Insulating the floor with penoplex is a common suggestion today. This heat insulator is chosen because of its low thermal conductivity, the ability to get by with a small thickness, as well as high compressive strength, which makes it possible to do without additional reinforcement when installing floors. They insulate floors laid on the ground, floors above basements, floors on floors, balconies and loggias. The material is also popular because the price of foam floors and screed is relatively affordable. As a finishing coating, tiles and veneer boards are installed, a screed with a “warm floor” system is installed, and penoplex is placed under the laminate and linoleum.

Insulation of wooden floors

The situation is quite rare. The construction of the structure on logs allows the use of budget building materials for insulation, because the main and most valuable quality of penoplex is rigidity; in such a floor it does not matter at all.

The exception is the installation of insulation over a plank floor and the installation of floors on joists in a house on stilts. In the latter case, insulation is done according to the following scheme:

- the rough flooring is being laid from boards;

- film waterproofing is laid;

- Penoplex is laid with shifts along the seams;

- insulation boards are screwed around the perimeter of each sheet to the rough base;

- seam gaps are filled with foam;

- a vapor barrier is placed on the insulation;

- lay the sheet base over the finishing coating. For more information about floor insulation using joists, watch this video:

When laying insulation on an old plank floor, it is necessary to secure all the boards to the joists: the floors should not sag or creak. Rotten or damaged boards should be replaced. Wooden floors should be treated with at least 2 coats of primer. Penoplex is laid on the dried base. Further, all work is carried out by analogy with a house on a pile foundation.

No matter how high-quality the laminate is, the service life of the flooring largely depends on the quality of preparation of the floor base. If the installation is carried out incorrectly, even after a short period of use, the locks will begin to come apart and other typical problems will appear. Correct installation involves leveling the base on which the laminate is laid and insulating the floor with penoplex. As a result, the house becomes cozy and comfortable. The main thing is to choose the right size penoplex depending on the place of work and the type of screed used.

Penoplex

Conclusion

In the video presented in this article you will find additional information on this topic. Also, based on the text presented above, we can conclude that penoplex is a very practical and high-quality insulation material. At the same time, there is nothing complicated in its installation and even a novice master can handle it.

It is worth noting that this material can be installed on almost any type of floor. At the same time, its excellent technical characteristics allow the use of penoplex even for outdoor work or in places with heavy surface loads.

Source: master-laminata.ru

Step by step process

First of all, it should be noted that installation will be carried out on a concrete slab. If you need to insulate the floor in a wooden house with penoplex, then the installation can be done directly on the ground or subfloor.

Creating waterproofing using film

Preparation and waterproofing

- First, find all the cracks on the concrete slab that need to be cut out using a chisel or hammer drill.

- Next, all defects and unevenness, including large differences, are straightened with a cement mixture.

- Then waterproofing is installed on the floor, which is used as bitumen or film.

- If the installation is carried out on the ground, then the manual, which tells how to insulate a floor with penoplex, first recommends installing a special material to protect it from moisture, and then using a small layer of sand as a soft substrate.

Advice! When you have to deal with a floor that has large differences, you can use sand to save money so as not to have to perform preliminary leveling.

Laying material on the surface

Insulation and beacons

- Penoplex is installed to insulate the floor end-to-end . In this case, the gaps can be sealed with mounting tape to ensure a tight adhesion.

- To fix the material, a special fastener is usually used or spacers are installed..

- Next, using a water level, measure the horizontal line, which is marked along the perimeter of the walls..

All seams can be sealed using polyurethane foam, which is also a good insulation material

- At the next stage, you need to install beacons, which are mounted directly on the laid out material.

- It is worth noting that penoplex insulation for floors can be used as a covering for a very small screed , only 4 cm thick. Therefore, beacons are oriented precisely to this size.

- They are made from metal profiles , which are fixed to the surface with mounting plaster.

- After installation, the finished structure is additionally checked with a water level for compliance with the horizontal.

Advice! To save money, waterproofing is not installed on top of the insulation. The fact is that this material itself is a good insulator and has excellent resistance to moisture.

To increase the strength of the screed, you can lay a metal mesh or grating on the surface, and place the beacons on top of it

Screed and finishing coat

- After the beacons have hardened, insulating the floors with penoplex involves tightening the surface with cement mortar. In this case, it is best to use a special rule in which a water level is built in.

- It is worth noting that the ratio of cement and sand in the solution should be 1 to 3.

- After two weeks have passed, which you should wait until the mixture completely hardens, the insulation of the floor of the first floor with penoplex can be considered ready and you should move on to the finishing coating.

