Replacing the membrane for a geyser (video)

Gas water heaters are so common today that few people don’t know how to handle them. However, when devices break down, many fall into despair. There are types of breakdowns that can be quickly eliminated. To do this, you can either contact a special service or do the repair yourself. But you should be extremely careful. Often, the cessation of heating by the water column is affected by the breakdown of the membrane. It is she who passes water to the heating device. Membranes can be made of rubber or silicone, but they all tend to wear out.

The process of replacing the membrane in a gas water heater

The membrane is designed to separate the cavities in the water regulator. Despite the quality of the column and its manufacturer, the membrane wears out over time, which leads to its ruptures. This type of malfunction is very common, but anyone who has first read the instructions can cope with choosing a new membrane and replacing the old one.

Before you start replacing the membrane in a gas water heater, you should watch a training video with a master class

Self-repair without special skills and knowledge may result in equipment damage. Also, self-repair is very dangerous because a gas leak may occur. If any difficulties arise during self-repair, you should immediately contact the gas service.

Membrane replacement process:

- Turn off the speaker.

- Turn off cold water and gas.

- Open the hot water tap slightly to change the pressure in the pipes.

- You need to open the tap that is located closer to the column. Usually we are talking about a faucet in the bathroom.

- When disassembly occurs, water from the heat exchanger and pipes will flow out through the open tap, and the siphon effect will help with this.

- There is no need to open a kitchen faucet that is located higher than the water regulator. This can result in 3 to 5 liters spilling onto the floor.

- Remove the column casing. Finding attachment points will not be difficult. The absence of a casing will make the internal structure of the column accessible.

- Remove the water regulator. To do this, you need to remove the union nuts and fixing screws.

- Disassemble the regulator and replace the membrane.

Changing the membrane is not difficult

But it is important to ensure that all actions are performed correctly. The membrane should not be upside down; the bypass channel, which facilitates the integration of the water unit, should not be blocked

Principle of operation

To correctly understand the principle of operation of a gas water heater, you must first understand how its security system works.

If the device is turned off, the control unit of the geyser stops receiving power, because The electrical circuit in the switch is broken. This occurs due to the fact that the pushing mechanism presses the switch plate and keeps it off.

The electromagnetic valve on the gas column is also in a closed state and blocks the gas flow from the inlet pipe, because No power is supplied to it either. However, not only does it prevent the passage of gas: the spring valve located in the gas module is also turned off, and the outflow of gas into the manifold is completely closed.

The main element of the water reducer of a gas water heater is a two-chamber module with a bending membrane, popularly called a “frog”. These modules communicate with each other using the appropriate channel. If the water supply is turned off, the pressure in the chambers is equalized.

Who is allowed to replace the column?

Often, when faced with the need to replace a gas water heater for the first time, its owners have a fair question: is it possible to connect a new gas water heater instead of the old one?

An unequivocal answer to this is given by the Decree of the Government of the Russian Federation No. 410 of May 14, 2013, which states that independent replacement of gas equipment is prohibited. It should only be carried out by specialized organizations with which an agreement has been concluded for the maintenance of gas appliances. Lists of companies with which such an agreement can be concluded are published in the notification registers on the regional websites of the State Housing Inspectorate.

A commissioning certificate must be issued for the installed gas water heater. In its absence, a fine of 10–15 thousand rubles is imposed. (according to Article 7.19 of the Code of Administrative Offenses of the Russian Federation). If an unauthorized connection leads to damage to property and people’s lives, criminal liability may arise, as stated in the Criminal Code of the Russian Federation.

You can choose an organization to enter into a contract for the maintenance and repair of VDGO and VKGO based on ratings, reviews, and study of permits

In addition, independent replacement will not allow you to put a new column under warranty. The organization that carried out the installation makes entries in the device passport and seals them. Only after this the dispenser is considered accepted for service and subject to warranty service.

In addition to the responsibilities to comply with standards and requirements, owners have the right to independently choose an organization to create a project and carry out installation work. The main condition is that they have the appropriate licenses.

All work related to the gas supply system can only be performed by specialists who have the appropriate permit to work with gas equipment and have passed annual recertification.

