A little about the types of insulation

Next, we will look at insulation materials suitable for insulating the attic floor, its gables and roof. There are a great variety of materials offered to us in stores, and they all have different physical and technical characteristics. Let's figure out which insulation is better for the attic.

Mineral wool

The most popular material for insulating the attic floor is produced by different companies - Rockwool, Ursa, etc. Mineral wool has low thermal conductivity and absorbs sound well. It is worth mentioning the fire safety of the material: slag wool begins to smolder at 300C°, stone wool at 600C°, and basalt wool in general only at 1000C°. Mineral wool has only one significant disadvantage: it gets wet.

It is produced both in rolls - soft, and in slabs - more rigid, with a higher density. If the attic has a ceiling, we “insulate” it with rolled rockwool or similar mineral wool from another company. For gables, slab types of mineral wool are better suited: roll types, due to their softness, when installed on a vertical surface, will sag over time.

The best way to insulate an attic from the inside: mineral wool

Insulation of the attic floor with penofol

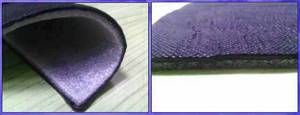

The material has good thermal insulation qualities, but insulation with penofol as an independent material is impossible, it is too thin. But it can be used as additional insulation and a replacement for vapor barrier, although due to its vapor resistance it requires good ventilation.

How to properly insulate an attic from the inside: penofol is suitable only as a vapor barrier

Penoplex and polystyrene foam for insulating the attic floor

Penoplex and polystyrene are both derivatives of polystyrene. Reviews about attic insulation with polystyrene foam are generally not bad. The same applies to penoplex. Both materials retain heat well, almost do not absorb moisture and are very light in weight. In addition, insulation with extruded polystyrene foam is quite cheap.

Insulating an attic with a simple roof with polystyrene foam is possible, but with a broken one you will have to tinker. No matter how precisely you cut the slabs of material, it will not fit 100% tightly to the roof structures, but our gables are adjacent to it. And foaming of cracks, which is usually used in such cases, cannot be used here.

How to insulate an attic floor: penoplex and polystyrene foam

An interesting way to insulate an attic with polystyrene foam: video of filling polystyrene foam granules under the film.

Sawdust and ecowool

Sawdust is the cheapest and most environmentally friendly material of all. The use of the material as insulation began a very long time ago; this is, so to speak, an old-fashioned way. Sawdust has good thermal insulation properties and will also protect against noise. However, the material is susceptible to fungal and putrefactive infections, easily absorbs water, and over time the sawdust cakes. They are not suitable for insulating the attic roof and its gables, but the material can be used for the floor.

Insulating the attic from the inside with your own hands: sawdust

Ecowool is probably not inferior to sawdust in terms of environmental friendliness. But in terms of technical qualities, it is much better. Ecowool does not cake, does not rot and is not affected by fungi. The quality of heat and sound insulation is excellent, suitable for installation on all surfaces. But you won’t be able to insulate an attic with ecowool yourself—the technology requires special equipment.

Insulation of the attic gable: dry blowing of ecowool under the vapor barrier membrane

Ecowool for attic insulation. Video of wet application of material.

Insulation of the attic floor with polyurethane foam

Reviews about attic insulation with polyurethane foam are, for the most part, very good. It is universal in use, equally suitable for insulating gables and ceilings, as well as for attic roofs. The material does not settle, does not absorb water, and during its installation there will be no cracks or joints, which means there will be no heat loss associated with them. Insulating an attic using polyurethane foam is done very quickly, however, as in the case of ecowool, polyurethane foam is applied to the surface using a special apparatus.

Which insulation to choose for the attic: polyurethane will be an excellent option, but you will have to call specialists to carry out the work.

How to properly insulate an attic: video of the polyurethane foam spraying process.

https://youtube.com/watch?v=DUFV8okh_xw

Which material is better?

As you know, heat is transferred from product to product in 3 ways:

- heated air;

- thermal conductivity of materials;

- radiation - heat transfer from one product to another occurs using electromagnetic waves in the infrared spectrum.

Let's look at some differences between penofol and other thermal insulation materials.

Most thermal insulation building materials (mineral wool, isolon, penoplex, tepofol) interfere with one type of heat transfer. A distinctive feature of foil material from other types of insulation is that it has a complex effect: foamed polyethylene is an obstacle to convection, and thanks to aluminum foil, the thermal reflection rate reaches 97%.

Penofol can be compared with only one group of thermal insulation materials - isolon. Comparing isolon and penofol, there is no significant difference in the quality and method of their use. To determine the winner, you need to look at the availability and price category of a particular building material. The only advantage of Izolon is that the range has been expanded with sheet building materials, the thickness of which ranges from 15 to 50 mm.

Penofol is mounted using glue, and the penoplex is fixed using fungal screws. Also, foil insulation does not accumulate heat, but rather reflects it.

Mineral wool is attached only to vertical slats. The price category of penofol is significantly lower than that of mineral wool.

Photos of distribution boards

Answers to popular questions

What is the best insulation for an attic under metal tiles?

Metal tiles do not place any special requirements on insulation. All types of mineral wool and foam plastics are suitable. The main condition is a sufficient layer of insulation, reliable waterproofing and vapor barrier.

Soundproofing insulation should be installed under a metal roof. Basalt wool and polystyrene foam have these qualities. In addition, roll and block insulation materials with a soundproofing substrate are produced.

How to insulate an attic if the roof is without waterproofing

If there is no waterproofing, it should be installed. With a cold roof, the absence of a water barrier is not critical - if there is no difference in the external and internal temperatures, there will be no condensation, as well as ice dams.

The waterproofing film can be laid from the inside, securely connecting the joints. In this case, the need for ventilation under the roofing should be taken into account. Therefore, there must be an additional sheathing above the waterproofing film to create a ventilation gap. If there is no gap, the roofing material is laid on the rafters, then it must be removed.

Waterproofing is laid on top, connected without gaps, sheathing is made and the roofing is installed.

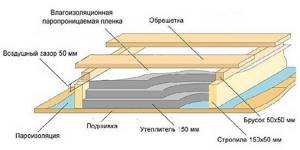

Insulating “pie” for thermal insulation of the attic

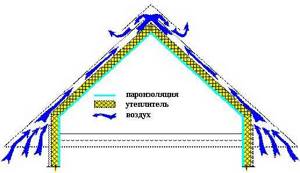

Only by observing the correct sequence of the insulation “pie” from the inside of the attic roof can you achieve comfort and coziness in the room at any time of the year. Moreover, this design has the following layers:

- finishing layer;

- ventilation with lathing;

- vapor barrier layer;

- ball of insulation - different types of mineral wool;

- waterproofing layer;

- finishing material used for roofing.

A vapor barrier layer is a mandatory requirement for laying cotton insulation. Thanks to this, you can effectively protect mineral wool from steam and condensation. When using polyurethane foam, a vapor barrier is not required.

