In 2015, the production of new Penpolex brands began, such as Osnova, GEO, Facade, and Pitched Roof. And many began to ask the question “What are the differences between Penoplex Comfort and Penoplex Basic?” Let's try to figure it out.

Differences between Penoplex Comfort and Penoplex Basis

The main technical characteristics (dimensions, thermal conductivity, vapor permeability and water absorption) of Penoplex Comfort and Penoplex Base are the same, the only difference between these brands is “compressive strength”. Penoplex Comfort has a compressive strength of 0.18 MPa, and Penpolex Base has a compressive strength of 0.20 MPa, i.e. Penpolex Base can withstand more load, and is correspondingly more rigid. This is due to the fact that Penoplex Comfort is only for retail sales, and Penoplex Osnova is intended for professional construction.

Differences between Penoplex Fundamen and Penpolex GEO

The essence of the difference between Foundation and GEO is similar to Basis/Comfort. Since these Penpolex brands are intended for use in structures with high loads, they have higher compressive strength. Penpolex Foundation has a compressive strength of 0.27 MPa, and Penoplex GEO has a compressive strength of 0.30 MPa. And also Penoplex GEO is not sold in retail stores and is intended only for professional construction.

began the history of Russian extruded polystyrene foam by launching in 1998 a production line for PENOPLEX boards at a plant in Kirishi, Leningrad Region.

Penoplex production method: Polystyrene granules enter an extruder, where they are heated and mixed under high pressure. At the same time, a gaseous blowing agent is supplied to the extruder. Thanks to high pressure and heat, the blowing agent enters the granules and increases their volume. The resulting mass is pressed through a die, the material is cooled and cut into slabs. As a result, small closed cells are formed in XPS, which give penoplex excellent thermal insulation properties and negligible water absorption.

Penoplex brands

For what purposes is it better to buy thin Penoplex

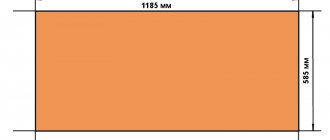

The manufacturer produces extruded polystyrene Penoplex in two sizes: 1185 x 585 x 20 and 1200 x 600 x 20 cm. It is most advisable to use the slabs for:

- implementation of atypical projects that require laying insulation of non-standard thickness: 70, 120 or 170 mm. Simply put, you can buy Penoplex 20 as an additional thermal insulation layer in a roofing pie, facade system, for installing heated floors, where you want to “increase” the standard extrusion thickness.

- insulation of window slopes where the existing opening needs to be reduced. Thanks to the use of a thin layer of polystyrene, you will not only save on finishing materials, but also speed up the finishing process, reduce heat loss through windows, prevent condensation, and therefore protect your house from fungus and mold.

The difference between Penoplex Base and Penoplex Comfort

In 2015, which has been producing PENOPLEX thermal insulation boards from extruded polystyrene foam for more than 18 years, began production of new brands of Penoplex such as Osnova, Facade and others.

What is the difference between the Basic and Comfort modifications?

The main technical characteristics, such as thermal conductivity, vapor permeability and water absorption, are the same for Penoplex Comfort and Basics.

Only the compressive strength indicator has different values. For penoplex Comfort, this figure is 0.18 MPa, and for Basics - 0.20 MPa. This means that the penoplex Base is able to withstand more load, and accordingly is more rigid.

This is due to the fact that the Comfort penoplex was initially intended only for retail sales, and the Osnova modification is intended for professional construction.

In conclusion, we can say that Penoplex Base is a unique and effective insulation material suitable for most surfaces. It gained its popularity due to its high quality and excellent thermal insulation properties.

Fodder beet growing technology

You cannot plant the roots in the same place the second year, as the soil there may be infected with pests.

Seeds are planted taking into account the principle of crop rotation. On large farms, beets are sown in forage and on-farm crop rotations. The best predecessors for growing fodder root crops are: rye and winter wheat, leguminous crops, vegetable crops with the exception of related ones (table beets) - early potatoes, carrots; annual grasses (alfalfa, phacelia), perennial grasses after a year of use.

ATTENTION! To obtain a good harvest after harvesting previous crops, the soil needs to be fertilized with manure and minerals, especially if the soil is light, sandy loam and poorly structured.

Let's consider the pros and cons

Are you considering using eco-friendly insulation when building or renovating a private home? If yes, that's great! There are several types of insulation. Extruded polystyrene , or penoplex, is one of the most popular.

Advantages

advantages

- Extremely low thermal conductivity coefficient . Only 0.032 W/(m×°K) - 22 times less than that of sand-lime brick.