Design and operating principle of PGV "Neva"

The series of instantaneous gas water heaters (PGW) of the Neva brand includes many models and modifications. Today, the most popular are NEVA-4510M, NEVA-4511, NEVA 4513M with electric ignition.

They are manufactured at the factories of the domestic company BaltGaz Group in accordance with GOST 31856-2012 and include:

- metal case;

- gas path;

- water circuit;

- burner;

- combustion path;

- security system;

- control system;

- adjustment block.

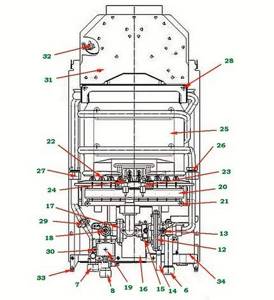

The listed nodes consist of many elements, some of which are shown in the diagram below.

Main positions: 6, 7, 8 – pipes for water supply, hot water supply and gas pipes; 12 – water block; 13 – tap for adjusting water flow; 15 – microswitch; 16 – control unit, 17 – gas unit; 18 – gas flow adjustment valve; 19 – electromagnetic gas valve; 20 – burner; 23 – candle; 24 – flame sensor; 25 – heat exchanger; 29 and 32 – overheating and draft sensors; 34 ¬ battery compartment

The water circuit begins with a pipe connected to the cold water pipeline and is pumped into the hot water supply pipe. This includes the water block, which plays a key role in electric ignition. It consists of a lower and upper chamber, between which there is an elastic membrane.

When the tap is turned on, a stream of cold water rushes to the heat exchanger, but along the way it passes through the lower chamber and completely fills it. Under water pressure, the membrane of the gas column bends and presses on the poppet valve of the rod located in the upper chamber.

The water block rod extends through the hole and acts on the coaxially located gas block rod. This, in turn, acts on a mechanical gas valve, the plate of which moves back and allows gas to pass through, instantly filling the burner manifold.

At the same time, when the rod moves, the microswitch plate is triggered, closing the electrical circuit.

Electrical current comes from batteries located in the battery compartment and powers the control unit, which supplies electrical voltage to the glow plug and opens the solenoid valve. Spark discharges occur between the burner nozzle and the spark plug electrode, igniting the burner.

The heat produced by burning gas is transferred to a heat exchanger pipe through which water flows. As a result, a few minutes after turning on the tap, hot water flows out of it. When the tap is turned off, the reverse processes occur and the burner goes out.

On the front side of the cladding there are adjustment knobs, as well as a display that displays the water temperature at the water intake point

Gas is one of the cleanest types of fuel in an environmental sense, but its combustion also releases carbon dioxide, water vapor, and nitrogen. They are removed from the combustion chamber to the outside through the gas exhaust pipe and chimney of the gas boiler. Removal of combustion products is possible only if there is proper draft in the chimney.

To control the operation of the column and ensure its safe operation, the following sensors are included in the design:

- presence of flame;

- presence of traction;

- water temperature.

Thanks to these components, gas flows to the burner only when the tap is turned on and there is water in the water supply. If the burner goes out for any reason, the gas supply is immediately stopped.

The automatic shutdown of the water heater is caused by the lack of proper draft in the chimney and an increase in the water temperature at the water intake point to 90°C. If the pressure in the water circuit reaches a critical value of 1000 kPa, the emergency valve is activated and excess water is drained.

Modern models are equipped not only with knobs for adjusting water and gas flow, but also with a “Winter/Summer” knob, which is set to the desired position depending on the time of year

Now that you have become familiar with the structure and design of the Neva gas water heater, you can move on to the next chapter of the article, in which we will list the most common malfunctions, the causes of their occurrence and solutions.

Please take into account that the manufacturer recommends that in order to perform maintenance and repair work related to disassembling the gas-water unit, you call the employees of the service center, with which an agreement has been concluded for the supply of gaseous fuel and equipment maintenance

Mandatory Precautions

When switching on, safety precautions are important. Ignition of the wick or burner is carried out using the instruction manual.

What you need to know:

- Advanced devices have several levels of protection. The work happens automatically. There are no special rules for use. The wick is lit after opening the hot water tap.

- Old models of geysers have problems in use. These include ignition with matches and the inclusion of brands with piezo ignition.

- You should not operate the device “at random”; the instructions for the device should be read first.

