Good evening. We have a Bosch wall-mounted gas boiler installed. It has been working for five years. An aluminum corrugation goes from the boiler to the pipe in the ceiling. And recently we had guests, and one friend casually noticed that corrugation cannot be used for a hood. But I don’t feel like calling raygaz and running into trouble. Tell me, is it possible or dangerous?

In some places it is strictly forbidden, in others it is not recommended. My advice is to definitely remove it. Sooner or later, the corrugation burns out, and carbon monoxide begins to flow into the house - an instant death for everyone. Aluminum corrugation is an element of AIR ducts, not chimneys. Replace it with an elbow or tee made of stainless steel or ferrous metal; now there are enough companies that make chimneys to size. Life and health are more valuable than any piece of iron.

Can corrugation be used as a hood for a gas boiler?

Guest wrote: Yes, this corrugation has been standing for years and nothing happens to it! And stainless steel costs 10 times more, you’re just cheating people!

No, we are thinking about your safety and ours. If we install corrugation during installation and something happens, who will be the last one? That's right, we will be responsible. And how many of these corrugations have already been burnt out, when you start dismantling, it falls apart in your hands. The only thing that saved the owners was the presence of draft in the chimneys. So think what is more important - life or wallet, as they say.

Act on unauthorized gas connection

Officials of gas services have the right to draw up this act. It must have the following elements:

- Information about the official who compiled it.

- Information about the offender.

- Information about connecting to networks bypassing the meter, illegal installation of gas equipment, the extent of natural gas theft, etc.

- Information about sanctions imposed on citizens.

- Orders to eliminate violations.

- Date of document preparation and information on appeal methods.

The citizen faces punishment in any case. However, its specific type depends on the situation in which a particular violation was detected.

A sample act can be downloaded here. ⇐

Can corrugation be used as a hood for a gas boiler?

It is absolutely not possible if this incomprehensible “corrugation” is intended for air ducts. You need to check in the certificate or other documents for this product whether it can be used to transport media with temperatures above 100 degrees. In addition, the corrugation has increased aerodynamic resistance, which does not have the best effect on traction. If the chimney is not very high (as is often the case in one-story houses with a low ridge), then its gravity may not be enough to ensure normal smoke removal.

Can corrugation be used as a hood for a gas boiler?

Rikota wrote: It is absolutely impossible if this incomprehensible “corrugation” is intended for air ducts. You need to check in the certificate or other documents for this product whether it can be used to transport media with temperatures above 100 degrees. In addition, the corrugation has increased aerodynamic resistance, which does not have the best effect on traction. If the chimney is not very high (as is often the case in one-story houses with a low ridge), then its gravity may not be enough to ensure normal smoke removal.

Rikota, you are wrong! According to the passport, aluminum corrugation can be used at temperatures up to 300C. This is quite enough to remove gases from the gas water heater! Many people have it in their apartments and it hasn’t even lost its original luster! It can be used for speakers. And the diameter must be selected based on the size of the outlet pipe of the column and there will be draft!

Types of heaters and boilers for apartments (including Khrushchev)

If we talk about gas heaters, they can be flow-through or storage. But in Russia, gas boilers are not widely used, because they are less convenient, cost more and take up a lot of space. They should only be installed if the gas supply is too weak. Mostly they install instantaneous gas heaters. You can find out how many sockets you need in the kitchen here.

Modern models may have a closed or open combustion chamber. Open ones are a little safer and require less paperwork during installation. They are needed if there is no chimney in the house. The latter are suitable if the old heater is being replaced with a new one, the chimney and gas supply have already been made and tested.

Suppliers offer 3 types of power. 17-20 kW is needed for a one-room apartment with 1 inhabitant. If a person takes a shower, there is no longer enough power to wash dishes. Devices with a power of 20-26 kW are indispensable for apartments. They provide 15 liters of water per minute at a temperature of 40 degrees. The power of an average heater is enough for a family of 4 people and an apartment with 1 shower and 2 sinks. A power of 26-28 kW is suitable for two-level apartments or houses. You can find out what kitchen hoods there are by following this link.

Can corrugation be used as a hood for a gas boiler?

Everyone uses aluminum everywhere I go. Just as agreed. A friend of mine had a speaker at home when he was in college, and they often hung out with him. The speaker was old, like NEVA or something, I remember that it turned on with a strong bang. The corrugation of the hood was aluminum and it did not darken at all over time, only a little from dirt, soot and dust. Nobody wants to overpay in short...

You do not have the necessary permissions to view the attachments in this message.

14 Feb 2013, 08:54

Folks, what should I use to make the connection to the hood for the gas water heater? There are stainless steel corrugations on sale, but they are expensive, and there are ventilation corrugations - aluminum. I don’t know if the column exhaust will burn through aluminum, because it melts at a temperature of only 660C. And the flame temperature exceeds 1000C.

14 Feb 2013, 09:10

This is a common misconception. Although the flame temperature is about 1300C, the exhaust temperature drops sharply to 200-300C. This is quite normal, aluminum holds up well. The farther from the gas water heater.