A waterproofing layer is needed in all situations and the quality protection of wooden elements of the roof structure will depend on its use. As waterproofing, it is advisable to use diffusion-type membranes, which freely allow vapor to pass out and do not allow moisture into the room.

There must be an air ventilation gap of at least 50 mm between the layers of heat insulation and waterproofing material. Its main purpose is to remove excess moisture from the insulation.

Preparatory work

Before insulating the roof, it is necessary to go through the preparatory stage of work, which is always carried out according to the standard scheme:

Inspection of roof truss elements for damage in the form of cracks or rot. If any are found, beams, bars and boards should be replaced.

Cleaning the inner surface of roof slopes from dirt. These could be stains of rust and grease, dust, traces of mold and the like.

Coating wooden roof elements with antiseptics, fire retardants and primer.

All protruding parts of fastening structures must be hidden in the wood to avoid damage to the thermal insulation from any nail or screw. At the same time, provision should be made for laying communications if the attic space is planned to be used as a heated attic.

How to insulate a roof

Insulating a house without an attic

To achieve the highest quality thermal insulation of a residential building, it is necessary to carry out insulation for each of its elements. Including thermal insulation is required for the roof of the house. But it can be done in different ways. Depending on this, a suitable insulation is selected.

If the house does not have an attic, then insulation becomes a fairly simple task. It is only necessary to block the paths of heat loss from the premises of the building. For this purpose, the insulation is laid on the surface of the attic floor, and then covered with a floor covering.

This method involves the use of a small amount of thermal insulation materials. Mineral wool is perfect as insulation. Just remember that you need to additionally provide waterproofing so that the thermal insulation materials are not damaged as a result of contact with moisture. Mineral wool slabs are easy to lay on the floor of the attic, which allows for minimal effort.

Insulation of the attic roof

A house with an attic is more functional, but insulating the roof can in any case pose serious problems. However, this situation does not always arise. Not every owner needs a residential attic, so roof insulation can be carried out using the previous technology. Just remember that as a result, the attic itself can only be used for living in the warm season.

Another thing is the creation of a residential attic. Given such a task, it will not be possible to get by with insulating the attic floor alone. The roof slopes will have to be insulated. For this purpose, thermal insulation material is fixed to them, which prevents heat from escaping from the attic itself.

The coverage area with this option is quite large, so you have to use more insulation. It is best to carry out the procedure using a heat-insulating material such as polystyrene foam. It has good thermal insulation abilities, but at the same time has a small thickness. Therefore, the area of the attic is practically not reduced.

Additional roof insulation options

It will be possible to increase thermal insulation using any of the described methods if you use wood for finishing purposes. The roof slopes can be covered with wooden clapboards, and a simple solid board can be laid on the floor of the attic. As a result, the insulation will become noticeably more pronounced.

General recommendations for installing penofol insulation when insulating the roof

The maximum effect is achieved when there is air space (1.5 - 2 cm) on both sides of the penofol. Remember: aluminum is a good conductor of electricity. Electrical wiring must be reliably protected! Before installation, make sure the electrical wiring is secure.

.

Reflective insulation Penofol reflects up to 97% of heat flow.

The inner layer of roof insulation (layer A) must be completely sealed. This is a vapor and waterproof layer

Options for installing PENOFOLA in attics and attics: OPTION No. 1: SOUL 1 OPTION No. 2: SOON 2 OPTION No. 3: LAYER 1 + LAYER 2

In the absence of Penofol, condensation may form and, as a result, moisture may penetrate into the roof space.

Penofol has the properties of both heat protection and vapor protection. Its installation helps to get rid of these unwanted effects.

It should be noted that penofol insulation of private houses and apartments is becoming increasingly popular for various reasons. There is also a lot of talk around this relatively new insulation, including about its unique properties and ease of use. Understanding what penofol is, as well as finding out the whole truth about its characteristics, is the purpose of this article. In addition, we will talk about how it is better to insulate walls and other structures from inside the house with this material.

How to properly insulate an attic roof yourself: work order

Correctness and consistency of actions in insulation are the key to successfully completed roof insulation work. The main rule is close contact between the rafter elements and the insulation itself. To make the attic roof suitable for winter living, you need to take the following steps:

- First, protect with waterproof film;

- attach the slats taking into account the free placement of the insulation;

- the last layer should cover the wooden beams so that cold air does not pass through them;

- if there are empty spaces left, they must be blown out with foam;

- You also need to install another layer of vapor barrier material.

If through holes occur during work, they will need to be closed.

We insulate the roof from the outside with our own hands

To insulate the outside of the roof, you need to use special dense materials such as slabs. Choose specimens that are moisture resistant. It is advisable to carry out thermal insulation work along with the facade of the entire house. It is necessary to nail boards from below that will prevent the pits from sliding down. The board must be equal in width and thickness to the material used.

Roof insulation work from the inside

Please note that all wood must be treated with antiseptics, fire retardants, and special solutions for outdoor use.

Before starting thermal insulation work, check whether there is a ventilation system in the space under the roof.

To make the attic warm without having problems with excessive humidity, you must strictly follow all the instructions for the work. If the roof is also the walls of the attic floor, and has a broken structure, then the algorithm for carrying out the work is as follows:

- The lower part is the inner lining. This could be drywall or lining.

- Next, the sheathing is installed.

- The vapor barrier is laid first, then the heat-saving material. The thickness of the insulation depends on the place of residence. For the middle zone, 200 mm is enough; for colder regions this figure should be higher.

- A superdiffuse membrane is placed on top. This leaves a gap for ventilation.

- The last step is to lay the roofing material.

The slabs themselves for insulation need to be laid out in a checkerboard pattern. Work must be carried out starting from the bottom. The film for waterproofing is also spread from below, moving upward, taking into account an overlap of 10-15 cm. The resulting borders must be taped with tape. This is necessary to protect against leaks and condensation.

This layer cake will allow you to retain heat, creating additional living space.

Insulation from the inside

The process of thermal insulation of the attic inside can be divided into two parts:

- Basic. When insulation is carried out during construction. Light insulation is used here if it will not be used as an attic in the future.

- Additional. When additional installation of insulation is carried out taking into account the creation of a full-fledged living space.

When it becomes necessary to insulate the structure of an attic roof from the inside, the most common problem in this case is the small thickness of the rafters.

Insulating the attic from the inside

Main article about working with walls.

To fix the problem, you will need to create additional sheathing or frame. Next, the work is carried out in several steps:

- Creation of sheathing and counter-lattens from wooden slats.

- Twine or a thick thread is stretched to the rafters over the entire area of the sheathing, which will hold the material during operation.

- We build a metal frame, which is mounted to the rafters with brackets.

- We insert insulation over all areas of the roof.

- The metal staples are unclenched; they will additionally hold the material during finishing.

Insulating the attic roof is the most popular method for attic spaces. It is advisable to select the material based on mineral wool. Sometimes ecowool or polyurethane foam is used, in which case a vapor barrier is not required.

