Flat roofing is a very common type of roofing in commercial buildings, business centers, shopping centers, and private homes. A flat roof is characterized by a horizontal arrangement with a relatively small degree of slope. Unlike pitched roofs, flat roofs are more vulnerable to moisture and water, since water can stagnate on the surface longer. That is why waterproofing a flat roof is one of the most important elements of the roofing pie.

In this article we will take a detailed look at all possible waterproofing materials and methods for installing them on a flat surface.

Why do you need flat roof waterproofing?

The flat roof is made in such a way that its slope towards the drain funnels in most cases does not exceed 10-20 degrees. Due to the slight slope, water stagnates on the surface and, in the absence of high-quality waterproofing, is absorbed into the base (or floor) slab and destroys it.

Why is it dangerous for water to enter a building through a flat roof?

- Formation of cracks and destruction - Moisture and water are absorbed into concrete, freeze in winter, and thaw in spring, forming microcracks and pores in the concrete floor. These cracks become larger every year, gradually threatening the integrity of the structure.

- Flooding of the premises – a leak in the roof can flood the premises underneath, which can lead to damage to the property in the building or home and the repairs made.

- The formation of high humidity, mold and mildew in the house that is dangerous to human health.

Types of flat roofing

There are several main types of flat roofing; their differences come from the final purpose of the roof. Depending on the type of roof, the location of different roofing elements, such as thermal insulation, waterproofing, etc., is determined in different places.

Main types of flat roofing:

- Traditional non-exploited - It is assumed that such a roof will not be constantly in use and there will not be recreation areas or other areas where people will constantly be located. This design is not designed to withstand constant loads and mechanical stress; its main task is to protect the building from the penetration of water, moisture and other weather elements.

- Exploitable - This type of roofing is designed so that terraces or other exploitable areas can be built on it, where people and various objects (equipment, sofas, tables, etc.) will constantly be located.

- Inversion roofing – This type of construction is suitable exclusively for flat roofs. With this type of structure, some traditional layers are swapped, namely thermal insulation and waterproofing. Thermal insulation is laid not under, but on top of the waterproofing. Inversion technology is used to protect the finishing layer from temperature fluctuations.

Features of house roof waterproofing

Why do you need roof waterproofing? Temperature changes lead to the appearance of condensation on the inner surface of the roofing material, which flows onto the thermal insulation and wooden structure of the roof, stimulating its rapid destruction. In this case, wet insulation loses its insulating properties and the ability to perform its functions efficiently.

Previously, the most common material for waterproofing the roof of a house was roofing felt, which is still found today. Considering that the base of the material is paper, its service life is significantly reduced when exposed to moisture. As a result, after 4-5 years of service, the roofing material cracks and allows moisture to pass through, necessitating roof repairs. In addition, the material can tear from a small load, and also has considerable weight, which makes its installation difficult. Typically, this material is used simultaneously as a roofing material for sheds or low-angle pitched roofs.

Insulation with a reinforced film hydrobarrier is a modern technology. This is the most inexpensive and easy-to-use material used for pitched roofs for any type of roofing material. A distinction is made between film and membrane, characterized by the presence of microholes. It is the same film, but capable of passing air only in one direction, therefore it is considered a new and more modern material. The main advantages are:

- high strength;

- light weight;

- ease of installation of waterproofing on the roof;

- presence of ventilation micro-holes.

Materials for waterproofing and technology for their installation

There are many different materials available for waterproofing flat roofs. Waterproofing materials differ from each other in their characteristics, reliability and method of installation.

Weldable roll coatings based on bitumen

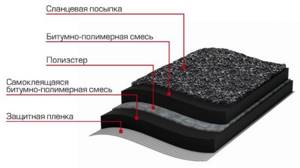

Built-up waterproofing is rolled sheets based on modified bitumen. The characteristics of rolled fused insulation make it possible to retain water for quite a long time.

To install a protective coating on the roof, weld-on membranes must be installed in 2-3 rows, overlapping the seams of the previous one, and if the top layer is the finishing layer, it must be with a special coating that protects it from exposure to solar ultraviolet rays.

Bitumen-based rolls are divided among themselves mainly by service life:

- Premium – service life 25-30 years

- Standard – service life 10-15 years

- Economy – service life up to 10 years

Installation of roll welded insulation

Installation method:

- It is necessary to prepare the base;

- A bitumen primer is applied to the surface;

- Rolled membranes are fused to the surface using a torch and fire. The welded sheets are installed overlapping each other in order to cover the existing seams.