- It is forbidden to change the design of the column with your own hands.

- Do not light the device if there is no draft or if there is reverse draft.

Reviews about the main benefits

By choosing a column of the Neva-4513 brand, you get a device that, according to consumers, has many positive features, among them the following should be highlighted:

- safe use;

- simple controls;

- presence of automatic ignition;

- lack of a constantly burning flame;

- two-stage hydraulic modulation of the burner flame.

As consumers emphasize, “Neva-4513” has automatic ignition, which indicates that the device can operate when the tap is opened. Everything happens automatically, as does the termination of functioning. The column is durable, in addition, it is capable of operating even at a minimum water pressure of 0.3 bar. Buyers especially note that the equipment is highly powerful and is also complemented by a safety system that has an ionization flame control sensor.

How to clean the frog?

The unit should be cleaned every year. After removing the cover or disassembling the gearbox into two parts, the inside of the unit is cleaned and the elements are maintained. The process of cleaning the unit removes scale and solid particles that have settled at the bottom of the unit. You should also clean the mesh on the inlet pipe. It is recommended to lubricate the rod with castor oil or grease. The gasket also needs to be lubricated if it feels like it has lost its elasticity.

Caring for the elements of the water block will extend the service life of the gas water heater and reduce the likelihood of any malfunctions.

During each cleaning, the functionality of the components is checked and, if necessary, they are replaced:

- replacement of the stem seal is usually required approximately every 3 years to protect the gas valve from moisture;

- the membrane should be changed when microcracks appear or ruptures occur.

Worn parts need to be replaced with new branded products. The membrane can be purchased separately, however, if desired, you can also find a kit that includes all the components for replacement.

Assembling the device

In old Neva and Astra water heaters, we replace the top cover of the water regulator and tighten the eight screws according to the principle of one opposite the other. We determine where the entrance to the regulator is and place it next to the pipe through which water enters the column. The water unit is inserted into the gas unit and three screws are tightened, with which they are attached to each other. It is advisable to change the gaskets at the inlet and outlet. After this, tighten the union nuts with a 24mm wrench.

In new water heaters, we tighten four screws on the water regulator and screw the water-gas unit to the burner. Next, we screw the burner block to the rear wall, connect the ignition and ionization electrodes, and tighten the union nuts with a wrench.

After assembly we check. With the hot water tap open, gradually turn on the water at the inlet of the column. We make sure that there are no leaks anywhere. You can double-check by running dry wipes on the union nuts. After a few minutes, close the tap and check the same connections, but under pressure. If everything is in order, the gas valve opens and the operation of the column is checked. It is important to check the gas connections by applying a soap solution. If there are no leaks anywhere and everything works, you can attach the column casing.

Also, see the video for replacing the membrane of the Astra VPG-21 1-B11-UHL 4.2 column:

Silicone membrane repair: tips

Gas water heaters in our country are represented by a large number of manufacturers. At the same time, the speakers themselves are almost no different from each other in terms of internal functional content. The disadvantage of many speakers is that the membrane often breaks.

If the silicone membrane is severely damaged, it is better to replace it

Many users claim that after replacing the rubber membrane with a silicone one, problems with water heating and leakage stop. But it is also impossible to guarantee the long service life of such a membrane. Therefore, many users ask questions about whether it is possible to repair a membrane made of silicone.

Silicone membrane repair:

- Try to seal it with sealant.

- Use Pentoelast.

- Choose a silicone sealant that has a high stretch coefficient.

- Try gluing the patch.

- Apply tape.

Many agree that the silicone membrane simply needs to be replaced. This approach may be justified, since constant repairs will lead to a waste of time, effort and nerves. Replacing a part is not that difficult if you know how to handle the column in general. The most common speaker models for which users are looking for new membranes are: “Vector”, “Beretta”, “Oasis”.

What are membranes for geysers?

A person's life should be comfortable. To achieve convenience, many people equip their homes with various modern devices. Some of them are necessary to have in every home, since without them the standard of living is significantly reduced.

The membrane for a geyser is a round rubber or silicone gasket

With the right choice of column and its use, you can be sure of its long service life. But it also happens that the column breaks. In such situations, owners often do not know where to start repairing. If the outlet water is not at sufficient temperature, the problem is definitely in the membrane, which may have become unusable.