But waterproofing is mandatory, regardless of the insulation material. For this purpose, special membranes are used that can allow steam to pass through without allowing moisture to pass through. A gap for ventilation is needed between the waterproofing material and the roof, the thickness of which varies depending on the type of roof. It will release excess steam from the insulation to the top.

Instructions for use

For domestic needs, three types of penofol are used: A, B, C.

The scope of application of this material as a heat-insulating building material is very extensive: walls, ceilings, floors, insulation of concrete surfaces, loggias, insulation of wooden and frame buildings.

You can easily do the installation of penofol with your own hands without the involvement of specialists, the main thing is that the safety instructions are followed.

On the floor

Before you begin fixing the insulation, you need to prepare the base of the floor with a concrete screed. For this purpose, a liquid cement solution is used, which is poured onto the surface and leveled.

The following actions are related to the selected type of penofol:

- If type A penofol is used, then a fixing adhesive is applied to the foam in an even layer, after which the penofol is fixed.

- If type C foil material is used, then no adhesive is applied. This type of material is already equipped with an adhesive solution on the back of the building material.

To prevent the waterproof adhesive solution from drying out prematurely, it must be covered with polyethylene. Before starting work, the plastic film is carefully removed, and then the foil material is laid out on the foam.

The building material is laid in such a way that the foil overlaps the walls (about 5 cm), and the resulting joints are sealed with aluminum insulating tape.

You need to lay the insulation with the foil side away from the floor, i.e., inside the room.

This will ensure reliable noise and vapor barrier of the material. Upon completion of installation, the protruding parts of the foil are carefully cut off using a mounting blade.

When installing a heated floor system, there are 2 main types of installation: the use of logs or concrete screed.

Wooden logs

Logs are used if a wooden floor will be installed on top of the insulation. In this case, wooden logs are installed along the floor on top of the heating elements.

The horizontal position of the beams must be controlled using a building level.

Then a wooden covering is mounted on top of the logs. Thus, the foil material will heat up and transfer heat from below to the wooden coverings.

The second variation is to install a warm floor system under the tiles. In this case, the special heating elements are covered with reinforced mesh and filled with concrete mixture.

For this type of installation it is necessary to use penofol type ALP.

For walls

To insulate internal walls, type B foil material is used. Its installation is more complex than other types of penofol, but this insulating material can create the most effective thermal insulation of a room.

Material with double-sided metal special coating is mounted as follows:

- Using dowels, you need to secure the bars to the concrete wall (thickness 1-2 cm).

- A layer of type B penofol is mounted on them using screws or mounting brackets.

- A plasterboard product is laid on top of the insulating building material, which is fixed to the slats with self-tapping screws. To leave gaps for ventilation, wooden blocks are installed on top of the insulating material, the thickness of which is similar to the previous slats. Then the drywall is fixed.

External waterproofing

When a vapor barrier is laid on the warm inner surface of the insulation, preventing the penetration of moist air from the room, then on the colder outer surface it is necessary to attach a waterproofing material that will protect the thermal insulation under the roofing pie from possible leaks.

If you purchase an inexpensive waterproofing material, then the moisture that gets into the thermal insulation will evaporate for a long time and with difficulty, as a result of which the dampness will soon destroy the insulation. An excellent solution is to purchase a modern, vapor-permeable membrane with a well-thought-out structure that does not let moisture in and allows water vapor to come out.

When installing diffuse material, it must be positioned as tightly as possible to the insulation without the slightest gap. Otherwise, the membrane will cool more strongly, and its temperature will become lower than that of the steam migrating through the heat insulator. As a result, ice will appear on the surface of the vapor barrier, and the membrane will lose its vapor-tight properties.

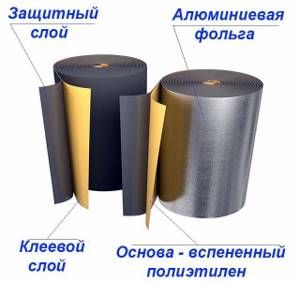

What is penofol

The material belongs to a new generation of ultra-thin polymer insulation, manufactured using foaming technology. In this case, we are dealing with polyethylene foam welded to a layer of reflective aluminum foil.

Thanks to the manufacturing technology, the small pores inside the penofol have a closed structure, which is why the insulation practically does not allow water vapor to pass through. According to the manufacturers, the foil layer is designed to reflect the flow of infrared heat coming from inside the premises. There are 3 main types of penofol:

- with one layer of heat-reflecting foil (type A);

- the foil is welded to the insulation on both sides (type B);

- on one side of the material there is foil, on the other there is an adhesive layer (type C).

Note. One of the latest innovations is single-sided (type A) perforated penofol. Many tiny holes are made in the insulation to make it vapor permeable.

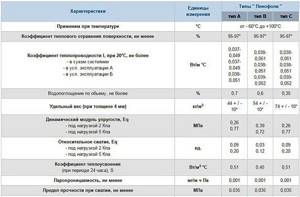

The scope of application of penofol is thermal insulation from the inside of houses and apartments, including balconies and loggias, as well as any industrial premises. The insulation is offered in thicknesses of 3, 4, 5, 8 and 10 mm. To finally understand all the properties of the material, we suggest that you familiarize yourself with its technical characteristics presented in the table:

Performance characteristics of fiber insulation

Glass wool

.

Her positive qualities include

:

- fire safety (2nd degree of fire resistance);

- environmental safety (does not contain resins);

- unattractive to mice (they do not build nests and passages);

- affordable price.

The main disadvantage is that when working with the material, caustic glass dust is formed; installation of the heat insulator requires care and the use of protective equipment

. In addition, over time, glass wool tends to deform and wrinkle, especially when moisture penetrates.

Mineral wool

. The material contains fibers of various origins (manufacturing materials - clay, stone, quartz sand, glass, etc.). Mineral wool is characterized by a multilayer heterogeneous structure with air lenses. Due to this, the material dampens sound waves well. Choosing mineral wool (primarily Isover, Ursa) is recommended for those who have decided to make metal roofing.

This heat insulator is fire-resistant, does not rot, and is easy to install. But rodents can settle in it, whose nests, passages and waste products reduce the performance properties of the insulation.

Basalt wool

. Consists of fibers obtained by melting rock. Withstands heat up to 1000 degrees, does not spread combustion. You should choose basalt wool carefully, checking quality and safety certificates: some manufacturers, in an effort to reduce the cost of products, use resins that emit toxic substances.

Basalt wool is resistant to fungus, but can be damaged by rodents. This is a good sound insulator and easy to install. But when choosing a material for insulating a rafter system, you should take into account the fairly large weight of stone wool slabs.

If you have to choose a fiber insulator for attic insulation, pay attention to the density of the material. The heat insulator should not lose its shape even after prolonged use. For mineral, basalt wool, the density should be about 40-45 kg/m3

For mineral, basalt wool, the density indicator should be about 40-45 kg/m3.