- Moisture resistance . The granules of Osnova products do not absorb water, so the performance characteristics remain normal.

- Decent durability . The material holds its shape well and is difficult to damage or tear, which cannot be said about foam plastic.

- High sound insulation . A nice bonus when there is a noisy highway outside the window, or the house is located in a densely populated area.

- Ease of installation . tongue-and-groove locks on the edges of the sheets , so during installation you can do without adhesives.

- Biostability . It is not destroyed by putrefactive bacteria and mold fungi.

- Environmental friendliness . The thermal insulation contains no harmful substances. After installing it indoors, you won’t have to keep the windows wide open for a month.

- Long life span . The manufacturer assures customers that the product will serve faithfully for at least 50 years.

Flaws

Penoplex Osnova thermal insulation also has disadvantages :

- High flammability . The insulation belongs to class G4 , which means that its flue gases heat up to temperatures above 450 °C. Even if the polymer just starts to smolder, you will have to stay away from it.

- Low vapor permeability . The walls will hardly “breathe”, and the windows will fog up, so you need to equip the room with a high-quality ventilation system.

- Susceptibility to UV rays . The insulator is “afraid” of ultraviolet radiation. Under the influence of the sun, the structure of the granules quickly collapses . The solution is to coat the polystyrene with a finish.

The material is lightweight, making it easier to work with. You can cut the sheets using a regular painting knife .

Technical characteristics of insulation

When choosing thermal insulation, you need to pay attention to 2 main technical characteristics:

- Coefficient of thermal conductivity . The lower it is, the better, because the material is needed to retain heat inside the room, and not to “heat the street.”

- Moisture absorption level . A low score is good. This means that the polymer does not absorb water and, as a result, lasts longer.

“ Penoplex Osnova ” differs from other types of insulation in its decent strength, long service life and structural stability. According to research results, insulation is 1.5 - 2 times higher than the energy efficiency of polystyrene foam and mineral wool.

PENOPLEX COMFORT® and PENOPLEX®WALL - what's the difference?

Each brand of PENOPLEX® thermal insulation has its own characteristics and its own area of application. Let's analyze the similarities and differences between PENOPLEX COMFORT® and PENOPLEX®WALL boards, and note their advantages over insulation from other brands.

PENOPLEX COMFORT® and PENOPLEX®WALL are made of extruded polystyrene foam, which is characterized by high heat-shielding properties (thermal conductivity coefficient not higher than 0.034 W/m∙K), zero water absorption, biostability, and durability of at least 50 years. The material has a wide temperature range of application and is resistant to temperature changes, including alternating ones.

PENOPLEX® does not contain chemically hazardous components. In the production of boards, the same grades of polystyrene are used as for the manufacture of children's toys, food packaging and medical products, and the most stringent sanitary standards are applied to materials for the food and medical industries. We also note that plastic processing waste is not used in its production; only virgin polystyrene is used.

PENOPLEX® is certified with a high degree of environmental safety. The slabs are painted orange, which symbolizes warmth and environmental friendliness.

These are the common features of the two insulation materials. PENOPLEX COMFORT® and PENOPLEX®WALL have the same technical characteristics, except for durability. PENOPLEX®WALL has slightly lower compressive strength, since this parameter is not important for products that are attached to the facade and will not experience compressive loads. The most important difference: in the texture of one flat surface. The PENOPLEX COMFORT® board has both smooth surfaces, while the PENOPLEX®WALL has one of the two surfaces rough.

Application of PENOPLEX®WALL boards

For structural reliability, double fastening of PENOPLEX® slabs to the insulated surface is usually practiced: with an adhesive composition and mechanically using a dowel system with self-tapping screws. Mechanical fastening can also be used on the other hand: for finishing materials, for example, siding. But there are types of finishes that cannot be secured with nails or screws. We are talking about plaster and tiles.