- Deposition of the 2nd and subsequent layers must be carried out by overlapping the seams of the previous one. If the last waterproofing contour is exposed to sunlight, then it must be made of materials with slate coating.

- It is recommended to secure the junction of the material to the vertical surface with a special clamping strip.

By clicking on the link, you can download detailed instructions for installing fused materials from our partners TechnoNIKOL - Instructions for installing waterproofing of a flat roof from fused bitumen-polymer roll materials.

Important: When installing built-up waterproofing, it is very important to strictly follow the numerous rules and instructions of the manufacturer. One of the many mistakes installers make is overexposing the fire to the bitumen layer of the seam, which ultimately leads to burning of the bitumen and weakening of the joint seam, through which water can subsequently pass into the roofing pie.

Video instruction:

Advantages:

- Availability in construction stores and markets;

- High service life of Premium category material;

- Relative resistance to mechanical loads;

- Resistance to ultraviolet solar radiation when using a special layer with coarse-grained coating on the front side.

Flaws:

- Presence of seams - Seams are the weakest points in the built-up waterproofing coating and water first begins to pass through the seams;

- Lack of adhesion – Fused materials do not have adhesion to the surface, which means that water can stagnate under the sheets and travel under the coating, appearing from the inside at the weakest point;

- Human factor – At the slightest mistake on the part of the workman, the integrity of the seam may be compromised, which can ultimately lead to leaks;

- Fire installation method.

Flat roof waterproofing TechnoNIKOL

The main manufacturer of fused rolled roofing materials is TechnoNIKOL Corporation.

The TechnoNIKOL company has a wide range of materials intended for the construction of protective waterproofing coatings using fused and other methods. Each type of roof has its own suitable material.

Main characteristics of roofing built-up insulation from the TechnoNIKOL company:

View characteristics of TechnoNIKOL roll insulation

| Indicator name | Unit change | Criterion |

| Weight | % | 5 |

| Weight of binder on the welded side | kg/m2 | 1,5 |

| Water absorption within 24 hours | % | 1 |

| Lost sprinkles | % | 15 |

| Heat resistance | OS | 80 |

Self-adhesive materials

Self-adhesive material is rolls on a durable polyester base with or without coarse slate coating, for waterproofing flat roofs. They are used for installing a single-layer roofing carpet for garages, outbuildings and country houses, change houses, etc...

Self-adhesive rolls can be installed on the roof surface without the need to use live fire.

How does self-adhesive material work?

Installation method:

- It is necessary to clean the surface from dirt and dust;

- The surface is primed with bitumen primer;

- Rolls are glued to the surface overlapping each other without the help of fire;

- It is recommended to secure the junction of the material to the vertical surface with a special strip.

Video instruction:

Advantages:

- Availability of material in construction stores and markets;

- Possibility of installation without the use of fire and burner;

- The laying speed is higher than that of weld-on analogues.

Flaws:

- Presence of seams - Seams are the weakest points in the coating and water first begins to pass through the seams;

- Lack of adhesion to the base – Pasting materials do not have 100% adhesion to the surface, which means that water can stagnate under the sheets and travel under the coating;

- Low reliability.

Polymer and PVC membranes

Membranes are film coatings based on various polymers for waterproofing various structures, including roofs. Membranes are an installed type of waterproofing materials.

Membranes are divided into several main types:

- PVC – Made from elastic polyvinyl chloride (PVC-P) and reinforced with polyester threads. These coatings are quite durable and resistant to water, moisture and aggressive environments. Widely used as waterproofing for terraces and roofs.

- EPDM – This is ethylene propylene diene monomer. Membranes of this type are made of synthetic rubber with various polymer additives, and in some cases they can be reinforced with polyester reinforcement.

- TPO – These are thermoplastic polyolefin membranes that are made from ethylene propylene rubber and polypropylene. These membranes are highly resistant to hydrostatic pressure.

Installation method:

- Preparation of the base;

- Laying the substrate;

- Laying the membrane – Membranes are attached to vertical surfaces using special clamping strips and slats. To avoid leaks, the membrane sheets are mounted with an overlap of at least 10 cm. The seams are welded with special glue or hot air using a special hair dryer.