The temperature is of course lower. At the entrance to the ventilation it does not exceed 100C at all.

You do not have the necessary permissions to view the attachments in this message.

Common mistakes

Errors when installing ventilation elements can lead to disruption of the proper operation of the structure and loss of operational safety. The most common are the following:

- Combination of hoods for a water heater and a gas stove, or for a gas boiler. In this case, reverse draft may occur in the ventilation shaft and carbon monoxide will return to the room;

- Do not connect two speakers to one chimney;

- The next mistake concerns the installation of a geyser - it is often placed in the bathroom, this cannot be done. All gas appliances must be installed in rooms with a window;

- Self-taught craftsmen often confuse the ventilation duct with the riser supplying water to the column. The consequences of such an error will be the replacement of all gas equipment, not only for you, but also for your neighbors below. Gas services remove liquid. They will turn off the gas and issue a hefty fine;

Is aluminum corrugation suitable for a geyser?

25 Mar 2013, 05:08

Igor_01 wrote: The most important thing here is to maintain the required diameter of the chimney. The smaller it is, the correspondingly higher the wall temperature will be. If you take a 125mm pipe, the temperature will not rise above 150C, but if it is 80C, then it may well float at the connection point.

Aluminum loses strength greatly at temperature; it is not steel.

In general, the diameter of the gas duct should not be taken at the sole discretion of the owner of the device, but strictly correspond to the design, without which gas-using equipment should not be installed.

When designing, the diameter is selected in accordance with the instructions in the passport for the column. Fundamentally, the technical documents for the so-called “corrugation” must indicate the maximum temperature of the environment for which this product is designed. If the temperature is higher (with a margin of at least 30 percent), then you can use it.

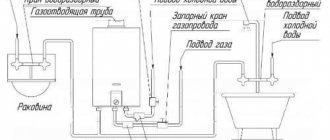

The chimney for a gas water heater is usually made in the form of a corrugated metal hose. There is another design - sections of steel pipes, coaxial chimneys. Because of their efficiency, coaxial chimneys have become widespread. The most important characteristics of the system are reliability, long service life, and preservation of its original qualities. A geyser is the optimal solution for hot water supply for houses, as well as for apartments. There will always be hot water, regardless of maintenance and repair work. A chimney is needed to remove combustion products. The dimensions and technical parameters of chimneys depend on the power and type of equipment.

Components of the chimney:

- the upper element is a cone - a protective head (umbrella)

- The next part of the system after the head is the chimney. It can be either with or without thermal insulation.

- the passage pipe provides insulation of the chimney from the wall of the building.

- brackets designed for fastening to the wall of the chimney.

- clamps installed at pipe joints.

- tee for transition from column to pipe.

- inspection window for monitoring the condition of the pipe.

- condensate collector. Condensation is formed as a result of the operation of the entire system.

Things to consider before installing a chimney:

Basic provisions for the chimney of a geyser:

Is it possible to install a corrugated chimney pipe?

A chimney made from corrugated pipes can be used for heaters, stoves and boilers. Pipe bends are used to complete heating equipment that runs on different types of fuel: diesel fuel, wood, gas and pellets.

Corrugated pipes are designed for the following operating conditions:

- Internal chimneys.

External smoke removal systems.

As adapters for connecting boilers and furnaces to the main smoke exhaust system.

For carrying out repair work - lining the chimney.

At the moment, there are two main types of products that have the same design, but differ in the material from which they are made. The consumer is offered products made of stainless steel and aluminum.

What types of chimneys are there for geysers?

Corrugated chimneys are made from material - laminated multilayer aluminum foil. Along the entire length of the pipe, between layers of aluminum, there is a reinforcing steel wire. The distinctive ability of corrugated foil pipes is the ability to increase their size up to three meters.

The chimney of the geyser is made of steel. Made from high quality steel. Executed in the form of pipe sections. Their length is from one to one and a half meters. On steel chimneys, no more than three bends are allowed. To protect the pipes, they are coated with heat-resistant enamel. The weak point is the need to insulate the pipe in the winter season.

Coaxial chimneys are made of two pipes located one inside the other. Connections are made using special jumpers. Because of them, the pipes do not touch. Street air is supplied to the burner through an external pipe. And the exhaust gases exit through the central one to the outside. Thanks to this design, the street air is heated from the central pipe, increasing the efficiency of the system.

There are two designs of coaxial chimney - horizontal and vertical.

Double-circuit chimney pipes. These chimneys are made from stainless steel. They consist of two pipes, one is inside the other. The inner pipe is separated by thermal insulation made of mineral wool. This has its positive aspects - there are no foreign odors, no condensation forms.

Installation

Installation work will depend on the selected duct.

- If you settled on a steel pipe, then you need to purchase the necessary adapters for it. To find out what length of pipe is required, measure the distance from the column to the ventilation duct opening. Installation of the pipe and adapters is quite easy and resembles the assembly of a construction set. To secure the duct and seal its connections, use sealant.

- If you decide to use a corrugated air duct, then you do not need to purchase any adapters. The corrugation is stretched to the required length to connect the ventilation system and the column. If you need to add length, use metal tape for this.