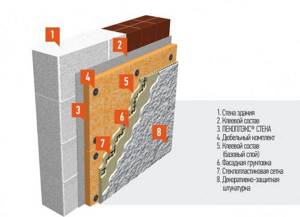

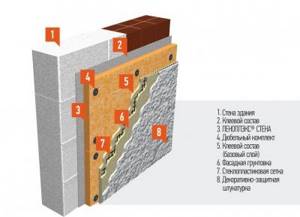

The process of constructing a wall with plaster finish is as follows. A layer of base plaster-adhesive composition is applied to the thermal insulation layer of PENOPLEX® slabs with a rough surface, reinforcing mesh is embedded into it, then, after drying, a façade primer is applied, and, finally, a finishing layer of decorative protective plaster. Therefore, for the reliability of such a plaster system, high adhesion (adhesion strength) of the insulation surface with the basic plaster and adhesive compositions is required. On the rough side of the PENOPLEX®WALL slab, this figure is, of course, significantly higher than on the smooth surface of PENOPLEX® slabs and the surfaces of other heat-insulating materials. In particular, it exceeds the adhesion of polystyrene foam by more than 1.5 times, and that of mineral wool by more than 2.5 times. It is important to note that the adhesive strength of the rough surface of PENOPLEX®WALL is 3 times higher than the standard value specified in the technical specifications for the use of adhesive compositions.

Thus, PENOPLEX®WALL slabs are intended for wall insulation followed by finishing with various types of plaster: cement, lime, lime-gypsum, cement-lime, polymer-cement, acrylic, etc. At the same time, PENOPLEX®WALL can be used both for external insulation with plastered wall, and internal with wall decoration with interior decorative plaster.

An example of a wall design with thermal insulation PENOPLEX®WALL and external finishing with plaster on a polymer mesh

From the smooth surface of PENOPLEX COMFORT® insulation, a layer of the base plaster-adhesive composition, polymer mesh, facade primer and decorative protective plaster may fall off over time due to insufficient adhesion.

Application of PENOPLEX COMFORT® boards

PENOPLEX COMFORT® is used where there is no need for a rough surface: for thermal insulation of balconies/loggias; heated floors (warm floor system) or pitched roofs. However, under certain conditions, PENOPLEX COMFORT® slabs can replace PENOPLEX®WALL slabs. The latter go on sale with a factory-quality rough surface. However, you can prepare the material for applying the plaster composition with your own hands. To do this, immediately before installation, notches are applied to PENOPLEX COMFORT® boards to improve adhesion. But it is better to buy a specialized plate that is prepared for plastering work in a factory.

Properties and characteristics

Before internal rebranding, when polystyrene boards were given more sonorous names, Penoplex Comfort was labeled as 31C and managed to earn a lot of positive reviews. These were sheets with a density of up to 31 kg/m3, treated with special reagents that promote self-extinguishing of the polymer. Now they are produced in a standard size of 1200x600 mm in 9 thickness options: from 20 to 150 mm. The specific gravity ranges from 25-32 kg/m3.

Like any extruded polystyrene foam, Penoplex Comfort insulation can boast an impressive list of advantages and positive properties:

- Thermal conductivity coefficient R is 0.03-0.032 W/m·K.

- Water absorption – 0.4-0.5%.

- Compressive strength – 120-180 kPa.

- Structural noise absorption – 23-41 dB.

- Resistant to biodegradation even in soil and high humidity.

- Good machinability and correct geometry.

- No shrinkage deformations.

- Service life of at least 50 years.

But despite its excellent performance characteristics, Penoplex also has disadvantages traditional for foam plastics: flammability (group G4) with the release of acrid smoke, as well as low temperature resistance - the operating range for this brand has an upper limit of +75 ° C. Another disadvantage, although not so significant, is the rapid aging and destruction of EPS under the influence of ultraviolet rays, so this insulation cannot be left outside the building for a long time without finishing.

Application

Penoplex slabs of the Comfort series have a profiled L-shaped edge: it is made in the form of a step, which allows you to lay insulation sheets in just one layer. Seams sealed in this way are not blown out and do not turn into cold bridges, so you can completely do without additional insulation of the joints. That is why extruded foam plastic is widely used in private construction, as well as for self-insulation of city apartments from the inside and outside.

Penoplex Comfort can be used in many facilities, but it is especially in demand where materials have to “work” in conditions of high humidity:

- Garages.

- Outbuildings.

- Swimming pools.

- Cellars and basements.

- Balconies and loggias.

It can even be used to insulate baths and saunas, but only where there is no influence of high temperatures, for example, to insulate washrooms or rest rooms. The manufacturer also included the blind area around the foundation and garden paths in the list of options for using Penoplex, but this is the limit of the capabilities of insulation of such a low density.

Reviews of Penoplex products

“I took Penoplex Comfort for the loggia when I connected it to the main area of the apartment. I did everything myself - I wanted to save as much as possible. It turned out that it is very convenient to work with thin slabs of 5 cm. Although for such small surfaces it would be better to purchase something without a stepped edge - I still had to cut off almost every sheet. But it fits well: no dust, cracks, crumbs. I couldn’t have done it so quickly with ordinary polystyrene foam myself.”