By clicking on the link, you can download detailed instructions for installing membrane waterproofing from our partners TechnoNIKOL - Instructions for installing a flat roof made of a polymer membrane.

Video instruction:

Advantages:

- Possibility of installation without the use of fire and burner;

- High water resistance.

Flaws:

- Presence of seams - Seams are the weakest points in the coating and water first begins to pass through the seams;

- Complete lack of adhesion to the base - The membranes lie on the surface like a carpet, which means that if a seam breaks somewhere or there is a small hole, water will penetrate under the membrane and spread throughout the entire roof;

- The lack of adhesion makes local repairs very difficult, since it is absolutely impossible to identify the entry point based on the nature of leaks from inside the room.

Lubricants and mastics

When we talk about coating materials, we mean various mastics that are supplied in liquid form and applied to the surface using rollers, spatulas and brushes. Today on the roofing mastic market there is a fairly large number of materials that differ in their characteristics and components.

Main types of coating waterproofing:

- Bitumen-based mastics - These compositions are based on bitumen and polymer additives. Some bitumen mastics require heating before application or dilution with various solvents, and some are supplied ready-to-use.

- Polyurethane mastics - Made from highly elastic hydrophobic polyurethane resin with the addition of polymers. Polyurethane waterproofing can be either one-component or two-component. Excellent for waterproofing and protecting roofs, balconies and terraces, as they are resistant to solar radiation and have a high coefficient of elasticity.

- Polymer-cement compositions are prepared on the basis of cement and various polymers. These compositions are one-component and two-component and are supplied in the form of a powder mixture, which is diluted with water and, if necessary, a second component is added to it. These are quite durable materials; if desired, tiles can be installed on them even without a clamping device.

Application method:

- Preparation of the base - Cleaning the surface from dust, dirt, flaking elements and sharp corners;

- Primer – Applying primer to the surface;

- Preparation of waterproofing mastic for work;

- Apply coating mastic in 1-3 layers, allowing the previous one to dry;

Advantages:

- Coatings based on polyurethane and liquid rubber have high elasticity and strength - due to which they do not deform or diverge when the building shrinks or the dynamics of the structure;

- No seams – ensures reliability and durability;

- 100% adhesion to the base - Thanks to which water cannot pass under the waterproofing and walk under it;

- Possibility of spot repairs – Thanks to 100% adhesion, you can easily understand where the leak is and perform spot repairs;

- Some coating waterproofing materials are resistant to ultraviolet radiation, for example, polyurethane ones;

- Some coating compositions can be used as a decorative finishing layer, since they can be tinted, for example, polyurethane;

- Without fire method of work.

Sprayed waterproofing

Sprayed waterproofing is a variety of 1- and 2-component materials that can be applied to the surface by spraying.

Main types of sprayed waterproofing:

- Liquid rubber – Bitumen-latex emulsion, which, when sprayed, forms a seamless, elastic and rubber coating on the surface with a thickness of 2-4 mm.

- Polyurea – This is the processing of polyurium and polyurea. Spraying with polyurea forms a seamless, durable coating on the surface, something between plastic and hard rubber.

- Polyurethane waterproofing - The main component of this spray-on composition is polyurethane. This material is very similar to polyurea, but it is not as expensive and has a higher elasticity coefficient. The seamless membrane formed after spraying is able to withstand mechanical loads and solar radiation.

Method of applying sprayed compositions:

- Preparation of the base - Cleaning the surface from dust, dirt, flaking elements and sharp corners;

- Primer – Application of primer;

- Preparation of installation for airless spraying;

- Spraying waterproofing composition;

- Cleaning the installation and its preservation - if the installation is not cleaned in time, the remaining clots in it can harden and damage the equipment.

Advantages:

- Speed of work - in 1 day you can apply from 400-800 m2 of waterproofing, with a team of 4 people;

- High elasticity;

- No seams;

- 100% adhesion to surface:

- Possibility of spot repairs;

- Some coating waterproofing materials are resistant to ultraviolet radiation, for example, polyurethane ones;

- Some coating compositions can be used as a decorative element, without subsequent finishing, since they can be tinted, for example, polyurethane;

- Without fire method of work.