What is a membrane:

- In most speakers, the membrane is made of rubber.

- The membrane for a geyser quite often becomes unusable, the material wears out, which leads to its rupture.

- The membrane is installed in the water unit of the device. It regulates water pressure.

- If the column is turned on, the membrane bends.

- Gas is supplied to the burner, starting the water heating process.

If the membrane is damaged, the column stops heating water efficiently, since cold water does not enter the heat exchanger. After a membrane breaks, many owners wonder how to find a new membrane, what quality it should be, and how to choose a membrane for a specific speaker model. It should be noted that in most cases the speaker design is similar.

Preparing for replacement

To change the membrane in a gas water heater, first of all, you should shut off the water at the inlet to the water heater or in the entire apartment. After this, the gas valve closes and the hot water tap opens. You should open the tap that is located lowest in the apartment, usually it is in the bathroom. Then all the water from the system will drain and will not interfere with repairs.

To replace the membrane, we will need Phillips and flat-head screwdrivers, 24 and 19 wrenches, a new membrane or a repair kit.

Before removing the casing, remove all the handles from the front side and disconnect the wires from the display, if present. In some speakers, the housing is additionally secured with screws that are located at the bottom and top of the speaker, under the adjustment knobs or decorative trims. The casing is also secured with simple latches.

Indications for repair

During the use of the column, due to the pressure on the membrane and the hard water entering the device, small cracks and areas of deformation appear on the diaphragm. To see them, you need to remove the membrane and inspect it carefully. Quite often, an assessment of the condition of the diaphragm and its subsequent replacement is performed during the annual maintenance of the column.

Problems with turning on the column will tell you that the membrane has worn out before the scheduled check. In this case, you should first make sure that gas is supplied to the column, and that water is supplied with sufficient pressure. If your column uses piezo ignition, clean the pilot burner(s). If after such cleaning the device does not turn on, most likely the membrane is damaged and the device needs to be disassembled.

If your column turns on via electronic ignition from batteries, when you turn it on and hear clicks, then everything is in order with the membrane, and the problem most likely concerns the gas path or the ignition electrode. If there are no clicks when turning on, damage to the membrane is the most likely cause of failure, which can be easily verified by disassembling the unit.

In some columns, the condition of the membrane can be determined by the rod that controls the switch of the electronic unit. After removing the column casing and opening the hot water, look to see if the rod has moved. If it's the diaphragm, the rod will stay in place.

In situations where damage to the membrane is minimal, but increases over time and leads to rupture, water will flow inside the cavities of the water regulator, which leads to the device not operating at all possible power. Gradually the power drops and eventually the speaker stops turning on completely.

Speaker malfunctions

Let’s immediately make a reservation that we will consider the problems of flow-through heaters with an open combustion chamber, of which there are a great many installed in apartments and houses. We will bypass the repair of fully automated turbocharged dispensers with power supply from the mains and ignition from a hydrogen generator. These devices are quite complex and intervention in their design by an ignorant person is contraindicated. Troubleshooting of supercharging units should be carried out by service or gas services.

The list of malfunctions inherent in geysers after several years of operation is as follows:

- smell of gas;

- problems with ignition and starting of the main burner;

- turning off the heater during operation;

- various leaks.

If you smell gas, whether constantly or periodically, you must immediately turn off the appropriate tap, open the windows and call the emergency service. Explain to the dispatcher the nature of the problem, and he will make a decision - to urgently send a team to your home or simply send a technician on a first-come, first-served basis. There are no other options; fixing methane leaks yourself is strictly prohibited

There are no other options; fixing methane leaks on your own is strictly prohibited.

Tips for choosing

- When choosing a suitable membrane for a gas-powered water heater, you need to take into account the brand of the device, since some columns have round diaphragms, while others have parts with a rather complex shape.

- If you were unable to find a round diaphragm specifically for your speaker, it is permissible to purchase and install instead a part of the same diameter for a speaker from another manufacturer, for example, a membrane with a diameter of 73 mm.

- If the column has been serving you for more than five years, buy the membrane immediately with the plastic parts that are adjacent to it (over time, plasticizers are washed out of them, which leads to fragility).