Polymer materials for insulation

We choose a polymer heat insulator for the roof and walls of the attic. This can be polystyrene foam, extruded polystyrene foam (these two types of insulation are available in the form of sheets and slabs of various thicknesses), as well as polyurethane foam, which is applied to structures by spraying.

The advantages of polymer insulation include low weight and low thermal conductivity. Such thermal insulation will not overload the rafter system and will successfully cope with the task of retaining heat.

The disadvantages of polymer insulation include extremely low vapor permeability. There is no gas exchange through insulated structures, so you cannot do without a well-thought-out ventilation system in the attic.

Thermal insulation made of extruded polystyrene foam (penoplex) and polyurethane foam will not allow heat and steam to pass through to the roof rafter frame, therefore, there is no need to install a vapor barrier on the room side. Despite the fact that the dew point during internal insulation of gables will shift towards the heat insulator, moisture, dangerous for wood, will not condense.

Manufacturers produce penoplex of various densities. For pitched roofs and attic walls, where heat loss is high, it is advisable to use slabs with a density of 30-35 kg/m3.

A suitable foam density is 35 kg/m3; at a break, the material should not crumble into individual balls

. Since polystyrene foam smolders when ignited, releasing toxic substances and is easily chewed by mice, it is not the best material for internal insulation.

Polymer insulation for the attic should not be considered as a soundproofing material for the roof - it will not save you from the sound of raindrops. But if you insulate the floor with it, it will reduce the vibration load from steps, creating acoustic comfort in the rooms under the attic.

The selected insulation option will last for many years if you purchase good material and take into account all the details of its installation.

Cross-linked polyethylene manufacturing technology

This material can be obtained by two methods - radiation and chemical. Let's talk about them in more detail. The chemically cross-linked foam material is produced under high pressure. During the manufacturing process, special antioxidants and reaction stimulants are added to the composition. Next, the base for polyethylene in a thermoplastic state is straightened and formed in accordance with the requirements for the finished product.

In turn, reactors in the form of peroxides act to create cross-links and disintegrate under the influence of high temperatures. In addition, cross-linked foamed polyethylene foil undergoes a reaction of substitution of hydrogen atoms with unsaturated carbon elements. This process makes it possible to form a spatial structure of bound radical elements, which in practical use results in high tensile strength of the material. In the application of radiation technology, the connection of molecules occurs not under the influence of a chemical reaction, but under conditions of a directed beam of energy.

Related Posts

- Foil insulation: types, properties and possibilities of use

- Insulation of a veranda in a wooden house

- Insulation for protecting pipes, made of foamed polyethylene (thermal insulation)

- Isover thermal insulation overview

- Underlay for insulation on the ceiling

- Insulating a balcony with panoramic glazing: useful to know

- Mineral wool, its characteristics and insulation composition

- Properties and types of dowel mushrooms for fastening insulation

- Insulation of a concrete floor in an apartment

- Polyethylene: properties and applications

- Choosing non-flammable insulation for walls and ceilings: tips and tricks

- Aluminum foil for bath insulation

- Baswool insulation: characteristics and scope of application

- How not to spoil the efficiency of a heating battery with a decorative screen

- Types of roll insulation and the distinctive features of each of them. roll insulation for walls: choosing the best thermal insulation special thermal insulation coating

- Insulating the attic from the inside if the roof is already covered: step-by-step instructions

- How to insulate a panel house from the outside

- Ecover insulation: pros and cons

- Do-it-yourself insulation of the loggia. if necessary? sequencing

- "penoplex" under a warm water floor, the advantages of the material, methods and technology for its installation

- Subtleties of attic floor insulation

- Izolon: what kind of material is it, features and use

- Underfloor heating: selection rules, characteristics, best brands, installation tips

- Izovol

- Effective methods of thermal insulation of sewer pipes

Read with this

- Foil insulation: types, properties and possibilities of use

- Insulation of a veranda in a wooden house

- Insulation for protecting pipes, made of foamed polyethylene (thermal insulation)

- Isover thermal insulation overview

- Underlay for insulation on the ceiling

- Insulating a balcony with panoramic glazing: useful to know

- Mineral wool, its characteristics and insulation composition

- Properties and types of dowel mushrooms for fastening insulation

- Insulation of a concrete floor in an apartment

- Polyethylene: properties and applications

What load can a profile pipe withstand?

The load that a profile pipe can withstand depends on its cross-section, wall thickness and the characteristics of the steel from which it is made. The manufacturing method also influences. But all these factors are taken into account only when calculating building frames, bridge spans, floor trusses, etc. In less critical structures, they are usually limited to assessing the level of load that can affect the structure, and the pipe is taken with approximately a 20% safety margin. This is insurance “just in case”.

| Profile pipe size | Maximum load (in kg) per span length | |||||

| 1 meter | 2 meters | 3 meters | 4 meters | 5 meters | 6 meters | |

| 40*40*2 | 709 | 173 | 72 | 35 | 16 | 5 |

| 40*40*3 | 979 | 231 | 96 | 46 | 21 | 6 |

| 50*50*2 | 1165 | 286 | 120 | 61 | 31 | 14 |

| 50*50*3 | 1615 | 396 | 167 | 84 | 43 | 19 |

| 60*60*2 | 1714 | 422 | 180 | 93 | 50 | 26 |

| 60*60*3 | 2393 | 589 | 250 | 129 | 69 | 35 |

| 80*80*3 | 4492 | 1110 | 478 | 252 | 144 | 82 |

| 100*100*3 | 7473 | 1851 | 803 | 430 | 253 | 152 |

| 100*100*4 | 9217 | 2283 | 990 | 529 | 310 | 185 |

| 120*120*4 | 13726 | 3334 | 1484 | 801 | 478 | 296 |

| 140*140*4 | 19062 | 4736 | 2069 | 1125 | 679 | 426 |

A few words about loads. A simple principle applies here: it’s better to play it safe and take a more “hardy” pipe than to redo everything all over again. Therefore, collecting loads is a very important step in choosing the section of a profile pipe. In private housing construction, a frame for a shed, gazebo, or shed is usually made from a steel profile. In such cases, the mass of snow must be taken into account. It is he who usually causes destruction.

| Rectangular pipe size | Maximum load (in kg) per span length | |||||

| 1 meter | 2 meters | 3 meters | 4 meters | 5 meters | 6 meters | |

| 50*25*2 | 684 | 167 | 69 | 34 | 16 | 6 |

| 60*40*3 | 1255 | 308 | 130 | 66 | 35 | 17 |

| 80*80*2 | 1911 | 471 | 202 | 105 | 58 | 31 |

| 80*40*3 | 2672 | 658 | 281 | 146 | 81 | 43 |

| 80*60*3 | 3583 | 884 | 380 | 199 | 112 | 62 |

| 100*50*4 | 5489 | 1357 | 585 | 309 | 176 | 101 |

| 120*80*3 | 7854 | 1957 | 846 | 455 | 269 | 164 |

Arches or pergolas, frames for retaining systems, and assembled fences are also made from profile pipes. In general, you need to be careful with arches. They are usually made for plants. When calculating, add the snow load to the weight of the trunks/branches. And in the summer it is worth taking into account the green mass and wind. In this combination, the loads are also not weak.