Andrey, Perm.

“I like the technical characteristics of the new Comfort. In addition, the manufacturer claims that it uses safe foaming agents in its production. So you can safely use it for internal insulation. But in this case it would be good to put the slabs on glue, but Penoplex has obvious problems with this. For reliability, I also had to fasten each sheet with fungi, so the work took more time than I would have liked.”

Nikolay, Rostov-on-Don.

“I bought Penoplex as a substrate for an infrared heated floor, plus I laid down a reflective film, and then attached plywood to the wooden sheathing, leaving a small air gap at the bottom. The insulation itself fits well and tightly like a “carpet”, although the surface still needs to be leveled so that the L-shaped joints fit together normally. By the way, a builder I know suggested not to use metal fasteners. According to his review, the glands will make rather large holes in the insulation in a few years due to the vibrations of the house.”

Vasily Makarov, Ekaterinburg.

“My neighbor at the dacha advised me to buy Comfort brand Penoplex when he was insulating his basement from the inside. I took EPPS for facade work. Overall, I really liked this material, and the effect was noticeable in the first winter. But gluing it turned out to be not so easy - here I agree with Nikolai’s review. The slabs, although not the highest density, are quite smooth on the outside: we had to scratch each one with sandpaper on the working side to ensure normal adhesion to the glue.”

Alexander, St. Petersburg.

“Equipping a country house of 100 square meters is an expensive pleasure, so for each part of it I considered thermal insulation separately, taking into account both efficiency and cost. But when it came to the base, it turned out that there was nothing to buy except Penoplex. A simple PSB does not hold the required load; everything else, as described, is afraid of high humidity. But with Comfort there are no such problems. The only thing is that insects love it very much. Within two days the first gnaws appeared in the finished layer, so we had to speed up the finishing.”

Pavel, Voronezh.

Cost of Penoplex slabs

Features: advantages and disadvantages

Previously, such insulation was called “Penoplex 31 C”. The high technical characteristics of this material are largely determined by its cellular structure. Cells ranging in size from 0.1 to 0.2 mm are evenly distributed throughout the entire volume of the product. This distribution gives strength and a high level of thermal insulation. The material practically does not absorb moisture, and its vapor permeability is 0.013 Mg/ (m*h*Pa).

The insulation manufacturing technology is based on the fact that polystyrene foams, enriched with inert gas. After this, the building material is passed under pressure through specialized press nozzles. The slabs are manufactured with clear geometry parameters. For comfortable joining, the edge of the slab is made in the shape of the letter G. The insulation does not contain harmful substances, so the material can be installed without using protective equipment.

Specifications:

- thermal conductivity index – 0.03 W/ (m*K);

- density – 25.0-35.0 kg/m3;

- long service life - more than 50 years;

- operating temperature range – from -50 to +75 degrees;

- fire resistance of the product;

- high compression rate;

- standard dimensions: 1200 (1185) x 600 (585) x 20,30,40,50,60,80,100 mm (for internal thermal insulation of a room, slabs with thickness parameters from 2 to 10 cm are used, for external finishing - 8-12 cm, for roofing – 4-6 cm);

- sound absorption – 41 dB.

Specifics of Penoplex production and its special properties

The first extrusion plant appeared in America more than half a century ago. During the production process, polystyrene granules are exposed to high pressure and temperature. The catalyst is a special foaming substance. This is usually a mixture of carbon dioxide and light freon. The resulting fluffy mass, reminiscent of well-whipped cream, is squeezed out of the extrusion unit. After some time, the freon evaporates, and air enters the cells in its place.

Thanks to extrusion, the produced material has a finely porous structure. Each of its identical tiny cells is insulated. The size of these cells ranges from 0.1 to 0.2 millimeters, and they are evenly spaced inside the material. This makes the material strong and warm.

Water absorption is minimal

For heat insulators, the ability to absorb moisture is an important characteristic. The following tests were carried out: Penoplex slabs were left in water for a month, completely immersed in it. Water was absorbed by them in small quantities only for the first 10 days, after which the material stopped taking up moisture. At the end of the period, the amount of water in the slabs did not exceed 0.6 percent of their total volume. That is, moisture can penetrate only into the outer cells of the penoplex insulation, which were damaged when cutting the material. But there is no access to water inside closed cells.