Making thin screed using penoplex

- To begin with, a special material is installed on the surface. It will serve as a shock-absorbing substrate and allow minor defects to be corrected. (See also the article Underfloor heating: features.)

- At the next stage, you need to use special plastic pads, which are mounted between the outer segments and the wall. As a result, a distance of 10 mm should appear. It is necessary to compensate for expansion due to heating.

Using a special underlay for laminate

- Further installation is done with your own hands, depending on the type of laminate chosen. One type of this coating requires special latches, while another product requires installation using special tenons and grooves at the ends that form locks.

- If you are using laminate for an installation that requires adhesive, the installation instructions recommend applying it to the area where the materials join each other.

Amateur photo of laminate installation using special latches

- For this work, you may need a hammer with a wooden block, as well as a clamp. These tools will ensure tight fixation and can be called basic during installation.

- It is worth noting that the price of such insulation is relatively low, since the main costs are the purchase of penoplex itself, and they usually save on the rest.

Advice! Before installing the laminate, it must be kept at room temperature for a day without removing it from the packaging. This will allow the material to take its working size for a certain climate.

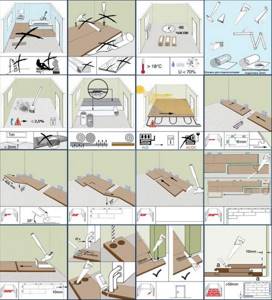

Graphic instructions for laying a laminate finish covering, which displays all the features of this installation and options for solving various technical problems that may arise during work

Is it possible to lay laminate flooring on penoplex without a screed?

Insulating the floor with penoplex is a common practice today. The thermal insulator is chosen due to its low thermal conductivity, the possibility of a small thickness, as well as high compression strength, which makes it possible to do without additional reinforcement when installing floors.

They are used to insulate constructed floors, floors on the ground, floors above basement floors, rooms on floors, balconies and loggias. The material is also popular because the price of penoplex flooring and screed is relatively affordable.

As a finishing coating, tiles are installed, veneered ones are installed, screed boards with a “warm floor” system, penoplex are placed under laminate and linoleum.

Penoplex - the basis of a warm floor

There are many floor insulation technologies. This includes expanded clay, mineral wool, and penoplex, of course. The latter is one of the best modern heat insulators, although, it should be noted, not the most suitable. For cheap floor insulation, the first 20-30 mm is enough (on slab floors it can be up to 50 mm), while the thickness of the mineral wool is increased, for example, two times more is recommended.

- The advantages of penoplex insulation for floors are as follows:

- Excellent moisture insulation Good

- properties thermal insulation

- Mechanical strength

- Durability

- installation Simple

Before installing penoplex on the laminate, you need to lay the insulation itself. This is quite easy to do. It all depends on what kind of leveling screed there will be - cement sheet or material (plywood, OSB boards, For). One GVL will need as smooth a rough surface as possible, for the other you will have to lay down wooden logs as the basis of the coating.

Under a cement screed on penoplex, after which the laminate will be laid, it is better to choose slabs with grooves at the ends for tighter joints. If the system assumes the presence of wooden logs, then the heat insulator can be taken without a shaped edge.

Installation of penoplex under laminate with concrete screed

- Prepare penoplex laminate with screed as follows:

- Place on top of a leveled base.

- its insulation is covered with waterproofing - so that liquid from the screed does not get into the joints.

- This is then filled with sand-cement screed.

- necessary When the surface is leveled with a self-leveler - it must be perfectly flat if the laminate is to be laid on polystyrene foam.

- Next, the substrate and finishing coating are installed in accordance with the technical requirements.

If you want to put a warm floor system under the laminate on a penoplex, the screed is installed using the technology provided for warm floors. It is better to stay on a warm water floor. Electrical systems usually heat up faster than water ones, and sudden temperature fluctuations are undesirable for our finishing coating.

Laying a laminate on the system and penoplex of an electric heated floor will only be justified if there are thermostats that ensure a smooth increase and decrease in temperature.

Installation of penoplex laminate under dry screed

Dry concrete floor screed, which does not require long concrete work, can also be used. In this case, it is attached to wooden logs. First, they are laid between the lags in principle. The insulation can be anything. Afterwards the screed is mounted.

They use plywood (it is better that in this case the heat insulator lies flush with the joists and provides an additional support surface), gypsum fiber boards (suitable) and other gypsum fiber board materials for dry screed.

so that the surface level must be adjusted for the precise subsequent laying of the laminate on penoplex and a dry screed, this is important. The last stage of installation will be the substrate and the actual installation of the laminate

substrate and Penoplex for laminate

As you know, when laying coatings, a substrate is used - cork polyethylene foam or. Is it possible to lay laminate flooring on a foam base? without Many “craftsmen,” as practice shows, have such a temptation to put penoplex on the laminate without any screeds. It seems that this material is durable, why bother with the screed? gender This will only bring problems.