Properties of penofol

The main purpose is to remove drafts or wind currents from building structures, eliminate condensation or moisture, steam that rise up the tiers. The material also isolates external noise or sounds. It is a universal type of insulator, as it increases sound insulation, vapor barrier, protects against moisture and retains heat. Such features are due to the structural organization of the material and the technology used in production. The main part of the material is foamed polyethylene . At the same time, the pores formed on it are closed and filled with air. This polyethylene foam is used in the form of skeins with different densities, thicknesses and different internal structures. Either on one or both sides, based on the purpose of the material, polyethylene is covered with aluminum foil. Before application, it is processed and polished to a shine with a maximum reflectivity coefficient (up to 97% and even more). More often, foil is applied using heat welding, which provides better adhesion of the material.

The thickness of penofol is from two to ten millimeters, the foil is only from 12 to 30 microns. The thickness of the material can be increased to 40 mm if it is necessary to create particularly powerful thermal insulation, for example, in arctic climate conditions.

The operation of penofol is based on the “Dewar vessel” principle known in physics. At the beginning of the last century, James Dewar established that every substance has a certain resistance to heat transfer. Whatever this indicator, the material can only stop or make the movement of heat slower, but not stop it altogether. At the same time, heat waves are collected in the substance and energy accumulates inside the substance; after some time, supersaturation is created, after which any material itself becomes a source of heat.

Experimenting further, Dewar isolated several substances that did not absorb thermal energy, but reflected it. Among these were all precious metals (platinum, silver and gold), as well as polished aluminum. In this case, heat rays are reflected from surfaces almost 100%. These reflectors themselves are excellent heat conductors and should be used together with heat absorbers.

A common thermos works in approximately the same way, and Dewar's research became the basis for the creation of space suits and materials for thermal insulation with a reflective effect.

The use of both double-sided and single-sided insulators reduces the cost of heating rooms in winter, and in warm summer weather they prevent the house from heating up too quickly.

Problems with arranging insulation in the attic space

According to statistics, after the first winter in 30% of attics the thermal insulation has to be redone. In this case, there is a need to dismantle the roof covering, and the insulation needs to be dried, and a significant part of the previously used building materials is not subject to further use. This means you need to purchase them again, which leads to unplanned costs.

Often, such troubles arise if the insulation of the attic inside was carried out without taking into account the climatic characteristics of the region where the house was built.

In Russia, cold, dampness, and weather with negative air temperatures are not uncommon. It is known that the lower the ambient temperature drops, the greater will be the volume of steam that is able to penetrate through the vapor barrier layer due to increased partial pressure differences.

Let us say right away that all wood that is used in the construction of the roof must be treated with antiseptics. Indeed, everything: battens and counter-battens, and rafters. All wooden parts. It is also necessary to make them less flammable. To do this, they are treated with fire retardants. All elements located on the street side are treated with compounds for exterior work. Treat all wooden parts facing the interior with impregnations for interior work. If you use a composition for outdoor use indoors, the specific smell will remain for several years. If it’s the other way around, the wood outside may be damaged: the degree of protection is insufficient. Therefore, do not save on this matter.

More. Before describing how to insulate an attic roof with your own hands, it is worth recalling this: a ventilation system must be organized in the under-roof space. For this purpose, special ventilation holes are installed on the ridge. Through them, air escapes from under the roofing material, carrying away excess moisture. And it must get under the roof deck through the overhangs. There is absolutely no way to do everything hermetically. This is where the air intake comes from. This is the only way the condensate will dry out in a timely manner and the roof will last a long time.

In order for the insulation to be correct and moisture to be removed in a timely manner, it is necessary to move air masses under the roofing material

Penofol ceiling insulation technology

The product can be laid on a floor made of any material, but operations must be performed in a certain sequence. Deviation from the technology of installing penofol on the ceiling will reduce the expected effect. In addition to the insulation, you will need glue to fix the insulator and metallized tape for the joints. The rules for choosing the components of the insulating “pie” are written below.

Tools and materials for work

If the ceiling is insulated with isolon (penofol) from the inside, then the following materials and tools will be needed for the work:

- wooden slats for lathing;

- drill or hammer drill;

- screws and dowels;

- wood screws;

- hacksaw;

- laser level;

- Ruler and pencil;

- roulette;

- foil insulator (material of the smallest thickness and a product of primary purpose);

- reinforced tape;

- ceiling primer;

- roller;

- putty;

- putty knife;

- containers for mixing solutions;

- scissors or a stationery knife for cutting insulation;

- construction stapler and staples;

- ladder.

Selecting consumables

For reliable insulation, along with penofol, glue is purchased for fixing to the surface and adhesive tape for connecting parts of the canvas. There are several modifications of penofol that can be used to insulate the ceiling:

- Type "A"

. Foil on one side only. Usually used with other thermal insulators as additional insulation. - Type "B"

. Foil film is located on both sides. It has proven itself well as the main heat insulator. - Type "C"

. There is a sticky layer that makes it easy to attach. - Type "ALP"

. The metal coating is protected with polyethylene film. They are often placed on the floors of specialized premises - greenhouses, incubators, chicken coops. Film-reinforced insulation is used in basements where it is not protected by a suspended ceiling.

It is not recommended to buy Penofol-2000. Its cost is low, but it retains heat poorly. Before insulating the ceiling with penofol, check the quality of the product. Pay attention to the following factors:

- The product must be manufactured in accordance with the requirements of TU 2244-056-4696843-98.

- The material is sold in rolls, the length of the product depends on its thickness.

- Tears and through holes are not allowed on the canvas.

- The winding of the rolls is tight, without distortions. The product is packaged in plastic film, the edges of which are secured with adhesive tape.

- Make sure that the product is stored on racks or pallets at a temperature of 20 degrees and a relative humidity of 50-70 percent. It is not allowed to store material closer than 1 meter from heating devices.

Products must have a label containing basic information:

- Name of the manufacturer;

- Basic dimensions;

- Release date and warranty period, usually the manufacturer allows storage of the material for no more than 1 year;

- Thermophysical indicators;

- Scope of application of the material;

- The protective layer on type “C” samples should be easy to peel off.

Attic roof insulation scheme

The scheme is a roofing pie. When properly executed, it consists of the following layers (calculation is carried out from inside the attic):

- finishing from gypsum plasterboard, lining, plywood or other material;

- ventilation space formed by the internal sheathing;

- vapor barrier;

- mineral wool;

- waterproofing;

- ventilation space formed by the outer sheathing;

- roofing material.

The roofing pie diagram for insulation from the inside is calculated from the attic side of the attic

Depending on the material used and the insulation method, the scheme may have minor changes. For example, penoplex does not need a vapor barrier for external insulation.