Comparison between materials in the table

The following table compares the main characteristics of the above materials:

See comparison in the table

| Sprayable compositions | Built-up bitumen-based rolls | Membranes | |

| Installation method | Without fire | Fire using a torch | Using a hair dryer and mechanical fastening |

| Presence of seams | No | Yes | Yes |

| Adhesion to the base | 100% | 40% | No clutch |

| Elasticity coefficient | 600-800% | 10-20% | 10-20% |

| Installation speed m2/1 day | 400-600 | 20-50 | 30-60 |

| Warranty period for work | 7 years | 3-5 years | 1-2 years |

Laying process

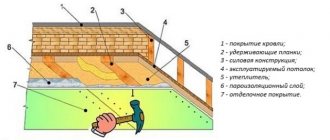

Installation of waterproofing film on a pitched roof is carried out according to the following scheme:

- vapor and heat insulation device;

- alternate laying of panels across the rafters, starting from the eaves of the slope;

- gluing seams, securing each layer with a stapler.

Installation of each upper waterproofing sheet is carried out with an overlap of at least 10 cm on the lower one. Carefully isolate joints, valleys and valleys.

The process of fusing or gluing waterproofing on a flat roof includes the following steps:

- surface preparation;

- sealing joints with ready-made fillets or made from mineral wool boards, cement-sand mortar;

- primer or mastic treatment;

- gluing or fusing the first panel using a torch, using material without sprinkling;

- installation of subsequent ones with an overlap of 80 mm in the longitudinal direction, 150 mm in the transverse direction, the joints should be spaced apart;

- laying the top layer, protected from external influences by sprinkling.

Particular attention is paid to the insulation of junctions, fastening of the roofing carpet to vertical structures, and complex assemblies of communication outlets to the roof.

Recommendation: What material is best to choose and what should not be forgotten

If your task is to do waterproofing once and for all, then it is recommended to choose a waterproofing system with the following characteristics:

- Without seams - the presence of seams means the presence of weak points in the waterproofing;

- With 100% adhesion to the surface - Lack of adhesion means that water can penetrate under the waterproofing in one place, and then move unhindered from one place to another;

- Elasticity - The more elastic the material, the less susceptible it is to deformation during shrinkage of the house or dynamic load;

- Price-quality ratio.

All these qualities are possessed by such waterproofing systems as:

- Polyurethane waterproofing

- Liquid rubber

Important: Regardless of which waterproofing system you choose, when installing waterproofing, do not forget to pay special attention to the following structures:

- Installing a fillet or small plinth when the waterproofing transitions from horizontal to vertical - this is necessary in order to prevent the waterproofing from breaking at this unit;

- Do not forget to make drain funnels correctly and seal them well;

- Try to make a good slope towards the drain funnels so that the water does not stagnate;

- Pay special attention to sealing the entry points of various communications into the building;

- Pay special attention to additional sealing of cold and expansion joints.

Material selection

The modern market offers a wide range of raw materials for waterproofing.

To choose the best material option, you need to know what type of roof is expected. Flat and inclined structures require their own specific materials and installation methods. Also, when selecting raw materials for moisture insulation, you need to pay attention to the following criteria: - Price. - Practicality. — Features of care. — Easy to install. — Suitable for partial repairs. - Environmental Safety. - Toxicity. — Fire safety. - Weight.

It is best to use waterproofing and vapor barrier raw materials from the same manufacturer, which has proven itself well in the market. This will make installation easier and increase the lifespan of the roof, as well as the entire house as a whole.

Prices for flat roof waterproofing

Below is a table of prices for work related to roof waterproofing. In the table you can see prices and the final cost of waterproofing work, depending on the method of their implementation and the material (type) used.

The prices indicated are preliminary, as they do not take into account the complexity of the work and other possible nuances. To receive an accurate price estimate, you need to send the dimensions of your roof to our email address or call an engineer to inspect your property by phone in the contacts section.

| Name of works | Unit _ | Price in Rubles |

| Work on the installation of built-up waterproofing | m2 | 360 |

| Work on installing a PVC membrane | m2 | 580 |

| Work on the installation of a pole weaver | m2 | 900 |

| Work on installation of mastic waterproofing | m2 | 200 |

| Work on the installation of liquid rubber spraying | m2 | 250 |

| Manual installation of liquid rubber | m2 | 330 |

| Work on installation of cement-mineral 2-component waterproofing | m2 | 600 |

| Work on installation of polyurethane waterproofing | m2 | 600 |

| Primer application | m2 | 100 |

Flat roof waterproofing cost calculator

Click to open the calculator and calculate the cost of work