Penoplex is not point-loaded, its strength is felt under static pressure. The heat insulator, according to the rules under the screed, can withstand a long time, and at the same time, it’s easy to make a hole in it with a pencil. And most pieces of furniture are that same point load.

An unsuccessfully placed cabinet with its foot caught in the lock of a laminate board may simply fall into the floor. Penoplex under a laminate base will not save you from destruction - there will be little of it, it is intended to protect from noise and moisture, and not to reinforce the base. In addition, such a coating will creak terribly.

Is it possible to lay laminate on penoplex: installation

Check Also

Painting a stove with water-based paint: advantages and application features Wood-burning stoves are still widespread today, despite widespread urbanization. They have found their successful application in bath structures and are the only source of heat in ...

Penoplex is one of the best floor insulation materials due to its technical characteristics. The technology for installing such material is quite simple and does not have any nuances, so laying penoplex on the floor is possible even with your own hands. This type of insulation is produced…

Vyacheslav Panov October 25, 2014 KnittingHomemade products for the home If you have a collection of old sweaters at home, do not rush to throw them away! From these you can make an original, useful homemade product with your own hands - a warm blanket from sweaters. "Knitted...

Molded larch products, their range, features and properties Larch wood is the basis of many decorative and residential structures. The variety of lumber expands the range of possible applications and allows you to choose the optimal design parameters. Construction of load-bearing elements and finishing...

Brick houses are very popular because this building material allows you to get a strong and durable structure. However, brick is different from brick, because there are many varieties of this material. If you decide to choose to build a house from...

Thermal insulation wisely: how to properly insulate the floor on the ground floor On the ground floor you almost always feel discomfort from a cold floor - and it doesn’t matter whether it’s a high-rise building or a private building. Is it worth fighting this? Definitely

After all …

How to install a faucet in a bathroom or kitchen With a faucet, that’s why it’s a faucet, because by mixing hot and cold water, it produces warm water at the output. Installing a faucet is not a difficult task and you have to pay someone to pay for it...

Plaster stucco molding - making your fantasies come true with your own hands The oldest examples of gypsum stucco molding are about 9000 years old. Gypsum was made by burning gypsum stone, crushing it into powder, and then mixing it with water. The resulting solution...

What material is the most practical for a bathroom partition? Designing and planning a bathroom is not an easy process, and therefore you should be patient and use some techniques to qualitatively change the characteristics of the bathroom in view of its structural features. ...

Dacha in a sheepskin coat: how to properly insulate a country house for the winter Country houses are often a “cold” box made of wooden beams or bricks, lined with clapboard inside, and therefore not intended for winter trips to your favorite hacienda. ...

Metal garage drawings must be made at the very beginning of the work. After all, then you can calculate everything and take the correct amount of materials. When making a drawing of a metal garage, you must immediately take into account some details of its installation. It's not just...

How to properly glue fillets if the pattern on the ceiling tile is large We are asked: Good afternoon! Please tell me how to properly glue the fillets if the pattern on the ceiling is large? Question: How can I remove mold from a plasterboard ceiling in a bathroom myself? ...

Installing a pond on the site: making your dream come true! How to make an artificial pond with your own hands - FORUMHOUSE experts and users give advice and share their experience On a hot afternoon, it’s so nice to plunge into the cool waters of a pond on ...

To make the right choice of sauna stoves, you need to know the basic selection criteria. First of all, it is necessary to take into account the creation of the correct microclimate in the steam room

It is very important! In addition, there are a sufficient number of important points. In this article..

Concrete is one of the most durable building materials, but very often builders use a technique such as reinforced concrete, which increases its strength and moisture resistance, as well as insulating properties. Concrete itself consists of such simple...

Characteristic

The material is distinguished by its safety and meets environmental requirements. It is made in several types. It all depends on the performance characteristics and thickness. Expanded polystyrene boards can have milled grooves to create a tight connection.

The thickness of the sheet does not exceed three millimeters. This size is mainly used for rooms where the floors must differ in their heat-insulating properties. Typically, sheets are produced packed in packs of 20 pieces.

For all its positive properties, extruded insulation also has several negative qualities:

- high price;

- not very high depreciation rate;

- there is no microventilation.

For a minimum difference in floor levels, you can install any version of polystyrene foam sheets. Thanks to the groove system, the material adheres more tightly to the floor surface and excellent air flow is maintained.