Common mistakes and installation tips

The main mistakes when insulating a wooden ceiling with isolon from the inside are in laying the material with an overlap. There is no air gap between the two layers, so condensation accumulates there, which then flows into the room and leads to damage to the finish. Correctly lay the foil insulator only end-to-end. After this, all joints are insulated with silicone sealant or sealed with tape. Joints should not be left unprotected because moisture can penetrate through the seams.

Reflective insulation is placed on the walls of the room to a height of 150 mm, and is not adjacent to the wall. It is also forbidden to attach electrical wires to the foil layer, because it conducts electricity well. The wiring must be well insulated, for example, using a special corrugated pipe.

When using foil insulation as the only insulation, the type with the greatest thickness is used. In this case, the foil layer should be on both sides. If there is an unheated attic behind the ceiling, then foam polyethylene insulation is used only in combination with another reliable heat insulator.

Basic properties of OSB board (OSB)

OSB boards are an indispensable and widely used material for construction work. Below is a list of the main useful properties of this material:

- withstands a lot of weight due to its high strength;

- the lightness and elasticity of the sheet allows the use of OSB when covering uneven surfaces;

- the uniformity of the material ensures integrity when bent, unlike plywood, which delaminates when bent;

- unlike wood, at high humidity, OSB is less susceptible to defects;

- easy processing with tools allows you to quickly fasten sheets;

- has high thermal insulation and at the same time sound insulation;

- the material is resistant to chemical and mechanical influences;

- not prone to the formation of mold and mildew;

Advantages and disadvantages

The main function of this multilayer material is to protect a certain structure or space from various environmental influences. This non-combustible building material has many advantages.

- Versatility. Penofol is used not only to preserve heat and protect against moisture. It has high vapor and sound insulation, allowing you to reduce the use of a large number of different films. The product can be used both indoors and outdoors, as it is not at all afraid of moisture.

- Subtlety of the material. The thickness of penofol is several times smaller than many similar insulation materials. When installed even in the tiniest room, you don’t have to worry about reducing the living space.

- Wide choose. The material is presented on the market in a wide range of types. Therefore, it is easy to choose exactly the one that is needed for the current job and taking into account specific conditions.

- Quality level. The material is made using the most modern technologies, which allows reducing heat loss to only 4%. In winter, a room decorated with penofol will be warm, and in summer it will be cool.

- Easy to install. The material, produced in rolls, is light and flexible. This allows a person with no experience in the construction industry to cope with work even in the most difficult areas. This building material, unlike old insulation materials, does not require the construction of a frame. It can be glued directly to the rough wall, and can be cut with ordinary scissors.

- Environmentally friendly. Unlike mineral wool, you can work with penofol even with bare hands, as it does not cause any irritation to the skin. This insulation can be safely used even for installation in kindergartens and schools.

- Practically does not burn. It can be described as highly flammable.

- No parasites. This insulation does not serve as food or home for rodents or insects.

- Easy transportation. The weight of one roll of penofol is so small that you can easily carry it in your hands all the way from the hardware store to your home. The material is difficult to deform or break.

- Radiation protection. It is perhaps the only insulating material that can reflect radiation exposure. This effect is achieved by aluminum foil and is necessary for some industrial facilities.

Unfortunately, with all its positive properties, penofol also has some disadvantages. Due to the soft surface of the material, finishing with plaster is impossible, since it simply does not stick to it and is easy to break. Installing such insulation with metal brackets will compromise its integrity and may reduce its thermal and waterproofing characteristics. It is necessary to either purchase it on a self-adhesive basis, or put it on a special composition, which is purchased separately.

Idea for an apartment: bright colors!

Dark blue, dark green, burgundy - these will also give you an impressive home decor. Dark colors should no longer overwhelm the interior. Skillfully applied, they will work even in a small room.

You can use deep shades in complements, but nothing prevents you from using them throughout the composition. Paint your bedroom wall a shade of bottle green, choose a burgundy headboard and accessorize with gold accessories. You don't need to brighten up your interior with white linens. Choose products that relate to the color of the walls and headboard, and the decor will be consistent and original.

An excellent color combination for the living room would be red and brown. Use brick cladding on one of the walls, the one behind the sofa. Choose a location in a caramel shade. Use a wooden table or a model with a black base and glass top.

Intense colors are an idea for interiors in accordance with the following trends:

- If you're tired of the ubiquitous white, choose a dark color palette,

- Use bottle green, burgundy or navy blue; you can also combine these colors as you like,

- Dark green on the walls would work great in a bedroom, paired with a bed with a burgundy headboard and bedding that's in these two deep colors,

- In the living room, you can use red brick on the wall. Against this background, a caramel sofa will look great.

Thermal insulation with foil insulation

Not long ago a new product appeared on the building materials market - foil insulation. It is used for waterproofing, sound insulation and thermal insulation of facades, roofs, walls, floors, ceilings, saunas, baths, partitions, pipelines. What is foil insulation, and how to install it correctly?

Foil insulation is used for waterproofing, sound insulation and thermal insulation of facades, roofs, walls, floors, ceilings, saunas, baths, partitions, pipelines.

What is foil insulation?

Foil insulation is a combined material. On one side it is a polished foil, and on the other, pre-foamed polyethylene. Thanks to its “aluminum” component, it is capable of reflecting and retaining heat in the room. According to research, the reflection effect is 97%. It is distinguished by its thinness and excellent water-repellent qualities, so that the walls and floors do not become damp. In addition, this material perfectly protects the building from wind and frost. Due to the properties of foil, almost all the heat remains inside the room.

Among the advantages of such insulation, experts also highlight excellent soundproofing properties, ease of installation and high environmental friendliness. It does not emit hazardous and toxic substances, unlike conventional mineral wool and other modern analogues. Due to its elasticity, foil insulation is easily and safely mounted on the surface, and even a non-professional can install it correctly simply using the simplest instructions.

Types of foil insulation

Foil insulation does not emit hazardous and toxic substances, unlike conventional mineral wool.

There are four types of such insulation; they differ from each other both in appearance and in their area of application and functional features.

- Foamed polyethylene coated with aluminum is used to insulate building walls and ventilation systems. Usually sold in roll form.

- Foiled polystyrene foam is used for floor insulation. It is produced in the form of thick steel-colored sheets.

- Mineral wool with a layer of foil is used mainly for insulating roofs, chimneys and baths. Sold in rolls.

- Basalt foil-coated thermal insulation material is used in all areas of construction, including the construction of gas stations. It has increased resistance to aggressive environments. Withstands temperatures from -200°C to +700°C.

Application of material

This material is ideal for insulating floors, bathhouses and attics - this way you will provide excellent hydro-noise and heat insulation. In addition, many people use it to increase the volume of heat supply by placing it behind the radiators with the “aluminum” side facing the room. As a result, for little money you can protect your home as much as possible from wind, frost and heat loss.