Thermal conductivity coefficient is small

Compared to many other thermal insulators, the thermal conductivity of Penoplex is significantly lower. Its value is 0.03 W*m* 0 C. Since the material practically does not absorb water, it is quite possible to use it where there is high humidity. At the same time, its thermal conductivity remains almost unchanged - it can vary only from 0.001 to 0.003 W * m * 0 C. Therefore, Penoplex slabs can be used to insulate both roofs with attics and foundations with floors and basements, without using an additional moisture-proof layer.

Vapor permeability – low

Like any extruded polystyrene foam, Penoplex is also characterized by increased resistance to moisture evaporation. A layer of slabs made of this material, only 2 centimeters thick, has the same vapor permeability as a layer of roofing felt.

Service life – long

By freezing Penoplex slabs many times and then thawing them, the researchers found that all the characteristics of the material remained unchanged. According to the conclusion of the NIISF Institute, these slabs can serve as thermal insulation for houses for at least 50 years. Moreover, this period is far from the limit; it is given with a large margin. At the same time, atmospheric influences are also taken into account.

Very resistant to compression

As already mentioned, extrusion makes it possible to achieve uniformity of the material structure. Evenly distributed tiny cells (tenths of a millimeter) improve the strength characteristics of penoplex insulation. It does not change its dimensions even under heavy loads.

Installation and processing – convenient and simple

This material can be easily cut with a regular knife. You can quickly cover walls with Penoplex slabs without using much effort. When working with this insulation, there is no need to be afraid that it will rain or snow. After all, Penoplex does not need protection from bad weather.

Environmental friendliness - at a high level

Perhaps someone may be scared by the fact that freons are used in the manufacture of this material. But the fact is that this type of freons is absolutely safe - they do not burn, are not poisonous and do not destroy the ozone layer.

Chemical activity – almost zero

Most chemicals used in construction are not able to react with Penoplex. There are, of course, exceptions - some organic solvents can soften insulation boards, disrupt their shape, or even completely dissolve them.

These substances include the following:

- Toluene, xylene, benzene and similar hydrocarbons (aromatic);

- formalin and formaldehyde;

- substances from the ketone class - methyl ethyl ketone, acetone;

- ethers, both simple and complex - methyl acetate and ethyl acetate solvents, diethyl ether;

- gasoline, kerosene and diesel fuel;

- polyesters used as epoxy resin hardeners;

- coal tar;

- oil based paints.

Here is also a list of substances that cannot damage Penoplex:

- Any types of acids – organic and inorganic;

- salts in the form of solutions;

- alkalis;

- alcohols and paints based on them;

- water and water-based paints;

- chlorine (bleach) lime;

- oxygen, carbon dioxide;

- butane, propane, ammonia;

- oils (both animal and vegetable), paraffins;

- cement and concrete mortars;

- freons.

It is also worth noting that the biostability of the slabs of this insulation is also high - they do not rot or decompose.

However, to ensure that the shape and size of Penoplex slabs remain unchanged, it is necessary to maintain the permissible ambient temperature at which this insulation can be used. Usually this parameter is indicated in the material passport. With excessive heating, not only the dimensions, but also the characteristics of Penoplex can change, since it can not only melt but also ignite. However, this is a drawback of all foam plastics, as you can see by watching the following video:

Video: How penoizol, polystyrene foam and Penoplex burn

Where is it used?

The performance qualities of Comfort penoplex allow it to be used not only in a city apartment, but also in a private house. If you compare insulation with other building materials, you can notice significant differences. Similar insulating products have a narrower specialization of application: thermal insulation of walls or roofs.

Penoplex "Comfort" is a universal insulation material that is used for thermal insulation of balconies, foundations, roofs, ceiling structures, walls and floors. The insulation is also perfect for thermal insulation of baths, swimming pools, and saunas. Penoplex Comfort insulation is used for both internal and external construction work.

Almost any surface can be finished with Comfort insulating material: wood, concrete, brick, foam block, soil.

Installation Tips

Insulation of external walls

- Preparatory work. It is necessary to prepare the walls, clean them of various contaminants (dust, dirt, old coating). Experts recommend leveling the walls with plaster and treating them with an antifungal agent.

- The insulation board is glued using an adhesive solution onto a dry wall surface. The adhesive solution is applied to the surface of the slab.

- Mechanical fastening of the slabs is carried out using dowels (4 pieces per 1 m2). In those places where windows, doorways and corners are located, the number of dowels increases (6-8 pieces per 1 m2).

- A plaster mixture is applied on top of the insulating board. For better adhesion of the plaster mixture and insulating material, it is necessary to make the surface slightly rough and corrugated.

- Plaster can be replaced by finishing with siding or wood.

