insulation are impressive: excellent thermal insulation properties, good fire resistance and complete resistance to biological factors. The material, produced in the form of slabs, is quite convenient and very easy to install. Glass wool can easily be classified as a budget insulation material if you take a closer look at the cost of alternative heat insulators. The main disadvantage of this material is its ability to cause irritation upon contact with open areas of the human body, so it is necessary to work with it only in a full set of personal protective equipment.

- Basalt (stone) wool . This material also contains fibers, but here they are represented by a natural mineral - basalt. Additional components include some carbonate rocks, bentonite clay and several other composites. Basalt wool is completely non-flammable, has excellent thermal insulation properties and is resistant to mold and mildew. The structure of this material is not so strong, and its price is about 1.5-2 times higher than glass wool, but safety and ease of installation have done their job - and therefore basalt wool is in much greater demand.

There is also a third type of mineral wool - slag wool. It is pointless to consider insulating a roof with your own hands from the inside using mineral wool of this type, since it is not used for internal roof insulation due to its extremely negative impact on the human body.

Instructions for insulating a flat roof

All flat roofs are divided into ventilated and non-ventilated. Let's consider both types.

Ventilated flat roof

The process of insulating it is similar to the scheme for working with a non-residential attic space. This roof design ensures a minimum distance between the slope and the ceiling, which makes it difficult to move in the under-roof space and reduces the functions of the room to technical ones only.

Mineral wool slabs 20 cm thick are suitable for work. The material is laid on the floor of the attic. Dowels are used as fastening elements. In addition to the mechanical installation method, it is possible to use glue or hot mastic, but the latter method has not gained much popularity. For proper operation of the insulation, it is necessary to place the construction film under it in one layer.

Stages of work

- First, the condition of the entire roofing pie is checked. Damaged elements must be replaced.

- To further insulate the attic, it is possible to lay a layer of mineral wool on top of the existing one.

- Before installing mineral wool slabs, you should clean the surface of the floor that will be insulated. When using reinforced concrete floor slabs, a vapor barrier is not necessary, because concrete does not allow moisture to pass through.

- The beams must also be insulated or covered with insulating materials, or mats must be laid (rolled insulation can be used) between the beams. But before this, it is necessary to install a vapor barrier layer.

- When using foil material, installation is carried out by placing the slabs with the foil down.

- A ventilation gap must be left near the cornice.

Unventilated flat roof

Structure of a non-ventilated flat roof

Concrete slabs or wood are used as the base, depending on the material from which the house is built. The peculiarity of this type of roof is the absence of any gap between the roof and the ceiling. Therefore, it is necessary to install mineral wool directly on the base.

Stages of work

- The vapor barrier film is laid on the base of the roof.

- After this, you can begin laying mineral wool slabs. It is recommended to do this with a checkerboard arrangement of the material so that the joints are not located along the same line. The slabs must be fitted tightly together. The most suitable thickness of the thermal insulation layer is 25 cm.

- Next, roofing felt is laid on top of the mineral wool slabs.

An unventilated flat roof can have various types of thermal insulation:

- Single layer. For this purpose, hard mineral wool slabs are used, which have increased strength. But their thermal insulation qualities are not great.

- Two layer system. For this purpose, elastic plates are suitable for forming the first row, and harder ones are used for the second. In this way, a structure is obtained in which the bottom layer exhibits excellent thermal insulation qualities, and the top layer helps to compensate for the sensitivity of the first row to various mechanical damage. The material used is basalt mineral wool.

- Mixed two-layer system. This option is similar in design to the previous one, but differs in the use of two types of mineral wool slabs. Glass wool is used for the bottom layer, and basalt wool is used for the top layer.

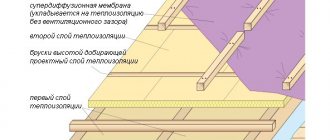

Installation between rafters

If the roof insulation is carried out from the inside, then it is most convenient to install thermal insulation material between the rafters of the frame. This method is suitable if the calculated thickness of the insulation layer is less than or equal to the width of the rafters, otherwise combined thermal insulation of the roof slope is performed. The technology for laying thermal insulation material between the rafters is as follows:

- Using a building level, the lower surface of the rafters is measured; it should be located at the same level. If the rafters were made from lumber of different sizes, then they need to be aligned so that they all lie in the same plane.