Installation: how to do it right?

Foil insulation is ideal for insulating floors, bathhouses and attics.

Required tools and materials:

- construction stapler;

- small nails;

- hammer;

- foil insulation;

- foil tape.

Many people, having bought foil insulation, wonder which side to lay it on correctly?

So, the first thing to consider is that the reflective surface of the insulation must be located indoors.

This is necessary to keep the heat in the room. In addition, it is important to leave a distance between the finish and the material of about 15-20 mm; this kind of air cushion will provide additional heat protection.

When laying on an insulated surface, the material must be in a wooden sheathing (2-3 cm thick) between the guides. Correctly attach it to the wall not overlapping, but end-to-end, using nails or a stapler. After all the sheets have been laid, the joints between them are taped with special foil tape. At this point the installation can be considered complete.

The cost of any insulation with aluminum foil is comparable to the cost of an alternative material with similar characteristics, but due to the fact that its installation is very simple, you can save a lot of time on installation and space (foil insulation is thinner than conventional ones). In addition, this material is environmentally friendly and fireproof. Before you choose and buy foil insulation, make sure that it is covered with aluminum foil and not aluminum coating. In the second case, the reflective properties of the material are unlikely to work correctly.

Thermal insulation of the attic with polystyrene foam

Taking advantage of the fact that penoplex and extruded polystyrene foam repel water by 100%, when insulating the attic, film or foil from the inside does not need to be used. It is optimal to lay the insulation in 2 layers, for which you take regular slabs and with a selected quarter. The first ones are tightly inserted between the rafters flush with the inner surface of the board. The second ones are laid on top, secured to the rafters and the first layer using self-tapping screws.

When installing the first layer of insulation, remember that you need to provide a ventilation gap and lay a diffusion membrane. By the way, it is necessary in any case, even if the insulation is placed on the attic floors, and the roof is not insulated at all. Waterproofing always protects the interior space from wind and water ingress.

Two layers of expanded polystyrene not only insulate the attic well, but also protect wooden structures from moisture that occurs inside the room. How best to do this is shown in the video:

Real thermal insulation characteristics

At the beginning of the publication, we mentioned the overestimation of the performance parameters of the material by unscrupulous sellers. Common myths about the properties of an insulator look like this:

- Innovative insulation "Penofol" has the best thermal insulation characteristics. The thermal resistance R of a 4 mm thick sheet reaches 1.2 m² • °C/W, which is comparable to 0.67 meter red brick masonry or 46 mm polystyrene foam.

- The Penofol layer serves as excellent sound insulation.

- The insulation can be freely filled with cement-sand screed, turning the foil up.

Material with an adhesive layer on the back side (type C)

Reference. The manufacturer claims: for the most effective operation, the heat insulator must be placed inside a closed air gap. When installed close to other materials, the aluminum coating will not perform its function of reflecting radiant heat. Infrared waves can penetrate open space, but not thick concrete.

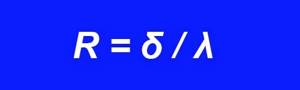

The heat transfer resistance of one insulating layer can be easily calculated using the classic formula from the building thermal physics course:

- R – the value of the thermal resistance of the material, m² • °C/W;

- δ – insulation thickness, m;

- λ – coefficient of specific thermal conductivity, W/(m • °C).

Substituting the manufacturer's data into the formula (we take the optimal option), we get R = 0.004 mm / 0.037 W/(m • °C) ≈ 0.11 m² • °C/W. Knowing the thermal conductivity of the foam (λ = 0.043), it is easy to determine the appropriate layer thickness: 0.11 x 0.043 = 0.0047 m = 4.7 mm. Roughly speaking, 5 mm of polystyrene foam and 4 mm of polyethylene foam will retain the same amount of heat; there is no talk of 46 mm.

Closed pores do not allow Penofol to become a full-fledged soundproofing material. Sound waves are only partially absorbed by the soft surface of the polymer.

To soundproof the floors, a special membrane made of 3 layers of polyethylene foam is used

For effective sound insulation, acoustic building materials with an open structure are needed:

- mineral wool;

- cork lining;

- foam rubber sheets;

- cellulose ecowool.

It is strictly not recommended to lay Penofol under a cement screed for heated floors for the following reasons:

- Under the weight of the solution, the soft polyethylene foam is crushed, air (or inert gas) is squeezed out of the chambers, and the insulation becomes twice as thin. Thermal resistance is reduced to a minimum.

- Aluminum foil embedded in concrete does not reflect infrared waves.

- Monoliths thinner than 6 mm shrink and crack along with the tiles.

The alkaline base of cement destroys thin aluminum in literally 4-5 weeks

Note. A full-fledged radiant heat reflector placed under the screed is a multifoil roll. The structure is large air cells that do not collapse under the load of concrete.

Under the monolith, the usual “Penofol” quickly loses its foil due to the aggressive effects of Portland cement, which is clearly demonstrated in the video below. The manufacturer suggests placing a special type of insulation under the screed - Penofol ALP, laminated with a protective polymer film. True, the issue of compression and destruction of closed pores from the weight of the monolith remains unresolved.

Conclusion. Foil-coated polyethylene products are not inferior to Penoplex and sprayed polyurethane in terms of thermal insulation properties. The weaknesses of Penofol are its small thickness and soft structure. The material must be used in certain places, following the technology and manufacturer’s instructions.

What is an attic?

And although many people believe that the attic is a type of attic, in fact, it is a completely different room, which differs in size from the first. And the main one is height. It must be at least 2.5 m.

In all other respects, this is an attic space, enclosed by a rafter system with roofing material laid on it. If the roof is gable, then the attic is enclosed on both sides by gables - vertical walls supporting the rafter structure. It is in them that windows and doors are made with access to the adjacent balcony. But the main walls of the room are the roof of the house with a certain slope of the slopes.

Scheme of assembling the roof of a private house according to the layers of materials used

The technology for assembling the rafter system and roofing material is that a waterproofing layer must be laid between them, protecting wooden structures from unexpected leaks from the side of the roofing. This is a kind of safety net. On roofs, roll-type waterproofing material is mainly used, which is laid in strips from the eaves to the ridge with an overlap of 20-30 cm and attached to the rafter legs. The film is laid with a slight slack in case of thermal tension or expansion, plus the edges of adjacent strips must be secured with tape or self-adhesive tape.

Then wooden slats, called counter-lattice, are laid along the rafters, and transverse slats, called lathing, are mounted on them. The roofing material with fastening is laid on the latter.

The view from the inside of the attic shows rafters covered with a waterproofing layer on top. It is this structure that will have to be insulated. The question of how to properly insulate an attic from the inside with your own hands, we emphasize - with your own hands - requires first of all the determination of the insulation, or rather, its selection. Because not all modern thermal insulation materials can be used independently. But we will deal with them all, and we will definitely identify the best one.