If it is impossible to provide thermal insulation from the outside, then the insulation is installed indoors. Installation is carried out in a similar way, but a vapor barrier is placed on top of the insulating material. Foil-coated polyethylene film is suitable for this purpose. Next, they install the gypsum boards, onto which wallpaper can be glued in the future.

In the same way, work on insulating balconies and loggias is carried out. The joints of the plates are glued with special tape. After installing the vapor barrier layer, the joints are also taped, creating a kind of thermos.

Insulation of floors with Comfort penoplex under screed may vary in different rooms. The rooms located above the basements have a colder floor, so thermal insulation will require a larger number of insulating layers.

- Preparatory work. The floor surface is cleaned of various contaminants. If there are cracks, they are sealed. The surface should be perfectly flat.

- The prepared floors are treated with a primer mixture.

- For those rooms that are located above the basement, it is necessary to perform waterproofing. A mounting tape is glued along the perimeter of the room at the bottom of the walls, which compensates for the thermal expansion of the floor screed.

- If there are pipes or cables on the floor, a layer of insulation is first laid. After that, a groove is made in the slab, in which communication elements will be located in the future.

- When the insulation boards are laid, it is necessary to install reinforced polyethylene film on top of the layer. This is necessary to protect the insulating material from moisture.

- A reinforcing mesh is laid on top of the waterproofing layer.

Insulation technology

Penoplex Base is excellent for insulating both floors and walls.

Insulation of a wooden floor with joists

Next, all wooden surfaces are impregnated with antiseptic agents to prevent rotting. Recesses and cracks found on the boards must be filled with special wood putty. Next, all wood surfaces are primed. After the primer has dried, the installation of insulation sheets begins. They are cut according to the distance between the joists and the length of the room and placed on boards.

The joints between the foam boards should remain as tight as possible; they are additionally secured with construction tape. Next, sheets of vapor barrier material are laid overlapping on the foam boards. Boards, plywood or chipboard are attached to the vapor barrier layer. The final stage is the installation of flooring (linoleum, laminate, parquet).

Floor insulation when laid on the ground

When insulating floors in a house with a pile or strip foundation, the method of laying insulating material on the ground is used. First, you need to level the layer of earth and then compact it.

Next, crushed stone and gravel are poured onto the ground. Sand is then poured in and compacted. Penoplex sheets are laid on the sand “pillow”, starting from the corner, pressing tightly.

To protect against moisture penetration, a waterproofing membrane is laid on the foam sheets so that its edges extend 10-15 cm up the wall.

To strengthen the structure, the screed is reinforced with metal mesh. Next, a cement-sand mixture is used for the screed, which is poured over the mesh. Finally, after the cement layer has completely dried, linoleum is laid on it or laminate or parquet is laid.

Insulating the floor under the screed

When using this method of insulation, it is recommended to choose the Foundation modification of penoplex.

Insulation of walls from the inside

Penoplex Base is often used when insulating the internal walls of a house. Firstly, the walls are cleaned of the old coating and a layer of primer is applied. Next, they begin to attach the foam sheets to the walls.

First, the underside of the base foam sheet is passed with a needle roller to ensure better adhesion. Next, an adhesive layer is applied to the sheet, the sheet is applied to the wall surface and held for half a minute.

Gluing begins from the bottom corner, then moving up and to the side. The glued foam sheets are additionally fixed with plastic dowels with an umbrella cap. After the glue has dried, use foam to fill the gaps between the sheets.

Important: recesses more than a centimeter wide must be filled with scraps of foam sheets.

At the next stage, the fiberglass plaster mesh is attached with glue or using dowels. Next, a leveling layer of plaster is applied, and then a finishing layer of putty. Finally, the surface is painted or wallpaper is glued to it.

Insulation of external walls

When insulating the walls of buildings and structures from the outside, it is recommended to use Penoplex Facade, which contains special flame retardant substances to reduce the risk of fire.

The main criterion for choosing insulation

Insulation is selected according to its heat-protective ability. This property is quantitatively expressed in thermal conductivity, which shows how much thermal energy per second will be released from the room by one meter thick insulation when the temperature difference between inside and outside is one degree. Extruded polystyrene foam, from which PENOPLEX ® slabs of all brands are made, has low thermal conductivity: from 0.029 to 0.034 W/m•K. In this, the material is superior to other widely used thermal insulators - mineral wool and polystyrene foam, whose thermal conductivity, respectively, fluctuates in the ranges of 0.037–0.055 and 0.041–0.059 W/m•K. Thus, to create the same temperature conditions in a room, a layer of thermal insulation made of mineral wool or polystyrene foam will need to be 30–70% thicker than PENOPLEX ® slabs. Useful space is saved.