- Waterproofing for the internal insulation of the roof slope is a film laid on the rafters before the covering is laid. If this was not done during the creation of the roofing pie, then the insulation will have to be left without protection from moisture, hoping that the roofing material will not fail.

- Rolls and slabs of mineral wool are cut into the required lengths. The insulation is installed by surprise, so the width of the material should be 2-3 cm greater than the pitch between the rafters. If the insulation is carried out in 2 layers, then the slabs are laid staggered so that the joints do not fall on top of each other.

- Vapor barrier membrane sheets are cut. They are attached over thermal insulation to protect the material from the penetration of air saturated with water vapor and from getting wet. The canvases are fixed perpendicular to the rafters along the roof slope, attached using a construction stapler.

- The insulation is covered with plasterboard, plywood, clapboard or edged boards in order to decorate the attic walls on top of them.

Important! If the roof slope has a slight steepness of less than 25 degrees, then insulation boards installed by surprise may fall out of the space between the rafters. To prevent this problem, the thermal insulation is held in place using cross slats or fishing line stretched between the rafters of the frame. Experience shows that on slopes with a slope of 40-45 degrees, the insulation holds well without additional help.

Thermal insulation methods

Depending on which structural element of the building is insulated, two methods can be distinguished.

Thermal insulation of the floor

The first option is to insulate the floor. The method is inexpensive and very easy to implement. It consists of laying wool on concrete base slabs or, in the case of a wooden floor, between structural elements. Any type of mineral wool will do, even soft and granular. Installation is simple, there is no need to go around the rafters, as when insulating roof slopes, you can easily fill all the gaps and cracks.

Thermal protection of stingrays

The second option is to insulate the roof slopes. If the room in the attic is not used, then this option is not economically viable. The consumption of materials increases significantly; more time is required due to bypassing the rafters and additional fastening of mineral wool.

Insulation of slopes can be done in two ways: on top of open rafters or between them. With the first option, wooden beams remain visible indoors and have an additional decorative function.

Insulation of a pitched roof

The technology for insulating a pitched roof depends on its structural features, as well as on the purpose of the attic. So, if the attic is non-residential, then the insulation is laid on the ceiling (attic floor), and not between the rafters. If mineral wool is used, then the following roof insulation scheme is recommended, photos of which can be seen on the pages of many specialized publications or websites: walkways are made along the attic joists, and a special membrane is laid on the layer of wool, ensuring steam removal and fiber filtration. After this, the floor is covered with OSB boards, and any floor covering is laid on top of them (useful article: “Types of roofing on pitched roofs”).

How to properly insulate a pitched roof, watch the video:

https://youtube.com/watch?v=C4QOujBaYVQ

If you plan to install a residential attic, then resort to a different insulation technology:

How to insulate a roof with mineral wool from the inside

Roof slopes can be equipped using different technologies, but their design always includes a heat-, hydro- and vapor barrier layer, as well as a counter-lattice that creates a ventilation gap and is used for additional fastening of materials.

The roof installation technology involves the following steps:

- Waterproofing is laid on the assembled and installed rafter system. Most often, high-density polyethylene is used as a waterproofing material, which can protect the roof from both moisture and gusty winds. The roof waterproofing is laid from the inside of the house with an overlap of about 20 cm and attached to the rafters with a construction stapler.

- A counter rail is installed above the film along each rafter. This element forms a small gap between the film and the roofing, due to which the structure is constantly ventilated.

- To lay a soft roof, sheets of moisture-resistant plywood are attached above the counter-lattice. Before insulating a metal roof, or a roof made of other solid roofing materials, you will need to create a regular sheathing with a well-calculated distance between its elements.

- After the sheathing is assembled, you can begin installing the roofing.