In homes, polystyrene foam boards of the “PSB-S-35” type have become the most popular. If the floors experience increased pressure, PSB-S-50 will be more reliable.

PSB-S-35 series

When choosing a brand of heat insulator, you need to take into account its service life. It is designed for 15 years. After the end of the guaranteed period, the structure may change and deformation of the material may appear.

Expanded polystyrene is a type of polystyrene foam. It has a smooth surface and microporous structure. The material is obtained by foaming polyethylene granules in special extruders.

To obtain a cellular structure and minimal weight, water vapor and some types of volatile petroleum products are supplied to the pressure zone. The lightness of the material does not affect its strength; it remains very high, and the thermal insulation performance is higher than that of other similar materials.

PSB-S-50 series

This polystyrene foam substrate has a large number of positive characteristics:

- does not allow moisture to pass through;

- mold does not appear on the surface;

- fungus never forms;

- does not cause an allergic reaction;

- high strength;

- does not lose stability under high pressure.

The production of such sheets for laminate coating is carried out using special equipment. The result is an excellent material that does not react to accidental snags. It functions as an excellent heat insulator and protector against moisture.

This insulation for laminate is produced in the form of separate sections, with dimensions 1000x500x20. The sections are joined together with a special foil-coated multilayer polymer fabric. The result is an original design that has a moisture-resistant base with well-sealed joints.

Such packs are not unpacked when sold. Therefore, the color scheme can have a variety of shades. However, this does not in any way affect the strength properties of the material.

How to put penoplex under laminate correctly

Contents Hide ▲ Show ▼

Insulating the floor with penoplex is a common suggestion today. This heat insulator is chosen because of its low thermal conductivity, the ability to get by with a small thickness, as well as high compressive strength, which makes it possible to do without additional reinforcement when installing floors.

They insulate floors laid on the ground, floors above basements, floors on floors, balconies and loggias. The material is also popular because the price of foam floors and screed is relatively affordable.

As a finishing coating, tiles and veneer boards are installed, a screed with a “warm floor” system is installed, and penoplex is placed under the laminate and linoleum.

Installation of penoplex under laminate with concrete screed

- Prepare penoplex laminate with screed as follows:

- Insulation is laid on the leveled base.

- It is covered with waterproofing on top to prevent liquid from the screed from getting into the joints.

- After this, it is filled with sand-cement screed.

- If necessary, the surface is leveled with a self-leveling device - it must be perfectly flat if the laminate is to be laid on polystyrene foam.

- Next, the substrate and finishing coating are installed in accordance with the technical requirements.

If you want to install a heated floor system under the laminate on penoplex, the screed is installed using the technology provided for heated floors. It is better to stay on a water heated floor.

Electric systems typically heat up faster than water systems, and extreme temperature fluctuations are not desirable for our finish.

Laying laminate flooring on penoplex and an electric heated floor system will be justified only if there are thermostats that provide a smooth increase and decrease in temperature.

Installation of penoplex under laminate with dry screed

Dry floor screed, which does not require long concrete work, can also be used. In this case, it is attached to wooden logs. First, insulation is laid between the joists. In principle, it can be anything. Afterwards the screed is installed.

They use plywood (it is better that in this case the heat insulator lies flush with the joists and provides additional support surface), gypsum fiber boards (GVL) and other materials suitable for dry screed.

It is necessary that the surface level be accurately adjusted - this is important for subsequent laying of the laminate on polystyrene foam and dry screed. The last step will be laying the substrate and actually installing the laminate.

Penoplex and laminate underlay

As you know, when laying the coating, a substrate is used - cork or polyethylene foam. Is it possible to lay laminate flooring on penoplex without a backing? Many “craftsmen,” as practice shows, are tempted to lay laminate flooring on polystyrene foam without any screeds. It seems that the material is durable, why bother with the screed? Such a floor will only bring problems.

Penoplex is not designed for point loads; its strength makes itself felt under static pressure. The heat insulator, according to the rules, placed under the screed, can withstand enormous weight, and at the same time it is easy to make a hole in it, even with a pencil. And most pieces of furniture are the same point load.

An unsuccessfully placed cabinet, with its leg caught on the lock of the laminate board, can simply fall into the floor. The foam underlay under the laminate will not save you from destruction - it will be of little use, it is designed to protect from noise and moisture, and not to reinforce the base. In addition, such a coating will creak terribly.

When insulating and covering the floor, it is still better to abandon “folk inventions” and rely on existing technologies. But they claim that it is impossible to install laminate directly on penoplex. It’s better to follow all the instructions and end up with a warm and beautiful floor than to start a new renovation six months later, correcting your own mistakes.