Calculation of insulation thickness

To create comfortable conditions in the house, it is necessary to select the material for insulation as carefully as possible. One of the most important characteristics is the thickness of the sheets of material. The choice of a certain thickness depends on the thermal conductivity of the materials from which the house is made, as well as on the average air temperature in winter. If a building located in the southern region is being insulated, sheets 30 mm thick are often purchased. In regions with a temperate continental climate, penoplex with a thickness of 50 mm is usually chosen. If the house is being built in a region with a sharply continental climate, it is worth purchasing sheets whose thickness is 100 mm.

Knowing parameters such as the thermal conductivity of walls and air temperature, you can easily select insulation. When choosing, it is important to find out about the manufacturer's recommendations. In addition, when purchasing, it is important to pay attention to the presence of a certificate of product compliance with the requirements. Its absence may indicate that the material is a fake.

Stability is a sign of class

PENOPLEX ® boards of all brands are durable. The service life of extruded polystyrene foam, according to test results at the Research Institute of Construction Physics, is at least 50 years. During all this time, the material stably retains its heat-protective properties due to zero water absorption. Water has a higher thermal conductivity than insulation and impairs the thermal insulation properties of non-moisture resistant materials, including fibrous mineral wool and granular foam.

Zero water absorption of PENOPLEX ® also deprives the source of life for bacteria, fungus, mold and other harmful microorganisms, for which this material, moreover, is of no interest as a food product. Thus, PENOPLEX ® is characterized by absolute biostability, which is confirmed by tests in mycological centers.

Material Sheet Size Options

Expanded polystyrene "Comfort" is produced in the form of sheets of standard size, 120 cm long and 60 cm wide. Extruded polystyrene foam, the sheet dimensions of which are 240 cm long, is considered non-standard.

The amount of material in the package depends on its thickness

The thickness of the heat-insulating material can range from 20 mm to 15 cm. The dimensions of the material packaging are 1.2 x 0.6 m, respectively, and the height is 30-42 cm. Thus, one package can contain from 1.44 m2 to 14.4 m2, depending on sheet thickness. When purchasing insulation, it is recommended to provide a reserve of about 10%, since small scraps of material are inconvenient to use.

Thermal insulation for buried structures: foundations, paths, septic tanks

For use in loaded structures!

Select sheet thickness:

—>

| 50 mm | 100 mm |

Description

PENOPLEX FOUNDATION® is a highly efficient thermal insulation material of the latest generation, manufactured by extrusion from general purpose polystyrene. Zero water absorption, high strength, low thermal conductivity and environmental friendliness are the main advantages of PENOPLEX insulation compared to other materials.

Application of PENOPLEX FOUNDATION®

A brand of slabs intended for use in private housing construction in loaded structures (for example, foundations, floors, plinths, garden paths). Plates of this type are characterized by increased strength and are able to withstand significant loads throughout their entire service life (more than 50 years).

Characteristics of PENOPLEX FOUNDATION®

- consistently low thermal conductivity;

- zero water absorption (homogeneous structure of sealed cells);

- high compressive and bending strength;

- absolute biostability;

- durability;

- environmental friendliness.

Norms/standards

- TU 5767-006-54349294-2014

- Production control and assessment is carried out by accredited laboratories

Appearance/Color

Surface: smooth Color: orange

Safety first

There are no toxic components in the composition of PENOPLEX ® boards. In their production, the same grades of polystyrene are used as for the manufacture of children's toys, food packaging and medical products. Materials for the food and medical industries are subject to strict sanitary standards. Consequently, PENOPLEX ® does not pose a danger to human health. We also note that plastic processing waste is not used in its production; only virgin polystyrene is used.

PENOPLEX ® is certified with a high degree of environmental safety. The slabs are painted orange, which symbolizes warmth and environmental friendliness.

A guarantee of high quality construction

PENOPLEX ® is stronger than other common heat insulators. Its compressive strength at 10% deformation is at least 15 t/m2. For the strongest mineral wool this figure does not exceed 7 t/m2, for polystyrene foam - 4.5 t/m2, which is why it is never installed on the roof.

Reliability is also important in construction. PENOPLEX ® has an L-shaped edge, which allows the boards to be tightly joined and thereby create a continuous heat-protective contour without cold bridges. This geometry, combined with the homogeneous structure of the material, distinguishes it favorably from mineral wool, which settles over time and voids form in the heat-protective system.