The final result of insulation

Stages of insulating an attic from the inside

The process of insulating an attic takes place in several stages, in addition to choosing the material:

The procedure for insulating the attic

- Roof insulation;

- Insulation of walls;

- Floor insulation.

Roof insulation in the attic

First, it’s worth telling what the process of insulating an attic roof from the inside should consist of. Stages of work:

When insulating the attic, do not forget about steam and waterproofing

- Main roof covering;

- Waterproofing device;

- Laying thermal insulation;

- Vapor barrier;

- Finishing work.

The initial stage, after the existing main roof covering, is waterproofing, which is laid along the entire height of the supports, from the bottom to the very ridge of the roof. Before laying the material, all wooden roof elements are treated with an antiseptic. If there are rotten or moldy parts, they must be replaced. Knowing the coefficient of thermal conductivity, you should make a decision to eliminate possible heat loss, whether one layer of insulation will be enough or whether it is worth laying a second layer. In the place where the insulation is laid to ensure ventilation, when installing this material, a gap is left between it and the roof. If the roofing material is wave-shaped (tiles, metal tiles), then the layer is left at least 2.5 cm. And if the roof is made of flat-format material (steel sheets, rolled materials), the space between the insulation and the roof should be doubled.

Thermal insulation is carried out by laying the selected material on top of the waterproofing layer.

The next stage is vapor barrier. The material is a special film, which in appearance can be like a regular film, or can be in the form of a membrane, foil or perforated film. The film is attached to the rafters using a construction stapler.

Decoration of the premises. At this stage, the following occurs: fastening plastic, drywall, lining, moisture-resistant chipboard, fiberboard or plywood sheets. At the same time, it needs to be fastened close to the vapor barrier, or it can be mounted on a thin type sheathing made of individual slats. Then, if necessary and desired, you can paste wallpaper, varnish or paint.

Insulation of walls in the attic from the inside

Insulation of attic walls is carried out when the roof does not reach part of the floor. So, when insulating walls, you should go through several stages to achieve the final result:

Treating wood with antiseptic

- Treating walls with an antiseptic, removing dust and dirt;

- Sheathing the roof surface from the inside using beams or untreated boards;

- Waterproofing;

- Laying a layer of selected insulation;

- Vapor barrier layer;

- Wall decoration.

A distinctive feature of wall insulation work is the absence of sheathing, unlike the roof. The rest of the process follows the same method as insulating the attic roof.

After treating the walls with an antiseptic, a vertical frame is installed on the surface of the walls from timber or untreated boards. The beam is attached to the wall using metal corners or dowels.

Plasterboard finishing of an insulated attic

Waterproofing walls involves laying material into the cells of the frame. Afterwards, the first layer of the selected insulation is formed.

The vapor barrier layer is fixed on top of the first layer of insulation. The vapor barrier material is a film, as mentioned above, which should fit tightly, without any sagging.

Wall finishing is carried out using facing materials: OSB boards, plasterboard, which are attached to a frame made of metal profiles or wooden blocks.

Insulating the floor in the attic

Basically, the attic floor is made in the form of a wooden structure. And to create complete and final comfort in the room, the floor also needs to be insulated. And floor insulation also takes place in several stages:

- Removing old floor covering;

- Inspection of logs, detection of damage and defects, elimination of defects;

- Fixing the vapor barrier film;

- Laying the first layer of insulation;

- Laying the second layer of vapor barrier;

- Sheathing joists.

The design of the insulated attic floor

The vapor barrier film is installed along the entire length and width of the insulated surface. The film is secured with a construction stapler. In this case, the film must exactly follow all the lines of the joist system, closely adjacent to the beams.

The first layer of insulation must be laid between the joists. Next comes the stage of laying a vapor barrier layer, which will become the second layer. Accordingly, the vapor barrier material is laid on top of the insulation.

And the final stage will be facing the logs using front coverings made of OSB boards or wooden boards.

Preparing to insulate the attic

A specific feature of the attic is the presence of a sloping ceiling. Moreover, according to SNiP 2.08.01-89 “Residential Buildings”, the height of the attic floor cannot be lower than 2.5 m. It is allowed to reduce the height in an area not exceeding 50% of the total area of the room.

Other features of the attic include:

- dependence of heat loss on the material from which the house is built: wood, cellular concrete, brick or a combination of them;

- dependence of the attic engineering systems on the existing ones in the house. This leaves its mark on technical solutions for communications;

- variety of architectural forms of the mansard roof: broken, single, gable roof;

- variety of design solutions. The material for the manufacture of load-bearing elements of the attic can be wood, metal, reinforced concrete;

- specifics of the location. The attic can be located within the building area or extend beyond its boundaries, supported by columns or a cantilevered extension of the interfloor ceiling.

Thus, when deciding how to insulate an attic for winter living, you need to proceed from the design features of the attic floor.

Please note that it is correct to carry out work on insulation of a residential building or apartment outside the premises, because... This approach ensures that the freezing point shifts towards the insulation mounted on the outside of the wall.

However, insulating the attic from the inside is a widespread option, because... all surfaces that are subject to insulation are located inside the attic (room) floor - ceiling, floor and walls. The exception is the pediment, which can be insulated as part of the attic insulation or along with the insulation of the entire house.

Factors affecting the thermal insulation of the attic

Professionals identify two key factors that have a significant impact on the level of heat loss and operational characteristics of the attic after insulation work has been completed.

Firstly, it is a thermal insulation material. Taking into account the fact that the attic floor is the coldest room in the house, and it is intended to insulate the attic with your own hands, you need to carefully approach the choice of insulation.

Secondly, it is a waterproofing film. It is precisely this that is designed to protect the insulation from moisture entering the attic premises from the outside (outside), through the roofing material, and from the inside, through the floor.

Methods of floor insulation

The floor of the attic is the ceiling of the lower floor. Its insulation serves more of a sound-proofing function than a heat-insulating one. Depending on the material from which the ceiling is made, the insulation method is also selected.

If the floor is wooden and there are beams on it, then the space between them is filled with insulation, having previously taken care of a vapor barrier layer.

Boards or OSB boards are laid on top of the beams. Mineral wool or polystyrene foam is perfect as insulation.

If the floor is a reinforced concrete slab, then a cement screed will be required:

- the surface of the slab must be cleaned of dust and all cracks sealed;

- a vapor barrier material is laid, and insulation is placed on top;

- a cement screed reinforced with mesh or reinforcement is poured over the thermal insulation;

- After the cement has completely dried, a decorative coating is applied.

Floor insulation with expanded clay is very common. This is a bulk material that has excellent heat and sound insulation properties and at the same time has a low cost compared to other insulation materials.

Expanded clay is suitable both for insulating wooden floors (it is poured between beams) and for installing cement screed, but since it is a porous material that absorbs moisture, it is necessary to take care of high-quality vapor and waterproofing.

I think we need to wrap this up, the material is already quite voluminous. And even in such a volume it is impossible to fit all the nuances, so be sure to ask questions - I will be happy to share my experience.