Penoplex Foundation

It is a polystyrene slab made by extrusion. The foamed mass passes through the molding nozzles by pressing. At the outlet, under the influence of high pressure and temperature, a porous structure containing cells with air is formed.

Main characteristics of Penoplex Foundation:

- Density 29-33 kg/m3

- Sound absorption – 41 dB

- Moisture absorption – about 0.5%

- Fire resistance – group G4

- Vapor permeability – 0.007-0.008

- Temperature range – 100 – +75c

- Compressive strength – 0.27 MPa

Application Limit

Features of the use of PENOPLEX COMFORT ® and PENOPLEX ® WALL are contained in their names. The first involves creating comfort, the second is intended for thermal insulation of wall structures. Let's consider the areas of application of these two products recommended by the company.

The scope of application of PENOPLEX COMFORT ® is as follows:

- insulation of apartment walls;

— thermal insulation of heated floors is allowed ("warm floor" system);

— thermal insulation of pitched roofs.

The first item on the list of areas of responsibility for PENOPLEX COMFORT ® are walls, which can be confusing. To prevent this from happening, let's look at the similarities and differences between the two brands.

They have the same technical characteristics. They differ from each other only in the texture of one flat surface. The PENOPLEX COMFORT ® slab has both smooth surfaces, while the PENOPLEX ® WALL has one rough surface, which is achieved by factory milling. Why process a smooth surface and thereby increase the cost of the product? Where is it appropriate to use it?

Insulation Penoplex TYPE 45 (2400 mm x 600 mm x 50 mm)

Designed for thermal insulation of loaded structures: inversion roofs, roads and railways, airfield runways.

1 package = 8 slabs. Area of the slabs in the package, m2 = 11.09. Packaging volume, m3 = 0.5544.

Designed for thermal insulation of loaded structures: inversion roofs, roads and railways, airfield runways.

- 40

- 50

- 60

- 100

- Geo

- Geo C

- Comfort

- Roof

- Roof Slope

- The basis

- Type 45

- Type 45C

- Facade

- Foundation

Insulating the soil under the coating allows you to eliminate or reduce its freezing and, thereby, prevent such processes. The ideal material for thermal insulation of road surfaces is Penoplex® 45.

Rough nuance

This is advisable where a rough surface is indispensable. PENOPLEX ® WALL slabs are used for thermal insulation of walls with finishing without mechanical fastening. In other words, where the finishing material cannot be attached using nails or dowels with self-tapping screws, but you have to rely only on adhesive forces (adhesion). We are talking about finishing with plaster and tiles.

Let us remind you that the plaster system is erected as follows. A layer of base plaster-adhesive composition is applied to the heat-insulating layer of PENOPLEX ® slabs with a rough surface, reinforcing mesh is embedded into it, then, after drying, a facade primer is applied and, finally, a finishing layer of decorative and protective plaster. Therefore, for the reliability of such a plaster system, high adhesion (adhesion strength) of the insulation surface with the basic plaster and adhesive compositions is required. On the rough side of the PENOPLEX ® WALL slab, this figure is, of course, significantly higher than on the smooth surface of PENOPLEX ® slabs and the surfaces of other heat-insulating materials. In particular, it exceeds the adhesion of polystyrene foam by more than 1.5 times, and that of mineral wool by more than 2.5 times. It is important to note that the adhesive strength of the rough surface of PENOPLEX ® WALL is 3 times higher than the standard value specified in the technical specifications for the use of adhesive compositions.

Thus, PENOPLEX ® WALL slabs are intended for wall insulation with subsequent finishing with various types of plaster: cement, lime, lime-gypsum, cement-lime, polymer-cement, acrylic, etc. At the same time, PENOPLEX ® WALL can be used both for external insulation with plastered wall, and internal with wall decoration with interior decorative plaster.

An example of a wall design with thermal insulation PENOPLEX ® WALL and external finishing with plaster on a polymer mesh.

PENOPLEX ® WALL is a highly specialized insulation, in contrast to PENOPLEX COMFORT ®, which can be called a wide-profile insulation.

Concluding the story about the differences between the brands PENOPLEX COMFORT ® and PENOPLEX ® WALL, we note another important possibility of using thermal insulation. PENOPLEX ® WALL slabs go on sale with a factory-quality rough surface. However, you can prepare the slab for applying the plaster composition yourself. To do this, immediately before installation, notches are applied to PENOPLEX COMFORT ® boards to improve adhesion. But it is more advisable to purchase specialized PENOPLEX ® WALL boards, which are prepared for plastering work in the factory.